Many engineers struggle with bronze CNC machining projects, facing unexpected material challenges, design complications, and performance issues. The frustration grows when parts don’t meet specifications, production delays occur, or costs spiral beyond budget expectations.

CNC machining bronze requires understanding specific material properties, proper alloy selection, and optimized machining parameters. Success depends on matching bronze grades to applications, implementing correct design principles, and following proven manufacturing practices.

I’ve worked with bronze machining projects at PTSMAKE for over 15 years, and I’ve seen how small design decisions can make or break a project. The difference between a successful bronze component and a problematic one often comes down to understanding the material’s unique characteristics and applying the right manufacturing approach. This guide walks you through everything from alloy selection to final inspection, giving you the practical knowledge to avoid common pitfalls and deliver high-performance bronze parts that meet your exact specifications.

Key Properties of Bronze Relevant to CNC Machining?

Have you ever selected a material that seemed ideal on paper, only to have it wear out and fail unexpectedly in a critical application? This can lead to costly downtime and redesigns.

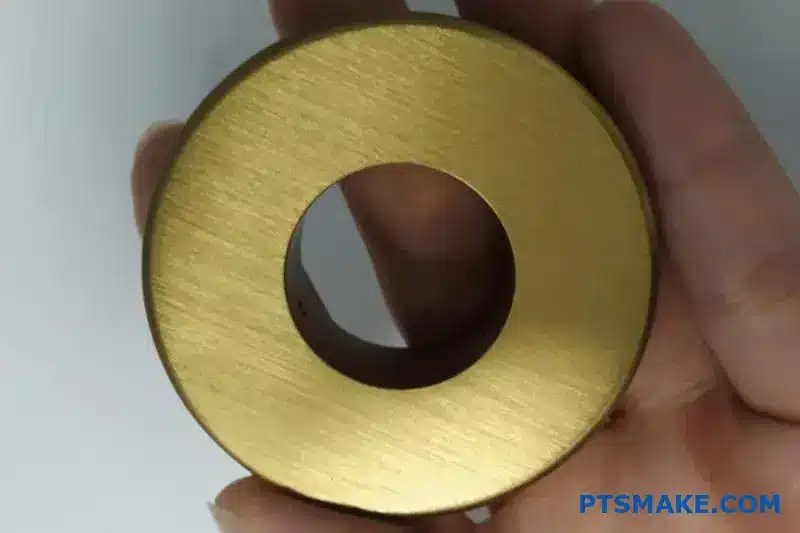

Bronze is a premier choice for CNC machining due to its exceptional wear resistance, low coefficient of friction, and superior corrosion resistance. These properties, combined with good machinability and thermal conductivity, ensure durable, high-performance parts like bearings, bushings, and gears.

Understanding Bronze’s Core Mechanical Advantages

When selecting a material for demanding mechanical parts, the fundamental properties are what separate success from failure. For bronze, its strengths are not just theoretical; they translate directly into reliability. In CNC machining bronze components, we are constantly leveraging these characteristics to meet tight specifications for high-stakes industries.

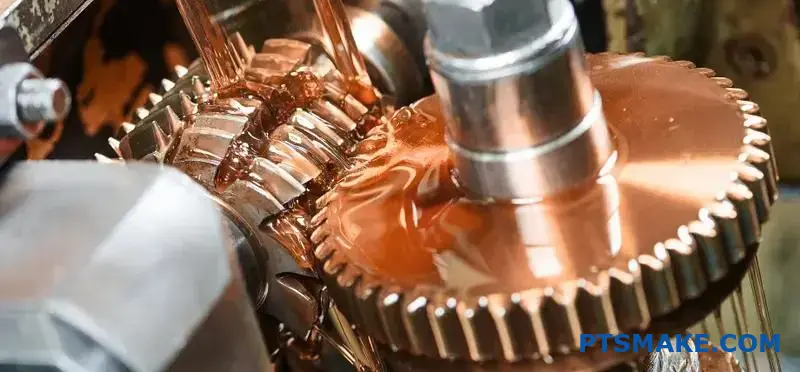

Exceptional Wear Resistance

One of the most celebrated attributes of bronze is its ability to withstand friction and wear. This is especially true for alloys like Aluminum Bronze (C95400), which possess high strength and hardness. This resistance isn’t just about surface durability; it’s about maintaining dimensional integrity over millions of cycles. When two metal surfaces slide against each other, the risk of adhesion and material transfer is high. Bronze’s unique crystalline structure minimizes this effect, which is why it’s a go-to material for gears and wear plates. A part that resists wear lasts longer, reduces maintenance schedules, and provides a better return on investment.

Low-Friction Surface Properties

Certain bronze alloys, particularly bearing bronzes like C93200, have inherently low-friction characteristics. This is often described as "lubricity." The material itself helps to create a smooth, low-resistance interface between moving parts. This property is crucial in applications where consistent lubrication is difficult or impossible. It reduces operational heat, minimizes energy loss, and prevents the destructive process of galling1, where surfaces essentially weld themselves together under pressure. In our experience at PTSMAKE, this self-lubricating quality is a key reason clients choose bronze for custom bushings designed for heavy-load, low-speed operations.

A quick comparison of popular bronze alloys highlights these strengths:

| Bronze Alloy | Tensile Strength (MPa) | Hardness (Brinell) | Key Feature |

|---|---|---|---|

| C93200 (Bearing Bronze) | 241 | 65 | Excellent lubricity & embeddability |

| C95400 (Aluminum Bronze) | 586 | 170 | High strength & wear resistance |

| C51000 (Phosphor Bronze) | 320 | 80 | Good fatigue resistance & springiness |

This table shows that you can select a bronze alloy specifically for the mechanical challenge you face, whether it’s brute strength or smooth operation.

How Properties Impact Performance and Machinability

Understanding the properties of bronze is one thing; knowing how they influence real-world part performance is what truly matters for engineers and product designers. The theoretical benefits of wear resistance or thermal conductivity become tangible advantages in the final application, and they also affect the manufacturing process itself.

