Finding the right CNC custom machining partner for your 2025 projects feels overwhelming when every supplier promises precision but few deliver the advanced capabilities your complex parts demand. You’re stuck evaluating countless providers while your competition moves ahead with innovative manufacturing solutions.

CNC custom machining in 2025 combines AI-powered automation, hybrid manufacturing processes, and advanced material expertise to deliver highly precise, complex components for aerospace, medical, and electronics industries with faster turnaround times and superior quality control.

The manufacturing landscape is shifting fast, and understanding these emerging trends will determine whether your next project succeeds or gets stuck in outdated processes. I’ll walk you through the key innovations transforming custom CNC machining, from hybrid manufacturing techniques to industry-specific applications that are reshaping how we approach precision manufacturing in 2025.

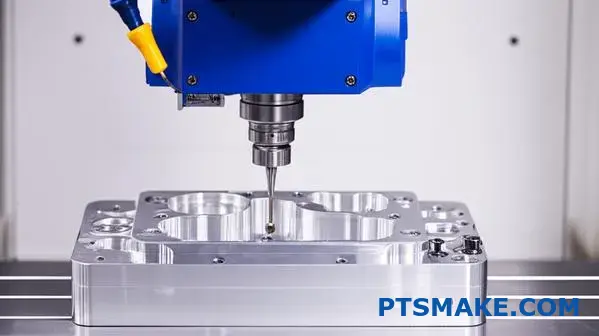

Why Custom CNC Machining Is Essential for Modern Manufacturing?

Have you ever struggled to find an off-the-shelf part that perfectly fits your unique design, forcing costly compromises? This bottleneck can stall entire projects, leading to delays and subpar performance.

Custom CNC machining is essential because it bridges the gap between digital design and physical reality with unparalleled precision. It enables the rapid production of complex, tailored components, driving innovation in an era where mass-produced parts are no longer sufficient for specialized applications.

The manufacturing landscape has fundamentally changed. We’ve moved away from the long-standing model of mass production, where factories churned out millions of identical items. Today, the market demands agility, specialization, and speed. This has ushered in the era of high-mix, low-volume (HMLV) manufacturing, where flexibility is more valuable than sheer output. Instead of one product for everyone, companies now need to produce a wide variety of parts in smaller quantities, often with short lead times. This is where custom CNC machining becomes not just an option, but a necessity. It eliminates the need for expensive and time-consuming tooling like molds or dies, allowing for direct production from a CAD file.

Enabling Complexity in Demanding Industries

The ability to create intricate and highly precise components on demand has revolutionized several key sectors. These industries operate under strict standards where failure is not an option, and generic parts simply don’t measure up.

Aerospace and Defense

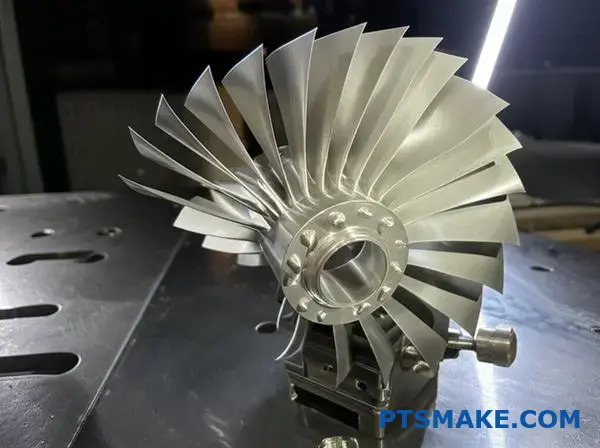

In aerospace, every gram matters. Components must be incredibly strong yet lightweight. Custom CNC machining allows us to work with advanced materials like titanium and aluminum alloys to create complex geometries that optimize strength-to-weight ratios. From turbine blades to structural brackets, parts require tight tolerances that only computer-controlled processes can achieve. Achieving this level of accuracy relies heavily on robust process control and a deep understanding of Geometric Dimensioning and Tolerancing1 (GD&T).

Medical Devices

The medical field requires absolute precision and biocompatibility. Custom surgical instruments, orthopedic implants, and components for diagnostic equipment must meet exacting specifications. For example, a hip implant must be tailored to a patient’s unique anatomy. CNC machining makes it possible to create these patient-specific parts from materials like medical-grade stainless steel or PEEK, ensuring a perfect fit and reliable performance.

| Feature | Mass Production | Custom CNC Machining |

|---|---|---|

| Volume | High | Low to Medium |

| Part Variety | Low | High |

| Tooling Cost | Very High (e.g., molds) | Low to Moderate |

| Lead Time | Long (initial setup) | Short |

| Design Flexibility | Low | High |

This shift means engineers can design for optimal function rather than being constrained by what’s easy to mass-produce.

Beyond industry-wide shifts, the growing demand for personalization is a major driver for custom manufacturing. Consumers and businesses alike now expect products that are tailored to their specific needs and preferences. This trend extends from customized consumer electronics to highly specialized industrial machinery. An off-the-shelf component is, by definition, a compromise. It’s designed to be "good enough" for a wide range of applications, but rarely is it perfect for any single one. When a project demands peak performance or must fit into a unique space, a generic part often becomes the weakest link. In past projects at PTSMAKE, we’ve seen how a single custom-machined bracket can solve complex integration challenges that would have otherwise required a complete redesign.

Solving Unique Application Challenges

Custom parts are not just about aesthetics or novelty; they are about solving specific engineering problems that standard components cannot address. This is where the true value of cnc custom machining shines.

Optimizing for Performance

Standard parts are designed with average performance in mind. With a custom part, you can optimize for specific factors like weight reduction, heat dissipation, or material strength. For instance, a generic heatsink might provide adequate cooling, but a custom-machined one can be designed to fit perfectly within a compact enclosure and maximize surface area for superior thermal management. This level of optimization can be the difference between a product that works and one that excels.

Rapid Prototyping and Iteration

The product development cycle is faster than ever. Engineers need to design, test, and iterate quickly. Custom CNC machining is an ideal partner in this process. It allows for the creation of functional prototypes in engineering-grade materials within days, not weeks. This allows teams to validate designs, test functionality, and make necessary adjustments before committing to expensive tooling for mass production. It accelerates innovation by making the feedback loop between idea and physical part incredibly short.

| Application | Standard Part Limitation | Custom CNC Solution |

|---|---|---|

| Robotics End-Effector | Cannot grip unique object shapes | Gripper jaws machined to match product geometry |

| Medical Implant | Standard sizes cause poor fit | Patient-specific implant based on MRI/CT scans |

| Automotive Prototype | Long lead times for casting/molding | Quickly machined engine block for fitment tests |

| Custom Jigs & Fixtures | Universal fixtures lack precision | Machined fixtures for repeatable assembly accuracy |

Ultimately, custom machining empowers engineers to build exactly what they envision without being limited by what’s available in a catalog.

In today’s manufacturing world, the shift from mass production to customized, high-mix orders is clear. Custom CNC machining is the core technology enabling this change. It provides the precision and flexibility needed to create complex components for demanding industries like aerospace and medical. More importantly, it empowers engineers to solve unique application challenges and meet the growing demand for product personalization, turning specific design requirements into high-performance physical parts without the constraints of traditional methods.

