Choosing the wrong brass polish for your precision components can turn a flawless design into a costly failure. Poor surface finishes lead to corrosion, reduced conductivity, failed inspections, and disappointed customers who expect mirror-quality results from their trusted suppliers.

Brass polish selection depends on your application requirements, environmental conditions, and desired finish quality. Industrial applications need specialized compounds that provide durability, corrosion resistance, and consistent results across production runs, unlike consumer-grade products that prioritize convenience over performance.

This guide covers everything from choosing the right polish chemistry to achieving mirror finishes that meet aerospace and medical device standards. You’ll discover proven techniques that ensure consistent quality from prototype through mass production.

Why Brass Polish Matters In Precision Engineering

In precision engineering, a component’s finish is not just about looks. It’s a critical aspect of its function. A proper brass polish does more than make a part shiny.

Performance and Perception

It ensures the part performs reliably. It also affects the first impression of the final product. Poor finishing can suggest poor quality.

This is especially true in B2B sectors. Industries like aerospace and medical devices demand perfection. The benefits of a professional polish are clear.

| Industriel sektor | Primary Benefit of Brass Polish |

|---|---|

| Luft- og rumfart | Modstandsdygtighed over for korrosion |

| Medicinsk udstyr | Sterilizability & Cleanliness |

| Elektronik | Enhanced Conductivity |

When dealing with high-stakes industries, every detail matters. The industrial brass polish benefits go far beyond simple aesthetics. They directly impact safety, reliability, and functionality. Think about it.

Luft- og rumfartsapplikationer

In aerospace, a polished brass component resists corrosion better. This small detail can extend the service life of a critical part, preventing failures. Even minor surface imperfections can become stress points over time.

Medical and Electronic Components

For medical devices, a smooth, polished surface is easier to sterilize. It prevents bacteria from gathering in microscopic crevices. This is a non-negotiable requirement.

In electronics, precision component finishing is key. A clean, polished surface ensures optimal electrical conductivity between components. This is vital for the performance of sensitive electronic assemblies. We’ve seen how a superior finish can improve the signal integrity of a connector. It reduces signal loss.

Lowering the overfladeruhed1 of a component can drastically reduce friction and wear. It also ensures a tighter seal for fittings.

| Anvendelse | Key Performance Impact |

|---|---|

| Tilslutninger | Improved Conductivity |

| Lejer | Reduceret friktion |

| Ventiler | Better Sealing |

| Implantater | Enhanced Biocompatibility |

At PTSMAKE, we focus on these details. A perfect finish is part of our commitment to delivering components that exceed specifications.

Brass polish is essential for function and perception in precision engineering. A quality finish enhances performance in critical sectors like aerospace and medical devices, directly impacting reliability and building client trust in the final assembly.

How To Choose The Right Brass Polish For Your Parts

Choosing the right brass polish is not just about looks. It’s a technical decision. You must balance aesthetics, durability, and protection.

Your part’s final use case is the most important factor. Is it a decorative piece or a functional component? This question guides your selection.

Here is a simple framework to start.

| Polish Type | Bedst til | Nøglefunktion |

|---|---|---|

| Højglans | Decorative Parts | Spejllignende glans |

| Satinfinish | OEM Components | Low glare, hides fingerprints |

| Antique Finish | Arkitektonisk | Aged, classic appearance |

| Protective Lacquer | Dele med høj slitage | Maximum corrosion resistance |

This basic guide helps you narrow down the options for your project.

A brass finish selection guide helps streamline your decision. At PTSMAKE, we guide clients through this process daily. We break it down into four key areas.

Desired Aesthetic

First, define the look you need. A high-gloss polish works for consumer products. It creates a premium feel. But for industrial equipment, a satin or matte finish is better. It reduces glare and looks professional.

Industry and Application

The industry sets the standard. Medical and aerospace parts often need non-reflective finishes for functional reasons. In contrast, architectural hardware might use an antique brass polish for a classic look. The best brass polish for OEM parts is often one that balances appearance with performance.

Durability Requirements

Consider the part’s environment. Will it be handled frequently? Or exposed to harsh conditions? A simple wax polish offers minimal protection. A clear lacquer or powder coat provides a much more durable barrier against wear and tear. This is critical for parts that must last. A part’s longevity can be impacted by galvanisk korrosion2 if it’s in contact with other metals.