Thermal and Dimensional Stability

Bronze exhibits excellent thermal conductivity compared to steels. In applications like bearings and bushings that generate significant frictional heat, bronze effectively dissipates that heat away from the contact surface. This prevents overheating, which can cause lubricants to break down and parts to expand beyond their specified tolerances. This thermal stability ensures dimensional stability. A CNC machined bronze part will maintain its precise dimensions even as operating temperatures fluctuate, which is critical for maintaining the clearance and fit in a precision assembly. This reliability under thermal stress is a major performance benefit.

Unbeatable Corrosion Resistance

Bronze’s ability to resist corrosion is legendary. It forms a protective outer layer, or patina, when exposed to the elements, which prevents deeper degradation. This makes it an outstanding choice for marine hardware, pump components, and valves used in chemical processing. Unlike many steels that will rust and seize, bronze components can operate for decades in saltwater or mildly corrosive environments. In past projects, we’ve machined bronze fittings for naval applications that replaced stainless steel parts, ultimately providing a much longer service life and reducing long-term maintenance costs for our client.

The Machinability Advantage

From a manufacturing perspective, the properties of bronze make it an excellent material for CNC machining. It is generally considered a "free-machining" alloy, meaning it produces small, manageable chips, exerts less force on the cutting tool, and allows for higher cutting speeds compared to tough materials like stainless steel or Inconel. This translates to several key benefits:

- Faster Production Times: We can machine bronze parts more quickly.

- Longer Tool Life: Cutting tools last longer, reducing tooling costs.

- Superior Surface Finishes: It’s easier to achieve a smooth, precise surface finish directly from the machine.

This machinability makes the entire process of creating high-precision bronze parts more efficient and cost-effective.

| Application | Key Property Requirement | Impact on Performance |

|---|---|---|

| Gears & Worm Gears | High Strength & Wear Resistance | Prevents tooth deformation and failure under heavy loads. |

| Bushings & Bearings | Low Friction & Thermal Conductivity | Reduces operational heat and ensures smooth rotation. |

| Marine Fittings | Corrosion Resistance | Guarantees long service life in harsh saltwater environments. |

| Valve Components | Dimensional Stability & Hardness | Ensures a tight seal and prevents leaks over time. |

Bronze’s unique combination of properties makes it an incredibly versatile and reliable material for CNC machining. Its inherent wear resistance, low-friction nature, and excellent corrosion resistance deliver tangible performance benefits. These attributes, coupled with its thermal stability and good machinability, ensure that components like bearings, gears, and bushings not only meet specifications but also provide a long, efficient service life in the most demanding applications. It’s a material that truly performs under pressure.

Selecting the Right Bronze Alloy for CNC Projects.

Have you ever selected a bronze alloy that seemed perfect on the spec sheet, only to have it underperform or fail in the field? The wrong choice can lead to costly rework and delays.

Selecting the right bronze for CNC machining means matching the alloy’s specific properties—like strength, corrosion resistance, and machinability—to the application’s unique demands. For example, C932 is ideal for bearings, C954 excels in high-strength uses, and C630 is a top choice for marine environments.

When diving into CNC machining bronze, it’s easy to get lost in the sheer number of available alloys. Each one has a unique personality, a specific set of strengths and weaknesses. In our projects at PTSMAKE, we often start by narrowing it down to a few common, reliable choices. Understanding these foundational alloys is the first step toward making an informed decision for your project.

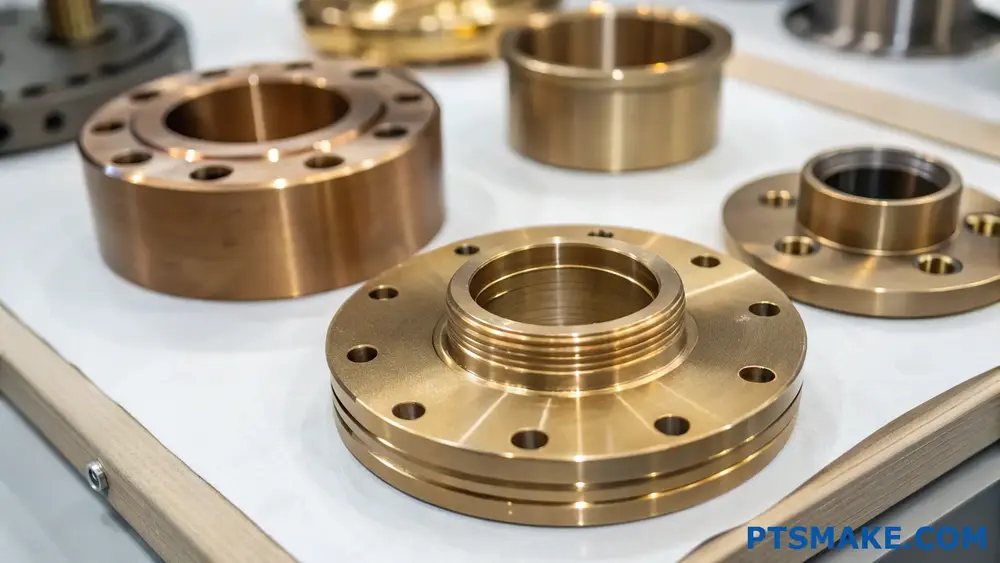

The Most Common Bronze Alloys in CNC Machining

Let’s break down the go-to alloys that we frequently work with. These cover a wide range of applications and provide a solid starting point for almost any design.

C932 Bearing Bronze (SAE 660)

This is arguably the most recognized bronze alloy. Its name says it all—it’s a fantastic material for bearings, bushings, and other wear-prone applications. The lead content in its composition gives it excellent lubricity, which helps reduce friction and prevent seizing. However, this same lead content means it’s not suitable for applications involving food or potable water. Its machinability is excellent, making it a favorite in many machine shops.