Top 4 Trends Revolutionizing CNC Custom Machining in 2025?

Are your projects being held back by outdated machining processes? Wondering how you can achieve faster turnarounds and higher precision without inflating your budget?

By 2025, the most significant trends reshaping CNC custom machining are AI-driven automation, robotics integration, hybrid manufacturing, and the digital thread. These advancements are pushing the boundaries of efficiency, precision, and scalability, transforming how complex parts are made from prototype to production.

The Rise of Intelligent Automation

The conversation around CNC machining is no longer just about cutting metal; it’s about making the entire process smarter. Artificial Intelligence (AI) and Machine Learning (ML) are at the forefront of this shift, moving from theoretical concepts to practical applications on the shop floor.

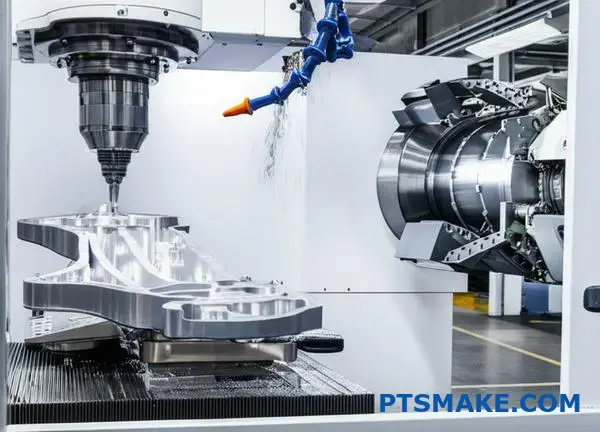

AI-Powered CAM and Toolpath Optimization

Traditionally, programming toolpaths in CAM software required extensive manual input from experienced engineers. Now, AI algorithms can analyze a part’s geometry and suggest the most efficient machining strategy. This isn’t just about speed. AI can optimize for tool life, surface finish, and material removal rates simultaneously. In some of our past projects at PTSMAKE, we’ve seen AI-optimized toolpaths reduce cycle times by up to 25% on complex components. The software can simulate thousands of possibilities in minutes, an impossible task for a human programmer. It can also learn from previous jobs to improve future performance, creating a self-improving system that gets more efficient over time. This approach allows us to use AI for generative design2, creating lightweight yet strong parts that were previously unimaginable.

Predictive Maintenance and Quality Control

Another game-changer is AI’s role in predictive maintenance. Instead of waiting for a machine to break down, which can halt production for days, sensors collect data on vibration, temperature, and power consumption. AI models analyze this data to predict when a component is likely to fail, allowing us to schedule maintenance proactively. This drastically reduces unplanned downtime. On the quality control front, AI-powered vision systems are becoming standard. These systems can inspect parts with incredible speed and accuracy, identifying microscopic defects that the human eye might miss. This ensures that every part leaving our facility meets the tightest tolerances required by industries like aerospace and medical devices.

| Trend Component | Traditional Method | AI-Enhanced Method |

|---|---|---|

| Toolpath Generation | Manual programming by engineer | AI suggests optimal paths |

| Maintenance | Reactive (fix when broken) | Predictive (fix before broken) |

| Quality Inspection | Manual or CMM spot-checks | Real-time, AI-vision inspection |

Unlocking New Possibilities with Advanced Technologies

Beyond intelligent automation, other trends are converging to create a more integrated and capable manufacturing ecosystem. These trends focus on combining processes and connecting data streams for a seamless workflow.

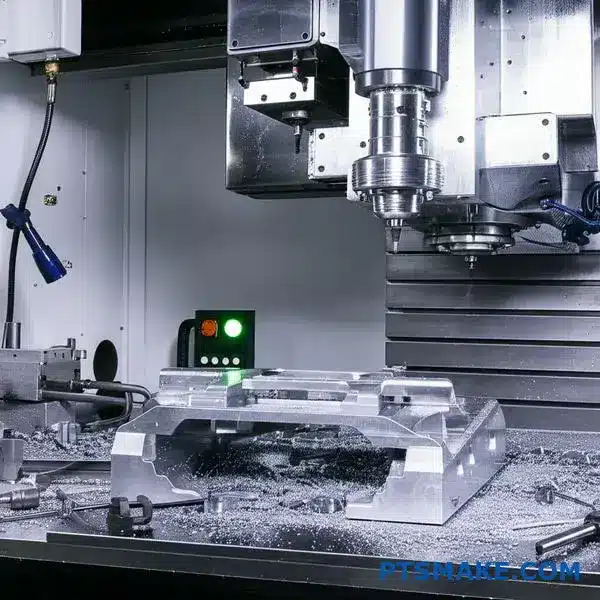

Hybrid Manufacturing: The Best of Both Worlds

For years, manufacturing was a choice between two camps: subtractive (CNC machining) and additive (3D printing). Hybrid manufacturing erases that line by combining both in a single machine. Imagine 3D printing a complex metal part with internal cooling channels and then using CNC milling to machine the critical mating surfaces to a mirror finish—all in one setup. This approach opens up incredible design freedom. It allows for the creation of parts with intricate internal geometries that would be impossible to machine traditionally. At PTSMAKE, we’re exploring hybrid solutions for clients in the automotive and aerospace sectors, where creating lightweight, high-strength components with complex internal features is a top priority. It reduces setups, minimizes the chance of error from moving a part between machines, and dramatically shortens the lead time from design to finished product.

The Digital Thread: A Single Source of Truth

The "digital thread" is the concept of creating a connected data flow that runs through a part’s entire lifecycle, from initial design to manufacturing and final inspection. It ensures that everyone—from the design engineer to the machine operator—is working from the same up-to-date information.

| Stage | Data in the Digital Thread | Benefit |

|---|---|---|

| Design | 3D CAD model, GD&T, material specs | Single source of truth for design intent |

| Manufacturing | CAM programs, tool data, machine settings | Eliminates manual data re-entry errors |

| Inspection | CMM reports, vision system data | Creates a full digital record for traceability |

This connectivity eliminates data silos and reduces errors caused by miscommunication or outdated files. When a design is updated, the change automatically propagates to the CAM software and the inspection plan. This seamless integration is critical for maintaining quality and consistency, especially in high-volume production for CNC custom machining. It provides complete traceability, which is a non-negotiable requirement for our clients in regulated industries.

In 2025, the landscape of CNC custom machining is being redefined by intelligent and connected technologies. AI and robotics are automating complex tasks, boosting efficiency and precision beyond previous limits. Meanwhile, hybrid manufacturing merges additive and subtractive processes to create previously impossible parts. Tying it all together, the digital thread ensures a seamless, error-free data flow from the initial design concept all the way through to the final quality inspection, delivering unprecedented reliability and speed.

Advanced Materials and Their Impact on Custom CNC Machining?

Ever found your project stuck because traditional metals can’t meet the performance demands? Are you facing part failures or excessive weight from using outdated materials for cutting-edge applications?

