Finding the right manufacturing partner for brass CNC machining can feel overwhelming when you’re juggling tight deadlines, complex specifications, and budget constraints. You’ve probably experienced the frustration of dealing with suppliers who promise precision but deliver inconsistent quality, or worse, miss critical delivery dates that put your entire project timeline at risk.

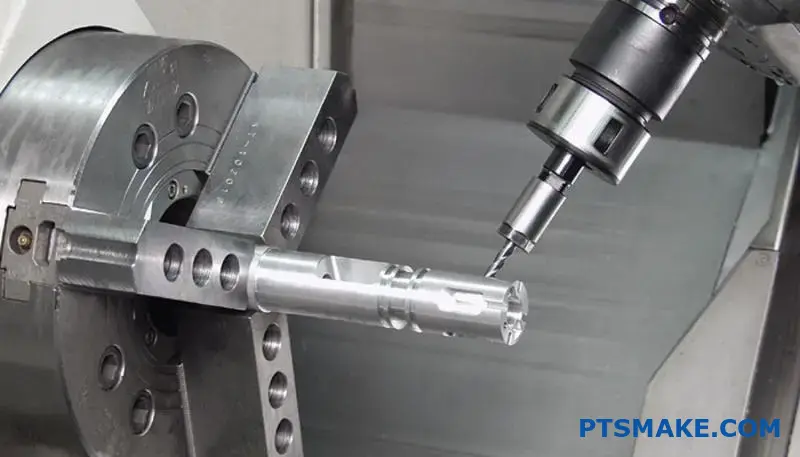

Brass CNC machining combines precision manufacturing techniques with versatile brass alloys to create high-quality components for electronics, automotive, plumbing, and industrial applications. Success depends on proper alloy selection, design optimization, and choosing experienced manufacturing partners.

The brass machining landscape has evolved significantly in recent years, with new alloy formulations and advanced CNC technologies opening up possibilities that weren’t available just a few years ago. Whether you’re developing prototypes for a new product line or scaling up to high-volume production, understanding the latest innovations in brass machining can make the difference between a project that exceeds expectations and one that struggles to meet basic requirements.

Innovative Applications of Brass CNC Machining Across Industries.

Ever struggled to find a material that’s strong, conductive, corrosion-resistant, and looks great? This balancing act often leads to design compromises, forcing you to sacrifice one key property for another.

Brass CNC machining is a versatile manufacturing process used to create precise components for industries like electronics, automotive, plumbing, and even musical instruments. Its widespread use is due to brass’s unique combination of excellent machinability, corrosion resistance, electrical conductivity, and aesthetic appeal.

When clients approach us at PTSMAKE for a new project, material selection is one of the first and most critical conversations. Brass is frequently on the shortlist, and for good reason. Its versatility is remarkable. The magic of brass cnc machining lies in its ability to transform this alloy into incredibly precise parts that serve vastly different functions. Let’s break down how some key industries leverage these properties.

The Backbone of Modern Electronics

In the electronics sector, performance is non-negotiable. Components must be reliable, conductive, and durable. Brass is a go-to material for connectors, terminals, and sockets. Why? Its excellent electrical conductivity ensures a stable signal and power transmission, which is critical for everything from consumer gadgets to industrial control systems. But it’s not just about conductivity. These parts are often small and complex. The free-machining nature of alloys like C360 Brass allows us to achieve tight tolerances and intricate geometries efficiently, keeping production costs in check without sacrificing quality. The material’s inherent corrosion resistance also means these critical connections won’t degrade over time, even in less-than-ideal environments.

Reliability in Automotive and Plumbing

The automotive and plumbing industries share a common need: components that can withstand constant exposure to fluids, temperature fluctuations, and pressure. This is where brass truly shines. In automotive systems, you’ll find machined brass components in fittings, valve bodies, and sensor housings. They resist corrosion from fuel, oil, and coolant, ensuring the longevity of the vehicle’s systems.

Similarly, in plumbing, brass has been a standard for decades. Valves, fittings, and taps made from brass resist rust and mineral buildup from water. In past projects, we’ve carefully selected brass alloys that are resistant to dezincification1, a form of corrosion that can weaken the material over time, ensuring the final parts are safe and durable for long-term use.

| Industry | Common Brass Components | Key Property Leveraged |

|---|---|---|

| Electronics | Connectors, Terminals, Pins | Electrical Conductivity, Machinability |

| Automotive | Sensor Housings, Hose Fittings | Corrosion Resistance, Durability |

| Plumbing | Valves, Faucets, Pipe Fittings | Corrosion Resistance, Anti-Bacterial |

| Industrial | Gears, Bearings, Bushings | Low Friction, Wear Resistance |

This table provides a snapshot, but the applications are far broader. The low-friction quality of brass also makes it ideal for industrial machinery parts like gears and bearings, reducing wear and extending the operational life of the equipment.

Beyond the purely functional, brass holds a special place in industries where aesthetics and sensory experience are paramount. The visual and even acoustic properties of brass open up a whole new range of innovative applications that go far beyond industrial fittings. It’s this blend of beauty and brawn that makes it such a fascinating material to work with.

The Intersection of Art and Precision

Think about the warm, resonant sound of a trumpet or a saxophone. That quality is no accident. The acoustic properties of brass are why it’s the material of choice for many musical instruments. Through precise brass cnc machining, we can create mouthpieces, valve casings, and keys with exact dimensions that influence the instrument’s tone, pitch, and playability. The process allows for the creation of complex internal passages and surfaces that are smooth and free of imperfections, which is essential for proper airflow and sound production. The material’s ability to be polished to a brilliant, gold-like finish adds that final touch of classic beauty.

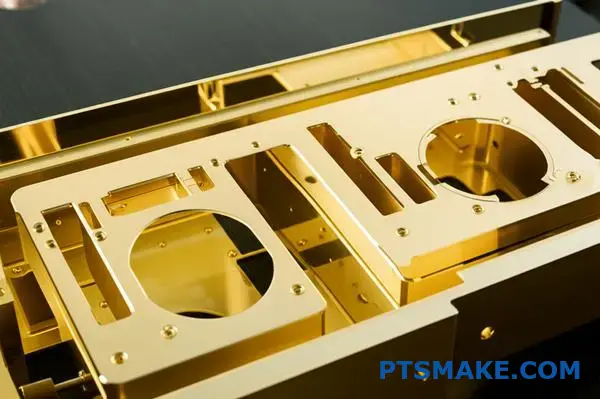

Luxury Goods and Decorative Hardware

The aesthetic appeal of brass extends into the world of luxury goods, particularly in watchmaking and high-end jewelry. The gears and plates inside a mechanical watch are often machined from brass. Its stability and machinability allow for the creation of minuscule, high-precision components that are the heart of the timepiece. Furthermore, its natural golden hue provides a beautiful contrast to steel and other materials, and it can be plated with gold or rhodium for different finishes.