C954 Aluminum Bronze

When you need strength and toughness, C954 is the alloy to consider. It’s one of the most popular aluminum bronzes for a reason. It offers superior resistance to wear and corrosion, especially in saltwater and non-oxidizing acids. While it’s incredibly strong, its machinability is lower than C932. Machining it requires rigid setups and sharp tooling to avoid work hardening. It is also susceptible to galling2 when in contact with similar materials under load.

C630 Nickel-Aluminum Bronze

For extreme environments, C630 is a high-performer. The addition of nickel enhances its already impressive strength and corrosion resistance, particularly at higher temperatures. It’s often used in aerospace applications, marine hardware, and heavy-duty industrial equipment. Its strength comes at a cost, though, as it’s more challenging to machine than C932 or even C954.

Here is a quick comparison of these common alloys based on our internal testing and project data:

| Alloy Code | Common Name | Machinability (Rating) | Tensile Strength (Approx.) | Key Characteristics |

|---|---|---|---|---|

| C932 | Bearing Bronze | 70 | 35 ksi | Excellent lubricity, general purpose |

| C954 | Aluminum Bronze | 60 | 85 ksi | High strength, wear resistance |

| C630 | Nickel-Aluminum Bronze | 30 | 110 ksi | Extreme strength & corrosion resistance |

| C544 | Phosphor Bronze | 80 | 68 ksi | Good spring qualities, conductivity |

This table provides a snapshot, but the real magic is in matching these properties to your specific needs.

Understanding the fundamental properties of bronze alloys is one thing; applying that knowledge to a real-world project is another. The best alloy on paper might not be the most practical or cost-effective choice for your specific application. It’s a balancing act where you have to weigh performance requirements against factors like manufacturing complexity and budget. This is where experience plays a huge role in guiding the decision-making process.

Matching the Alloy to Your Application

The key to success in CNC machining bronze is to think about the part’s end-use from the very beginning. What job does this part need to do, and what conditions will it face?

Load-Bearing and Wear Applications

If your part is a bushing, bearing, or gear, the primary concerns are lubricity and wear resistance.

- High-Load, Low-Speed: C932 Bearing Bronze is the standard choice here. Its self-lubricating properties are perfect for preventing component seizure.

- High-Load, High-Impact: For parts that will take a beating, like heavy-duty gears or wear plates in industrial machinery, C954 Aluminum Bronze is a much better option. Its high strength and toughness can withstand significant impact and stress.

Electrical Conductivity Requirements

Bronze isn’t as conductive as pure copper, but some alloys are designed for electrical applications.

- Connectors and Springs: C544 Phosphor Bronze is an excellent choice. It combines decent electrical conductivity with good spring properties, making it ideal for electrical contacts, switches, and connectors that need to maintain pressure over time. Its machinability is also a significant plus, allowing for the creation of intricate features.

Exposure to Harsh Environments

Corrosion resistance is one of bronze’s most famous attributes, but not all alloys are created equal, especially when faced with specific chemicals or conditions.

- Marine Applications: For parts exposed to saltwater, such as propellers, pump components, or valve bodies, aluminum bronzes like C954 and nickel-aluminum bronzes like C630 are top contenders. They form a tough, protective oxide layer that resists marine corrosion exceptionally well.

- Chemical Exposure: If a part will be exposed to specific industrial chemicals, you must check the alloy’s compatibility. For example, some bronzes perform poorly in the presence of oxidizing acids or certain sulfur compounds. In past projects with our clients, we’ve always cross-referenced material specs with the chemical exposure charts to avoid costly failures down the line.

Ultimately, the selection process is a conversation between the design requirements and the material’s capabilities.

Choosing the right bronze alloy for your CNC project is more than just picking from a list. It involves a careful analysis of your application’s specific needs. Consider factors like load, wear, and environmental exposure. Alloys like C932 excel in bearing applications, while C954 offers superior strength for high-impact parts. For marine or harsh chemical environments, C630 provides robust corrosion resistance. Matching the alloy’s properties to the part’s function is the key to ensuring long-term performance and reliability.

Industrial Applications of CNC Machined Bronze Components.

Struggling to find a material that withstands extreme pressure, corrosion, and friction all at once? Your component’s failure might be a material mismatch, not a design flaw.

CNC machined bronze components are the solution in demanding sectors like marine, mining, and hydraulics. Their exceptional wear resistance, corrosion resistance, and low friction make them ideal for critical parts like bearings, bushings, and valves, ensuring reliability where other materials fail.

Bronze is not just one material; it’s a family of alloys, each with unique strengths. This versatility is why it’s a cornerstone in so many heavy-duty applications. When we talk about CNC machining bronze, we’re talking about creating incredibly precise parts that can handle some of the toughest jobs out there.

The Backbone of Heavy Industry: Mining and Hydraulics

In the mining and hydraulics industries, equipment failure isn’t just an inconvenience—it’s a costly and dangerous event. Components are constantly subjected to immense pressure, heavy loads, and abrasive environments. This is where bronze shines.

Bushings and Bearings: The Unsung Heroes

Bronze bushings and bearings are essential for heavy machinery. They reduce friction between moving parts, preventing wear and tear. Unlike many other metals, bronze can handle high loads and slow speeds without seizing. Its excellent tribological3 properties mean it can often operate with minimal lubrication, which is a huge advantage in dirty environments like a mine. Based on our tests with clients in the mining sector, switching to a specific high-strength bronze alloy for their crusher bushings extended the service life by over 40%.

| Application Area | Key Bronze Property | Common Bronze Alloy |

|---|---|---|

| Mining Equipment | High Compressive Strength | C93200 (SAE 660) |

| Hydraulic Cylinders | Low Friction | C95400 Aluminum Bronze |

| Heavy Machinery Pins | Wear Resistance | C86300 Manganese Bronze |

Thriving in Harsh Waters: Marine Applications

The marine environment is relentless. Saltwater is highly corrosive to most metals, but bronze, particularly aluminum bronze and silicon bronze, holds up exceptionally well. This makes it the go-to material for a wide range of marine components.