Advanced materials like titanium alloys, composites, and high-performance plastics are revolutionizing product design. Their impact on cnc custom machining is profound, demanding specialized tools, advanced machinery, and deep process knowledge to handle their unique properties and unlock superior strength, lighter weight, and enhanced durability.

The shift from standard aluminum and steel to advanced materials isn’t just a trend; it’s a necessity for innovation in sectors like aerospace, medical, and automotive. However, these materials don’t play by the old rules. Each presents a unique set of hurdles that can quickly derail a project if you’re not prepared. In my experience at PTSMAKE, successfully navigating these challenges is what separates a standard machine shop from a true manufacturing partner.

The Machining Minefield: Taming Advanced Materials

Machining advanced materials is a different ballgame. It’s less about raw cutting speed and more about finesse, control, and a deep understanding of material science. The properties that make these materials so desirable—strength, hardness, and low thermal conductivity—are the very things that make them difficult to machine.

Titanium Alloys (e.g., Ti-6Al-4V)

Titanium is famous for its incredible strength-to-weight ratio, but it’s infamous on the shop floor. Its low thermal conductivity means heat doesn’t dissipate through the workpiece or chips. Instead, it concentrates on the cutting tool, leading to rapid tool wear and potential failure. It also has a tendency for work hardening3, where the material becomes harder as it’s being cut, creating even more stress on the tool. To counter this, we use high-pressure coolant systems, specialized carbide tools with tough coatings, and carefully controlled, lower cutting speeds to manage heat and prevent tool burnout.

Carbon Fiber Composites (CFRP)

Composites are strong and incredibly lightweight, but they are abrasive and prone to delamination. The carbon fibers are tough on cutting tools, wearing them down quickly. More importantly, improper cutting techniques can cause the layers to separate (delaminate) or create fiber pull-out, compromising the structural integrity of the part. We rely on polycrystalline diamond (PCD) tools, which are extremely hard and wear-resistant. We also use specific strategies like orbital drilling and high-speed, low-feed milling to get clean cuts without damaging the material’s internal structure.

High-Performance Engineering Plastics (PEEK, Ultem)

Plastics like PEEK offer excellent chemical resistance and high-temperature performance, making them metal replacements in many applications. The main challenge here is managing thermal expansion and avoiding melting. These materials have a low melting point compared to metals. Too much friction from the cutting tool generates heat, which can melt the plastic, leading to a poor surface finish and dimensional inaccuracy. At PTSMAKE, we use extremely sharp tools, often with specific geometries for plastics, and apply air or cold-air blasts instead of traditional coolant to prevent thermal shock and achieve a clean, precise cut.

A quick comparison highlights the difference:

| Material Property | Aluminum 6061 | Titanium (Ti-6Al-4V) | Carbon Fiber (CFRP) | PEEK |

|---|---|---|---|---|

| Machinability | Excellent | Poor | Fair (Abrasive) | Good |

| Primary Challenge | Gummy, Chip Control | Heat Generation, Tool Wear | Delamination, Abrasion | Melting, Thermal Expansion |

| Typical Tooling | HSS, Carbide | Coated Carbide | PCD Diamond | Sharp, Uncoated Carbide |

| Coolant Strategy | Flood Coolant | High-Pressure Coolant | Dry or Cold Air | Dry or Cold Air |

While the challenges are significant, the opportunities unlocked by these materials are even greater. The ability to properly machine them opens the door to creating parts that were previously impossible. It’s about more than just cutting material; it’s about enabling the next generation of technology. A well-executed cnc custom machining process turns a block of advanced material into a critical component that can withstand extreme environments, reduce overall weight, or meet stringent biocompatibility requirements.

Opportunities Forged by Expertise

Successfully machining these materials is where true value is created. It allows engineers to design components that are lighter, stronger, and more durable than ever before. This isn’t just an incremental improvement; it’s a leap forward in performance.

Unlocking Performance in Aerospace and Automotive

In aerospace, every gram matters. Titanium alloys and carbon fiber composites allow for the creation of components that offer the same or greater strength as steel at a fraction of the weight. This translates directly to improved fuel efficiency and increased payload capacity. In one of our past projects at PTSMAKE, we helped a client transition a structural bracket from aluminum to a titanium alloy. While the cnc custom machining process was more complex and required a 30% increase in machine time per part, the final component was 40% lighter while increasing its load-bearing capacity, a critical trade-off for their application.

Revolutionizing Medical Devices

For medical implants and surgical instruments, materials like PEEK and medical-grade titanium are game-changers. Their biocompatibility means they can be safely used inside the human body without causing adverse reactions. PEEK is also radiolucent, meaning it doesn’t interfere with medical imaging like X-rays or MRI scans. Machining these materials to the tight tolerances required for medical devices demands a highly controlled environment and process. For example, producing a spinal fusion cage from PEEK requires maintaining surface finishes that prevent bacterial growth and ensuring absolute dimensional accuracy for a proper fit.

Elevating Industrial and Robotics Applications

In robotics and industrial machinery, components made from materials like Ultem or reinforced composites can reduce the mass of moving parts. Lighter robotic arms, for instance, can move faster and more precisely, with less energy consumption. This improves overall system efficiency and performance. The challenge lies in machining these materials without introducing internal stresses that could lead to premature failure under high-cycle fatigue conditions. Careful toolpath strategies and stress-relief steps are crucial.

This table shows how a material choice directly connects to a market opportunity:

| Advanced Material | Key Property | Industry Application | Resulting Opportunity |

|---|---|---|---|

| Titanium Alloys | High Strength-to-Weight | Aerospace | Lighter, more fuel-efficient aircraft |

| Carbon Fiber | Extreme Stiffness & Low Weight | Automotive/Motorsport | Faster, more responsive vehicles |

| PEEK | Biocompatibility, Radiolucency | Medical | Safer and more effective implants |

| Ultem | High Strength & Heat Resistance | Robotics/Industrial | More efficient, higher-speed automation |

Advanced materials present significant hurdles in cnc custom machining, from extreme tool wear when cutting titanium to the risk of delamination in composites. However, these challenges are directly linked to the very properties that make them so valuable. By embracing specialized tooling, refined techniques, and deep expertise, these materials unlock unparalleled opportunities for innovation. They enable the creation of lighter, stronger, and more resilient components that redefine performance standards in industries from aerospace to medical devices.

Industry-Specific Applications: From Aerospace to Medical Devices?

Ever wonder if a single manufacturing process can meet the extreme demands of aerospace, the life-or-death precision of medical devices, and the high-volume needs of the automotive world?

Yes, CNC custom machining is uniquely tailored to key industries by leveraging specific materials, achieving ultra-tight tolerances, and adhering to strict regulatory standards. It provides the precision for aerospace, the biocompatibility for medical, and the reliability for automotive components.

When we talk about industry-specific applications, we’re moving beyond general capabilities. We’re discussing how a process adapts to solve unique, high-stakes problems. In my experience, no field tests the limits of CNC machining quite like aerospace.