This same appeal makes brass a favorite for decorative hardware.

From Design to Final Product

When a client comes to us with a design for a luxury consumer product, such as a high-end razor handle or a custom cabinet knob, brass is often the top contender. Here’s a quick look at why it’s so suitable:

| Feature | Advantage for Luxury Goods | Example |

|---|---|---|

| Aesthetic | Warm, golden color that ages beautifully. | Watch cases, designer pens |

| Weight | Has a satisfying heft, conveying quality. | Custom knobs, high-end faucets |

| Finish | Can be polished, brushed, or plated. | Decorative light fixtures, jewelry |

| Feel | Smooth and solid to the touch. | Premium product casings |

Its ability to be machined into elegant, intricate shapes and then finished to perfection makes it a designer’s dream. The patina it develops over time can also be a desired characteristic, adding a sense of character and history to the object.

From the critical electrical connectors in your phone to the precise gears in a luxury watch, brass is a surprisingly versatile workhorse. Its unique blend of properties—conductivity, corrosion resistance, machinability, and aesthetic appeal—makes it an indispensable material. Through precise CNC machining, we can shape brass to meet the demanding specifications of countless industries, proving that a material known for centuries can still be at the forefront of modern innovation and design.

Selecting the Right Brass Alloy for CNC Machined Parts.

Have you ever specified a brass alloy only to see it fail in the field due to unexpected corrosion or cracking? Making the wrong choice can compromise your entire design and budget.

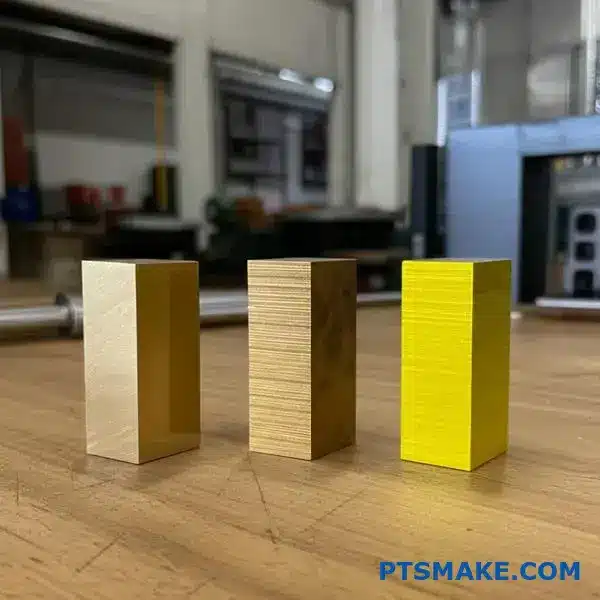

Selecting the right brass alloy means matching its properties—like machinability, durability, and corrosion resistance—to your part’s specific application. The key is understanding how the copper, zinc, and lead content affects performance, which directly impacts the final cost and reliability of your CNC machined parts.

Understanding the Core Components: Copper, Zinc, and Lead

The properties of any brass alloy come down to its chemical composition. The ratio of copper to zinc is the primary driver, but other elements, especially lead, play critical roles.

Copper is the base metal. A higher copper content generally improves corrosion resistance, electrical conductivity, and ductility. This makes the alloy easier to form or bend without fracturing.

Zinc is added to copper to create brass. Increasing the zinc content increases the material’s strength and hardness but can reduce its corrosion resistance. A common issue in high-zinc brasses exposed to corrosive environments is Dezincification2, where zinc is selectively leached from the alloy, leaving behind a porous, weakened copper structure.

Lead is the secret ingredient for excellent machinability. It doesn’t dissolve into the brass matrix. Instead, it exists as small, soft particles that act as a lubricant and chip breaker during cutting. This is why "free-cutting" or "free-machining" brass alloys are so popular for brass cnc machining.

The Machinability Index: A Critical Metric

To standardize how easily a material can be machined, the industry uses a machinability rating. This index is based on a percentage, with C360 Free-Cutting Brass serving as the benchmark at 100%. An alloy with a rating of 70% is 70% as easy to machine as C360. A higher rating means faster cutting speeds, longer tool life, and a better surface finish, which often translates to a lower cost per part.

Here’s a quick comparison of some common brass alloys we work with at PTSMAKE:

| Alloy (UNS No.) | Common Name | Composition (Approx. %) | Machinability Rating |

|---|---|---|---|

| C26000 | Cartridge Brass | 70% Cu, 30% Zn | 30% |

| C36000 | Free-Cutting Brass | 61.5% Cu, 35.5% Zn, 3% Pb | 100% |

| C38500 | Architectural Bronze | 57% Cu, 40% Zn, 3% Pb | 90% |

| C46400 | Naval Brass | 60% Cu, 39.2% Zn, 0.8% Sn | 30% |

Balancing Strength and Formability

There is always a trade-off between an alloy’s strength and its formability (or ductility).

- Alpha Brasses (e.g., C260): These have a higher copper content (over 65%) and a single-phase crystal structure. They are highly ductile and excellent for cold working processes like deep drawing, spinning, and bending. However, their strength is lower.

- Alpha-Beta Brasses (e.g., C360, C385): With more zinc, these alloys have a two-phase structure that makes them stronger and harder but less ductile. They are ideal for machining but not for extensive cold forming.

For a component like an ammunition casing, which is formed through deep drawing, C260 Cartridge Brass is the perfect choice. For a threaded plumbing fitting that requires extensive machining and moderate strength, C360 is the industry standard.

A Practical Comparison of Common Brass Alloys

Choosing the right alloy often comes down to the specific demands of the application. In our projects at PTSMAKE, we frequently guide clients through this decision by focusing on the primary function of the part.

For High-Speed Machining: C360 Free-Cutting Brass

This is the workhorse of the brass cnc machining world for a reason. Its 3% lead content gives it an unmatched machinability rating of 100%. Chips break away cleanly, allowing for high cutting speeds, minimal tool wear, and excellent surface finishes right off the machine. This makes it extremely cost-effective for high-volume production of parts like fasteners, valve components, fittings, and hardware. If your part requires complex geometries and tight tolerances created through machining, C360 is almost always the starting point.

For Strength and Corrosion Resistance: C464 Naval Brass

When a part is destined for a marine or highly corrosive environment, C464 is a superior choice. It contains about 1% tin, which significantly inhibits dezincification in saltwater. While its machinability rating is only 30%, its enhanced durability and corrosion resistance are non-negotiable for applications like marine hardware, propeller shafts, and valve stems exposed to seawater. The trade-off in slower machining speeds is justified by the part’s longevity.

