Achieving perfect optical clarity and precision tolerances in acrylic CNC machining seems straightforward until stress cracks appear, surfaces cloud over, or dimensional accuracy falls short. These failures cost time, waste materials, and delay critical project timelines when you need reliable results most.

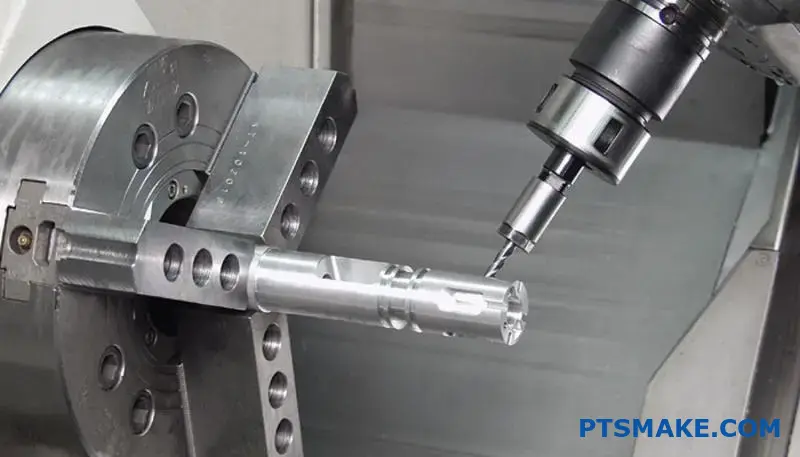

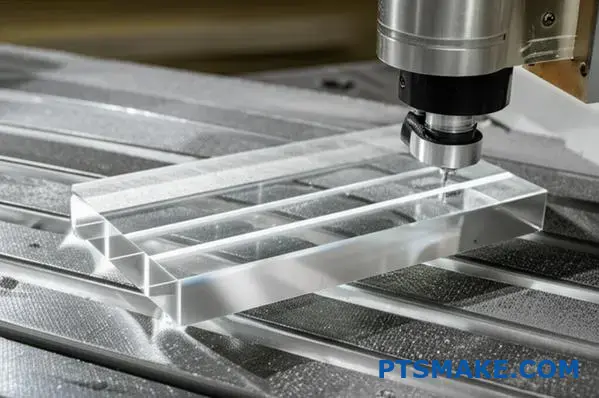

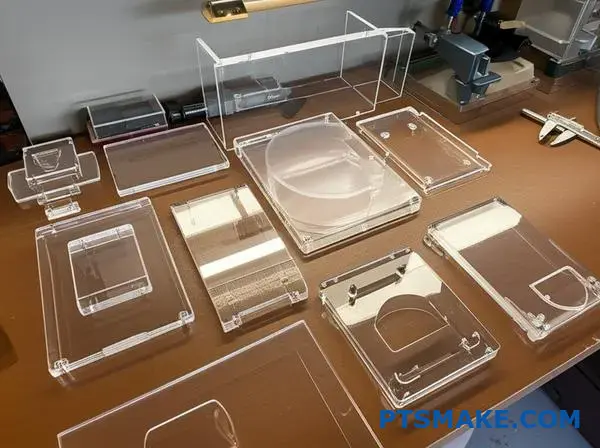

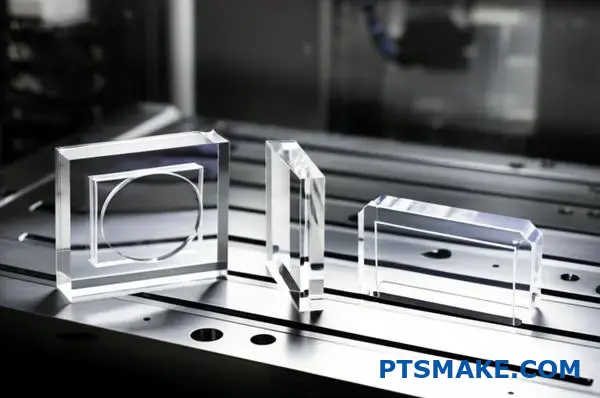

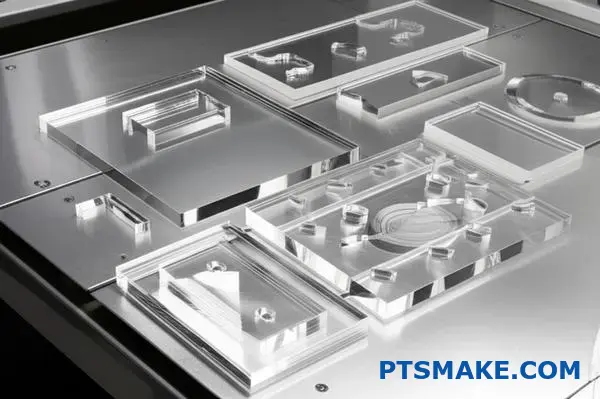

Acrylic CNC machining combines computer-controlled cutting tools with transparent thermoplastic to create precise optical components, display panels, and functional prototypes. Success requires proper tooling, cooling strategies, and post-processing techniques to maintain clarity while achieving tight tolerances.

Working with acrylic demands specific knowledge that generic machining guides miss. The material’s unique properties – from brittleness to thermal sensitivity – create challenges that require targeted solutions. This guide covers everything from industry applications to quality control, giving you the practical knowledge to avoid common pitfalls and deliver consistently excellent results across automotive, medical, and optical applications.

Industry-Specific Uses of Acrylic CNC Machining.

