Choosing the right bronze for your machining project can be frustratingly complex. With dozens of alloys available, each with different properties and machinability ratings, it’s easy to select a material that wastes time, dulls tools prematurely, or fails to meet your application requirements. I’ve seen many engineers struggle with this decision.

The best bronze for machining is typically C954 aluminum bronze for general applications, C642 aluminum bronze for wear resistance, and C360 brass for high-speed operations. These alloys offer excellent machinability, good mechanical properties, and relatively low tool wear compared to other bronze compositions.

I’ve worked with countless bronze alloys throughout my career, and I can tell you that selecting the right one makes all the difference in your machining operations. The perfect bronze can cut production time, extend tool life, and deliver superior part performance. Let me share what I’ve learned about these remarkable alloys and help you make the best choice for your specific application needs.

Is Bronze Easier To Machine Than Steel?

Ever found yourself pondering if bronze offers a smoother path in the workshop compared to steel? Or perhaps questioned if the common perception of bronze’s machinability always rings true for every alloy and application?

Yes, generally, bronze is considered easier to machine than most common grades of steel. This is primarily due to bronze’s lower hardness, better thermal conductivity, and the typically more manageable chip formation it produces, leading to faster machining and longer tool life.

When we talk about machining, the ease of cutting a material is a big deal. It affects everything from the speed of the job to the wear on our cutting tools. At PTSMAKE, we frequently work with both bronze and steel, and the differences in their machinability are quite apparent in our day-to-day operations.

Understanding Machinability: Bronze vs. Steel

Machinability isn’t just a simple "yes" or "no" quality. It’s a combination of factors. Let’s break down why bronze often gets the nod for being easier to work with, especially in cnc machining bronze1 applications.

Key Factors Influencing Machinability

- Hardness and Strength: Steel, especially alloy steels or those that have been heat-treated, is typically much harder and stronger than bronze. Higher hardness means more force is required to cut the material, which puts more stress on the cutting tool and the machine. Bronze alloys, while diverse, generally sit lower on the hardness scale.

- Thermal Conductivity: Bronze alloys usually have excellent thermal conductivity. This means they dissipate heat from the cutting zone more effectively than many steels. Less heat buildup means cooler tools, which can significantly extend tool life and allow for higher cutting speeds.

- Chip Formation: This is a crucial aspect. Bronze often produces small, manageable chips that break easily and are cleared away from the cutting area without much fuss. Many steels, particularly softer, more ductile ones, can produce long, stringy chips that can tangle around the tool or workpiece, leading to poor surface finish and potential tool breakage.

A Quick Comparison

To give you a clearer picture, here’s a simplified comparison based on general characteristics. Remember, specific alloys within both bronze and steel families can vary widely.

| Feature | Bronze (General) | Steel (Common Carbon/Alloy) |

|---|---|---|

| Hardness | Lower | Higher |

| Thermal Conductivity | Higher | Lower |

| Chip Characteristics | Often small, brittle | Can be long, stringy |

| Tool Wear | Generally Lower | Generally Higher |

| Cutting Speeds | Can be Higher | Often Lower |

| Lubrication Needs | Can be less demanding | Often more demanding |

In our experience at PTSMAKE, when a client has a design that could potentially use either material, and ease of machining is a significant cost or time driver, bronze often presents a more straightforward path. However, it’s vital to remember that "steel" is a vast category. Some free-machining steels are designed for easier cutting, and some specialized bronze alloys can be tougher to work with.

It’s not just about how fast you can cut. The quality of the finished surface and the dimensional accuracy achieved are also part of the machinability equation. Bronze typically allows for excellent surface finishes with less effort. This means less time spent on secondary finishing operations, which can be a real advantage in production environments.