For Excellent Cold Working: C260 Cartridge Brass

C260, also known as 70/30 brass, has the best ductility among common brasses. It is not a good candidate for machining due to its gummy nature and low machinability rating (30%). Instead, its strength is in its ability to be bent, formed, and drawn into complex shapes without cracking. We see it used for decorative items, lamp fixtures, and, famously, ammunition casings, where the material must be formed into a precise shape while remaining durable.

Cost-Effectiveness: More Than Just Material Price

A common mistake is selecting an alloy based solely on its price per pound. True cost-effectiveness is a combination of material cost, machining time, and lifecycle performance. C360 might have a slightly higher material cost than some other brasses, but its incredible machinability can reduce cycle times by over 50% compared to an alloy like C464. This reduction in machine time and tool wear often makes the final part cheaper. Conversely, using a less expensive but corrosion-prone alloy in a critical application could lead to premature failure and costly replacements, making a more robust alloy like C464 the more economical choice in the long run.

Selecting the right brass alloy is a critical step that balances performance and cost. The key is to match the alloy’s properties—driven by its copper, zinc, and lead content—to the part’s end-use. C360 excels in high-speed machining, C464 provides superior corrosion resistance for marine applications, and C260 is ideal for parts requiring extensive forming. Considering machinability and lifecycle needs, not just material price, ensures the most reliable and cost-effective outcome for your brass cnc machining project.

Design Optimization for Brass CNC Machined Components.

Have you ever designed a brass component that looked perfect in CAD but caused major headaches and cost overruns during production? It’s a frustratingly common scenario.

Optimizing your brass component design is about balancing performance requirements with manufacturability. By simplifying geometry, specifying practical tolerances and surface finishes, and collaborating early with your manufacturing partner, you can significantly reduce costs, minimize waste, and improve the final part’s functionality.

Great designs for brass CNC machining don’t just happen; they are a result of intentional choices that consider the manufacturing process from the very beginning. It’s a dialogue between the designer’s vision and the realities of the machine shop floor. The goal is to create a part that is not only functional but also efficient to produce. This efficiency translates directly into lower costs and faster lead times.

Balancing Tolerances and Costs

One of the most common issues we see at PTSMAKE is over-tolerancing. Engineers often apply tight tolerances across an entire part, even on non-critical features. While precision is essential, unnecessary tightness dramatically increases machining time and cost. Each tightened tolerance can require more precise tooling, slower cutting speeds, and additional inspection steps. The key is to apply tight tolerances only where they are functionally necessary. For non-mating surfaces or non-critical features, using standard tolerances can reduce costs by up to 25-30% based on our past project data. Always ask yourself: "Does this feature truly need to be this precise?" The answer will often simplify your design and your budget.

Surface Finish: Function vs. Aesthetics

Surface finish is another area where design intent can heavily influence cost. A mirror-like finish looks impressive, but it requires multiple fine machining passes, and sometimes secondary processes like polishing or lapping. For a brass component that will be internal and unseen, a standard machined finish (like 125 Ra µin) is often perfectly adequate. However, for a part where tribological3 properties are critical, such as a bearing or a sealing surface, a specific, smoother finish is non-negotiable. The design should clearly specify different surface finishes for different areas of the part based on their function.

| Feature Type | Recommended Tolerance | Typical Surface Finish (Ra µin) | Impact on Cost |

|---|---|---|---|

| Mating Surfaces | ±0.001" (±0.025 mm) | 32 – 63 | High |

| Clearance Holes | ±0.005" (±0.127 mm) | 125 | Low |

| External, Non-Functional | ±0.010" (±0.254 mm) | 125 – 250 | Low |

| Sealing Surfaces | ±0.002" (±0.050 mm) | 16 – 32 | Very High |

Simplifying Part Geometry

Complex geometry can be challenging, even with advanced 5-axis machines. Here are a few geometry tips for brass CNC machining:

- Internal Corners: Avoid sharp internal corners. Standard cutting tools have a radius, so designing with an internal radius slightly larger than the tool’s radius prevents the need for slower, more expensive processes like EDM.

- Thin Walls: Brass is a relatively soft metal. Excessively thin walls can vibrate or distort during machining, leading to inaccuracies. As a general rule, try to keep wall thickness above 0.030 inches (0.75 mm).

- Deep Pockets: The deeper the pocket, the longer the tool needs to be. Longer tools are less rigid, which can lead to chatter and a poor surface finish. A good rule of thumb is to keep pocket depth to less than six times the tool’s diameter.

Beyond the fundamental principles of geometry and tolerances, effective design optimization involves thinking about the part’s entire lifecycle and its interaction with the manufacturing process. This is where early collaboration with your manufacturing partner becomes invaluable. A machinist can offer insights that are not always obvious from a CAD model alone.

Integrating Functional Features Smartly

Designing functional features with manufacturability in mind is crucial.

- Threads: When designing threads, specify standard sizes whenever possible. Custom threads require special tooling, which adds cost and lead time. Also, provide a relief groove at the end of the thread run. This gives the tool a place to exit, preventing tool breakage and ensuring a clean thread. For internal threads, ensure the hole is drilled to the correct pre-drill diameter and deep enough to accommodate the full thread length plus a small margin.

- Undercuts: Undercuts are possible but require special "lollipop" or "T-slot" cutters. If an undercut is necessary, design it with enough clearance for the tool to enter and exit. In some past projects, we’ve collaborated with clients to redesign a part as two simpler components that are later assembled, completely eliminating a complex and costly undercut.

Material-Specific Design for Brass

Brass is known for its excellent machinability, which allows for high cutting speeds and feeds. Your design can take advantage of this. Because it produces small, manageable chips, features like deep holes and small pockets are easier to machine in brass than in gummy materials like aluminum or stainless steel. However, its high thermal conductivity means heat can build up quickly. Designs that allow for good coolant flow are beneficial. Avoid deep, narrow slots where chips and heat can become trapped.

| Design Consideration | Standard Approach | Optimized for Brass CNC Machining | Benefit |

|---|---|---|---|

| Feature Integration | Multiple separate parts | Combine features into a single part | Reduced assembly time, improved strength |

| Tool Access | Complex internal features | Design for clear tool paths | Faster machining, better finish |

| Deburring | Assume manual deburring | Add small chamfers on all edges | Lower post-processing costs |

| Workholding | No specific features | Add temporary tabs or flat surfaces | More secure setup, higher accuracy |

The Power of Early Collaboration

The single most effective tip I can offer is to involve your machining partner early in the design process. Before you finalize your drawings, send them a preliminary model. At PTSMAKE, we often provide Design for Manufacturability (DFM) feedback that identifies potential issues and suggests minor modifications. A 10-minute conversation can often save days of machining time and a significant portion of the budget. This collaborative approach ensures that the final design is not just a theoretical success, but a practical and cost-effective one.