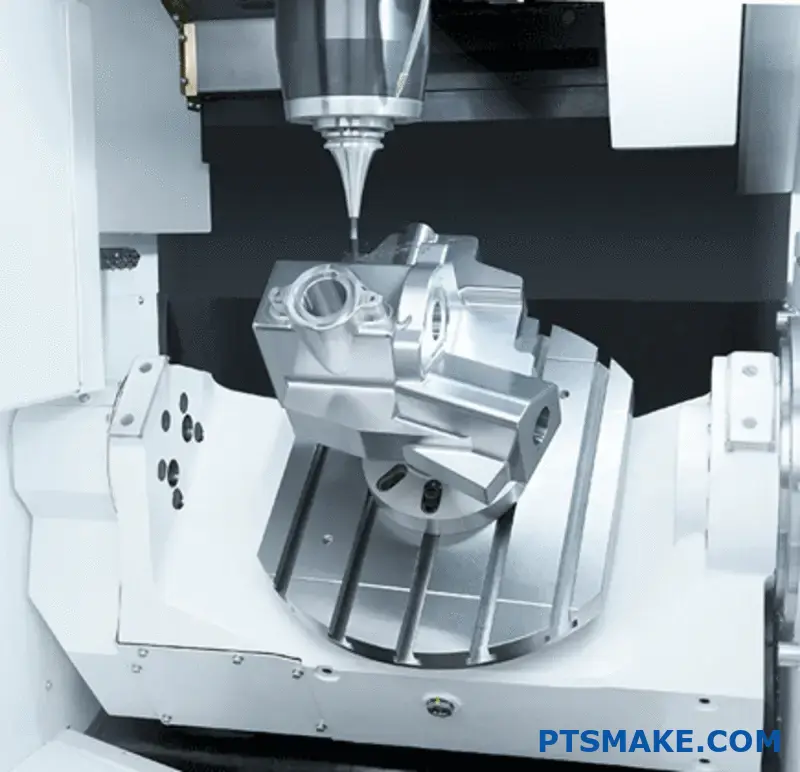

Aerospace: Pushing the Limits of Precision and Materials

In the aerospace sector, there is no margin for error. A single component failure can have catastrophic consequences, which is why the standards are so incredibly high. The parts are often complex, lightweight, and must withstand extreme temperatures, pressures, and stresses. This is where the true value of high-precision CNC machining shines.

The Challenge of Exotic Materials

Aerospace engineers often specify superalloys like Inconel, Titanium, and specialized aluminum alloys. These materials are chosen for their exceptional strength-to-weight ratios and resistance to corrosion and heat. However, they are notoriously difficult to machine. At PTSMAKE, we’ve found that success requires more than just advanced equipment; it demands a deep understanding of material science. The cutting speeds, feed rates, and even the type of coolant must be perfectly calibrated to avoid work hardening or tool breakage. We once worked on a turbine blade project where the client’s previous supplier failed because they couldn’t manage the internal stresses in the titanium billet, causing micro-fractures. Our solution involved a multi-stage machining process with carefully controlled thermal management, ensuring the final part’s Geometric Dimensioning and Tolerancing (GD&T)4 was flawless.

Navigating Regulatory Compliance

Compliance is non-negotiable. The AS9100 standard, for example, governs the quality management system for aviation, space, and defense organizations. It requires meticulous traceability from the raw material billet to the final packaged part. Every step of the cnc custom machining process must be documented and verifiable. This includes material certifications, machine calibration records, and final inspection reports. For clients, this provides the critical assurance that every component meets the exact specifications required for flight-safe applications.

| Feature | Titanium (Ti-6Al-4V) | Inconel 718 | Aluminum 7075 |

|---|---|---|---|

| Primary Use | Structural components, engine parts | Turbine blades, exhaust systems | Fuselage, wing structures |

| Key Property | High strength-to-weight ratio | Extreme heat resistance | Lightweight and strong |

| Machinability | Difficult | Very Difficult | Good |

| Compliance Focus | Material purity, stress relief | Heat treatment verification | Traceability, finish quality |

This level of detail is what separates a standard machine shop from a trusted manufacturing partner in the aerospace industry.

While aerospace demands peak performance in extreme conditions, the medical device industry presents a different, yet equally critical, set of challenges. Here, the focus shifts from mechanical stress to biocompatibility and sterilization, where the interaction between the component and the human body is paramount.

Medical Devices: Where Biocompatibility Meets Complexity

For medical parts, precision ensures a device functions as intended, whether it’s a bone screw or a component in a diagnostic machine. But beyond that, the materials themselves must be safe for human contact. This introduces a layer of complexity that requires specialized knowledge in both machining and medical regulations.

Material Selection and Sterilization

Medical-grade materials like 316L stainless steel, PEEK, and titanium are common choices. They are selected for their non-reactive properties and ability to withstand repeated sterilization cycles, such as autoclaving. The machining process itself must not compromise these properties. For instance, using the wrong cutting fluids can leave behind residues that are difficult to remove and could cause adverse reactions in a patient. We machine these parts in a highly controlled environment, often using specific cutting tools and lubricants that are approved for medical applications. The surface finish is also critical; a smooth, polished surface is easier to clean and sterilize and is less likely to harbor bacteria.

Automotive: Balancing Performance and Scalability

The automotive industry is a fascinating blend of high-performance demands and the need for cost-effective, scalable production. While stamped and cast parts dominate high-volume production, CNC custom machining is essential for several key areas.

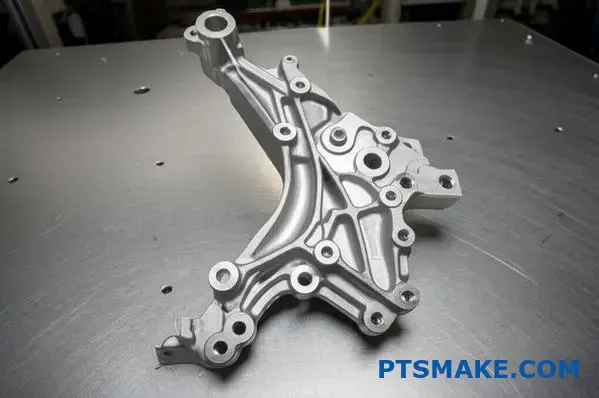

Prototyping and Performance Parts

Before a new engine block or suspension component goes into mass production, it undergoes rigorous testing. CNC machining is the go-to method for creating these initial prototypes because it’s fast, accurate, and allows for quick design iterations. For performance and racing applications, CNC machined parts are often the final product. Custom pistons, intake manifolds, and brake components are machined from solid blocks of aluminum or steel to achieve strength and precision that casting cannot match.

Here’s a quick comparison of the primary drivers in these three key industries:

| Industry | Primary Concern | Key Material Trait | Governing Standard (Example) |

|---|---|---|---|

| Aerospace | Reliability & Safety | Strength-to-Weight Ratio | AS9100 |

| Medical | Patient Safety | Biocompatibility | ISO 13485 |

| Automotive | Performance & Cost | Durability | IATF 16949 |

In past projects at PTSMAKE, we’ve helped automotive clients rapidly develop and test new electric vehicle (EV) components, using our CNC capabilities to produce functional prototypes in days rather than weeks. This speed is a significant competitive advantage in a fast-moving market.