Modstandsdygtighed over for korrosion

Brass naturally resists corrosion well. But salt spray, moisture, and chemicals can accelerate tarnishing. For marine applications or outdoor use, a polish with added corrosion inhibitors or a sealed lacquer is essential. Our tests show lacquered finishes can extend a part’s life significantly in harsh environments.

Selecting the right brass polish involves weighing aesthetic desires against functional needs like durability and corrosion resistance. Using a clear decision framework ensures your parts not only look great but also perform reliably in their intended application.

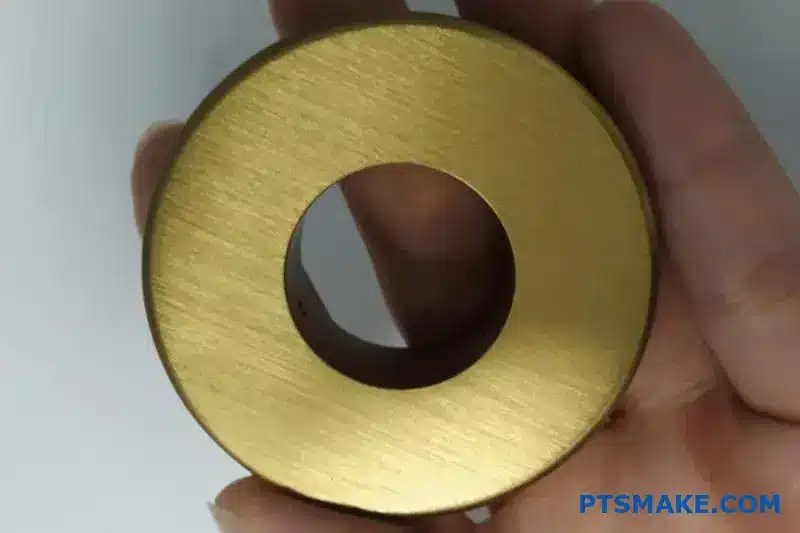

Secrets To Achieving Mirror Finish On Brass Components

Achieving a true mirror finish on brass is not about magic. It’s a methodical process. It relies entirely on the right tools, abrasives, and compounds. Guesswork only leads to frustrating scratches.

For high-gloss brass parts, precision is key from start to finish. You must follow a systematic progression of abrasives. This begins with sanding to remove machine marks. Then you can move to the actual brass polish compounds.

Here is a typical abrasive progression we follow:

| Trin | Abrasive Type | Grit/Grade | Formål |

|---|---|---|---|

| 1 | Sandpapir | 400-600 | Fjern dybe ridser |

| 2 | Sandpapir | 800-1200 | Refine the surface |

| 3 | Sandpapir | 1500-2000 | Gør klar til polering |

| 4 | Polishing Compound | Grov | Initial cut & buff |

| 5 | Polishing Compound | Fint | Final high-gloss shine |

After preparing the surface, the real art of the mirror finish brass polish begins with compounds. These aren’t just simple pastes. They are a careful mix of fine abrasive particles suspended in a carrier liquid or wax.

Selecting the Right Polishing Compound

The abrasive itself, often aluminum oxide or diamond, dictates the cutting speed. The carrier, typically oil or water-based, affects lubrication, heat dissipation, and cleanup. Engineers value this level of control.

At PTSMAKE, we use a multi-stage compound process for critical components. This ensures maximum clarity and reflectivity on the final part.

| Sammensat type | Abrasive Grade | Typisk brugssag |

|---|---|---|

| Cutting (Brown) | Grov | Heavy defect removal |

| Polishing (White) | Medium | Brightening and refining |

| Finishing (Blue/Red) | Ultra-Fine | Final mirror gloss |

One critical factor to watch for is abrasive agglomeration3. When these fine particles clump together, they act like a much coarser grit. This creates deep, random scratches that are very difficult to remove later.

Proper lubrication and using clean buffing wheels are essential CNC brass polishing tips to prevent this. This discipline ensures a consistent, flawless surface required for high-gloss brass parts. It separates an acceptable finish from an exceptional one.

Achieving a mirror finish on brass demands a disciplined approach. It requires a careful sequence of abrasives to remove all imperfections, followed by the correct selection of polishing compounds to create that flawless, reflective surface.