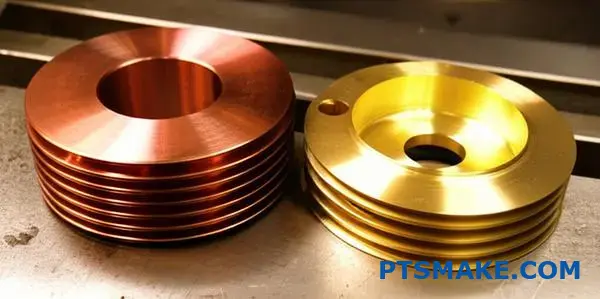

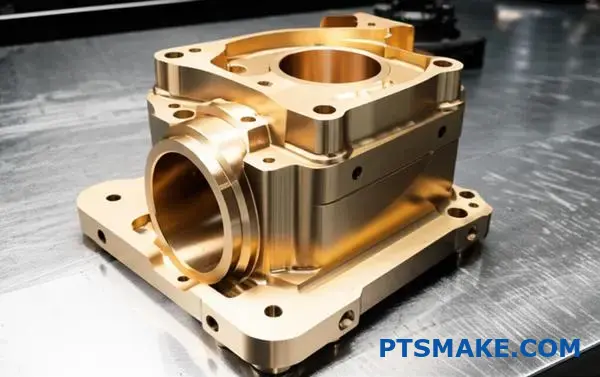

What Is The Difference Between 932 And 954 Bronze?

Stuck between 932 and 954 bronze for your next part? Making the wrong call can really impact performance and cost, can’t it?

932 bronze, or bearing bronze, excels in wear resistance for bushings and bearings. 954 aluminum bronze, on the other hand, offers higher strength and corrosion resistance, making it suitable for more demanding structural and marine applications. Their compositions dictate these distinct advantages.

When you’re looking at bronze alloys, 932 and 954 often come up, but they serve quite different purposes. It’s not just a subtle variation; their fundamental makeup leads to distinct performance characteristics. At PTSMAKE, we’ve machined both extensively, and understanding these differences is key to successful component manufacturing.

Core Compositional Differences

The primary distinction lies in their alloying elements.

C932 Bronze (Bearing Bronze)

C932, often known as SAE 660, is a tin bronze. Its typical composition includes copper, tin, lead, and zinc. The lead content, usually around 7%, is crucial as it significantly improves machinability and provides excellent bearing properties. This makes it a go-to for applications where friction is a concern.

C954 Bronze (Aluminum Bronze)

C954, on the other hand, is an aluminum bronze. It primarily consists of copper and aluminum (around 10-11%), with additions of iron and sometimes nickel. This composition gives C954 superior strength and remarkable corrosion resistance, especially against seawater.

Performance and Application Showdown

Let’s compare them side-by-side in key areas:

| Feature | C932 (Bearing Bronze) | C954 (Aluminum Bronze) |

|---|---|---|

| Primary Use | Bearings, Bushings, Washers | Structural, Wear Parts, Marine |

| Strength | Moderate | High |

| Corrosion Resistance | Good | Excellent (especially to seawater) |

| Wear Resistance | Good (anti-frictional) | Very Good (abrasion resistance) |

| Machinability | Excellent | Fair to Good (can be abrasive) |

| Heat Treatable | No | Yes (for enhanced properties) |

When we approach a cnc machining bronze2 project, these properties directly influence material selection. For example, if a client needs high-strength components for a marine environment, 954 is often the clear winner. If the application involves sliding contact and moderate loads, 932 is usually more suitable and cost-effective to machine. We’ve seen projects where choosing 932 for a high-stress application led to premature failure, simply because the strength of 954 was overlooked.

Machining Considerations

While 932 is known for its excellent machinability due to its lead content, which acts as a lubricant and chip breaker, 954 aluminum bronze can be tougher on cutting tools. Its higher strength and the presence of aluminum oxides can make it more abrasive. This doesn’t mean 954 is difficult to machine; it just requires the right tooling, speeds, and feeds. In our CNC machining bronze operations at PTSMAKE, we adjust our parameters accordingly to ensure optimal results for both alloys. For instance, carbide tooling is often preferred for 954 to handle its abrasive nature.

What Rockwell Is Bronze?

Ever wondered how a simple number like a Rockwell value can dictate the destiny of your bronze part? Or perhaps felt puzzled trying to connect that hardness rating to real-world performance and machinability?

Rockwell hardness for bronze is a standardized test measuring its resistance to indentation, typically expressed on the B scale (HRB). This value indicates the bronze’s relative hardness, directly impacting its wear resistance, strength, and machinability characteristics for various applications.