Propellers, Shafts, and Fittings

From propellers that must resist cavitation and corrosion to underwater fittings that need to remain sealed and strong for years, bronze is the trusted choice. Its resistance to biofouling—the accumulation of microorganisms—is another key benefit, reducing maintenance needs. We often perform CNC machining on bronze for parts like rudder shafts and seawater pump valves, where reliability is a matter of safety. The precision of CNC machining ensures perfect fits and seals, which is critical when you’re miles from shore.

Beyond the heavy-duty sectors, bronze finds critical roles in applications that require a unique mix of electrical properties and manufacturability. The precision afforded by CNC machining unlocks even more potential for this ancient alloy in modern technology.

Power and Precision: Electrical Components

You might not immediately associate bronze with electrical applications, but certain alloys are perfect for specific roles. It’s not as conductive as pure copper, but its added strength and corrosion resistance make it a superior choice for components that need to be both durable and electrically functional.

Electrical Contacts and Connectors

Phosphor bronze is a popular choice for electrical contacts, springs, and connectors. It maintains its spring properties over many cycles and resists corrosion, ensuring a reliable electrical connection for years. In past projects at PTSMAKE, we’ve machined intricate bronze connectors for high-end audio equipment and industrial control panels. The challenge is maintaining tight tolerances to ensure consistent contact pressure, something that our CNC machining processes are optimized for.

| Component | Required Property | Why Bronze is Chosen |

|---|---|---|

| Electrical Contacts | Good Conductivity & Springiness | Phosphor bronze resists fatigue and corrosion. |

| Spark-Proof Tools | Non-Sparking | Beryllium copper (a bronze alloy) is safe for explosive environments. |

| High-Current Switches | Strength & Arc Resistance | Aluminum bronze handles physical stress better than pure copper. |

The Go-To for Custom Machinery

When engineers are designing one-of-a-kind machines or prototypes, material choice is critical. They need something strong, reliable, and easy to work with. Bronze often fits the bill perfectly.

Custom Gears and Wear Plates

The machinability of bronze is a significant advantage. It allows us to create complex geometries for custom gears, worm gears, and wear plates with high precision. These components are often used in power transmission systems where low friction and high wear resistance are needed. For a client developing a new robotic arm, we prototyped a series of custom bronze gears. The material allowed for rapid iteration and testing, as it was easy to machine yet strong enough to handle the operational loads, helping them get their product to market faster. CNC machining bronze parts makes it possible to create these highly specific components cost-effectively, even in low volumes.

From the depths of a mine to the precision of an electrical switch, CNC machined bronze proves its worth. Its unique combination of strength, corrosion resistance, low friction, and machinability makes it an indispensable material. It excels in harsh environments like marine and hydraulic systems and provides reliable performance for custom machinery and electrical components. Bronze is a versatile solution for engineers facing complex design challenges, ensuring parts are both durable and dependable.

Design Considerations for Bronze CNC Machined Parts.

Ever designed a bronze component that looked perfect in CAD, only to face unexpected machining costs and delays? It’s a frustratingly common scenario that can derail project timelines.

For successful bronze CNC machined parts, focus on practical design. This means avoiding thin walls, standardizing hole sizes for efficiency, ensuring tool access, and clearly defining tolerances and surface finishes to match the part’s function and budget.

When designing for CNC machining bronze, the geometry of your part is the single biggest factor influencing cost and lead time. A design that is easy to machine will always be more affordable and delivered faster. The key is to think like a machinist from the very beginning.

Wall Thickness and Structural Integrity

One of the most common issues we see in designs for bronze parts is walls that are too thin. Bronze, while strong, can be prone to vibration and chatter during machining if not properly supported. Thin walls can also warp from the heat generated by the cutting tool. This makes holding tight tolerances incredibly difficult. As a general rule, we advise our clients at PTSMAKE to maintain a minimum wall thickness of 1.5mm (0.060 inches) for most bronze alloys. For larger parts, you might need to go even thicker or add supporting ribs to maintain rigidity. Properly managing wall thickness also helps dissipate heat more effectively, which can reduce the risk of surface defects.

Standardizing Features for Efficiency

Every custom tool or non-standard operation adds time and cost to your project. Standardizing features is a simple way to streamline the manufacturing process.

Hole Sizes and Depths

Instead of specifying a custom hole diameter like 7.3mm, check if a standard 7.5mm or 7.0mm drill size would work. Using standard sizes eliminates the need for special tooling. Also, pay attention to the depth-to-diameter ratio. Drilling a deep, narrow hole in bronze can be challenging due to chip evacuation and tool wear. A ratio of 8:1 is generally a safe limit for standard drilling operations. Anything deeper requires specialized techniques like peck drilling, which increases cycle time.

Radii and Fillets

Sharp internal corners are impossible to create with a standard rotating cutting tool. They require a secondary process like electrical discharge machining (EDM), which significantly increases costs. Always design internal corners with a radius that is slightly larger than the cutting tool’s radius. A larger radius allows for a faster, smoother cutting path and a better surface finish. It also reduces stress concentrations in the final part.

| Feature | Non-Optimal Design | Optimized for CNC Machining | Impact |

|---|---|---|---|

| Internal Corners | Sharp, R=0mm | R ≥ 1mm (standard tool size) | Reduced machine time, lower cost |

| Hole Diameter | 5.35mm (Custom) | 5.5mm (Standard) | No custom tooling needed, faster setup |

| Wall Thickness | 0.5mm, unsupported | ≥ 1.5mm, with ribs if needed | Prevents vibration and galling4 |

Beyond individual features, optimizing the overall part geometry and clearly defining your specifications are crucial for balancing performance with manufacturing costs. This is where a deep understanding of the CNC process pays dividends.