Optimizing a design for brass CNC machining is a strategic process that pays significant dividends. It’s not about compromising your part’s performance but enhancing its manufacturability. By focusing on practical tolerances, functional surface finishes, and simplified geometry, you can create components that meet all technical requirements efficiently. Remember, early collaboration with your manufacturing partner is key to unlocking cost savings and ensuring your design is a success from the CAD screen to the finished part.

Sustainable Practices in Brass CNC Machining?

Have you ever considered the environmental footprint behind your precision brass parts? It’s easy to focus on the final product, but what about the waste and energy consumed to create it?

Sustainable brass CNC machining minimizes environmental impact by focusing on key strategies. This includes recycling nearly 100% of brass scrap, utilizing energy-efficient equipment, and applying lean manufacturing principles to drastically reduce material waste and energy consumption.

Understanding the Environmental Footprint

To truly improve, we first need to understand the impact. The process of transforming a raw brass block into a finished component has several environmental touchpoints. It’s not just about the shiny part at the end; it’s about the entire journey. In past projects at PTSMAKE, we’ve broken this down to identify where we can make the most significant improvements for our clients and the planet.

Material Waste: More Than Just Scraps

When you machine brass, you create chips and swarf. This leftover material can sometimes account for a significant portion of the original workpiece. If not managed properly, this becomes pure waste. Beyond the obvious material loss, there’s also the energy and resources used to extract and process the virgin material in the first place. Every gram of brass we save from the landfill is a win. A comprehensive Life Cycle Assessment4 would reveal the full impact of this waste, from mining to disposal.

Energy Consumption: The Power-Hungry Process

CNC machines are powerful tools, and they require a lot of electricity to run. The spindle, servos, coolant pumps, and control units all draw energy. Older machines can be particularly inefficient, consuming power even when idle. The energy footprint also includes the factory’s lighting, HVAC systems, and air compressors. Reducing this consumption isn’t just good for the environment; it directly lowers operational costs.

Coolants and Emissions

Cutting fluids, or coolants, are essential for brass cnc machining. They reduce heat, lubricate the cutting tool, and flush away chips. However, traditional petroleum-based coolants can be difficult to dispose of safely and can create airborne mists. Proper management, filtration, and a shift towards more environmentally friendly, bio-based alternatives are crucial for sustainable operations.

A simple comparison shows the path forward:

| Aspect | Traditional Approach | Sustainable Approach |

|---|---|---|

| Material Waste | Scrap is a byproduct | Scrap is a resource to be fully recycled |

| Energy Use | Machines run continuously | Energy-efficient machines with idle-stop functions |

| Coolant | Dispose-and-replace mindset | Filtration, recycling, and use of bio-based fluids |

| Process | Focus solely on part output | Focus on overall process efficiency |

Actionable Strategies for Green Brass Machining

Understanding the impact is the first step; taking action is what creates change. Sustainability isn’t just a buzzword; it’s a practical set of principles that lead to a more efficient, responsible, and often more profitable manufacturing process. We’ve found that implementing these strategies not only reduces our environmental footprint but also delivers better value.

The Power of Recycling: Towards Zero-Scrap

Brass has a unique advantage: it is almost infinitely recyclable without any degradation in quality. This property is the cornerstone of sustainable brass cnc machining. A zero-scrap operation is a realistic goal. At our facility, we implement a closed-loop system. All brass chips, swarf, and rejected parts are meticulously collected, segregated, and sent to certified recyclers. This material is then melted down and re-formed into new brass stock, ready for machining. This process uses significantly less energy—up to 80-90% less—than producing brass from raw copper and zinc ore.

Investing in Energy-Efficient Technology

Modern CNC machines are engineered with energy efficiency in mind. Features that were once rare are now becoming standard. These include:

- Intelligent Standby: Machines automatically power down non-essential components after a period of inactivity.

- High-Efficiency Motors: Spindle and servo motors are designed to provide maximum power with minimum energy draw.

- Regenerative Braking: Some advanced systems capture energy during deceleration and feed it back into the power grid, similar to a hybrid car.

Upgrading to this technology represents an initial investment, but the long-term savings on energy bills are substantial.

Lean Manufacturing Principles in Action

Lean manufacturing is fundamentally about eliminating waste in all its forms—not just material. Applying these principles to a machining environment yields impressive results.

| Lean Principle | Application in Brass CNC Machining | Environmental Benefit |

|---|---|---|

| 5S (Sort, Set in Order, Shine, Standardize, Sustain) | An organized workspace prevents errors and reduces the need for rework. | Fewer rejected parts mean less wasted material and energy. |

| Just-In-Time (JIT) | Materials are ordered and parts are produced only as needed. | Minimizes energy for warehousing and reduces risk of material obsolescence. |

| Kaizen (Continuous Improvement) | We regularly analyze and optimize toolpaths for shorter cycle times. | Less machine run-time directly translates to lower energy consumption per part. |

By constantly refining our processes, we not only improve efficiency but also systematically reduce our environmental impact.

Embracing sustainable practices in brass CNC machining is not just an ethical choice; it’s a smart business strategy. By understanding the environmental impacts of waste, energy, and emissions, we can implement effective solutions. Key actions include establishing a robust recycling program to aim for zero scrap, investing in energy-efficient machinery, and adopting lean principles. These steps reduce our ecological footprint, lower operational costs, and build a more resilient and responsible manufacturing operation for the future.

Waste Management and Environmental Compliance in CNC Machining.

Ever wondered if your workshop’s waste disposal methods are truly compliant, or just a ticking time bomb of potential fines and environmental damage? The complexity of regulations can be overwhelming.

Effective waste management in CNC machining involves segregating waste streams like brass chips and coolants, adhering to regulations like the EPA’s Resource Conservation and Recovery Act (RCRA), and using certified disposal services to prevent pollution and ensure full environmental compliance.

Properly managing waste is not just about being "green"; it’s a legal and ethical necessity. Failing to comply with environmental regulations can lead to severe financial penalties, operational shutdowns, and damage to a company’s reputation. The core of compliance lies in understanding exactly what you’re dealing with and the specific rules that govern its disposal.

Understanding Key Waste Streams

In any shop focused on brass cnc machining, you’ll encounter three primary waste categories, each with its own set of challenges and regulatory requirements.

- Metal Shavings and Swarf: Brass chips are the most obvious byproduct. While brass itself is highly recyclable, it can be contaminated with cutting fluids and oils. This contamination dictates how it must be handled and processed.

- Used Coolants and Lubricants: These fluids degrade over time, accumulating metal fines, tramp oils, and bacteria. Disposing of them improperly, such as pouring them down a drain, is illegal and environmentally catastrophic.

- Oily Rags and Absorbents: Materials used to clean machines and parts become saturated with oils and solvents, classifying them as hazardous waste in many jurisdictions.