Understanding Rockwell hardness is crucial when you’re selecting a bronze alloy for any application. It’s not just an abstract figure; it’s a practical indicator of how the material will behave. At PTSMAKE, we frequently refer to Rockwell values to guide our customers toward the best material choices for their specific needs, especially when dealing with precision components requiring specific mechanical properties.

Decoding Rockwell Hardness for Bronze Alloys

So, what exactly does a Rockwell test tell us about bronze? In essence, it measures the material’s resistance to permanent deformation when a specific indenter is pressed into its surface under a fixed load. The shallower the indentation depth3, the harder the material. For most bronze alloys, the Rockwell B scale (using a 1/16-inch steel ball indenter and a 100 kgf major load) is the most commonly referenced.

Why This Number Matters

The Rockwell hardness value directly correlates with several key performance attributes:

- Wear Resistance: Generally, harder bronzes (higher HRB values) offer better resistance to abrasive wear. This is critical for parts like bearings, bushings, and gears.

- Strength: While not a direct measure of tensile or yield strength, there’s often a positive correlation. Harder bronzes tend to be stronger.

- Machinability: This is where it gets interesting. Extremely hard bronzes can be more challenging to machine, potentially leading to increased tool wear and slower production times. Conversely, very soft bronzes might result in gummy chips and poor surface finishes. There’s a sweet spot, and understanding the Rockwell value helps find it for

cnc machining bronzeprojects.

Typical Rockwell Ranges for Common Bronzes

Different bronze alloys exhibit different Rockwell hardness values due to their unique chemical compositions and, in some cases, heat treatments. Here’s a general idea for some popular choices we often work with at PTSMAKE:

| Bronze Alloy | Typical Rockwell B (HRB) | Key Characteristics Related to Hardness |

|---|---|---|

| C932 (Bearing Bronze) | 55-65 | Good anti-frictional properties, moderate wear resistance |

| C954 (Aluminum Bronze) | 85-100 | High strength, excellent wear and corrosion resistance |

| C863 (Manganese Bronze) | 80-95 | Very high strength, good for heavy loads, fair wear |

| C510 (Phosphor Bronze) | 70-85 | Good spring qualities, good fatigue resistance |

| C63000 (Nickel Al. Bronze) | 90-100 (often HRB/HRC) | Very high strength, excellent corrosion resistance |

This table provides a snapshot. It’s important to consult specific datasheets for the exact grade you are considering, as values can vary slightly between manufacturers and material conditions (e.g., cast vs. wrought, or heat-treated states for alloys like C954). After comparing our test results on various batches, we’ve found these ranges to be quite consistent.

Applying Rockwell Knowledge to Your Project

Simply knowing the Rockwell number isn’t enough. The key is to interpret it in the context of your application’s demands. If you’re designing a high-load bearing, an alloy like C954 or C863 with higher HRB values would be preferable. For general-purpose bushings where machinability is also a key factor, C932 might be a more balanced choice. In my 15+ years of experience in precision manufacturing, I’ve seen that a well-informed material selection, considering hardness alongside other properties like corrosion resistance or thermal conductivity, is fundamental to project success.

What Is The ASTM For Bronze?

Ever felt lost in a sea of codes, wondering which ASTM standard actually governs the bronze you need for your design? Or perhaps concerned that overlooking the right spec could compromise your entire project?

ASTM International publishes a comprehensive suite of standards for bronze alloys, defining their chemical compositions, mechanical properties, forms (like castings or wrought products), and testing procedures. Key specifications include ASTM B505 for continuous cast alloys and ASTM B22/B584 for sand castings, ensuring consistent quality.

Understanding these standards is more than just a box-ticking exercise; it’s fundamental to achieving reliable and predictable results in your engineering projects.

Why ASTM Standards Are Your Friend

Think of ASTM standards as a universal language for materials. When you specify a bronze alloy according to an ASTM designation, you’re communicating precise requirements for its chemical makeup, how it should perform mechanically, and often, how it’s manufactured and tested. This helps everyone, from the foundry to the machine shop like us at PTSMAKE, to be on the same page. It ensures you get the material performance you expect and helps prevent costly mistakes or material failures down the line. In my experience, adhering to these standards from the outset saves a lot of headaches.

