Sie haben ein komplexes Aluminiumteil vor sich, das schnell und sauber bearbeitet werden muss. Die falsche Wahl des Aluminiums kann Ihr Projekt in einen Alptraum aus gebrochenen Werkzeugen, schlechter Oberflächenqualität und verpassten Terminen verwandeln. Jeder Zerspanungsmechaniker weiß, dass die Wahl der Aluminiumsorte über Erfolg oder Misserfolg eines CNC-Auftrags entscheiden kann.

6061-T6-Aluminium ist das am einfachsten zu bearbeitende Aluminium aufgrund seiner hervorragenden Bearbeitbarkeit, seiner ausgewogenen Härte und seiner nachsichtigen Zerspanungseigenschaften, die mit Standardwerkzeugen und -parametern gut funktionieren.

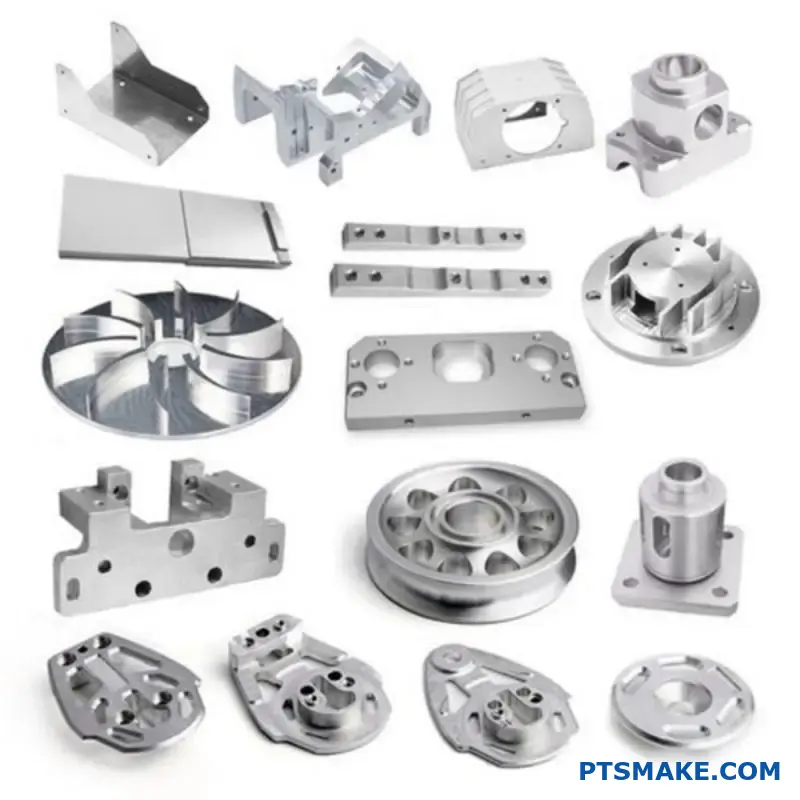

Ich bearbeite täglich Aluminiumteile bei PTSMAKE und habe gesehen, wie die richtige Materialwahl sowohl Zeit als auch Geld spart. 6061-T6 bietet das perfekte Gleichgewicht für die meisten Anwendungen, aber es gibt auch andere Werkstoffe, die Sie je nach Ihren spezifischen Anforderungen in Betracht ziehen sollten. Ich möchte Ihnen erläutern, warum bestimmte Aluminiumlegierungen CNC-freundlicher sind als andere, damit Sie die beste Option für Ihr nächstes Projekt wählen können.

Welche Aluminiumsorten sind am besten für die CNC-Bearbeitung geeignet?

Haben Sie schon einmal eine Aluminiumsorte für ein Projekt ausgewählt, nur um dann festzustellen, dass sie unter Belastung versagt oder unerwartet korrodiert? Die Wahl des falschen Werkstoffs kann Ihre gesamte Produktionsplanung zum Scheitern bringen.

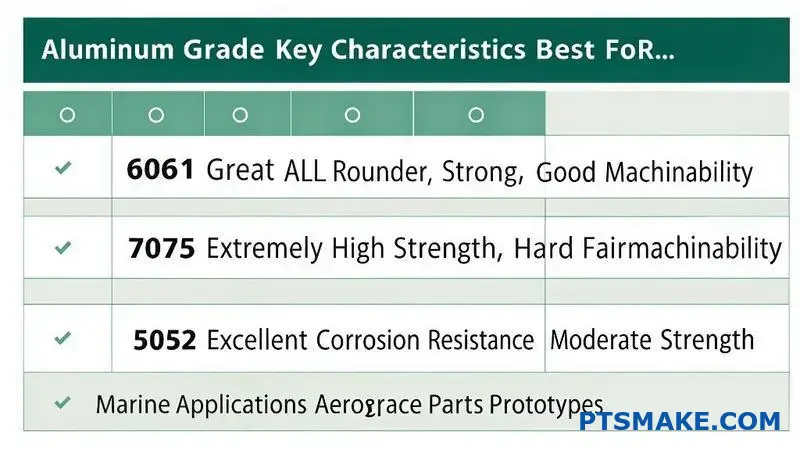

Die beliebteste und vielseitigste Aluminiumsorte für die allgemeine CNC-Bearbeitung ist 6061, die für ihre hervorragende Bearbeitbarkeit, gute Festigkeit und Korrosionsbeständigkeit geschätzt wird. Für hochbeanspruchte Anwendungen, die eine hohe Festigkeit erfordern, ist 7075 die erste Wahl, während 5052 ideal für Blechteile ist, die eine ausgezeichnete Korrosionsbeständigkeit erfordern.