The Regulatory Landscape

Navigating environmental laws can feel like a full-time job. In the U.S., the Environmental Protection Agency (EPA) sets the primary standards under the Resource Conservation and Recovery Act (RCRA). However, state and local regulations can be even more stringent. Ignorance of a local ordinance is not a valid defense. The key is documentation. Every drop of waste oil and every pound of contaminated swarf must be accounted for from its creation (cradle) to its final disposal (grave). Failure to maintain this paper trail is a common, and costly, mistake. Improper disposal can lead to soil and groundwater contamination, where harmful chemicals form a toxic Leachate5 that poisons the surrounding ecosystem for decades.

| Waste Stream | Primary Contaminants | Common Regulatory Guideline |

|---|---|---|

| Brass Shavings | Cutting Oils, Lubricants | Must be free of excess fluid before recycling |

| Used Coolants | Tramp Oils, Metal Fines, Bacteria | Prohibited from sewer disposal; requires treatment |

| Contaminated Rags | Solvents, Oils | Must be stored in sealed, labeled containers |

| Hydraulic/Lubricating Oils | Heavy Metals, Additives | Classified as hazardous waste; requires licensed hauler |

Beyond simple compliance, adopting proactive and innovative waste management strategies can create significant value. It reduces long-term liability, improves operational efficiency, and enhances brand image. Modern solutions focus not just on disposal but on reduction and reuse, turning waste streams into potential revenue streams. In our work with clients at PTSMAKE, we’ve found that a forward-thinking approach to waste often uncovers hidden inefficiencies in the entire production process.

Innovative Recycling and Disposal Solutions

The goal is to move beyond the simple "out of sight, out of mind" disposal mentality. Technology offers better ways to handle waste that are both environmentally and economically superior.

For Brass Shavings:

Instead of selling loose, wet chips to a scrap dealer at a low price, consider investing in a chip spinner or briquetting press. A chip spinner uses centrifugal force to reclaim a high percentage of cutting fluid from the chips. A briquetting press compacts the dry chips into dense pucks. In our experience, scrap dealers pay a premium for these briquettes because they are easier to transport and melt, and the reclaimed coolant can be filtered and reused, cutting new fluid purchase costs significantly.

For Coolants and Lubricants:

Coolant recycling systems have become increasingly accessible. Technologies like tramp oil skimmers, centrifuges, and coalescers can extend the life of your cutting fluids dramatically. By continuously removing contaminants, you maintain the coolant’s performance, reduce the frequency of full machine cleanouts, and minimize the volume of waste fluid requiring expensive disposal. Some shops we’ve worked with have cut their coolant waste volume by over 70% with these systems.

Choosing Eco-Friendly Alternatives

The best way to manage waste is to not create it in the first place. The market for green-friendly machining fluids has matured, offering high-performance options that are less harmful to the environment and your employees.

| Fluid Type | Performance Characteristics | Environmental Impact |

|---|---|---|

| Petroleum-Based | High lubricity, stable | High; non-renewable, disposal is hazardous |

| Semi-Synthetic | Good balance of cooling & lubrication | Moderate; contains petroleum |

| Full-Synthetic | Excellent cooling, long life | Low; biodegradable options available |

| Vegetable-Based (Ester) | Excellent lubricity, biodegradable | Very Low; renewable, high operator safety |

Switching to a biodegradable, vegetable-based cutting fluid, for example, can simplify disposal and reduce the health risks associated with oil mists in the workshop. While the initial purchase price might be slightly higher, the total cost of ownership is often lower when you factor in reduced disposal fees and a safer work environment.

Navigating waste management in CNC machining requires understanding both the legal obligations and the practical solutions available. By correctly identifying waste streams, adhering to regulations like the RCRA, and tracking disposal, you avoid fines and environmental harm. Furthermore, embracing innovative technologies for recycling brass chips and coolants, alongside choosing eco-friendly fluid alternatives, not only ensures compliance but also enhances operational efficiency and profitability. It’s a strategic move towards a more sustainable and responsible manufacturing process.

Quality Assurance and Inspection Techniques for Brass CNC Parts?

Ever worried that a single, out-of-spec brass component could derail your entire project schedule? How do you ensure every part is a perfect match for your design, every single time?

Modern inspection techniques like Coordinate Measuring Machines (CMMs) and optical scanners, combined with rigorous traceability and documentation, are fundamental to guaranteeing the dimensional accuracy, surface integrity, and overall quality of brass CNC machined parts, ensuring they meet the strictest industry standards.

Modern Inspection Methods for Uncompromising Precision

Achieving tight tolerances on brass parts requires more than just skilled machining; it demands verification using advanced metrology equipment. Traditional tools like calipers and micrometers have their place, but for complex geometries and high-precision requirements, they are simply not enough. Modern inspection technology removes guesswork and provides objective, repeatable data. At PTSMAKE, we integrate these tools directly into our quality workflow to validate every critical feature of the parts we produce.

Coordinate Measuring Machine (CMM)

The CMM is the cornerstone of modern quality assurance in precision manufacturing. It uses a highly sensitive probe to touch various points on a part’s surface, creating a 3D map of its geometry. This data is then compared directly against the original CAD model. For complex brass CNC machining projects with intricate features and tight Geometric Dimensioning and Tolerancing (GD&T) callouts, a CMM is non-negotiable. It can accurately measure features that are impossible to check with hand tools, such as true position, flatness, and profile tolerances. In our experience with clients in the automotive and aerospace sectors, CMM reports are often a required deliverable, providing undeniable proof of compliance.

Optical and Non-Contact Measurement

For certain applications, especially high-volume production runs or parts with delicate surfaces, non-contact measurement is ideal. Optical measurement systems, like vision systems and laser scanners, capture millions of data points in seconds without physically touching the component. This is particularly useful for brass parts, as it avoids any risk of scratching or marring the finished surface. These systems excel at verifying 2D profiles, checking multiple features simultaneously, and performing rapid first-article inspections. They provide a comprehensive view of the part’s surface, catching deviations that might be missed by touch-based methods. This speed and accuracy help us maintain process control during production, ensuring consistency from the first part to the last. We use a combination of these methods, including specialized tools for surface analysis like Profilometry6, to get a complete picture of a part’s quality.

The Backbone of Quality: Traceability and Documentation

Inspection tools tell you if a part is good or bad, but a robust quality system tells you why. This is where traceability and documentation become critical. They provide a complete history of each part, creating a transparent and accountable manufacturing process. This isn’t just about creating paperwork; it’s about building a system of trust and control that prevents defects from ever reaching the customer. For any serious brass CNC machining project, a failure to document is a failure to control quality.