Comparing Brass Polish vs Plating For Industrial Parts

When choosing a finish for industrial brass parts, the decision isn’t just about looks. It’s a critical choice between aesthetics and function. The debate of brass polish vs plating comes down to your component’s end-use.

A brass polish simply enhances the material’s natural surface. It brings out the inherent warm, golden luster of the brass alloy itself. Plating, however, is an additive process. It deposits a new layer of metal onto the brass.

This fundamental difference dictates the final properties of your part.

| Funktion | Poleret messing | Plated Brass |

|---|---|---|

| Proces | Abrasive (Removes Material) | Additive (Adds Layer) |

| Primært mål | Enhance Natural Look | Add New Properties |

| Overflade | Original Brass Alloy | New Metal Layer |

This initial comparison helps frame the decision. It’s about revealing what’s there versus adding something new.

Functional Impact on Performance

From an engineering standpoint, functionality is paramount. A simple brass polish is great when you need to maintain the base material’s properties. It keeps the original electrical and thermal conductivity of the brass alloy intact. This is often sufficient for many applications.

However, for high-performance electroplated brass components, plating offers significant advantages. We can add a layer of a different metal, like nickel or tin, to dramatically improve corrosion resistance. For electrical contacts, a thin layer of silver or gold can enhance conductivity and prevent oxidation. The choice dictates the part’s lifespan in harsh environments.

Aesthetic and Durability Trade-offs

Aesthetically, plating provides far more options and consistency. You can achieve finishes like bright chrome, satin nickel, or even black zinc. These looks are uniform and highly repeatable across large production runs. Polished brass offers a classic, warm appearance but it will tarnish over time without a protective lacquer.

Durability is another key differentiator. A hard chrome plating, for instance, is vastly more resistant to scratches and wear than bare brass. At PTSMAKE, we carefully manage the process to ensure strong Substratets vedhæftning4, preventing the plated layer from flaking under stress. This is vital for moving parts.

This table helps clarify the best finish for conductivity and look.

| Ejendom | Brass Polish | Brass Plating (e.g., Nickel) |

|---|---|---|

| Ledningsevne | Native to Brass | Varies by Plating Metal |

| Modstandsdygtighed over for korrosion | Low (Tarnishes) | Høj til meget høj |

| Hardness/Wear | Base Metal Hardness | Betydeligt forøget |

| Farvemuligheder | Brass Only | Multiple (Silver, Chrome, etc.) |

The choice between polishing and plating hinges entirely on your part’s intended application. Polishing is best for aesthetic parts in controlled environments. Plating is essential for components needing enhanced durability, corrosion resistance, or specific electrical properties.

How Brass Polish Impacts Corrosion Resistance In Harsh Environments

In critical sectors, a high-quality brass polish is non-negotiable. It’s more than aesthetics; it is a functional requirement. It directly impacts component reliability and lifespan.

For aerospace and marine parts, failure is not an option. A superior polish creates a smooth, non-porous surface. This minimizes points where corrosion can begin. The right corrosion-resistant brass polish is a primary defense.

Performance in Key Industries

| Industri | Key Benefit of High-Quality Polish |

|---|---|

| Luft- og rumfart | Prevents micro-pitting, ensures structural integrity |

| Marine | Resists saltwater corrosion and biofouling |

| Medicinsk | Facilitates sterilization, ensures biocompatibility |

En ordentlig protective brass surface finish is the first line of defense in these demanding fields.

The link between polish quality and performance is direct. A smoother surface, measured by a lower Ra value, leaves fewer microscopic pits. These tiny imperfections are where corrosion, like rust or tarnish, starts.

Aerospace and Marine Challenges

In aerospace, components face extreme temperature shifts and atmospheric pressure changes. A flawless protective brass surface finish prevents moisture from getting trapped. This mitigates the risk of stress corrosion cracking.

Marine environments are even tougher. They combine constant moisture with salinity. Here, a high-quality brass polish is crucial to prevent accelerated degradation from saltwater. It also helps prevent galvanisk korrosion5 when brass is in contact with other metals.

At PTSMAKE, we achieve ultra-smooth finishes for these applications. This ensures our clients’ parts perform reliably for their intended service life.