Decoding Common ASTM Bronze Specifications

ASTM standards for metals typically start with the letter ‘B’, followed by a number. For bronze, there are numerous specifications, often tailored to the manufacturing process (cast or wrought) and the specific alloy family.

Standards for Cast Bronzes

Cast bronze components are formed by pouring molten bronze into a mold. Some widely used ASTM standards include:

- ASTM B505/B505M: This covers continuously cast copper alloy rod, bar, tube, and shapes. Many common bearing bronzes like C93200 or C95400 fall under this when continuously cast. It specifies chemical requirements and typical mechanical properties.

- ASTM B22/B22M: This specification is for copper-alloy sand castings for bridges and turntables, often for very heavy-duty applications.

- ASTM B584: This is a crucial one for general engineering, covering copper alloy sand castings for general applications. It lists numerous common alloys, including tin bronzes, leaded tin bronzes, high-leaded tin bronzes, and aluminum bronzes.

Standards for Wrought Bronzes

Wrought bronzes are mechanically worked into their final shape (e.g., rolled, drawn, extruded). This process often enhances their mechanical properties. Common standards here are:

- ASTM B139/B139M: This standard applies to phosphor bronze rod, bar, and shapes. Phosphor bronzes are known for their strength, toughness, and good wear resistance.

- ASTM B150/B150M: This covers aluminum bronze rod, bar, and shapes. These alloys are excellent for their high strength and corrosion resistance, particularly in marine environments. When we’re doing

cnc machining bronzefor demanding applications, materials specified under ASTM B150 are often considered.

Key Information Within an ASTM Bronze Standard

So, what exactly do you find when you look up one of these ASTM specifications? They are quite detailed, and for good reason. Typically, you’ll find:

| Information Category | Typical Details Covered |

|---|---|

| Scope | Alloy types/UNS numbers, forms (castings, bar, sheet), applications |

| Referenced Documents | Other ASTM standards for testing methods, etc. |

| Terminology | Definitions of terms used in the standard |

| Ordering Information | What to specify when purchasing |

| Chemical Composition | % limits for each alloying element (e.g., Cu, Sn, Zn, Al, Pb) |

| Mechanical Properties | Requirements for tensile strength, yield strength, elongation, hardness |

| Dimensions & Tolerances | Permissible variations in size and shape |

| Workmanship, Finish & Appearance | Quality expectations for the material surface |

| Sampling & Testing | Procedures for taking samples and conducting tests |

| Certification | Requirements for material test reports |

Understanding these metallurgical4 and dimensional details is vital. At PTSMAKE, when a customer specifies an ASTM grade, we use the standard to verify incoming raw materials and ensure our manufacturing processes align with any specific requirements, guaranteeing the final parts meet the intended design performance. It’s a critical part of our quality assurance.

What Is Equivalent To C84400 Bronze?

Ever struggled to pinpoint a perfect substitute for C84400 bronze when it’s unavailable or not ideal for a specific aspect of your project? Finding that balance can be tricky, can’t it?

While no single alloy offers an exact identical match, C83600 (SAE 40) is widely regarded as the closest functional equivalent to C84400 bronze. This is due to their very similar chemical compositions, comparable mechanical properties, good machinability, and corrosion resistance.

C84400, often known as semi-red brass or leaded semi-red brass, is a popular choice for general-purpose plumbing fittings, fixtures, and low-pressure valves. Its appeal comes from a good combination of moderate strength, decent corrosion resistance, and excellent machinability, primarily due to its lead content. However, situations arise where an alternative is necessary, perhaps due to availability, specific regulatory requirements (like stricter lead limits in some applications), or a desire for slightly different performance characteristics.

Understanding the Key Contender: C83600 (SAE 40)

C83600, also commonly referred to as 85-5-5-5 bronze (indicating its nominal composition of 85% Copper, 5% Tin, 5% Lead, and 5% Zinc), lines up very closely with C84400. The metallurgical characteristics5 of these two alloys are quite similar. At PTSMAKE, when clients are looking for an alternative to C84400 for general cnc machining bronze applications, C83600 is often our first recommendation.