The Indispensable Role of Traceability

Traceability means having the ability to track every aspect of a part’s journey. This starts with the raw material itself. We document the heat lot and supplier of the specific brass alloy used for your parts, ensuring the material properties meet your specifications. From there, we track which machine was used, who the operator was, the date of production, and the results of every inspection. Why is this so important? Imagine a critical component fails in the field. With full traceability, we can instantly identify the exact production batch, investigate the root cause—whether it was a material issue or a process deviation—and isolate any other potentially affected parts. This capability is essential for risk mitigation, especially in regulated industries.

Documentation: Your Proof of Quality

Clear, consistent documentation is the foundation of a reliable quality management system. It ensures that specifications are understood and followed at every stage. It also provides the customer with tangible proof that their parts have been manufactured and verified correctly.

| Document Type | Purpose |

|---|---|

| Material Certificate | Verifies the chemical and mechanical properties of the raw brass alloy. |

| First Article Inspection (FAI) | A detailed report confirming the first part produced meets all specifications. |

| In-Process Inspection Sheet | Records measurements taken during the production run to monitor consistency. |

| Final Inspection Report | Provides a summary of all final dimensional and visual checks before shipping. |

| Certificate of Conformance (CoC) | A formal declaration that the parts meet all customer and industry standards. |

This suite of documents creates a comprehensive quality record for every order. In our work at PTSMAKE, we’ve found that providing clear and thorough documentation builds long-term trust, as it gives our partners complete confidence in the components they receive.

In summary, achieving superior quality in brass CNC parts relies on a dual approach. Advanced inspection tools like CMMs and optical scanners provide the hard data to verify dimensional accuracy and surface integrity. Simultaneously, a disciplined system of traceability and comprehensive documentation creates a transparent and accountable process. This combination ensures that every part not only meets the design specifications but is also backed by a complete record of its manufacturing journey, delivering true peace of mind.

Scaling Production: From Prototyping to High-Volume Brass CNC Machining?

Have you ever perfected a brass prototype, only to find that scaling to production feels like starting from scratch? The costs, tolerances, and logistics suddenly become immense challenges.

Scaling brass CNC machining from a single prototype to high-volume production requires a fundamental shift in strategy. This transition hinges on selecting the right automated equipment, optimizing every step of the workflow, and implementing rigorous production planning to ensure consistency and efficiency at scale.

Moving from a single perfect part to thousands of identical ones is where the real engineering begins. The machine that created your prototype, likely a standard CNC milling or turning center, is often not the right tool for mass production. It’s built for versatility, not for speed at volume. Scaling successfully means rethinking the entire manufacturing process, starting with the hardware itself. At PTSMAKE, we guide our partners through this transition, ensuring the chosen approach aligns with their volume, complexity, and cost targets.

Choosing the Right Machinery for Scale

The key is to match the machine to the job. For high-volume brass parts, specialized equipment offers immense advantages in speed and cost per part.

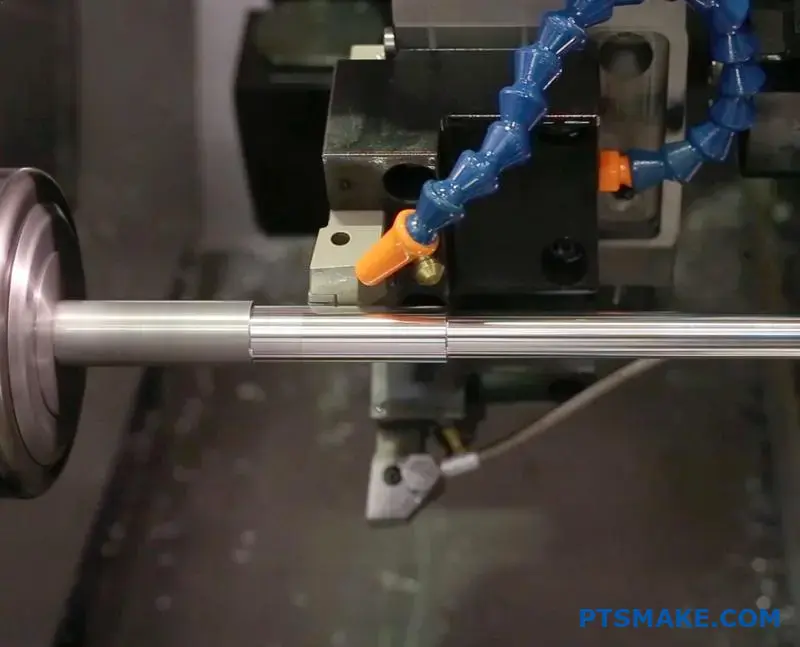

Swiss Screw Machines

These machines are ideal for small, complex, and slender brass parts. They work by feeding bar stock through a guide bushing, machining the part right near the point of support. This minimizes deflection and allows for incredibly tight tolerances on long parts. For components like connectors, pins, and shafts, a Swiss machine can often complete the part in a single operation.

Multi-Spindle Lathes

When raw speed is the goal for simpler part geometries, multi-spindle machines are the champions. They have multiple spindles (typically 6 or 8) that machine multiple parts simultaneously. As the drum indexes, each spindle performs a different operation. This parallel processing dramatically reduces cycle times for high-volume orders.

Automation and Workflow Integration

Beyond the primary machine, scaling involves integrating automation. This includes bar feeders, part catchers, and robotic arms that move parts between stations. A well-designed workflow minimizes manual handling, reduces the chance of errors, and keeps the machines running continuously. We often set up production lines using a Cellular manufacturing7 approach, where a sequence of machines is grouped together to produce a family of parts, cutting down on transit time and improving overall flow. This is a core part of effective brass cnc machining at scale.

| Machine Type | Best For | Volume | Cycle Time |

|---|---|---|---|

| CNC Turning/Milling Center | Prototyping, Low-Volume | Low-Medium | High |

| Swiss Screw Machine | Small, Complex Parts | Medium-High | Medium |

| Multi-Spindle Lathe | Simple, High-Volume Parts | Very High | Low |

Once the right equipment is in place, the focus shifts to planning and execution. A machine is only as efficient as the process that feeds it. High-volume production is a game of consistency, where small, repeated inefficiencies can quickly add up to significant costs and delays. This is where meticulous planning and addressing potential challenges head-on becomes critical.

Strategic Production Planning

Effective planning is the backbone of any successful high-volume manufacturing operation. It’s not just about scheduling machine time; it’s about creating a robust system that anticipates and mitigates potential issues.

Material and Tooling Management

For brass, material consistency is key. When scaling up, we establish relationships with trusted suppliers to source large batches of brass with certified chemical compositions. This ensures predictable machinability from the first part to the last. Tooling strategy also changes. Instead of running a tool until it breaks, we use tool life monitoring systems. Based on our tests, we can predict when a tool will start to wear and schedule changes during planned downtime, preventing out-of-spec parts and broken tools from halting production.