Bei der Wahl der "besten" Sorte geht es nicht um eine einzige richtige Antwort, sondern darum, die richtige Lösung für Ihre spezielle Anwendung zu finden. Die optimale Wahl hängt von einem Gleichgewicht mehrerer Schlüsselfaktoren ab. Bei PTSMAKE helfen wir unseren Kunden bei dieser Entscheidung, indem wir die Leistung des Materials mit den besonderen Anforderungen ihres Projekts abgleichen. Der Prozess der CNC-Bearbeitung von Aluminium wird in hohem Maße von den Eigenschaften des Materials selbst beeinflusst. Diese Eigenschaften zu verstehen, ist der erste Schritt zum Erfolg. Die Eigenschaften eines Materials Wärmebehandelbarkeit1 kann seine endgültigen mechanischen Eigenschaften erheblich verändern, was für Strukturbauteile von entscheidender Bedeutung ist.

Schlüsselfaktoren für die Auswahl von Sorten

Bearbeitbarkeit vs. Festigkeit

Oft gibt es einen Kompromiss. Weichere Legierungen sind leichter zu bearbeiten, bieten aber eine geringere Festigkeit. Härtere Legierungen wie 7075 bieten eine unglaubliche Festigkeit, können aber schwieriger und teurer in der Bearbeitung sein.

Korrosionsbeständigkeit

Für Teile, die Feuchtigkeit oder aggressiven Chemikalien ausgesetzt sind, sind Güten wie 5052 oder 6061 eine ausgezeichnete Wahl.

Bei früheren Projekten haben wir bei PTSMAKE festgestellt, dass die direkte Zuordnung der Anwendung zur Werkstoffsorte den Auswahlprozess vereinfacht. Ein häufiger Fehler ist das Over-Engineering durch die Wahl einer teuren, hochfesten Legierung, wenn eine kostengünstigere Sorte perfekt geeignet gewesen wäre. Wenn Sie von der Endanwendung ausgehen, können Sie unnötige Kosten und komplizierte Herstellungsprozesse vermeiden.

Allgemeine Anwendungen und empfohlene Qualitäten

Im Folgenden finden Sie eine einfache Aufschlüsselung, die wir häufig verwenden, um unseren Kunden eine erste Auswahl zu ermöglichen:

| Art der Anwendung | Empfohlene Note | Hauptvorteil |

|---|---|---|

| Allgemeine Zwecke, Prototypen | 6061-T6 | Beste Allround-Balance |

| Luft- und Raumfahrt, hochbeanspruchte Teile | 7075-T6 | Höchste Stärke |

| Marine, chemische Exposition | 5052-H32 | Hervorragende Korrosionsbeständigkeit |

| Automobilkomponenten | 6061-T6 / 6082-T6 | Gute Festigkeit und Schweißbarkeit |

Diese Tabelle ist ein guter Ausgangspunkt für jede Diskussion über CNC-Bearbeitungsdienstleistungen für Aluminium.

Bei der Auswahl der besten Aluminiumsorte für die CNC-Bearbeitung müssen Bearbeitbarkeit, Festigkeit und Korrosionsbeständigkeit mit den Anforderungen Ihrer Anwendung in Einklang gebracht werden. Während 6061 ein hervorragender Allrounder ist und 7075 sich in hochbeanspruchten Bereichen auszeichnet, hängt die optimale Wahl immer von der endgültigen Funktion und Umgebung des Teils ab.

Wie dünn kann man Aluminium CNC-bohren?

Haben Sie schon einmal ein schlankes, leichtes Aluminiumteil entworfen, das sich dann auf der Maschine verzieht oder reißt? Wenn man ohne klare Vorgaben an die Grenzen der Dünnheit stößt, kann das frustrierend und kostspielig sein.

In der Regel ist eine Wandstärke von 0,020 Zoll (0,5 mm) für die meisten CNC-Bearbeitungsprojekte von Aluminium erreichbar. Mit speziellen Werkzeugen, strategischen Spannvorrichtungen und optimierten Schnittparametern haben wir jedoch für bestimmte Anwendungen erfolgreich Wandstärken von bis zu 0,25 mm (0,010 Zoll) bearbeitet.

Schlüsselfaktoren, die die Wanddicke beeinflussen

Wie dünn Sie werden können, ist keine einzelne Zahl, sondern das Ergebnis mehrerer zusammenwirkender Faktoren. Die richtigen Entscheidungen machen hier den Unterschied zwischen einem erfolgreichen Teil und einem Stück Schrott aus.

Auswahl der Aluminiumlegierung

Die Art des Aluminiums ist die erste Überlegung. Weichere Legierungen wie 6061 sind weit verbreitet, können aber "gummiartig" sein, während härtere Legierungen wie 7075 sauberer zu bearbeiten sind und dünnere Wände ermöglichen. Die ursprüngliche Form des Materials - ob es sich um einen gegossenen Block oder ein gewalztes Blech handelt - bringt auch Variablen mit sich wie anisotrope Eigenschaften2 die sich auf die Stabilität während der Bearbeitung auswirken.