Optimizing Part Geometry for Tool Accessibility

A machinist must be able to physically reach every surface that needs to be cut. Deep pockets with narrow openings or features that are obstructed by other parts of the geometry can make machining impossible or require highly specialized, long-reach tooling. When designing, always visualize how a cutting tool will approach the part. Ensure there is enough clearance around features for the tool holder and spindle. In some projects, a minor design tweak, like widening a channel or changing the angle of a surface, can be the difference between a simple 3-axis job and a complex, expensive 5-axis operation. Simplifying the design to be machined from the fewest number of setups possible will always result in a lower cost.

The Critical Role of Tolerances and Surface Finish

Specifications for tolerance and surface finish have a direct and significant impact on the cost of CNC machining bronze parts. It’s essential to define them based on function, not just preference.

Specifying Tolerances Wisely

Tighter tolerances are exponentially more expensive to achieve. They require more precise machines, specialized inspection equipment, and slower machining speeds, all of which increase costs. Before applying a tight tolerance across an entire part, ask yourself which features are truly critical. For example, the diameter of a hole for a press-fit bearing needs a very tight tolerance, but the outer dimensions of the housing it sits in might not. Apply tight tolerances only to critical interfaces and functional surfaces. For all other non-critical features, use a standard, looser tolerance.

Choosing the Right Surface Finish for Bronze

Bronze is often chosen for its appearance and low-friction properties, making surface finish an important consideration. A standard machined finish (around 3.2 μm Ra) is the most cost-effective. If you need a smoother finish for a bearing surface or for aesthetic reasons, specify that clearly on the drawing using a callout like 1.6 μm Ra or 0.8 μm Ra. Just remember that each step up in finish quality requires additional machining passes or secondary processes like polishing or grinding, which adds to the final price.

| Tolerance Level | Example Application | Relative Cost Impact | Machining Process |

|---|---|---|---|

| Loose (±0.1mm) | General housing, non-critical features | Base Cost | Standard milling/turning |

| Standard (±0.025mm) | Mating parts, alignment pins | +20-40% | Precision milling, reaming |

| Tight (±0.005mm) | Bearing fits, high-precision shafts | +100-300% | Grinding, honing, lapping |

Effective design for CNC machining bronze hinges on practical choices. By avoiding overly thin walls, standardizing features like holes and radii, and ensuring tools can access all areas, you drastically cut costs. Furthermore, specifying only necessary tolerances and the appropriate surface finish ensures you get a high-performance part without overspending. These principles are key to bridging the gap between a great design and a manufacturable, cost-effective component.

Post-Machining Processes and Surface Finishing Options.

Ever felt that a perfectly machined bronze part just didn’t look or feel complete? Those small burrs or inconsistent surfaces can compromise the entire design, affecting both form and function.

Post-machining processes like deburring, tumbling, and polishing are essential for finishing CNC machined bronze. These techniques improve aesthetics, boost corrosion resistance, and ensure the part meets its final dimensional and functional requirements, turning a raw component into a finished product ready for its application.

The Fundamentals of Surface Preparation

After the primary CNC machining is complete, the bronze part is rarely ready for its end-use. It requires a series of post-machining steps to refine its surface and prepare it for assembly or final finishing. These initial processes are foundational to the part’s quality and performance.

Removing Imperfections: Deburring

The first and most critical step is deburring. Machining processes, especially milling and drilling, inevitably leave small, sharp ridges of material called burrs along the edges. If not removed, these burrs can cause problems with assembly, create stress concentration points leading to part failure, or even pose a safety hazard.

- Manual Deburring: For parts with complex geometries or delicate features, we often rely on skilled technicians to manually remove burrs using specialized tools. This method offers precision and control, ensuring no damage to critical surfaces.

- Tumbling (Mass Deburring): For batches of smaller, more robust parts, tumbling is an efficient solution. Parts are placed in a rotating barrel with abrasive media, which gently grinds away the burrs, creating smooth, rounded edges.

Achieving a Clean Slate: Cleaning and Degreasing

Once deburred, the part must be thoroughly cleaned. Cutting fluids, oils, and microscopic metal particles from the machining process cling to the surface. We find that ultrasonic cleaning is particularly effective for bronze parts. It uses high-frequency sound waves to create tiny bubbles in a cleaning solution, which dislodge contaminants from even the most intricate features and internal channels, a process known as cavitation5. A perfectly clean surface is non-negotiable for any subsequent finishing, like plating or coating, as it ensures proper adhesion.

The table below outlines common tumbling media used for bronze and their effects.

| Media Type | Abrasiveness | Resulting Finish | Best For |

|---|---|---|---|

| Ceramic Media | High | Matte, can remove material | Aggressive deburring, edge rounding |

| Plastic Media | Medium | Smooth, semi-gloss | General-purpose deburring, pre-polishing |

| Corn Cob/Walnut Shell | Low | Clean, bright polish | Light cleaning, polishing, drying |

Advanced Finishing for Aesthetics and Performance

Beyond basic preparation, various finishing techniques can be applied to enhance specific properties of CNC machined bronze parts. The choice of finish is driven entirely by the application’s requirements, whether it’s for visual appeal, environmental protection, or improved mechanical function.

Polishing for Visual Appeal

When the look of a bronze part is paramount, nothing beats polishing. This multi-step process typically involves using progressively finer abrasives to smooth the surface until it achieves a mirror-like shine.

- Mechanical Polishing: This involves using buffing wheels and polishing compounds to achieve a high-gloss finish. It is often used for decorative items, architectural hardware, and luxury consumer products where a brilliant, reflective surface is desired.

- Electropolishing: An electrochemical process that removes a microscopic layer of material from the surface. While less common for purely aesthetic bronze, it can produce a very smooth, clean, and bright finish that also improves corrosion resistance.

Protective and Functional Coatings

For applications where bronze parts are exposed to harsh environments or require enhanced surface properties, coatings are the solution.

- Clear Coats (Lacquering): Applying a transparent lacquer is a simple way to protect a polished bronze surface from tarnishing and oxidation. It preserves the natural color and shine of the metal while providing a barrier against moisture and air.