CNC custom machining is not a one-size-fits-all solution. Its true strength lies in its adaptability to meet the unique demands of different sectors. For aerospace, it delivers unparalleled precision with difficult materials under strict AS9100 regulations. In the medical field, it ensures patient safety through biocompatible materials and sterile-ready finishes compliant with ISO 13485. For automotive, it provides the speed for prototyping and the performance for high-end components, blending quality with scalability.

Integrating Advanced Quality Control Systems for Flawless Parts?

Struggling with unexpected defects in complex parts appearing only at final inspection? Are post-production quality checks causing frustrating delays and costly rework, undermining your entire project timeline?

These challenges are solved by integrating advanced quality control systems directly into the cnc custom machining workflow. Technologies like in-process inspection, 3D laser scanning, and AI-driven analysis catch deviations in real-time, ensuring consistent quality, minimizing defects, and enabling flawless production.

The days of relying solely on a final inspection are over. Modern manufacturing, especially in high-stakes industries like aerospace and medical, demands a proactive approach to quality. We’ve moved quality assurance from a final gatekeeper to an integrated part of the entire machining process. This shift is powered by incredible technologies that provide real-time data and control.

In-Process Inspection: Catching Errors as They Happen

In-process inspection involves measuring the part while it’s still on the CNC machine. This is often done using automated touch probes that can check critical dimensions, feature locations, and depths between machining steps. Instead of waiting until the end to discover a tool has worn slightly or a setup has shifted, we can detect these tiny deviations immediately.

This method acts as a real-time feedback loop. If a probe detects a feature is drifting out of tolerance, the system can alert the operator or even make automatic adjustments to the machining parameters for subsequent parts. At PTSMAKE, we find this indispensable for multi-operation jobs where an early error could compound and ruin the entire workpiece. It’s a simple concept that dramatically reduces scrap rates and improves overall consistency.

3D Laser Scanning: Capturing a Complete Digital Twin

For parts with complex curves and organic shapes, traditional measurement tools like calipers or even a CMM can be slow and may miss subtle surface imperfections. This is where 3D laser scanning excels. A non-contact laser scanner sweeps across the part, capturing millions of data points on its surface to create a detailed digital model.

This incredibly dense Point Cloud5 is then digitally overlaid onto the original CAD model. Software automatically generates a color map showing any deviation, instantly highlighting areas that are out of tolerance. This technique is invaluable for verifying complex geometries, identifying warping after a heat-treating process, or reverse-engineering legacy parts. It provides a level of comprehensive detail that manual inspection simply cannot match.

| Feature | Traditional Inspection | Advanced In-Process Inspection | 3D Laser Scanning |

|---|---|---|---|

| Timing | Post-production | During production | Post-production (fast) |

| Data Points | Limited, specific points | Key features, real-time | Millions of points |

| Complexity | Best for simple geometry | Good for critical features | Ideal for complex surfaces |

| Defect Detection | Catches final errors | Prevents compounding errors | Identifies subtle deviations |

Implementing these technologies is more than just buying new equipment; it’s about building a smarter, data-driven manufacturing ecosystem. The true power emerges when these systems work together, creating layers of verification that make defects nearly impossible to miss. This integrated approach is what separates a good machine shop from a trusted manufacturing partner.

The Rise of AI-Driven Autonomous Quality Assurance

The next frontier in quality control is leveraging Artificial Intelligence (AI) and Machine Learning (ML). While probes and scanners collect massive amounts of data, AI is what turns that data into predictive insights. AI-driven systems can analyze trends from hundreds of production runs, identifying subtle patterns that precede a quality issue.

For example, an AI algorithm might correlate tiny increases in spindle temperature with microscopic changes in surface finish. By flagging this trend, it can predict tool wear and schedule a replacement before any parts go out of spec. This moves quality assurance from a reactive or even proactive state to a predictive one. It enables autonomous quality control, where the system self-corrects based on historical and real-time data, reducing the need for constant human oversight and minimizing the potential for human error. In our experience with customers, this predictive capability is a key factor in achieving true lights-out manufacturing for certain high-volume projects.

Creating a Synergistic Quality Ecosystem

These advanced systems are most effective when they are not used in isolation. A truly robust quality strategy for cnc custom machining integrates them into a seamless workflow. Imagine a complex aerospace component being manufactured. An in-process probe verifies the diameter of a critical bore immediately after it’s drilled. Once the part is complete, a 3D laser scanner performs a full-surface scan to check for any warping or distortion. All this data is fed into an AI-powered system that logs the results, monitors long-term trends, and provides a complete digital record of quality for that specific part—a concept known as a "digital thread." This ecosystem ensures that quality is not just inspected but is built into every step of the process.

| Metric | Without Advanced QA | With Integrated Advanced QA |

|---|---|---|

| Defect Rate | Higher, discovered late | Significantly lower, caught early |

| Inspection Time | Long, manual process | Automated, much faster |

| Rework/Scrap Costs | High due to late detection | Drastically reduced |

| Process Consistency | Relies on operator skill | Data-driven and automated |

| Complex Part Viability | Risky and difficult to verify | High confidence and traceability |

Ultimately, integrating advanced quality control is about removing uncertainty from the cnc custom machining process. Instead of hoping a part is correct, technologies like in-process inspection, 3D scanning, and AI provide data-driven certainty. This allows manufacturers like us at PTSMAKE to confidently produce highly complex parts with exceptional consistency. By embedding quality checks throughout the workflow, we minimize costly rework and delays, ensuring that the final part delivered is a perfect match to the design intent.

Sustainability and Eco-Friendly Practices in CNC Custom Machining.

Struggling to align precision manufacturing with environmental responsibility? Does the push for sustainability seem to conflict with your budget and quality standards for custom parts?

Sustainable CNC custom machining integrates energy-efficient machinery, material recycling, and waste reduction. These practices not only lower environmental impact but also lead to significant cost savings, ensure regulatory compliance, and boost your brand reputation by meeting modern expectations.

Adopting sustainability in manufacturing isn’t just about feeling good; it’s a core business strategy that delivers tangible results. In the world of CNC custom machining, where precision and efficiency are paramount, eco-friendly practices create a more resilient and profitable operation. It starts with a shift in mindset, viewing waste not as a byproduct but as a sign of inefficiency. By focusing on key areas, any machine shop can make significant strides toward a greener future without compromising on the quality that clients expect. At PTSMAKE, we’ve focused our efforts on practical changes that yield the greatest impact on both the environment and our operational excellence.

The Pillars of Green CNC Machining

The journey toward sustainability can be broken down into three fundamental areas: energy consumption, material management, and waste reduction. Each offers unique opportunities for improvement.

Energy-Efficient Machinery and Operations

Modern CNC machines are far more energy-efficient than their predecessors. Upgrading to equipment with features like energy-saving standby modes and variable frequency drives (VFDs) can drastically reduce electricity consumption. Based on our internal analysis, newer machines can cut idle energy use by over 30%. Beyond hardware, optimizing toolpaths is crucial. Advanced CAM software can create shorter, more efficient cutting cycles, reducing machine run-time and, consequently, energy usage per part. A shorter cycle doesn’t just save power; it also increases throughput, making it a win for both sustainability and productivity.