Teil-Geometrie

Eine einfache, flache Wand ist leichter dünn zu bearbeiten als eine komplexe, gekrümmte Wand. Auch die Gesamtgröße des Teils spielt eine Rolle. Ein kleines, dünnes Merkmal ist stabiler als eine große, ungestützte dünne Wand, die sehr anfällig für Vibrationen ist.

| Faktor | Auswirkungen auf die Mindestdicke |

|---|---|

| Legierung Härte | Härtere Legierungen ermöglichen im Allgemeinen dünnere Wände. |

| Teil Komplexität | Einfachere Geometrien unterstützen dünnere Merkmale. |

| Nicht unterstützter Bereich | Größere freitragende Flächen erfordern dickere Wände. |

Bearbeitungsstrategie und Werkzeugbau

Selbst bei perfektem Material und Design führt ein falscher Bearbeitungsansatz zum Scheitern. Der Erfolg bei der CNC-Bearbeitung von Aluminium, insbesondere bei dünnen Wänden, liegt in den Details des Prozesses selbst.

Spanntechnik ist alles

Man kann nicht bearbeiten, was man nicht sicher halten kann. Bei ultradünnen Teilen können Standardschraubstöcke zu Verformungen führen. Bei früheren Projekten bei PTSMAKE haben wir oft kundenspezifische Spannvorrichtungen, Vakuumspannvorrichtungen oder "Zwiebelschalen"-Techniken verwendet, bei denen eine letzte dünne Schicht bis zum Ende belassen wird, um die Steifigkeit zu erhalten.

Schneidwerkzeuge und Parameter

Scharfe, hochwertige Schaftfräser sind unverzichtbar. Die Verwendung von Werkzeugen mit einem hohen Schrägungswinkel trägt dazu bei, dass die Späne effizient abgeführt und die Schnittkräfte reduziert werden. Wir stimmen Spindeldrehzahl und Vorschubgeschwindigkeit sorgfältig aufeinander ab - zu aggressiv, und das Teil verbiegt sich; zu langsam, und es kommt zu Wärmestau und Verzug.

| Technik | Vorteil bei dünnen Wänden |

|---|---|

| Kundenspezifische Befestigung | Bietet maximalen Halt und verhindert Spannverzug. |

| Scharfe, hochseilige Werkzeuge | Reduziert den Schnittdruck und verbessert die Spanabfuhr. |

| Optimierter Kühlmittelverbrauch | Beherrscht den Wärmestau, um thermische Verformungen zu verhindern. |

Das Erreichen ultradünner Aluminiumteile ist ein Balanceakt. Während 0,020" ein sicherer Ausgangspunkt ist, sind Faktoren wie die Wahl der Legierung und die Geometrie entscheidend. Der Erfolg hängt letztlich von einer präzisen Prozesssteuerung ab, von speziellen Spannvorrichtungen bis hin zu optimierten Werkzeugen und Schnittparametern.

Welche Schnittgeschwindigkeiten eignen sich am besten für die CNC-Bearbeitung von Aluminium?

Haben Sie schon einmal endlos an Ihren Einstellungen gefeilt, nur um ein schlechtes Oberflächenfinish oder ein kaputtes Werkzeug zu erhalten? Den richtigen Punkt für Aluminium zu finden, kann sich wie ein Ratespiel anfühlen.

Für die meisten Aluminiumlegierungen wie 6061 liegt ein guter Ausgangspunkt für die Schnittgeschwindigkeit zwischen 800 und 1.500 Oberflächenmetern pro Minute (SFM). Die optimale Geschwindigkeit hängt jedoch stark von Ihren spezifischen Maschinenfähigkeiten, Werkzeugen, der genauen Legierung und der Schnitttiefe ab.

Der erste Schritt ist das Verstehen der grundlegenden Parameter. Die beiden wichtigsten Werte sind die Schnittgeschwindigkeit und die Spindeldrehzahl (RPM). Sie hängen zwar zusammen, sind aber nicht dasselbe. Die Schnittgeschwindigkeit (SFM oder m/min) ist die relative Geschwindigkeit zwischen der Schneide des Werkzeugs und dem Werkstück. Bei unseren früheren Projekten bei PTSMAKE haben wir festgestellt, dass die richtige Einstellung der Schlüssel zur Vermeidung von Problemen wie einer Aufgebaute Kante3 auf dem Werkzeug.

Schlüsselfaktoren, die die Geschwindigkeit beeinflussen

Aluminium-Legierung

Verschiedene Legierungen haben unterschiedliche Zerspanbarkeitswerte. Aluminium 7075 ist zum Beispiel härter als 6061 und erfordert in der Regel etwas niedrigere Geschwindigkeiten, um Hitze und Werkzeugverschleiß effektiv zu bewältigen.

| Aluminium-Legierung | Empfohlenes Start-SFM | Anmerkungen |

|---|---|---|

| 6061-T6 | 1000 - 2000 | Sehr häufig, ausgezeichnete Bearbeitbarkeit. |

| 7075-T6 | 800 - 1500 | Härter, stärker, erfordert mehr Kontrolle. |

| 2024-T3 | 600 - 1200 | Gummy, kann eine Herausforderung sein. |

Neben der Hauptdrehzahl müssen Sie auch die Vorschubgeschwindigkeit und die Spanbelastung berücksichtigen. Die Vorschubgeschwindigkeit gibt an, wie schnell sich das Werkzeug durch das Material bewegt, während die Spanlast die Dicke des von jeder Schneide (Spannut) des Werkzeugs abgetragenen Materials angibt. Eine höhere Spanlast kann die Zykluszeiten verbessern, erhöht jedoch die Schnittkräfte. Für eine erfolgreiche Aluminium-CNC-Bearbeitungist es wichtig, diese auszugleichen. Ein langsamer Vorschub mit einer hohen Drehzahl kann zu Reibung statt zu Schneiden führen, was übermäßige Hitze erzeugt und zu einem vorzeitigen Werkzeugausfall führt.