Here’s a quick comparison based on typical properties:

| Property | C84400 (Typical) | C83600 (Typical) |

|---|---|---|

| Copper (Cu) | ~81% | ~85% |

| Tin (Sn) | ~3% | ~5% |

| Lead (Pb) | ~7% | ~5% |

| Zinc (Zn) | ~9% | ~5% |

| Tensile Strength | 241 MPa (35 ksi) | 255 MPa (37 ksi) |

| Yield Strength | 117 MPa (17 ksi) | 124 MPa (18 ksi) |

| Machinability Rating | 80 (Free-Cutting Brass=100) | 90 (Free-Cutting Brass=100) |

As you can see from our internal data and industry standards, C83600 generally offers slightly higher strength and even better machinability. The lower lead content in C83600 can also be an advantage in regions with stricter environmental or health regulations.

Other Considerations and Potential Alternatives

While C83600 is the closest all-around equivalent, other alloys might be considered depending on the most critical property for your application:

If Enhanced Bearing Properties Are Needed:

- C93200 (SAE 660 Bearing Bronze): This alloy has higher lead content (typically 6-8%) and tin (6.3-7.5%), making it superior for bearing and bushing applications where wear resistance and anti-frictional properties are paramount. However, its overall mechanical strength is comparable or slightly lower than C84400/C83600.

If Higher Strength is Required (and some machinability can be sacrificed):

- C86300 (Manganese Bronze): This offers significantly higher tensile and yield strength but is tougher to machine. It’s not a direct equivalent but a step-up in strength if needed.

In my 15+ years at PTSMAKE, we’ve guided many clients through these material selection nuances. The key is to identify the most critical performance requirements. For instance, if pressure tightness is the main concern for a plumbing component, both C84400 and C83600 perform well. If it’s a part that will see more dynamic loads or wear, we might lean towards a slightly different alloy after discussing the trade-offs.

Ultimately, the "best" equivalent depends on the specific demands of your part. C83600 provides an excellent starting point and is often a direct drop-in replacement for many C84400 applications, especially where ease of cnc machining bronze is a factor.

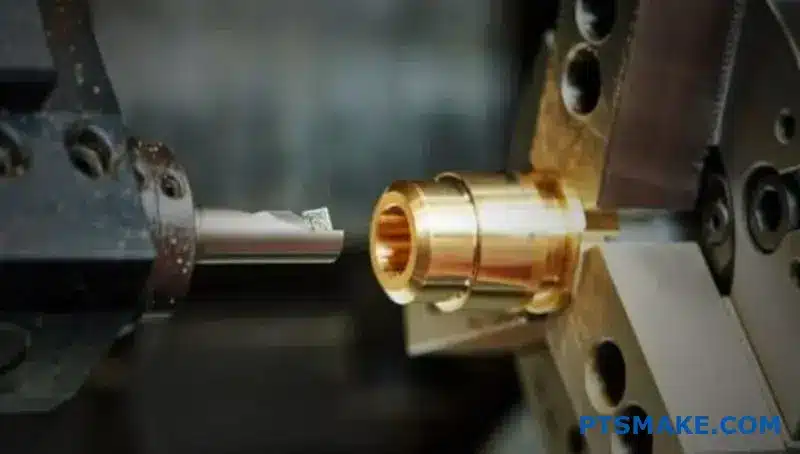

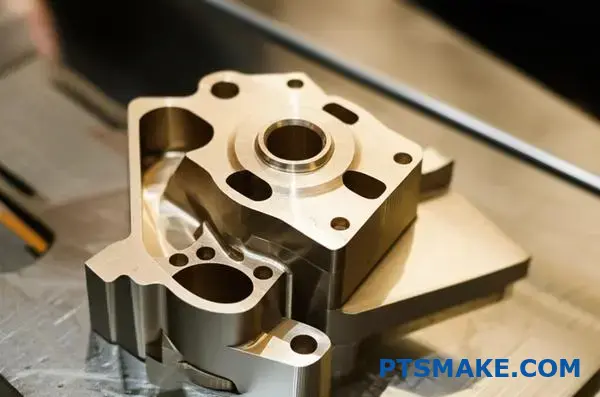

How Does CNC Machining Enhance Bronze Part Quality?