- Plating: Applying a thin layer of another metal, such as nickel, tin, or even gold, can drastically alter the bronze part’s properties. For instance, tin plating is often used on bronze electrical connectors to improve solderability and prevent corrosion, which is a common requirement in projects we’ve handled at PTSMAKE.

- Patination: This is a chemical process used to accelerate the natural aging process of bronze, creating a desired patina (often green, brown, or black). It’s primarily used for artistic and architectural applications to achieve a specific antique or weathered look.

Here’s a guide to help you select a finish based on common end-use cases:

| Application | Key Requirement | Recommended Finish | Why It’s Chosen |

|---|---|---|---|

| Marine Fittings | Corrosion Resistance | As-Machined or Clear Coat | Allows natural protective patina to form or seals the surface. |

| Bushings/Bearings | Dimensional Accuracy | Light Tumble Deburr | Removes burrs without significantly altering tight tolerances. |

| Decorative Trim | High-End Aesthetics | High Polish + Lacquer | Delivers a brilliant shine and prevents tarnishing over time. |

| Electrical Terminals | Conductivity & Durability | Tin or Nickel Plating | Enhances electrical contact and provides wear resistance. |

In summary, post-machining processes are not an afterthought but a critical stage in manufacturing high-quality CNC machined bronze parts. From essential steps like deburring and cleaning to advanced finishes like polishing and plating, each process serves a distinct purpose. The right choice enhances not only the part’s appearance but also its corrosion resistance, durability, and overall performance. Selecting the appropriate finish ultimately depends on the specific requirements of the end-use application, balancing aesthetics with functional needs.

Quality Control and Inspection for Bronze CNC Parts?

Ever received a batch of bronze parts that looked perfect but failed during assembly? A tiny dimensional error or an overlooked surface flaw can derail your entire project schedule and budget, which is incredibly frustrating.

Effective quality control for bronze CNC parts involves a multi-stage inspection process. This includes precise dimensional checks with tools like CMMs, thorough surface finish assessments, and rigorous tolerance verification. Meticulous documentation is also key to ensuring every part meets exact specifications and provides full traceability.

Quality control isn’t just a final step; it’s a philosophy integrated throughout the entire manufacturing process. For bronze components, where properties like lubricity and corrosion resistance are paramount, a superficial check simply won’t do. A robust inspection plan ensures that every part leaving the shop floor is a perfect match for the design intent. It’s the ultimate guarantee that the part will perform as expected.

The Three Pillars of Post-Machining Inspection

After the CNC machine finishes its work, the part enters a critical verification phase. We break this down into three core areas to ensure nothing is missed. Each pillar addresses a different aspect of the part’s quality, and together, they form a comprehensive evaluation.

Dimensional Accuracy Checks

This is the most fundamental inspection. Does the part match the numbers on the drawing? We use a range of calibrated instruments to verify every critical dimension.

- Basic Measurements: For simpler features, we rely on digital calipers and micrometers to check lengths, diameters, and thicknesses. These tools are fast and accurate for straightforward verification.

- Complex Geometries: For parts with intricate shapes, angled holes, or complex profiles, a Coordinate Measuring Machine (CMM) is essential. The CMM’s probe touches multiple points on the part, creating a 3D map that we can compare directly against the original CAD file. This process detects even the slightest deviation that would be impossible to catch by hand.

Surface Quality Assessment

The surface of a bronze part is often critical to its function, especially in applications involving moving components or seals.

- Visual Inspection: The first step is always a trained eye looking for obvious defects like scratches, burrs from machining, or discoloration.

- Quantitative Measurement: For applications requiring a specific texture, we use a surface roughness tester (profilometer). This instrument measures the microscopic peaks and valleys on the surface, providing a quantifiable value like Ra (Roughness Average). This ensures, for example, that a bearing surface is smooth enough to minimize friction.

Tolerance Verification

Tolerances define the acceptable range of variation for a dimension. Verifying them is what separates a good part from a perfect one. A part can be dimensionally correct on average but fail if it exceeds its tolerance limits. We check not only dimensional tolerances but also those defined by Geometric Dimensioning and Tolerancing6, which controls the form, orientation, and location of features relative to each other.

Beyond checking the part itself, the instruments and the data they generate are the backbone of a reliable quality system. Without the right tools and a solid documentation process, inspection becomes inconsistent and loses its value. This is a non-negotiable aspect of professional manufacturing, especially in the context of cnc machining bronze for critical applications.

The Tools and Documentation That Guarantee Quality

You can have the best inspection process in the world, but it’s meaningless without properly calibrated tools and a rigorous documentation trail. This is where trust is built and compliance is proven.

Using Precision Measuring Instruments

The quality of your inspection is limited by the quality of your tools. Relying on uncalibrated or inappropriate instruments is a recipe for disaster.

- Calibration is Key: At PTSMAKE, all our measuring instruments, from calipers to CMMs, undergo regular calibration traceable to national standards. This ensures that when we measure a dimension, the reading is accurate and reliable. An uncalibrated tool can lead you to accept bad parts and reject good ones.

- The Right Tool for the Job: We match the instrument to the tolerance. You wouldn’t use a tape measure to check a tolerance of ±0.01mm. The "10-to-1 rule" is a good guideline: the measurement device should be ten times more precise than the tolerance being measured.

The table below shows some common instruments and their typical applications for bronze parts.

| Instrument | Best For | Precision Level | Typical Use Case (Bronze Parts) |

|---|---|---|---|

| Digital Caliper | Quick, general dimensional checks | Moderate | Overall length, width, outer diameters |

| Micrometer | High-precision diameter/thickness measurement | High | Shaft diameters, wall thickness |

| CMM (Coordinate Measuring Machine) | Complex 3D geometries, tight tolerances | Very High | Intricate housings, multi-feature parts |

| Surface Roughness Tester | Quantifying surface finish (Ra) | High | Bearing surfaces, sealing faces |

The Importance of Documentation

Documentation is not just administrative overhead; it’s the official record of quality.