Optimieren von Werkzeug- und Schnittparametern

Auswahl der Werkzeuge

Das richtige Werkzeug macht einen großen Unterschied. Für Aluminium sind polierte Schaftfräser mit 2 oder 3 Schneiden in der Regel am besten geeignet, da sie eine effiziente Spanabfuhr ermöglichen.

| Werkzeug Nutenzahl | Empfohlene Verwendung | Chip-Evakuierung |

|---|---|---|

| 2-flutig | Schruppen, Schlitzen | Ausgezeichnet |

| 3-Flöte | Allgemeine Zwecke, Veredelung | Gut |

| 4+ Flöte | Nur Endbearbeitung | Angemessen (Gefahr der Splitterbildung) |

Die optimale Schnittgeschwindigkeit für Aluminium lässt sich nicht auf eine einzige Zahl festlegen. Es handelt sich um einen ausgewogenen Bereich, der von Ihrer Legierung, Ihren Werkzeugen und Ihrer Maschineneinstellung bestimmt wird. Beginnen Sie mit den empfohlenen SFM-Werten und nehmen Sie dann eine Feinabstimmung von Vorschub und Spanmenge vor, um die beste Oberfläche und Werkzeugstandzeit zu erzielen.

Wie viel kostet die professionelle CNC-Bearbeitung von Aluminium?

Hatten Sie schon einmal Probleme, die Endkosten für Ihre bearbeiteten Teile vorherzusagen? Unerwartete Ausgaben können selbst die am besten geplanten Budgets zum Scheitern bringen und zu frustrierenden Verzögerungen und unangenehmen Fragen im Nachhinein führen.

Die endgültigen Kosten für die professionelle CNC-Bearbeitung von Aluminium lassen sich nicht mit einer einzigen Zahl beziffern. Sie werden von Faktoren wie Materialqualität, Maschinenzeit, Komplexität des Teils, Toleranzen und Nachbearbeitung bestimmt. Ein einfaches Teil kostet weit weniger als eines mit komplizierten Merkmalen und engen Spezifikationen.

Verstehen der wichtigsten Kostentreiber

Die Grundlage eines jeden Angebots für die CNC-Bearbeitung von Aluminium beginnt mit zwei Hauptfaktoren: dem Rohmaterial und der Betriebszeit einer CNC-Maschine. Die von Ihnen gewählte Aluminiumlegierung hat einen direkten Einfluss auf den Preis. Aluminium 7075 zum Beispiel ist stärker, aber teurer und schwieriger zu bearbeiten als die gängigere Legierung 6061. Diese Schwierigkeit führt zu längeren Bearbeitungszeiten und erhöhtem Werkzeugverschleiß, was die Kosten weiter in die Höhe treibt. Die Zerspanbarkeit eines Werkstoffs, oder Bearbeitbarkeit4ist eine entscheidende Variable, die sich direkt auf den Maschinenstundensatz und die Gesamtkosten auswirkt.

| Merkmal | Aluminium 6061 | Aluminium 7075 |

|---|---|---|

| Relative Kosten | Unter | Höher (~20-40% mehr) |

| Bearbeitbarkeit | Ausgezeichnet | Messe |

| Gemeinsame Nutzung | Allgemeiner Zweck | Hohe Belastung, Luft- und Raumfahrt |

Sekundäre Faktoren, die den Endpreis beeinflussen

Abgesehen von den Grundlagen beeinflussen mehrere andere Elemente Ihr Budget erheblich. Ein wichtiger Faktor ist die Komplexität der Teile. Kompliziertere Geometrien mit komplexen Kurven und tiefen Taschen erfordern mehr Programmierung, spezielle Werkzeuge und längere Laufzeiten. Ebenso erfordern engere Toleranzen präzisere Maschineneinstellungen und strenge Qualitätskontrollen, was die Arbeits- und Maschinenkosten erhöht. In unseren Projekten bei PTSMAKE weisen wir unsere Kunden häufig darauf hin, dass Nachbearbeitungsschritte wie Eloxieren oder Lackieren ebenfalls einen beträchtlichen Prozentsatz der Endkosten eines Aluminium-CNC-Bearbeitungsprojekts ausmachen können.

| Toleranzgrenze | Auswirkungen auf die Kosten | Bearbeitung Ansatz |

|---|---|---|

| Standard (±0,1 mm) | Basislinie | Standardeinrichtung, schnellerer Zyklus |

| Dicht (±0,025 mm) | +25% bis +100% | Langsamere Geschwindigkeiten, häufige Kontrollen |

| Sehr eng (<±0,01mm) | +100% bis +300% | Spezialisierte Werkzeuge, Klimakontrolle |

Um die Kosten für die CNC-Bearbeitung von Aluminium effektiv zu kalkulieren, sollten Sie nicht nur die Oberfläche betrachten. Die endgültigen Kosten sind eine Mischung aus Materialauswahl, Maschinenstunden, Teilekomplexität, erforderlichen Toleranzen und Endbearbeitungsleistungen. Das Verständnis dieser Schlüsselfaktoren ist entscheidend für eine genaue Projektprognose und die Vermeidung unerwarteter Ausgaben.

Welche Toleranzen können bei der CNC-Bearbeitung von Aluminium erreicht werden?