Struggling to get bronze parts that consistently meet your quality standards? Are variations and defects causing headaches and project delays for you?

CNC machining enhances bronze part quality by delivering superior precision, consistent repeatability, excellent surface finishes, and the capability for complex geometries, all while maintaining the material’s structural integrity and minimizing defects.

When we talk about making top-notch bronze parts, CNC (Computer Numerical Control) machining really stands out. It’s a process that brings a level of refinement and reliability that older methods often can’t match. At PTSMAKE, we rely heavily on CNC technology to deliver the quality our clients expect for their bronze components.

Unmatched Precision and Tight Tolerances

CNC machines follow exact digital blueprints. This means they carve bronze with amazing accuracy. It really cuts down on human error. So, at PTSMAKE, we consistently hit tight tolerances that old-school manual methods often can’t reach.

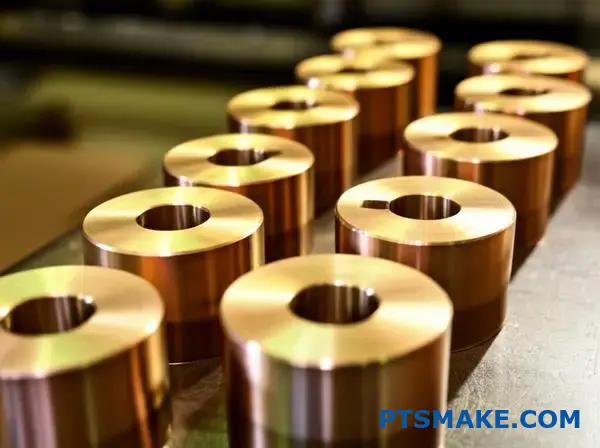

Think about making lots of bronze bushings for a big assembly. For these kinds of projects, CNC machining makes sure every single part is almost exactly the same. This kind of consistency is a big plus for quality when you’re doing cnc machining bronze.

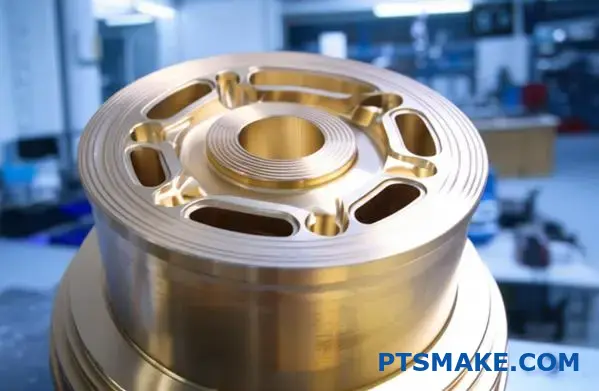

Better Surface Finishes and Complex Shapes

Another big win is the surface finish. CNC machines can make bronze parts super smooth, right off the machine. This often means less time, or no time, spent on polishing them up afterwards. That saves time and money, which is something we always aim for in our projects.

Plus, CNC is fantastic for making complex shapes. We’ve used it to create some really detailed bronze pieces, whether for art or for very specific jobs. Trying to make these with older methods would be incredibly tough, if not impossible.

Keeping Bronze Strong and Using Less Material

CNC machining works by carefully cutting away material. This controlled way of working helps protect the bronze’s inner strength, its metallurgical integrity6. We can set the cutting just right to avoid too much stress or heat. This is super important for some types of bronze that don’t like getting too hot.

When you compare it to something like traditional casting, cnc machining bronze often means fewer hidden flaws inside the part, like tiny air bubbles. So, you get a stronger, more dependable part. Plus, being so precise means less wasted bronze. From what we’ve seen in our work at PTSMAKE, here’s a quick look at how they stack up:

| Feature | CNC Machining Bronze | Traditional Casting Bronze |

|---|---|---|

| Precision | Very High | Moderate to Low |

| Surface Finish | Excellent | Fair to Good (needs more work) |

| Complexity | High (intricate details) | Moderate (simpler shapes) |

| Material Waste | Lower (efficient cutting) | Higher (e.g., gates, sprues) |

| Internal Defects | Rare | Potential for porosity |

This ability to refine every aspect of the bronze part, from its dimensions to its surface, is why CNC machining is a cornerstone of modern manufacturing for quality components.