Smart Material Management and Recycling

Waste begins before the first cut is even made. Choosing the right stock size and nesting parts effectively on the material sheet can significantly reduce scrap. For the scrap that is inevitably produced, a robust recycling program is essential. Metal chips, or swarf, from materials like aluminum, steel, and titanium are highly valuable and can be collected, segregated by alloy, and sold back to suppliers. This not only prevents material from ending up in a landfill but also generates a revenue stream that offsets material costs. A comprehensive Life Cycle Assessment6 of a product often reveals that raw material extraction has one of the highest environmental impacts, making recycling a critical step.

| Practice | Traditional Approach | Sustainable Approach | Key Impact |

|---|---|---|---|

| Coolant Use | Petroleum-based flood coolants | Vegetable-based oils or MQL | Reduced toxicity and easier, cheaper disposal. |

| Scrap Metal | Discarded as mixed waste | Segregated by type and recycled | Generates revenue and conserves resources. |

| Energy Use | Machines run at full power idle | Energy-saving modes, VFDs | Lowers electricity bills and carbon footprint. |

| Packaging | Single-use plastic and foam | Reusable bins or recycled cardboard | Reduces packaging waste and material costs. |

The benefits of embracing sustainability in CNC custom machining extend far beyond environmental stewardship. These practices create a powerful business case, driving financial gains, simplifying regulatory adherence, and building a brand that resonates with today’s market. Integrating green initiatives is not an expense but an investment that pays dividends across the entire organization. From the shop floor to the executive board, the positive effects are clear and measurable, creating a competitive advantage that is difficult for others to replicate. In our work with clients from demanding sectors like automotive and medical, a demonstrable commitment to sustainability has become a key factor in building long-term, trusted partnerships.

The Business Case for Sustainable Manufacturing

Implementing eco-friendly practices directly strengthens your bottom line and market position. The return on investment is often much quicker than anticipated.

Unlocking Direct Cost Savings

The most immediate benefit of sustainability is reduced operational costs. Energy-efficient machines and optimized processes lead to lower utility bills. Recycling scrap metal turns waste into revenue. A less obvious but equally important saving comes from coolant management. By switching from traditional petroleum-based coolants to biodegradable alternatives or implementing Minimum Quantity Lubrication (MQL) systems, we’ve seen clients reduce coolant purchase and disposal costs significantly. Hazardous waste disposal is expensive, and minimizing it provides a direct financial advantage.

Navigating Regulatory Compliance with Confidence

Environmental regulations are becoming stricter globally. Adhering to standards like ISO 14001 is no longer optional for companies that want to work with top-tier clients, especially those in the US and Europe. A proactive approach to sustainability ensures you are always compliant, avoiding potential fines and operational disruptions. More importantly, it demonstrates that you are a reliable and forward-thinking partner. For our clients, knowing that our processes meet and exceed environmental standards gives them confidence that their supply chain is secure and responsible.

Building a Stronger, More Resilient Brand

In today’s market, brand reputation is invaluable. A clear commitment to sustainability differentiates you from competitors. It attracts not only eco-conscious customers but also top talent who want to work for responsible companies. This enhanced reputation builds trust and fosters loyalty. When clients are choosing a partner for a critical cnc custom machining project, they are increasingly looking for suppliers whose values align with their own. Sustainability is no longer a niche concern; it’s a core component of a modern, resilient brand identity.

| Benefit Area | Specific Advantage | Example From Our Experience |

|---|---|---|

| Financial | Lower utility and material costs | Up to 20% energy savings from new machinery. |

| Operational | Improved process efficiency | Optimized toolpaths reduce machine run-time and tool wear. |

| Regulatory | Simplified compliance journey | Proactive adherence to ISO 14001 standards. |

| Marketing | Enhanced brand image and trust | Attracting new clients with transparent sustainability reports. |

Ultimately, integrating sustainability into CNC custom machining is a strategic imperative. It moves beyond simple compliance to become a powerful driver of efficiency and value. By focusing on practical steps like investing in energy-efficient machines, implementing robust material recycling programs, and minimizing waste, businesses can achieve significant cost savings. These actions not only enhance brand reputation and ensure regulatory adherence but also build a more resilient, competitive, and forward-thinking operation prepared for the future of manufacturing.

Hybrid Manufacturing: Combining Additive and Subtractive Processes.

Have you ever been forced to choose between the design freedom of 3D printing and the precision of CNC machining? What if you didn’t have to compromise on your complex parts?

Hybrid manufacturing merges additive (3D printing) and subtractive (CNC machining) technologies into a single, seamless workflow. This powerful combination allows for the creation of intricate parts with the high precision and superior surface finish characteristic of traditional machining, dramatically reducing lead times and expanding design possibilities.

Hybrid manufacturing represents a significant leap forward from using additive and subtractive methods in isolation. Instead of 3D printing a part and then moving it to a separate CNC machine for finishing, a hybrid system does it all in one setup. This integration is the key to unlocking its full potential.

The Integrated Workflow Advantage

The process typically involves building up a part layer by layer using an additive process and then using a multi-axis CNC tool to machine critical features before adding more material. This cycle can be repeated multiple times. For example, you could print a complex internal channel, machine its connecting port to a tight tolerance, and then continue printing the rest of the part around it. This is impossible with either technology alone.

Key Benefits of the Hybrid Approach

The fusion of these two processes delivers compelling advantages, especially for complex custom components.

- Unmatched Design Freedom: Engineers can design parts with complex internal geometries, lattices, and curved channels—features that are difficult or impossible to machine traditionally.

- Superior Precision and Finish: While 3D printing creates the near-net shape, the integrated cnc custom machining capability ensures that all critical surfaces, holes, and threads meet exact specifications and have a smooth finish.

- Reduced Production Steps: By eliminating the need for multiple machine setups and part refixturing, hybrid manufacturing simplifies the entire production chain. This consolidation reduces the chance of errors and significantly cuts down on lead time. In projects we’ve explored with clients, this can shorten the prototype-to-test cycle by over 40%.

The table below contrasts hybrid manufacturing with standalone processes.

| Feature | Additive Manufacturing (3D Printing) | Subtractive Manufacturing (CNC) | Hybrid Manufacturing |

|---|---|---|---|

| Geometric Complexity | High (internal features) | Limited (by tool access) | Very High (best of both) |

| Surface Finish | Moderate to Rough | Excellent | Excellent (on critical areas) |

| Lead Time | Fast for single parts | Moderate (setup time) | Very Fast (fewer steps) |

| Material Waste | Low | High | Low |

This approach allows for building features using methods like Directed Energy Deposition7 and then immediately finishing them to spec.

While the benefits are clear, adopting hybrid manufacturing requires a shift in thinking about part design and production logistics. It’s not just about having a new machine; it’s about leveraging a new manufacturing paradigm. At PTSMAKE, we guide our clients through this process to determine if it’s the right fit for their specific application.

When to Choose Hybrid Manufacturing

This advanced technique is not a universal solution for every part. It provides the most value for specific types of components where its unique capabilities can be fully utilized.