Quality Control at Scale

Inspecting every single feature on every part is impossible in high-volume production. Instead, we implement Statistical Process Control (SPC). By taking systematic samples and measuring key features, we can monitor the process in real-time. If we see a trend of a dimension drifting towards a tolerance limit, we can intervene and adjust the process before any bad parts are made. Automated systems like Coordinate Measuring Machines (CMMs) and in-process probes are integrated into the workflow for efficient and reliable verification.

Overcoming Common Scaling Challenges

Transitioning to high volume introduces unique obstacles that aren’t present in prototyping. Here’s how we address them in our projects.

| Challenge | Our Solution at PTSMAKE |

|---|---|

| Maintaining Tight Tolerances | Implement SPC and automated in-process gauging to monitor and control process variables in real-time. |

| Managing Chip Evacuation | Utilize high-pressure coolant systems and optimized toolpaths designed specifically for continuous brass machining to prevent chip buildup. |

| Cost Creep | Conduct Design for Manufacturability (DFM) analysis early on and continuously optimize cycle times by microseconds. |

| Ensuring Process Stability | Standardize setups, document every process parameter, and conduct regular machine maintenance to ensure repeatable performance. |

Successfully scaling from a prototype to high-volume brass CNC machining is a complex but manageable process. It requires moving beyond a one-off mindset to a systems-based approach. The transition hinges on selecting specialized, automated equipment like Swiss screw machines or multi-spindle lathes. Just as crucial are optimized workflows, meticulous production planning for materials and tooling, and implementing robust quality control systems like SPC to overcome challenges in consistency, cost, and efficiency at scale.

Cost Optimization Strategies in Brass CNC Machining Projects.

Are you finding it difficult to balance your project budget while maintaining the quality standards for your brass parts? Do unexpected costs frequently derail your financial planning for brass CNC machining?

Optimizing brass CNC machining costs involves smart material utilization, reducing setup times through design for manufacturability (DFM), leveraging batch production, and selecting the right supplier. Brass’s excellent machinability inherently offers a significant cost advantage over other metals, allowing for faster cycle times and lower tool wear.

To effectively control costs, we must start with the material itself. Brass possesses a unique combination of properties that make it inherently economical for CNC machining compared to many steels or stainless steels. Its machinability is a primary driver of cost savings.

Leveraging Brass’s Natural Machinability

Brass allows for significantly higher cutting speeds and feed rates. In our testing, machining a common brass alloy like C360 can be up to five times faster than machining tough steels. This speed directly translates to shorter cycle times per part, which reduces machine time and labor costs. Furthermore, the free-machining nature of brass produces small, manageable chips and causes less wear on cutting tools. This extends tool life, reduces the frequency of tool changes, and minimizes the risk of tool breakage, which are all hidden costs that can accumulate quickly. Less tool wear also means more consistent part quality over a production run, preventing costly rework.

Smart Material Utilization Strategies

How you manage the raw material is another critical area for optimization. Wasted material is wasted money.

Near-Net Shape Sourcing

Instead of starting with a large block of standard-sized stock, consider sourcing material that is already close to the final part’s dimensions. Using extruded profiles or custom-sized rods minimizes the amount of material that needs to be machined away. This not only reduces material costs but also shortens machining time, creating a dual cost benefit. In past projects at PTSMAKE, we’ve helped clients reduce material waste by over 30% simply by switching to near-net shape stock.

Maximizing Scrap Value

Brass has excellent recycling value. The chips and scrap material from your brass cnc machining process can be collected and sold. While it won’t cover the initial material cost, it provides a rebate that can be factored into the total project budget. A well-organized shop will have a system for segregating brass scrap to maximize its resale value. The high density and demand for brass make its scrap more valuable than that of many other common metals.

Minimizing Setup Times with DFM

Design for Manufacturability (DFM) is a collaborative process where we analyze a part’s design to find ways to make it easier and cheaper to produce. Complex setups are a major cost driver in any CNC project.

| DFM Consideration | Impact on Setup Cost | Example |

|---|---|---|

| Standardize Features | Reduces Tool Changes | Use the same hole diameter or thread size across the part. |

| Simplify Geometry | Allows for Single Setup | Redesign a complex curve into a series of simpler radii. |

| Accessible Tolerances | Eases Fixturing Needs | Avoid overly tight tolerances on non-critical features. |

| Reduce Part Handling | Minimizes Operator Input | Design features to be machined from one side if possible. |

By simplifying designs and standardizing features, we can often reduce the number of required tool changes and even machine a part in a single clamping operation. This dramatically cuts down on non-productive setup time, a common factor that leads to surface imperfections like galling8 when tool paths are not optimized.

Beyond the technical aspects of design and material, your production strategy and choice of partner play an equally important role in cost optimization. A low per-part quote doesn’t always translate to the lowest total cost.

The Power of Batch Production

Economies of scale are very real in CNC machining. The initial setup—which includes programming the CNC machine, preparing tools, and creating fixtures—is a fixed cost. Whether you produce 10 parts or 1,000 parts, this initial investment of time and resources remains largely the same.

Amortizing Setup Costs

When you run a larger batch, that fixed setup cost is spread across more units. This significantly lowers the cost per individual part. For brass cnc machining projects, where cycle times are already fast, the setup cost can represent a substantial portion of the total price for small runs. Increasing the quantity is one of the most effective ways to drive down the unit price.

| Production Quantity | Setup Cost per Part (Illustrative) |

|---|---|

| 50 Units | High |

| 500 Units | Medium |

| 5,000 Units | Low |

Optimized Material Purchasing

Just as batch production lowers machining costs, it also helps with material costs. Suppliers almost always offer better pricing for bulk material purchases. Ordering material for a run of 1,000 parts will secure a much better per-pound or per-foot price than ordering for a run of 50. We pass these savings directly to our clients, further enhancing the cost-effectiveness of larger production volumes.

Selecting the Right Manufacturing Partner

Your choice of a supplier is perhaps the most critical long-term cost optimization strategy. A partnership approach yields far better results than a purely transactional one.

Look Beyond the Per-Part Price

The cheapest quote is not always the best value. A supplier who cuts corners may deliver parts with inconsistent quality, leading to costly assembly problems, field failures, or the need for a complete re-run. Consider the total cost of ownership, which includes the risk of delays, communication overhead, and the cost of poor quality. At PTSMAKE, we focus on long-term trust and reliability, ensuring you get it right the first time.

Expertise in Brass CNC Machining

A partner with deep experience in brass knows the nuances of different alloys. They can recommend the best alloy for your application, balancing cost with performance requirements like corrosion resistance or strength. They understand the optimal feeds, speeds, and tooling to use, ensuring both efficiency and a high-quality surface finish. This specialized knowledge prevents costly trial-and-error and ensures your project runs smoothly from the start.