Haben Sie schon einmal eine enge Toleranz für ein Aluminiumteil festgelegt, nur um dann mit unerwarteten Kostenüberschreitungen oder Produktionsverzögerungen konfrontiert zu werden? Dieses häufige Problem kann Projektzeitpläne und Budgets durcheinander bringen.

Bei der Standard-CNC-Bearbeitung von Aluminium können normalerweise Toleranzen von ±0,005 Zoll (±0,127 mm) erreicht werden. Für hochpräzise Anforderungen ist es möglich, viel engere Toleranzen zu erreichen, wie ±0,001 Zoll (±0,025 mm) oder sogar bis zu ±0,0005 Zoll (±0,013 mm) mit fortschrittlichen Maschinen und Verfahren.

Es ist wichtig, die Faktoren zu verstehen, die diese Ergebnisse beeinflussen. Die endgültige Toleranz ist nicht nur eine Zahl, die Sie wählen, sondern das Ergebnis mehrerer zusammenwirkender Elemente.

Schlüsselfaktoren, die die Toleranzen beeinflussen

Die Qualität und Kalibrierung der CNC-Maschine selbst sind von grundlegender Bedeutung. Eine robuste, gut gewartete 5-Achsen-Maschine wird eine weniger robuste 3-Achsen-Maschine immer übertreffen. Außerdem ist die spezifische Aluminiumlegierung von Bedeutung. So ist beispielsweise 6061-T6 ein Arbeitspferd, das für seine gute Bearbeitbarkeit bekannt ist, während eine 7075-T6-Legierung, obwohl sie stärker ist, aufgrund von inneren Spannungen schwieriger mit extrem engen Toleranzen zu bearbeiten sein kann. Eine ordnungsgemäße Werkstückspannung und die Verwendung scharfer, hochwertiger Schneidwerkzeuge sind für die Präzision ebenfalls unverzichtbar. Diese Elemente bilden zusammen ein System, bei dem das schwächste Glied das Endergebnis bestimmt. Geometrische Bemaßung und Tolerierung5 Fähigkeit.

Aluminiumlegierung vs. erreichbare Toleranzen

| Aluminium-Legierung | Allgemeine Stimmung | Bearbeitbarkeit | Typische Standardtoleranz |

|---|---|---|---|

| 6061 | T6 | Gut | ±0,005" (±0,127 mm) |

| 7075 | T6 | Messe | ±0,005" (±0,127 mm) |

| 2024 | T3 | Gut | ±0,004" (±0,102 mm) |

| 5052 | H32 | Messe | ±0,005" (±0,127 mm) |

Obwohl es technisch möglich ist, sehr enge Toleranzen zu erreichen, ist dies nicht immer praktisch oder kosteneffektiv. Jeder Dezimalpunkt, der zu einer Toleranzspezifikation hinzugefügt wird, kann einen erheblichen Einfluss auf die Endkosten des Teils haben.

Die Kosten der Präzision

Die Forderung nach engeren Toleranzen als funktionell erforderlich ist ein häufiges technisches Versehen, das die Kosten drastisch erhöht. Dies liegt daran, dass eine höhere Präzision bei der CNC-Bearbeitung von Aluminium langsamere Maschinengeschwindigkeiten, häufigere Werkzeugwechsel, spezielle Prüfgeräte und oft mehrere Nachbearbeitungsschritte erfordert. In unseren Projekten bei PTSMAKE arbeiten wir häufig mit unseren Kunden bei der Überprüfung des Designs für die Herstellbarkeit (DFM) zusammen. Dieser Prozess hilft bei der Identifizierung von Merkmalen, bei denen die Toleranzen gelockert werden können, ohne die Funktion des Teils zu beeinträchtigen, was zu erheblichen Kosten- und Zeiteinsparungen führt. Fragen Sie immer, ob eine engere Toleranz wirklich einen Mehrwert bringt.

Toleranz vs. Relative Kosten

| Toleranzgrenze | Relativer Kostenanstieg | Bearbeitungs- und Inspektionsprozess |

|---|---|---|

| Standard (±0,005") | Grundlinie (1x) | Standardgeschwindigkeiten, grundlegende QC-Kontrollen |

| Dicht (±0,001") | 2x - 4x | Langsamere Geschwindigkeiten, CMM-Prüfung |

| Hochpräzise (±0,0005") | 5x - 10x+ | Mehrere Aufstellungen, erweiterte Messtechnik |

Die CNC-Bearbeitung von Aluminium kann Toleranzen von standardmäßig ±0,005" bis zu hochpräzisen ±0,0005" liefern. Dies hängt von der Maschinenqualität und dem Material ab. Engere Toleranzen erhöhen jedoch die Kosten, so dass eine Überprüfung der Herstellbarkeit (Design for Manufacturability) unerlässlich ist, um Präzision und Budget in Einklang zu bringen.

Wie wirken sich Endbearbeitung und Nachbearbeitung auf Ihren Zeitplan für die CNC-Bearbeitung von Aluminium aus?

Haben Sie schon einmal erlebt, dass sich die Fertigstellung eines perfekt bearbeiteten Teils um Wochen verzögert? Es ist frustrierend, wenn der letzte Schliff zum größten Engpass wird und Ihre Projektfristen gefährdet.

Die Nachbearbeitung und Endbearbeitung kann die Gesamtvorlaufzeit für die CNC-Bearbeitung von Aluminium um einige Stunden bis zu mehreren Wochen verlängern. Die genaue Dauer hängt stark von der Art der Nachbearbeitung, der Komplexität des Prozesses und davon ab, ob sie intern oder extern durchgeführt wird.