Anvendelser af medicinsk udstyr

For medical instruments, the stakes are just as high. A non-porous surface is easier to clean and sterilize completely. This reduces the risk of bacterial growth and ensures patient safety. The right polish contributes to the material’s biocompatibility.

| Funktion | Aerospace/Marine Benefit | Medicinsk ydelse |

|---|---|---|

| Low Surface Roughness | Reduced drag, fewer corrosion sites | Improved cleanability, less bacterial adhesion |

| Uniform Finish | Consistent material performance | Predictable interaction with tissues |

| Enhanced Hardness | Increased wear resistance | Better durability against repeated sterilization |

A superior brass polish is a critical engineering step. It directly enhances component reliability and longevity in harsh aerospace, marine, and medical environments by creating a robust, protective surface.

The Long Game: How Polished Brass Pays Off

Polishing brass is more than aesthetics. It’s a strategic investment in your product’s future and brand. This finish directly impacts long-term performance and customer perception.

A key benefit is enhanced polished brass durability. A professionally polished surface is not just shiny; it’s a more resilient component.

This simple step adds a layer of protection. It helps guard against minor scratches and environmental corrosion. Over the product’s lifespan, this detail ensures longevity.

Performance vs. Customer Impression

The connection between the physical properties and what the customer feels is direct. Our analysis shows a clear correlation.

| Faktor | Langsigtede resultater | Customer Impression |

|---|---|---|

| Modstandsdygtighed over for korrosion | Betydeligt højere | Appears well-maintained |

| Overfladens hårdhed | Marginally increased | Feels smooth and solid |

| Renlighed | Easier to wipe down | Looks premium and clean |

A polished surface does more than protect. It silently communicates your brand’s standards. This is a crucial aspect of OEM branding through surface finish.

Consider the end-user’s first interaction. When they pick up a product with a polished brass part, it feels substantial. It immediately signals high quality.

This positive haptisk opfattelse6 is powerful. It builds subconscious trust. Customers link that feeling of quality with your brand, creating a lasting positive association.

Building Brand Equity Through Finish

At PTSMAKE, we consistently see how finish becomes an unspoken part of brand identity. It acts as a silent promise of the quality within. A tarnished or rough surface might imply shortcuts were taken elsewhere.

In contrast, a bright, smooth polish suggests meticulous attention to detail. It shows a commitment to excellence that customers notice.

The Ripple Effect of Quality Perception

This initial perception influences loyalty. A customer who trusts the quality of your components is far more likely to make repeat purchases. The initial investment in a superior brass polish pays for itself through customer retention and brand reputation.

| Færdiggør kvalitet | Customer Takeaway | Impact on OEM Brand |

|---|---|---|

| Højpoleret | "This feels well-made." | Perceived as premium, reliable |

| Dull/Unfinished | "Is this a cheap part?" | Seen as basic, budget-focused |

| Inkonsekvent | "They lack attention to detail." | Brand appears unprofessional |

A quality brass polish delivers tangible ROI. It boosts polished brass durability for superior performance. This creates a premium customer impression, strengthening OEM branding through surface finish and building lasting value for your entire product line.

Customer Case Study: Brass Finish For Medical Device Compliance

A client approached us with a challenge. They had a critical brass component for a diagnostic device. However, it repeatedly failed regulatory checks.

The issue was not the design or material. The surface finish failed to meet stringent medical device finish standards.

Our task was to refine their brass polish process. This ensured the component was not only functional but also fully compliant. This brass polish case study highlights how finish is critical.

| Stat | Surface Condition | Compliance Status |

|---|---|---|

| Before | Micro-pitting, inconsistent Ra | Mislykket |

| After | Smooth, uniform, <0.4μm Ra | Passed |

The Regulatory Hurdle

The component required direct contact with sensitive biological samples. This meant the surface had to be non-reactive and easy to sterilize. Any microscopic flaws could harbor contaminants. This risked patient safety and test accuracy.

Initial Failures

Their first prototypes had a visually appealing shine. But under microscopic inspection, the surface was too rough. This roughness failed the necessary medical device finish standards for cleanability. The surface directly impacts a device’s safety profile.

The PTSMAKE Solution: A Multi-Step Process

We abandoned the standard single-step polishing method. At PTSMAKE, we developed a multi-stage process. It was designed for their specific brass alloy. This approach ensured a consistent and ultra-smooth surface. The final finish was crucial for achieving device Biokompatibilitet7.