Ideal Application Scenarios

- Parts with Inaccessible Features: Components like molds with conformal cooling channels or manifolds with complex internal pathways are prime candidates. The additive process creates the channels, and the subtractive process finishes the outer surfaces and ports with high precision.

- Repair and Addition to Existing Parts: High-value components, such as turbine blades or industrial molds, can be repaired by additively depositing material onto worn areas and then machining it back to the original specifications. This is far more cost-effective than manufacturing a new part from scratch.

- Part Consolidation: Multiple components of a complex assembly can be redesigned and manufactured as a single, consolidated part. This reduces weight, eliminates potential points of failure (like welds or fasteners), and simplifies the supply chain.

Material and Cost Considerations

Hybrid systems work with a variety of materials, primarily metals like stainless steel, titanium, and Inconel. However, the initial investment in hybrid machinery and the expertise required to operate it are significant. Therefore, the process is best suited for high-value, low-to-medium volume production runs where the benefits of complexity and performance outweigh the higher per-part cost compared to traditional cnc custom machining for simpler geometries.

| Project Factor | Low Suitability | High Suitability |

|---|---|---|

| Part Complexity | Simple, solid geometry | Complex internal channels, lattices |

| Production Volume | High-volume runs (>10,000) | Prototypes, low-volume (<1,000) |

| Part Value | Low-cost, disposable parts | High-value, critical components |

| Primary Goal | Lowest possible cost | Highest performance, light-weighting |

Making the right choice depends on a careful analysis of the part’s function, complexity, and budget.

Hybrid manufacturing effectively ends the compromise between design freedom and manufacturability. By integrating additive and subtractive processes, it unlocks the ability to create highly complex parts with the precision and surface quality of CNC machining. This consolidated workflow not only accelerates prototyping and production but also opens the door to innovative designs that were previously impossible to produce, making it a transformative tool for modern engineering challenges, especially in demanding custom applications.

Leveraging Technology to Streamline Your Custom CNC Machining Workflow?

Struggling to manage complex CNC projects with outdated spreadsheets and endless email chains? Are critical details getting lost in translation, putting your timelines and budgets at risk?

The solution is to leverage modern technology, including advanced CAD/CAM software for simulation and DFM analysis, alongside collaborative platforms for real-time project tracking. This approach drastically reduces errors, shortens lead times, and improves overall project transparency.

Technology is no longer just a tool in manufacturing; it’s the central nervous system of any successful cnc custom machining project. Relying on traditional methods for complex projects is like navigating a modern highway with a paper map. You might get there eventually, but it will be slow, inefficient, and fraught with potential wrong turns. The modern approach integrates technology from the very first design file to the final shipped part, creating a seamless and transparent workflow. It’s about working smarter, not just harder, to turn intricate designs into tangible, high-quality components.

The Power of a Digitally-Driven Front End

The most significant gains often happen before we even cut the first chip of metal. The planning and preparation stages are where technology provides the most leverage, helping to avoid costly mistakes down the line. It’s about front-loading the problem-solving process.

Advanced CAD/CAM Software

Modern CAD/CAM software does far more than just translate a 3D model into instructions for a machine. At PTSMAKE, we use it as a primary risk mitigation tool. For instance, integrated Design for Manufacturability (DFM) analysis automatically flags features that could be problematic, such as walls that are too thin, internal radii that are too sharp for our tools, or undercuts that require complex setups. This feedback loop allows for design adjustments early on, saving immense time and cost. The software also optimizes the toolpaths, ensuring the machine runs as efficiently as possible, which directly impacts the final cost and lead time. This optimization process involves converting the design into a highly efficient set of machine instructions, known as G-code8, which dictates every movement of the CNC machine.

Simulation and Virtual Prototyping

Why create a physical prototype when you can create a perfect digital one first? Digital twin simulations allow us to run the entire machining process virtually. We can see exactly how the tool will interact with the material, identify any potential collisions between the tool, holder, and workpiece, and accurately predict the cycle time. This virtual run-through is invaluable for complex geometries and tight-tolerance parts. It validates the manufacturing process without consuming any material or machine time.

| Aspect | Traditional Approach | Technology-Enhanced Approach |

|---|---|---|

| Design Review | Manual check, relies on engineer’s memory | Automated DFM analysis |

| Process Validation | Physical prototype, trial and error | Digital twin simulation |

| Error Discovery | During production (costly) | During pre-production (cheap) |

| Time Estimation | Based on experience, often inaccurate | Calculated precisely via simulation |

By embracing these technologies, we transform the initial phase of a custom CNC project from a source of uncertainty into a predictable, optimized, and de-risked process.

While front-end technology sets the stage for success, the tools we use during and after production are what guarantee a project stays on track and meets every specification. It’s one thing to have a great plan; it’s another to execute it flawlessly while keeping everyone informed. This is where technology bridges the gap between the workshop floor and the client’s office, fostering trust and transparency throughout the entire journey of creating custom CNC parts.

Fostering Transparency and Quality Through Collaboration Tools

Effective communication is the backbone of any custom manufacturing project. When a client is thousands of miles away, they need confidence that their project is progressing as planned. Technology makes this level of transparency not just possible, but standard practice.

Real-Time Project Management

Endless email threads are a recipe for confusion. Important files get buried, feedback is missed, and version control becomes a nightmare. We’ve moved past that by using centralized project management platforms. These systems provide our clients with a single source of truth. They can log in anytime to see the current status of their project, view photos of the parts in progress, access inspection reports, and communicate directly with our engineering team. A client working on a tight deadline for a new robotics device told us this real-time visibility saved his team hours of weekly follow-up meetings and gave them the confidence to focus on their own assembly tasks.

Data-Driven Quality Assurance

Quality control in modern cnc custom machining services is driven by data, not just a visual check. We utilize advanced inspection equipment like Coordinate Measuring Machines (CMMs) that can measure parts with incredible accuracy. These tools generate detailed, shareable reports that prove every dimension meets the specified tolerance. This isn’t just about catching errors; it’s about validating quality with objective data. Furthermore, technology enables complete traceability. We can track a part from its raw material certificate all the way to its final inspection report, with every step documented digitally. For industries like medical and aerospace, this level of documentation isn’t a luxury—it’s a requirement.

| Technology | Core Function | Client Benefit |

|---|---|---|

| Client Portal | Centralized project status & communication | Full transparency and reduced follow-up |

| Automated CMM | High-precision dimensional inspection | Verifiable proof of quality and compliance |

| Digital Reporting | Instant access to inspection data | Faster approvals and decision-making |

| ERP System | Material and process traceability | Guaranteed material integrity and process control |

By integrating these tools, we don’t just make parts; we build trust. We provide the peace of mind that comes from knowing your project is in capable hands and that you have full visibility every step of the way.

Successfully navigating the complexities of custom CNC machining projects requires moving beyond traditional methods. Instead of reacting to problems, leveraging technology allows for proactive risk mitigation. By integrating advanced CAD/CAM software for pre-production simulation and adopting collaborative platforms for real-time project management and data-driven quality control, you can ensure transparency, efficiency, and precision. This tech-forward approach transforms potential challenges into a streamlined process, delivering high-quality parts on time and building a foundation of trust between client and manufacturer.