Die Reise eines Aluminiumteils endet nicht, wenn die CNC-Maschine anhält. Die Nachbearbeitung ist eine kritische Phase, die den endgültigen Liefertermin erheblich beeinflussen kann. Die Wahl der Oberflächenbehandlung wirkt sich direkt auf die Zeit und die Leistung des Teils aus.

Gemeinsame Veredelungsoptionen

Einfache mechanische Bearbeitungen wie Entgraten oder Perlstrahlen können nur ein paar Stunden in Anspruch nehmen. Komplexere chemische Behandlungen sind jedoch eine andere Geschichte. Zum Beispiel kann ein Standardverfahren wie Eloxieren6 kann den Zeitplan um mehrere Tage verlängern, wenn man die Lagerung, Verarbeitung und Trocknung berücksichtigt. Speziellere Veredelungen erfordern sogar noch mehr Zeit.

| Veredelungsprozess | Typische Zeitaddition | Wichtigste Überlegung |

|---|---|---|

| Unbearbeitet | 0 Tage | Schnellste Option, kann sichtbare Werkzeugspuren aufweisen. |

| Perlstrahlen | 0,5 - 1 Tag | Erzeugt eine gleichmäßig matte Oberfläche. |

| Eloxieren (Typ II) | 2 - 4 Tage | Sorgt für Korrosionsbeständigkeit und Farbe. |

| Pulverbeschichtung | 3 - 5 Tage | Bietet eine dauerhafte, dicke, dekorative Oberfläche. |

Neben dem spezifischen Prozess spielt auch die Logistik eine große Rolle. Bei PTSMAKE wickeln wir viele Endbearbeitungsprozesse intern ab, was den Arbeitsablauf strafft und Verzögerungen verringert. Wenn ein Prozess ausgelagert werden muss, müssen Sie versteckte Zeitverluste einkalkulieren.

Die versteckten Verzögerungen: Logistik und Qualitätskontrolle

Der Versand von Teilen zu einem Drittanbieter und zurück verlängert die Transitzeit. Noch wichtiger ist, dass Ihre Teile in die Produktionswarteschlange gelangen, was bedeuten kann, dass sie hinter anderen Aufträgen zurückbleiben.

Verwaltung der ausgelagerten Endbearbeitung

Ein weiterer Faktor ist die Qualitätskontrolle. Was ist, wenn eine Charge vom Veredler außerhalb der Spezifikationen zurückkommt? Die Teile müssen dann möglicherweise entnommen und neu bearbeitet werden, was zu erheblichen Verzögerungen führt. Deshalb ist ein zuverlässiger Partner, der die gesamte Lieferkette, einschließlich qualifizierter Veredler, verwaltet, von unschätzbarem Wert für jedes Unternehmen. Aluminium-CNC-Bearbeitung Projekt.

| Mögliche Verzögerung | Zeitliche Auswirkungen | Strategie zur Risikominderung |

|---|---|---|

| Transit zum/vom Verkäufer | 2 - 5 Tage | Nutzen Sie einen Anbieter aus einer Hand, der über eigene Kapazitäten verfügt. |

| Verkäufer-Warteschlange Zeit | 1 - 10+ Tage | Arbeiten Sie mit einem Hersteller zusammen, der über gute Lieferantenbeziehungen verfügt. |

| Nacharbeit/Ablehnung | 3 - 7 Tage | Durchführung strenger Qualitätskontrollen bei der Ein- und Auslieferung. |

Die Endbearbeitung ist ein kritischer, aber oft unterschätzter Teil des Zeitplans für die CNC-Bearbeitung von Aluminium. Die Berücksichtigung spezifischer Prozesse, potenzieller logistischer Verzögerungen und Qualitätskontrollschritte von Anfang an ist unerlässlich, um unerwartete Engpässe zu vermeiden und die pünktliche Lieferung Ihrer Teile zu gewährleisten.

Welche Oberflächenbehandlungen gibt es für CNC-Aluminium?

Haben Sie schon einmal eine Oberfläche für ein Aluminiumteil spezifiziert und dann festgestellt, dass diese nicht Ihren Anforderungen an Haltbarkeit oder Ästhetik entspricht? Diese Unstimmigkeit kann zu kostspieligen Nacharbeiten und Projektverzögerungen führen.

Die gebräuchlichsten Oberflächenveredelungen für CNC-Aluminiumteile sind Rohbearbeitung, Perlstrahlen, Eloxieren (Typ II und III), Pulverbeschichtung, Lackierung und chemische Filmbeschichtung. Jede Oberfläche bietet einzigartige Vorteile in Bezug auf Schutz, Aussehen und Funktionalität für Ihre CNC-gefertigten Aluminiumteile.

Bei der Auswahl einer Oberfläche ist es wichtig, nicht nur auf das Aussehen zu achten. Die Hauptfunktion des Teils bestimmt oft die beste Wahl. Für Anwendungen, die eine hohe Haltbarkeit und Korrosionsbeständigkeit erfordern, sind Schutzbeschichtungen unerlässlich.