We worked with the client’s team through several iterations. Together, we perfected the technique. Our process not only met but exceeded the required specifications for their application.

| Trin | Standardproces | Our Enhanced Process |

|---|---|---|

| 1 | Mechanical Sanding | Controlled Lapping |

| 2 | Single-Compound Buff | Multi-Compound Buffing |

| 3 | Chemical Wash | Ultrasonic Cleaning & Passivation |

| 4 | Visuel inspektion | 3D Surface Metrology |

This detailed method guaranteed regulatory approval.

This case study demonstrates that for medical devices, brass polish is not cosmetic. A precise finishing process is critical for meeting stringent regulatory standards and ensuring product safety, ultimately leading to successful market entry.

How PTSMAKE Ensures Brass Polish Consistency From Prototype To Mass Production

Scaling from a single prototype to mass production is a critical test. It’s where many projects face challenges.

A perfect prototype is a great start. But achieving that same consistent brass finish across thousands of units requires a robust system.

From Sample to Scale

At PTSMAKE, we ensure PTSMAKE polish repeatability through documented processes. This systematic approach turns a craft into a reliable science. We build trust by delivering predictable quality every time.

| Scene | Vigtigt fokus | Resultat |

|---|---|---|

| Prototype | Achieving the target finish | A single, perfect part |

| Produktion | Replicating the finish | Thousands of identical parts |

This discipline is fundamental to our manufacturing philosophy.

The Bridge from One to One Thousand

The transition from a single perfect part to thousands is not magic. It is a carefully managed engineering process. We document every variable from the prototype phase. This data becomes the foundation for mass production.

Standard driftsprocedurer (SOP'er)

We create detailed SOPs for every brass polish project. These documents are not just guidelines. They are strict instructions for our technicians. They cover everything from machine settings to the specific grade of abrasive used.

This ensures every operator, on every shift, produces the same result.

Key Controlled Parameters

We precisely control multiple variables. This removes guesswork and guarantees a consistent brass finish. The study of tribologi8 informs our understanding of how materials interact during the polishing process, allowing for finer control.

| Parameter | Kontrolmetode | Hvorfor det er vigtigt |

|---|---|---|

| Polishing Speed | Digital RPM Control | Affects heat and material removal rate |

| Slibende korn | Sourced & Verified Batches | Determines final surface roughness |

| Applied Pressure | Calibrated Tooling | Ensures uniform material contact |

| Cyklustid | Automated Timers | Guarantees consistent duration |

Our Commitment to Repeatability

Our focus on PTSMAKE polish repeatability is relentless. We use statistical process control to monitor outcomes. Any deviation is immediately flagged and corrected. This proactive approach ensures your final production run matches the approved prototype perfectly.

Successfully scaling a brass polish finish requires moving from craft to science. PTSMAKE achieves this with detailed SOPs and strict process controls. This ensures the prototype’s quality is perfectly replicated in every part during mass production.

Packaging Polished Brass Parts For Scratch-Free Delivery

The final brass polish is perfect. Now, the most critical journey begins: from our facility to yours. Proper packaging is not just a final step. It is a core part of the manufacturing process.

Effective logistics for polished brass ensures your parts arrive factory-fresh. It prevents costly rework or rejection. The right anti-scratch packaging material is key.

Primary Packaging Layers

Choosing the correct initial wrap is essential. It’s the first line of defense against scratches and environmental factors.

| Materiale | Scratch Risk | Tarnish Risk |

|---|---|---|

| Microfiber Cloth | Meget lav | Lav |

| VCI Paper | Lav | Meget lav |

| Standard Bubble Wrap | Høj | Medium |

| PE Foam Wrap | Lav | Lav |

The right materials are crucial for protecting your investment. At PTSMAKE, we’ve refined our processes to eliminate shipping damage. This protects the delicate brass polish from abrasion and environmental factors during transit. A pristine part reflects our commitment to quality.

Avanceret materialevalg

We avoid common materials like standard bubble wrap. Its surface can leave impressions on a mirror finish. We also steer clear of kraft paper, which can be abrasive. Instead, we opt for specific anti-scratch packaging material designed for sensitive surfaces.

Our go-to solution is a multi-layer approach. It starts with a soft, non-abrasive layer. This could be a lint-free cloth or a specialized polyethylene (PE) foam sheet. This layer makes direct contact with the part.