Effectively managing costs in brass CNC machining hinges on a multi-faceted approach. By leveraging brass’s superior machinability, implementing smart DFM principles, optimizing material use, and planning for batch production, you can significantly lower expenses. Ultimately, choosing an experienced manufacturing partner like PTSMAKE who understands these nuances is crucial for achieving cost efficiency without sacrificing the high quality your project demands. It’s about a holistic strategy, not just cutting corners on a quote.

Case Studies: Successful Brass CNC Machining Projects.

Have you ever faced project delays because your machined brass components failed to meet critical specifications? This frustration can derail timelines and inflate budgets, casting doubt on the entire production strategy.

Successful brass CNC machining projects consistently demonstrate that overcoming challenges in material selection, process optimization, and quality control leads to significant improvements. These case studies show how targeted solutions can reduce lead times, minimize waste, and enhance final product performance.

Theory is one thing, but real-world application is where we truly see the value of a well-executed manufacturing plan. In our work at PTSMAKE, we’ve partnered with clients to solve complex challenges in brass machining. These examples aren’t just about success; they’re about the specific problems we faced and the practical steps we took to achieve measurable results. They highlight how a strategic approach can turn a potential production bottleneck into a streamlined success.

Case Study 1: High-Pressure Fluid Connectors for Automotive

A client in the automotive sector needed a high-volume run of custom brass fluid connectors. The parts had to withstand high pressures and extreme temperature fluctuations without any leaks.

The Challenge: Material Integrity and Cycle Time

The initial challenge was twofold. First, the previous supplier experienced a high scrap rate due to micro-cracks forming during the threading process. Second, their cycle time per part was too long, making it difficult to meet the client’s production schedule and cost targets. The pressure was on to find a solution that guaranteed part integrity while also improving efficiency for the brass cnc machining process.

Our Solution and Implementation

We approached this by analyzing the entire process, from raw material to final inspection.

- Alloy Optimization: After collaborating with our client’s engineering team, we recommended switching from a standard brass alloy to C360 Free-Cutting Brass. This alloy offers superior machinability, which reduces stress on the material during cutting.

- Tooling and Parameter Adjustment: We implemented specialized thread-forming taps instead of cutting taps. This method forms the threads by displacing material rather than cutting it, which avoids creating stress points that could lead to work hardening9 and micro-cracks.

- Process Automation: We integrated a robotic loading/unloading system into the CNC lathe, allowing for continuous, 24/7 operation. This drastically reduced manual intervention and idle time.

The Achieved Outcome

The results from our collaborative testing and implementation were immediate and impactful. The new approach not only solved the quality issues but also provided significant efficiency gains.

| Metric | Before PTSMAKE | After PTSMAKE | Improvement |

|---|---|---|---|

| Scrap Rate | 12% | < 0.5% | 95.8% Reduction |

| Cycle Time per Part | 75 seconds | 48 seconds | 36% Reduction |

| Part Performance | Met minimum specs | Exceeded burst pressure tests by 20% | Enhanced Safety |

This project shows how a combination of material science and process innovation can deliver superior brass components.

Solving one problem often reveals opportunities for broader improvements. The success in the automotive sector reinforced our belief that a deep dive into the specifics of an application is always the best starting point. Another project, this time in the consumer electronics space, presented a completely different set of challenges that required a focus on aesthetics and precision on a micro-scale. It pushed us to refine our techniques for achieving flawless surface finishes while maintaining incredibly tight tolerances.

Case Study 2: Intricate Housings for High-End Audio Equipment

A manufacturer of premium audio equipment approached us to produce a series of brass housings for their new line of amplifiers. The primary requirements were a flawless, highly polished surface finish and absolute dimensional accuracy to ensure a perfect fit with other components.

The Challenge: Aesthetics and Precision

Brass is beautiful but unforgiving. The main difficulty was eliminating all tooling marks and surface blemishes during the machining process itself, as post-machining polishing was time-consuming and could compromise the sharp edges of the design. The internal geometry was also complex, requiring tight tolerances for mounting electronic boards. The success of this brass cnc machining project depended on achieving aesthetic perfection straight from the machine.

Our Solution and Implementation

Our strategy focused on precision from the very first step.

- CAM Programming: We developed custom toolpaths using high-speed machining (HSM) techniques. This involved using smaller stepovers and higher feed rates, which minimizes tool pressure and heat, resulting in a much smoother surface.

- Specialized Tooling: We invested in diamond-coated end mills specifically for the final finishing passes. While more expensive, these tools produce a mirror-like finish that is nearly impossible to achieve with standard carbide tools.

- In-Machine Inspection: A Renishaw probe was used to perform in-process measurements of critical features. This allowed for automatic tool offset adjustments, compensating for any minor tool wear in real-time and ensuring every part was identical.

The Achieved Outcome

The meticulous approach paid off, delivering results that delighted the client and streamlined their assembly process. The housings were not only beautiful but also functionally perfect.

| Metric | Previous Supplier | PTSMAKE Solution | Improvement |

|---|---|---|---|

| Rejection Rate (Aesthetics) | 8% | < 1% | 87.5% Reduction |

| Manual Polishing Time | 15 mins/part | 2 mins/part | 86.7% Reduction |

| Assembly Fit-Up Issues | 3% | 0% | 100% Elimination |

This case illustrates that with the right technology and expertise, even the most demanding aesthetic requirements can be met efficiently through advanced brass machining techniques.

These real-world examples from PTSMAKE projects show that successful brass CNC machining is about more than just cutting metal. It involves a holistic strategy, addressing everything from material choice to advanced programming and in-process quality control. By tackling specific challenges like material integrity or aesthetic perfection with targeted solutions, we consistently deliver parts that not only meet but exceed expectations, leading to tangible improvements in lead time, cost, and overall product performance for our clients.

Unlock Superior Brass CNC Machining Solutions with PTSMAKE

Ready to elevate your projects with high-precision brass CNC machining? Contact PTSMAKE today for a fast, customized quote. Trust our expertise to deliver consistent quality, optimal material selection, and scalable production—seamlessly from prototype to volume. Partner with us for reliability and results you can measure.

Understand how to select the right brass alloy to prevent this common form of material failure. ↩

Click to understand how this corrosion process affects brass and how to select alloys to prevent it. ↩

Understand how friction and wear influence the durability and performance of your brass components. ↩

Understand how this framework evaluates a product’s environmental impact from start to finish. ↩

Understand the serious environmental risks associated with improper waste fluid disposal by exploring this term. ↩

Learn how this surface measurement technique directly impacts your part’s performance and functionality. ↩

Learn how this production layout can drastically reduce lead times and improve your part quality. ↩

Understand how preventing this specific wear mechanism can extend tool life and improve your part’s surface finish. ↩

Learn how this material property can affect your brass part’s durability and machining process. ↩