Schützende und funktionelle Veredelungen

Eloxieren (Typ II & Typ III)

Eloxieren ist ein elektrochemisches Verfahren, das eine dauerhafte, korrosionsbeständige Oxidschicht auf der Oberfläche von Aluminium bildet. Typ II oder "farbloses/farbiges" Eloxieren eignet sich gut für ästhetische Zwecke und bietet mäßigen Schutz. Typ III, das so genannte Hartanodisieren, erzeugt eine viel dickere, dichtere Schicht, die eine höhere Verschleiß- und Abriebfestigkeit bietet. Bei früheren Projekten von PTSMAKE haben wir festgestellt, dass die Hartschicht-Eloxierung für Teile in stark beanspruchten mechanischen Baugruppen unerlässlich ist. Es ist ein kritischer Prozess, vor allem, wenn die Teile potenziellen Belastungen standhalten müssen. galvanische Korrosion7 bei Kontakt mit anderen Metallen.

| Merkmal | Eloxieren (Typ III) | Chemischer Film |

|---|---|---|

| Primäre Verwendung | Abnutzungswiderstand | Korrosionsschutz |

| Dicke | Dicker (25-125 µm) | Sehr dünn (<1 µm) |

| Leitfähigkeit | Elektrisch isolierend | Elektrisch leitfähig |

| Erscheinungsbild | Dunkler, undurchsichtig | Klar bis Gelb/Gold |

Neben dem Schutz steht bei vielen Anwendungen auch das Aussehen und die Haptik des Endprodukts im Vordergrund. Ästhetische Veredelungen können Bearbeitungsspuren verbergen, Farbe verleihen und eine besondere Textur erzeugen, was den wahrgenommenen Wert des Teils erheblich steigert.

Ästhetische und vorbereitende Veredelungen

Perlstrahlen

Beim Perlstrahlen werden feine Glasperlen mit hohem Druck geschleudert, um eine gleichmäßige, ungerichtete matte oder satinierte Oberfläche zu erzeugen. Es ist ein hervorragendes Verfahren zur Beseitigung kleinerer Oberflächenfehler und Werkzeugspuren, die bei der CNC-Bearbeitung von Aluminium entstehen. Wir verwenden es oft als Vorbehandlung vor dem Eloxieren, um eine hochwertige, nicht reflektierende Oberfläche zu erzielen, die unsere Kunden lieben.

Pulverbeschichtung und Lackierung

Wenn es um Farbe und eine dauerhafte Schutzschicht geht, sind Pulverbeschichtung und Lackierung die beste Wahl. Bei der Pulverbeschichtung wird ein trockenes Pulver elektrostatisch aufgetragen und dann unter Hitze ausgehärtet. So entsteht eine Oberfläche, die in der Regel widerstandsfähiger ist als herkömmliche Flüssiglacke.

| Merkmal | Perlstrahlen | Pulverbeschichtung | Malerei |

|---|---|---|---|

| Erscheinungsbild | Matte/Satin Textur | Glatt/Texturiert, Farbe | Glatt, glänzend/matt |

| Funktion | Versteckt Werkzeugmarkierungen | Farbe, Langlebigkeit | Farbe, Schutz |

| Als Vorbehandlung | Ja | Manchmal | Häufig |

Bei der Wahl der richtigen Oberfläche für CNC-Aluminiumteile müssen funktionale Anforderungen wie Verschleißfestigkeit mit ästhetischen Zielen in Einklang gebracht werden. Die Optionen reichen von Schutzbeschichtungen wie Eloxieren und Chemiefilm bis hin zu optisch ansprechenden Oberflächen wie Perlstrahlen und Pulverbeschichtung, so dass für jede Anwendung eine geeignete Wahl getroffen werden kann.

Welche Branchen nutzen die CNC-Bearbeitung von Aluminium am meisten?

Haben Sie sich schon einmal gefragt, warum so viele Hightech-Komponenten so aussehen und sich auch so anfühlen, als seien sie aus demselben hochwertigen Metall gefertigt? Das hat nicht nur ästhetische Gründe, sondern auch einen praktischen.

Die Luft- und Raumfahrt, die Automobilindustrie und die Unterhaltungselektronik sind die wichtigsten Anwender der CNC-Bearbeitung von Aluminium. Diese Branchen verlassen sich auf Aluminium wegen seines außergewöhnlichen Verhältnisses von Festigkeit zu Gewicht, seiner hervorragenden Korrosionsbeständigkeit und seiner ausgezeichneten Wärmeleitfähigkeit, was es zum idealen Werkstoff für Hochleistungsanwendungen und Leichtbauanwendungen macht.

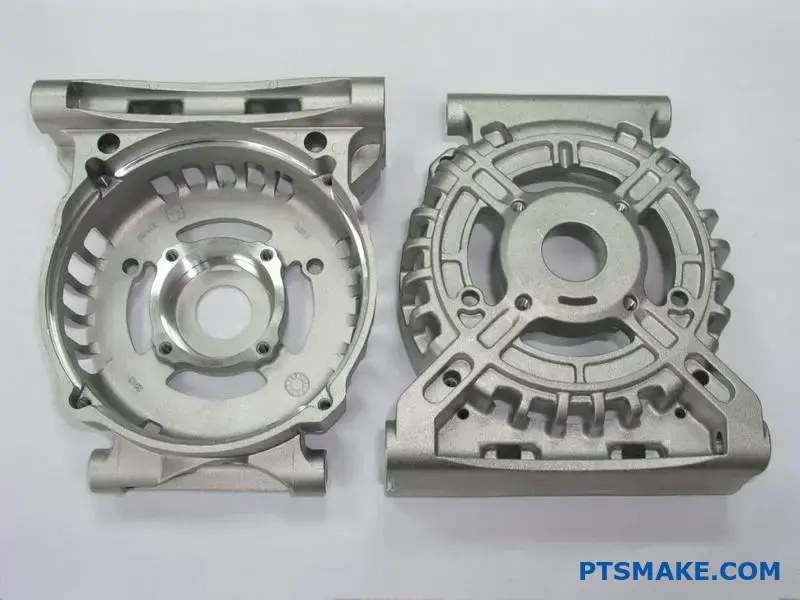

Wenn wir über die wichtigsten Nutzer sprechen, kommt man an der Luft- und Raumfahrtindustrie nicht vorbei. Bei Flugzeugen kommt es auf jedes Gramm an. Das Ziel ist es, das Gewicht zu reduzieren, ohne die Festigkeit zu beeinträchtigen, was sich direkt auf die Treibstoffeffizienz und die Nutzlastkapazität auswirkt. Bei unserer Arbeit bei PTSMAKE bearbeiten wir häufig Teile für Kunden aus der Luft- und Raumfahrt, bei denen enge Toleranzen nicht verhandelbar sind.