Next, we might use VCI (Vapor Corrosion Inhibitor) paper. This is especially important for long-distance or sea freight. It helps prevent tarnishing. Some paper materials can be hygroskopisk9, which can trap moisture against the surface. VCI paper actively combats this risk.

Comparing Advanced Protective Wraps

After testing, we’ve found clear winners for protecting a high-quality brass polish.

| Materiale | Beskyttelsesniveau | Bedste brugssag |

|---|---|---|

| Lint-Free Microfiber | Fremragende | Primary wrap for mirror finishes |

| VCI Paper/Bags | Fremragende | Anti-tarnishing, long transit |

| Cross-linked PE Foam | Meget god | Cushioning & scratch prevention |

| Acid-Free Tissue | God | Interleaving between flat parts |

This careful selection in the logistics for polished brass is non-negotiable for delivering perfection.

Proper B2B shipping protection is a science. It involves choosing the right anti-scratch packaging material and creating a system that prevents movement, abrasion, and corrosion. This ensures every part, with its perfect brass polish, arrives ready for assembly.

Optimizing Design For Easier Polishing In Manufacturing

Achieving a flawless brass polish begins at the design stage. It is not just a final step. Smart design choices make polishing much easier, faster, and more cost-effective for your project.

A part not designed for finishing often needs rework. This leads to inconsistent quality and higher costs.

DFM for Polished Brass CNC

Proper DFM ensures your part is finish-ready. This approach minimizes the intense manual labor required for a high-quality brass polish. It is a critical step for consistent outcomes.

| Design-funktion | Difficult to Polish | Easy to Polish |

|---|---|---|

| Indvendige hjørner | Sharp, tight | Generous, rounded |

| Overflader | Complex, multi-faceted | Large, flat, or gently curved |

| Recesses | Deep, narrow | Shallow, wide access |

Polishing brass is a craft, but you can heavily influence the outcome with good design. At PTSMAKE, we work with clients to ensure every brass part design finish-ready for an exceptional result. This collaboration is key.

Simplify Geometry for Access

Complex shapes with many features are hard to polish evenly. Polishing tools, especially automated ones, struggle to reach every surface. This often results in a varied, inconsistent shine.

Opting for simpler geometries with large, accessible surfaces makes a big difference.

Always Radius Internal Corners

Sharp internal corners are a major challenge. Buffing wheels simply cannot reach into a sharp corner. This leaves dull, unpolished spots that stand out.

A simple DFM tip is to add a generous radius. This small change allows polishing tools full access.

Plan the Pre-Polish Surface

The initial surface finish from CNC machining directly affects the final brass polish. A smoother machine finish requires less polishing time. It also reduces the risk of removing too much material. This property can be affected by the material’s Anisotropi10, which can influence cutting and polishing.

| Parameter | Anbefalet retningslinje | Hvorfor det er vigtigt |

|---|---|---|

| Internal Radii | > 1 mm | Allows tool and buff access |

| Overfladens ruhed | < Ra 0.8 μm | Reduces manual polishing time |

| Væggens tykkelse | Konsekvent | Prevents distortion during buffing |

In summary, a superior brass polish is designed, not just applied. Simple considerations like rounded corners and smooth surfaces significantly reduce polishing effort, cost, and lead time. Planning ahead is the most effective strategy.

Work With PTSMAKE For Unmatched Brass Polish Precision

Ready to achieve flawless, high-performance brass finishes for your industrial projects? Contact PTSMAKE for a fast, tailored quotation—our experts ensure consistent, corrosion-resistant brass polish from prototype to production. Take the next step in quality and partner with PTSMAKE today!

Learn how this surface metric directly influences component friction, wear, and overall lifespan. ↩

Learn how contact with other metals can impact your brass parts’ lifespan. ↩

Understand how abrasive particle behavior impacts surface quality and learn techniques to prevent scratching. ↩

Understand how this bond is critical for the long-term reliability and performance of your plated components. ↩

Understand the electrochemical process that causes one metal to corrode when touching another in an electrolyte. ↩

Learn how tactile qualities influence a user’s perception of product quality and overall value. ↩

Understand the key material properties required for safe medical device applications. ↩

Explore how the science of friction and wear helps us perfect polishing techniques for superior consistency. ↩

Learn how material moisture absorption can affect your parts during shipping. ↩

Learn how a material’s directional properties can influence the final polished surface and design outcomes. ↩