What Tolerances Can Be Achieved In CNC Machined Bronze?

Pushing for those ultra-precise dimensions on your bronze components? Ever found that the unique nature of bronze alloys makes hitting exact tolerance targets a bit of a nail-biter?

Typically, CNC machining can achieve tolerances for bronze parts ranging from ±0.005 inches (±0.127 mm) down to ±0.001 inches (±0.025 mm). Tighter tolerances are often possible with specialized equipment, careful process control, and depend on the specific bronze alloy and part complexity.

Achieving tight tolerances in CNC machined bronze isn’t just about having a good machine; it’s a combination of factors. From my 15+ years in precision manufacturing, I’ve learned that understanding these variables is key to success. When we at PTSMAKE approach a project involving cnc machining bronze, we consider several critical aspects to ensure we meet, and often exceed, our clients’ specifications.

Key Factors Influencing Bronze Machining Tolerances

Several elements play a crucial role in determining the final precision of a bronze part. Getting these right is fundamental.

The Role of Bronze Alloy Selection

Not all bronze alloys are created equal when it comes to holding tight tolerances. Some, like leaded bronzes (e.g., C93200), are prized for their machinability, which can contribute to better dimensional control. Others, such as aluminum bronzes (e.g., C95400), are stronger and more wear-resistant but can be more challenging to machine to extremely fine limits due to their toughness. The alloy’s inherent stability and how it reacts to cutting forces are important.

CNC Machine Capabilities and Tooling

The quality and condition of the CNC machine itself are paramount. A well-maintained machine with high-quality spindles, minimal backlash, and robust construction will inherently produce more accurate parts. Sharp, appropriate cutting tools designed for bronze, along with optimized feeds and speeds, reduce cutting forces and tool deflection, leading to better tolerance control. In past projects at PTSMAKE, we’ve seen significant improvements by simply selecting the optimal tool geometry for a specific bronze grade.

Part Design and Geometric Complexity

The design of the part itself heavily influences achievable tolerances. Features like very thin walls, deep and narrow pockets, or complex internal geometries can be challenging. Thin sections might deflect under cutting pressure, while deep cavities can make chip evacuation difficult, potentially affecting surface finish and accuracy.

Thermal Considerations in Bronze Machining

Bronze alloys, like all metals, expand and contract with temperature changes. The Coefficient of Thermal Expansion7 (CTE) varies between different bronze alloys. During machining, heat is generated, and if not managed properly with coolants and appropriate cutting parameters, it can cause the workpiece to expand. This expansion, if not accounted for, means the part might be out of tolerance once it cools to ambient temperature. We’ve learned through careful process development how to mitigate these thermal effects effectively.

Standard vs. Precision Tolerances for CNC Machined Bronze

While general guidelines exist, the "achievable" tolerance is often project-specific.

| Tolerance Class | Typical Range (inches) | Typical Range (mm) | Notes |

|---|---|---|---|

| Standard | ±0.005" – ±0.010" | ±0.127 mm – ±0.254 mm | Suitable for many general applications. |

| Precision | ±0.001" – ±0.004" | ±0.025 mm – ±0.102 mm | Requires careful setup, good tooling, and process control. |

| High-Precision | < ±0.001" | < ±0.025 mm | Often involves specialized machines, environments, and techniques. |

Achieving those high-precision figures, especially below ±0.001 inches, often requires secondary operations like grinding or lapping, particularly if the bronze alloy is on the more challenging side to machine. However, for many cnc machining bronze applications, the precision range is well within the capabilities of modern CNC centers when operated with expertise. At PTSMAKE, we always discuss tolerance requirements upfront to align expectations and ensure the manufacturing strategy is optimized for the client’s needs.