- Traceability: For industries like aerospace and medical, traceability is mandatory. Inspection reports that link a specific part back to the raw material batch, the machine it was made on, and the inspector who approved it provide a complete history.

- Compliance and Certification: We provide documentation like First Article Inspection Reports (FAIR) and Certificates of Conformance (CoC) to prove that the parts meet all drawing specifications and industry standards.

- Continuous Improvement: By analyzing inspection data over time, we can identify trends and potential issues in the

cnc machining bronzeprocess before they lead to defects. This data-driven approach allows us to refine our methods and deliver consistently better parts.

In summary, a comprehensive quality control strategy is essential for producing reliable bronze CNC parts. This involves meticulous inspection steps covering dimensional accuracy, surface quality, and tolerance verification. The process is supported by the use of calibrated, high-precision measuring instruments and thorough documentation. This rigorous approach not only ensures that each part meets specifications but also provides the traceability and compliance required for critical applications, turning a machined component into a trusted, high-performance part.

Challenges and Solutions in Machining Complex Bronze Components?

Ever faced the frustration of a bronze part warping just moments after machining, or struggled with burrs that ruin a perfectly good surface finish? This can quickly turn a profitable job into a costly remake.

Overcoming challenges in CNC machining bronze requires a multi-faceted approach. Key solutions include implementing robust fixturing to counteract material movement, using appropriate coolants to manage heat buildup, and applying advanced CNC strategies like optimized toolpaths and sharp tooling to prevent burr formation and ensure dimensional accuracy.

Bronze, while prized for its properties, presents a unique set of hurdles in CNC machining. Unlike steel or aluminum, its characteristics demand a more nuanced approach. Understanding these challenges is the first step toward mastering the process. In our past projects at PTSMAKE, we’ve identified three primary issues that consistently appear when dealing with complex bronze components.

Understanding Material Movement and Warping

Bronze alloys, especially those with higher copper content, are relatively soft and have a high coefficient of thermal expansion. This combination is a recipe for trouble. As the cutting tool generates heat, the material expands. When it cools, it contracts, often unevenly. This can lead to warping, bowing, or other dimensional inaccuracies that render the part useless. This is particularly problematic in parts with thin walls or intricate features where material stability is already compromised. We’ve seen parts that meet spec on the machine but fail inspection once they’ve cooled to room temperature.

Managing Excessive Heat Buildup

Heat is the primary enemy in CNC machining bronze. The material’s gummy nature can cause chips to weld to the cutting tool, increasing friction and generating even more heat. This thermal buildup doesn’t just cause warping; it can also lead to premature tool wear, work hardening of the material surface, and a poor surface finish. The heat can even alter the metallurgical properties of the bronze alloy at a microscopic level, affecting its performance in the final application. One of the most subtle but damaging effects is galling7, where material from the workpiece frictionally adheres to the tool, leading to catastrophic failure.

The Persistent Problem of Burr Formation

Burrs are another common headache. Because bronze is so ductile, it tends to be pushed or "smeared" by the cutting tool rather than being sheared cleanly. This results in small, raised edges of material—burrs—along the toolpath. While they might seem minor, burrs can:

- Interfere with the assembly of mating parts.

- Pose a safety hazard with their sharp edges.

- Break off during operation, potentially contaminating sensitive systems.

Removing burrs requires secondary operations, adding time and cost to the production process. The goal is always to minimize their formation in the first place.

| Challenge | Primary Cause | Consequence |

|---|---|---|

| Material Movement | High thermal expansion, low rigidity | Dimensional inaccuracy, warping |

| Heat Buildup | Friction, chip welding | Tool wear, work hardening, poor finish |

| Burr Formation | Material ductility | Added labor cost, assembly issues |

Successfully machining complex bronze components is less about fighting the material’s properties and more about working with them. Through numerous projects, we’ve refined our strategies to turn these challenges into predictable, manageable variables. The right combination of physical setup, programming, and tooling makes all the difference.

Solutions for Fixturing and Workholding

To combat material movement, your workholding strategy needs to be rock-solid without distorting the part.

Low-Stress Fixturing

Instead of applying massive clamping force in one or two spots, we use multiple points of contact with lower, evenly distributed pressure. Custom soft jaws machined to match the part’s contour are excellent for this. For particularly delicate parts, we might use a vacuum chuck or even a specialized adhesive for initial operations before moving to more traditional clamps.

Strategic Machining Sequence

The order of operations matters. We often perform roughing passes on all features first, leaving a small amount of stock. Then, we might unclamp and re-clamp the part to relieve any induced stress before running the finishing passes. This two-step process helps ensure the final dimensions are stable.

Coolant and Tooling Strategies

Managing heat and burrs comes down to what happens at the cutting edge.

Coolant Application

A consistent flood of high-quality coolant is non-negotiable. It serves three purposes: lubricating the cut, cooling the workpiece and tool, and, most importantly, flushing chips away from the cutting zone. In some of our applications, we’ve found that high-pressure, through-spindle coolant systems are particularly effective at preventing chip welding and evacuating chips from deep pockets or holes.

Tool Selection and Geometry

Sharpness is key. We use tools with positive rake angles and highly polished flutes designed specifically for non-ferrous materials. These geometries promote a clean shearing action and help chips curl and evacuate smoothly. Coated tools can also reduce friction, but the coating must be compatible with bronze to avoid adverse chemical reactions.

| Solution | Targeted Challenge(s) | Implementation Notes |

|---|---|---|

| Low-Stress Fixturing | Material Movement | Use multiple clamping points, soft jaws, or vacuum chucks. |

| Optimized Toolpaths | Heat Buildup, Burr Formation | Employ trochoidal milling, climb milling, and constant tool engagement. |

| Proper Coolant Use | Heat Buildup, Burr Formation | Use high-pressure flood coolant to lubricate and clear chips. |

| Sharp, Specific Tooling | Burr Formation, Heat Buildup | Use tools with high positive rake angles and polished flutes. |

Navigating the complexities of CNC machining bronze means directly addressing its inherent challenges. Issues like material movement, heat buildup, and burr formation can compromise quality if ignored. However, by implementing strategic solutions—such as robust, low-stress fixturing, effective coolant management, and the use of sharp, material-specific tooling with optimized toolpaths—these obstacles are overcome. This proactive approach ensures the production of dimensionally accurate bronze components with excellent surface integrity, meeting the demanding specifications required in high-performance applications.