Die Rolle der spezifischen Legierungen

Verschiedene Anwendungen erfordern unterschiedliche Aluminiumlegierungen. Die Wahl ist entscheidend für die Leistung. So erfordern beispielsweise Strukturbauteile oft hochfeste Legierungen, während Teile, die den Elementen ausgesetzt sind, eine verbesserte Korrosionsbeständigkeit durch Verfahren wie Eloxierung8.

Gängige Legierungen für die Luft- und Raumfahrt

| Legierung | Wesentliche Merkmale | Typische Anwendung |

|---|---|---|

| 6061-T6 | Gute Festigkeit, Schweißbarkeit, Korrosionsbeständigkeit | Flugzeugeinrichtungen, Fahrwerk |

| 7075-T6 | Sehr hohe Festigkeit, gute Ermüdungsbeständigkeit | Flügelholme, Rumpfspanten |

| 2024-T3 | Hohe Festigkeit, gute Ermüdungsbeständigkeit | Strukturelle Komponenten, Scherstege |

Diese Präzision wird erreicht durch fortschrittliche Aluminium-CNC-Bearbeitung.

Die Automobilindustrie folgt dicht hinter der Luft- und Raumfahrt, insbesondere mit dem Aufkommen von Elektrofahrzeugen. Leichtere Fahrzeuge bedeuten eine größere Reichweite und bessere Leistung, was Aluminium zu einem der Hauptakteure macht. Von Motorblöcken in herkömmlichen Autos bis hin zu Batteriegehäusen und Fahrwerkskomponenten in Elektrofahrzeugen ist Aluminium unverzichtbar. Bei früheren Projekten haben wir unseren Kunden geholfen, durch die Umstellung von Stahl- auf Aluminiumteile erhebliche Gewichtseinsparungen bei ihren Komponenten zu erzielen.

Auswirkungen auf die Fahrzeugleistung

Bei der Umstellung auf Aluminium geht es nicht nur um das Gewicht. Seine thermischen Eigenschaften sind entscheidend für das Wärmemanagement in Hochleistungsmotoren und Batteriesystemen.

Aluminium vs. Stahl in der Automobilindustrie

| Komponente | Aluminium Vorteil | Stahl Vorteil |

|---|---|---|

| Motorblock | Leichter, bessere Wärmeableitung | Geringere Kosten, höhere Lebensdauer |

| Fahrgestell | Verbesserte Handhabung und Kraftstoff-/Batterieeffizienz | Höhere Steifigkeit zum Preis von |

| Karosserie-Paneele | Gewichtsreduzierung, Korrosionsbeständigkeit | Geringere Material- und Reparaturkosten |

Diese Ausgewogenheit der Eigenschaften macht Aluminium-CNC-Bearbeitung ein Eckpfeiler der modernen Automobilproduktion.

Die Luft- und Raumfahrt, die Automobilindustrie und die Elektronikindustrie sind führend bei der CNC-Bearbeitung von Aluminium. Die einzigartige Mischung aus geringem Gewicht, hoher Festigkeit und Wärmeleitfähigkeit des Werkstoffs ist entscheidend für die Herstellung von Hochleistungskomponenten, die diese Branchen ausmachen - von Flugzeugrahmen bis hin zu Batteriegehäusen für Elektrofahrzeuge.

Entdecken Sie, wie die Wärmebehandlung die Festigkeit und Haltbarkeit von Aluminium für Ihre Bauteile verbessern kann. ↩

Erfahren Sie, wie sich die Richtungsabhängigkeit des Materials auf die Festigkeit eines Teils und den Bearbeitungserfolg bei dünnwandigen Komponenten auswirkt. ↩

Verstehen Sie, was eine Aufbauschneide ist und wie Sie sie verhindern können, um eine hervorragende Teilequalität zu erzielen. ↩

Klicken Sie hier, um zu erfahren, wie sich die Zerspanbarkeit einer Legierung direkt auf den Zeitplan und die Endkosten Ihres Projekts auswirkt. ↩

Erfahren Sie, wie diese symbolische Sprache sicherstellt, dass Ihre Designabsicht von den Herstellern perfekt verstanden wird und kostspielige Fehlinterpretationen vermieden werden. ↩

Erfahren Sie mehr über diesen elektrochemischen Prozess und darüber, wie sich die verschiedenen Typen auf die Eigenschaften und den Zeitplan Ihres Teils auswirken können. ↩

Erfahren Sie mehr über die Verhinderung dieses elektrochemischen Prozesses, der zur Zersetzung von Bauteilen aus unterschiedlichen Metallen führen kann. ↩

Erfahren Sie mehr über dieses wichtige Veredelungsverfahren, das die Haltbarkeit und das Aussehen von Aluminium verbessert. ↩