How to Select the Right CNC Custom Machining Partner?

Have you ever faced production delays because your machined parts arrived out of spec? Or struggled with a supplier who just doesn’t grasp the critical details of your design?

Selecting the right CNC custom machining partner involves a thorough evaluation of their technical capabilities, quality certifications, material expertise, and communication practices. A true partner invests in understanding your project to ensure success from prototype to production, not just cutting metal.

Choosing a partner for your cnc custom machining needs goes far beyond just comparing quotes. It’s about finding a team that becomes an extension of your own. In my experience, the most successful projects stem from partnerships built on technical alignment and trust. You need to dig into the details of their operations to see if they truly have what it takes.

Assessing Technical Capabilities and Equipment

The first thing to look at is their machine fleet. A shop’s equipment directly dictates its capabilities. Does your project require the complex geometries that a 5-axis mill can produce, or will a standard 3-axis machine suffice? Don’t just take their word for it; ask for a detailed equipment list. At PTSMAKE, we believe transparency is key, so we’re always open about the specific machines we use for a project. This ensures we match the right technology to the required part complexity and tolerance.

| Machine Type | Primary Use Case | Key Advantage |

|---|---|---|

| 3-Axis CNC Mill | Prismatic parts, drilling, simple contours | Cost-effective for less complex geometries |

| 5-Axis CNC Mill | Complex curves, single-setup machining | Reduces setups, improves accuracy, enables intricate designs |

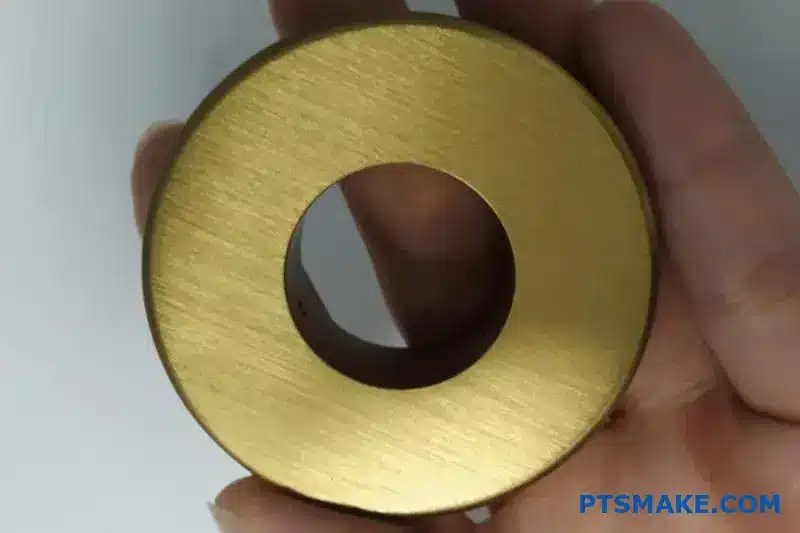

| CNC Lathe/Turning | Cylindrical parts, shafts, rings | High-speed production of rotational parts |

| Swiss-Type Lathe | Small, complex, long cylindrical parts | Exceptional precision for high-volume, small-diameter parts |

Quality Assurance and Certifications

A potential partner’s commitment to quality is non-negotiable. Ask about their quality management system (QMS). Are they certified to standards like ISO 9001? For industries like aerospace or medical, you might need even more stringent certifications such as AS9100 or ISO 13485. These aren’t just pieces of paper; they represent a deep-seated commitment to process control, documentation, and continuous improvement. A robust QMS includes rigorous in-process inspections and final quality checks using advanced Metrology9 tools like CMMs (Coordinate Measuring Machines) and optical scanners. A partner who can provide detailed inspection reports with every shipment gives you the confidence that your parts will meet every specification.

Beyond the hardware and certifications, the human element of a partnership is what often determines the success or failure of a critical project. How a company communicates, manages projects, and approaches problem-solving reveals its true value as a long-term partner. A low price is quickly forgotten when you’re dealing with poor communication and missed deadlines.

Communication and Customer Support

From the very first interaction, pay close attention to a supplier’s communication style. How quickly and thoroughly do they respond to your RFQ? A dedicated point of contact, usually an experienced project manager or engineer, is a great sign. This person should be able to answer technical questions and provide regular updates without you having to chase them down. In past projects with clients, we’ve found that establishing a clear communication cadence from the start prevents misunderstandings and keeps the project on track. Can they provide Design for Manufacturability (DFM) feedback? A proactive partner will analyze your design and suggest minor tweaks that could reduce machining time, lower costs, or improve the part’s final performance. This collaborative approach is a hallmark of a premier cnc custom machining service.

Evaluating Turnaround Times and Project Management

Realistic and reliable lead times are crucial. Ask a potential partner about their typical turnaround time for projects of similar complexity and volume. Be wary of promises that seem too good to be true. A trustworthy shop will provide a detailed project timeline, including milestones for material procurement, programming, machining, and quality inspection. Also, inquire about their capacity. Can they handle your project without compromising their commitments to other customers?

| Evaluation Point | What to Look For | Red Flag |

|---|---|---|

| Responsiveness | Quick, clear answers to RFQs and emails (within 24 hours) | Vague responses or days of silence |

| Technical Feedback | Proactive DFM suggestions to improve your part | Simply provides a quote with no design input |

| Project Updates | Regular, scheduled updates on project status | You have to constantly ask for information |

| Problem Solving | Informs you of issues immediately with proposed solutions | Hides problems until it’s too late to fix them |

Ultimately, a partner should be scalable. They should have the processes and infrastructure to support you from a single prototype to full-scale production runs. This scalability saves you the immense effort of re-qualifying a new supplier when your demand grows.

Choosing the right CNC custom machining partner is a critical decision that impacts your project’s timeline, budget, and quality. It requires looking beyond the quote to assess technical capabilities, quality systems, and material expertise. Equally important are the "soft skills": clear communication, proactive problem-solving, and a genuine commitment to a long-term relationship. By conducting a thorough evaluation of these hard and soft criteria, you can find a supplier who operates as a true extension of your team.

Supercharge CNC Custom Machining Success with PTSMAKE Today

Ready to unlock next-generation precision and reliability for your CNC custom machining projects? Partner with PTSMAKE—your trusted industry leader since 2002—for rapid quotes, expert support, and exceptional quality from prototype to production. Send your inquiry now and experience worry-free manufacturing excellence!

Learn how GD&T ensures your part functions exactly as designed. ↩

Understand how AI algorithms can create optimal, high-performance designs based on a set of constraints. ↩

Click to understand how this material property affects tool life and machining strategies in custom CNC projects. ↩

Learn about this symbolic language used on engineering drawings to define and communicate tolerances. ↩

Understand how this dense data set forms the foundation of modern 3D inspection and reverse engineering. ↩

Learn how this analysis evaluates a product’s full environmental impact, from raw material to disposal. ↩

Learn more about this core additive method that enables building and repairing parts in hybrid systems. ↩

Discover how this foundational machine language is optimized to create your high-precision parts with maximum efficiency. ↩

Discover how the science of measurement ensures your parts achieve flawless precision and reliability. ↩