Design Tips for Engineers: Ensuring Manufacturability and Performance.

Ever designed a bronze component that looked perfect in CAD, only to face staggering production quotes or unexpected failures in the field? This gap between design intent and manufacturing reality is a common engineering headache.

To ensure both manufacturability and performance for CNC machined bronze parts, engineers must balance design complexity with practical production limits. Key strategies include simplifying geometry, specifying realistic tolerances, designing for standard tooling, integrating features to reduce assembly, and planning for future maintenance.

Balancing Performance and Practicality

The ultimate goal is to create a part that performs its function flawlessly over its intended lifespan. However, achieving this doesn’t have to mean making the part difficult or expensive to manufacture. The key is finding the sweet spot where performance requirements meet efficient production. This balance is crucial for any project involving CNC machining bronze.

Wall Thickness and Internal Radii

Bronze alloys, while strong, are softer than steel. This affects how they behave during machining.

- Thin Walls: Designing walls that are too thin can lead to chatter or deformation when the part is clamped in the CNC machine. As a rule of thumb, for most bronze alloys, we recommend keeping wall thickness above 1.5mm (0.060 inches) to maintain structural integrity during the machining process.

- Internal Radii: Sharp internal corners are a classic design trap. They require very small, specialized cutting tools that are fragile and slow. Worse, they create stress concentration points that can lead to part failure. Always design internal corners with a radius that is slightly larger than the cutter’s radius. A larger radius allows us to use a more robust standard endmill, which speeds up the process and reduces cost.

Tolerances: The Hidden Cost

Tolerances define how much a feature’s final dimension can vary. While tight tolerances are sometimes necessary, over-tolerancing is one of the biggest drivers of unnecessary cost. Every tight tolerance requires more careful setups, slower machining speeds, and more frequent inspections. In some of our past projects at PTSMAKE, relaxing non-critical tolerances has reduced part cost by as much as 30-40%. Before finalizing your drawing, critically review every tolerance. Ask yourself if it’s truly essential for the part’s function. The material’s properties, such as Anisotropy8, can sometimes influence dimensional stability.

Here’s a general guide we use to illustrate the cost impact:

| Tolerance Level | Relative Machining Cost | Typical Application |

|---|---|---|

| Loose (e.g., ±0.5mm) | 1x | General housings, non-mating surfaces |

| Standard (e.g., ±0.1mm) | 2x – 3x | Mating parts, standard fits |

| Tight (e.g., ±0.025mm) | 5x – 10x | Bearing bores, precision shafts |

Smart Design for Efficiency and Longevity

Good design goes beyond a single part’s geometry. It considers the entire product lifecycle, from assembly to maintenance. Thinking about these stages during the initial design phase can lead to significant savings and a more reliable product.

Integrating Features to Reduce Assembly

Every separate part in an assembly adds complexity. It means another component to source, another step in the assembly process, and another interface where tolerance stack-up can cause problems. With the precision of modern CNC machining, it’s often possible to combine several functions into a single bronze component.

For instance, instead of designing a plate with separate pressed-in bushings, consider machining the bearing surfaces directly into the plate. This creates a stronger, more integrated part, eliminates the press-fit operation, and removes a potential point of failure. At PTSMAKE, we frequently collaborate with engineers on DFM (Design for Manufacturability) reviews to identify opportunities for part consolidation.

Designing for Modularity and Maintenance

While integrating parts is powerful, you should also plan for the inevitable reality of wear and tear. A modular design approach can make maintenance far simpler.

- Ease of Access: Think about how the component will be serviced. Can wear-prone surfaces be accessed easily? For example, designing a bronze wear pad as a simple, bolt-on component allows it to be replaced quickly without disassembling an entire machine.

- Standardization: Avoid using custom thread sizes or unique fastener patterns unless absolutely necessary. Sticking to standard metric or imperial hardware makes repairs faster and cheaper for the end-user. There’s nothing more frustrating than needing a custom tool for a simple replacement.

These design choices directly impact production efficiency. A part designed to be machined from the fewest possible setups will always be faster and more cost-effective to produce. By considering manufacturability and maintenance from the start, you create a part that is not only high-performing but also efficient to produce and easy to live with.

Thoughtful engineering is the foundation of every successful CNC machined bronze component. It’s about a strategic balance between ideal performance and manufacturing practicality. By simplifying geometries, applying realistic tolerances, and designing for the entire product lifecycle—from assembly to maintenance—you can create parts that are not only effective and durable but also cost-efficient to produce. This proactive design philosophy is key to bridging the gap between a great concept and a successful final product.

Discover CNC Machining Bronze Excellence with PTSMAKE

Ready to optimize your CNC machining bronze projects? Trust PTSMAKE to deliver high-precision, reliable bronze components tailored to your exact requirements. Contact us now for a personalized quote and experience why industry leaders rely on PTSMAKE for consistent quality, rapid response, and long-term manufacturing partnerships.

Understand galling in-depth to prevent this common failure mode in metal-on-metal applications and improve component reliability. ↩

Understand how to prevent this common form of wear in your CNC machined bronze parts. ↩

Learn how the study of friction and wear helps in designing more durable mechanical parts. ↩

Understand galling to prevent surface damage and component seizure, especially in high-load applications. ↩

Discover how ultrasonic cleaning works to achieve a perfectly clean surface for superior finishing results. ↩

Click to understand how this symbolic language ensures your part’s form and function, not just its size. ↩

Learn how this specific form of material transfer can impact your tool life and part finish. ↩

Understand how material directionality can affect your bronze part’s strength and performance. ↩