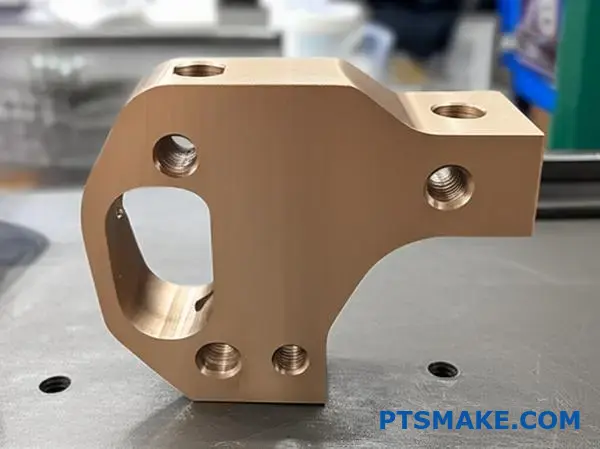

What Are The Limitations of Using Bronze in CNC Machining?

Thinking bronze is the perfect fit for every CNC job? Could overlooking its specific drawbacks lead to unexpected design or production hurdles for your components?

Key limitations include its relatively higher material cost compared to some steels or aluminums, lower strength-to-weight ratio than certain alternatives, and potential for galling with some alloys if machining parameters aren’t optimized. Specific bronze types also have specialized, not universal, applications.

While bronze offers many advantages for CNC machined components, it’s not always the perfect material choice for every situation. Understanding its limitations is just as important as knowing its strengths. At PTSMAKE, we believe in providing a balanced view to help you make the best decisions for your projects.

Cost Considerations

One of the primary limitations can be the upfront material cost.

Raw Material Price

Generally, bronze alloys tend to be more expensive per pound or kilogram than many common grades of steel or aluminum. This difference can be significant, especially for larger parts or high-volume production runs. This is a factor we always discuss with clients when exploring material options.

Machinability of Certain Alloys

While many bronze alloys are known for good to excellent machinability, some high-strength or specialized bronzes (like certain aluminum bronzes or manganese bronzes) can be tougher and more abrasive on cutting tools. This can lead to slightly slower machining speeds or increased tool wear, which can incrementally add to the overall cost of cnc machining bronze parts.

Strength-to-Weight Ratio

When structural efficiency is paramount, bronze might not always be the top contender.

Comparison with Alternatives

While bronze alloys offer good strength, materials like heat-treated alloy steels or certain aluminum alloys can provide a superior strength-to-weight ratio. If minimizing component weight while maximizing strength is a critical design driver, alternatives might be more suitable.

Here’s a very general comparison:

| Feature | Bronze (Typical) | Steel (Carbon/Alloy) | Aluminum (Alloy) |

|---|---|---|---|

| Density (Approx.) | Higher | Higher | Lower |

| Strength (Typical) | Moderate to High | High to Very High | Moderate to High |

| Strength-to-Weight | Lower | Moderate to High | Higher |

This is a simplified view, of course, as specific alloys within each category vary widely.

Specific Alloy and Processing Challenges

Certain bronze alloys come with their own set of considerations.

Galling and Wear

Some bronze alloys, particularly those with lower hardness or certain compositions, can be prone to galling or a susceptibility to cold welding8 when in sliding contact with other metals, including cutting tools if not managed. This requires careful selection of cutting parameters, tool coatings, and coolants. Our experience at PTSMAKE in past projects has shown that optimized setups mitigate this effectively.

Environmental and Application Nuances

Leaded bronzes, while offering excellent machinability, face increasing restrictions in certain applications (like potable water systems or RoHS-compliant products) due to environmental and health concerns over lead. Also, not every bronze alloy is suited for every environment; for example, some may not perform well in highly acidic or specific chemical exposures where specialized stainless steels might excel. It’s about matching the right bronze to the right job, a principle we adhere to closely.

Explore how specific bronze alloys perform in CNC machining, affecting speed, tool life, and finish quality. ↩

Learn more about selecting the right bronze alloy for your specific CNC machining needs and applications. ↩

Understand how this specific test parameter directly influences material suitability for diverse engineering needs. ↩

Discover why these metallurgical details are vital for material selection and quality. ↩

Explore how these internal structures dictate material strength, ductility, and machinability. ↩

Learn how material structure affects part performance and durability. ↩

Understand how this material property critically affects precision during and after machining bronze components. ↩

Learn about this adhesion process critical to understanding material compatibility in machining. ↩