Struggling to find one material that works for rugged automotive parts and delicate medical devices? This challenge often leads to compromises in design, durability, or even project budget.

Acrylic CNC machining is the solution, offering unparalleled precision and versatility across industries like automotive, medical, and retail. It enables the creation of everything from durable, transparent automotive headlights and high-precision medical components to eye-catching retail displays, meeting diverse and stringent sector-specific requirements.

Acrylic, often known by trade names like Plexiglas or Lucite, is more than just a clear plastic. When shaped by computer numerical control (CNC) machines, its potential explodes across various demanding industries. The process allows us to cut, drill, and polish this material to incredibly tight tolerances, making it a go-to choice for applications where both form and function are critical. Let’s look at a couple of key sectors where we see its impact daily.

Automotive: Clarity and Impact Resistance

In the automotive world, safety and aesthetics go hand-in-hand. Acrylic CNC machining is crucial for prototyping and producing parts like headlight lenses, taillight covers, and interior light pipes. The material’s superior optical clarity ensures maximum light transmission, which is a key safety requirement. But it’s also about durability. Automotive components need to withstand constant exposure to UV radiation, road debris, and temperature fluctuations. CNC machining allows for the creation of complex lens geometries that precisely control light beams, a feat difficult to achieve with other methods during low-volume production or prototyping. In past projects at PTSMAKE, we’ve machined acrylic prototypes for instrument clusters that required both perfect transparency and precise cutouts for gauges and warning lights. The machinability of Poly(methyl methacrylate)1 makes it an ideal candidate for such custom, high-stakes applications.

Medical: Precision and Biocompatibility

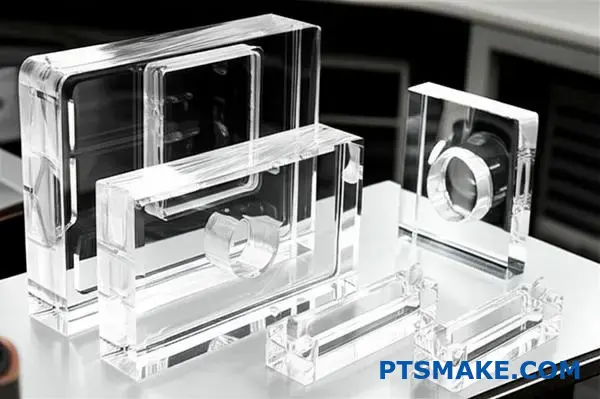

The medical industry’s demand for precision is non-negotiable. Here, acrylic CNC machining is used to create components for diagnostic equipment, lab-on-a-chip devices, and enclosures for sensitive electronics. Certain grades of acrylic are biocompatible and can be sterilized, making them suitable for tools and devices that come into contact with patients. We machine microfluidic channels into acrylic blocks with tolerances measured in microns, enabling precise control over fluid samples for analysis. The material’s chemical resistance is another vital property, ensuring it doesn’t degrade when exposed to cleaning agents or reagents.

| Feature | Automotive Industry | Medical Industry |

|---|---|---|

| Key Requirement | UV Resistance & Impact Strength | Biocompatibility & Sterilizability |

| Common Applications | Headlight lenses, interior panels | Lab equipment, device housings |

| Machining Focus | Optical surfaces, complex curves | Micro-channels, tight tolerances |

| Surface Finish | Vapor polishing for clarity | Optically clear or matte finish |

Beyond the road and the laboratory, the applications of CNC machined acrylic extend into environments where visual appeal and customer interaction are paramount. The material’s unique combination of light weight, shatter resistance, and optical brilliance makes it a favorite among designers in retail and electronics. The precision of CNC machining transforms a simple acrylic sheet into a component that can define a brand’s image or protect delicate technology.

Retail & Signage: Highlighting Products and Brands

Walk into any high-end retail store, and you’ll likely see the results of acrylic CNC machining. It’s used to create stunning point-of-purchase (POP) displays, illuminated signage, and protective cases for luxury goods. Unlike glass, acrylic is much more impact-resistant and lighter, reducing shipping costs and breakage risks. CNC routers can carve intricate logos and letters with sharp, clean edges. Furthermore, acrylic’s ability to be edge-lit allows for the creation of displays that glow, drawing a customer’s eye directly to the product. In our experience with clients, a well-executed, flame-polished acrylic display can significantly enhance the perceived value of the item it holds, turning a simple shelf into a premium showcase.

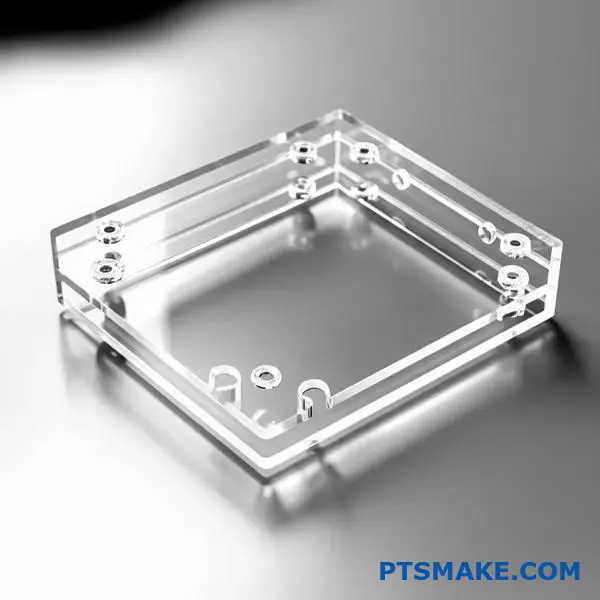

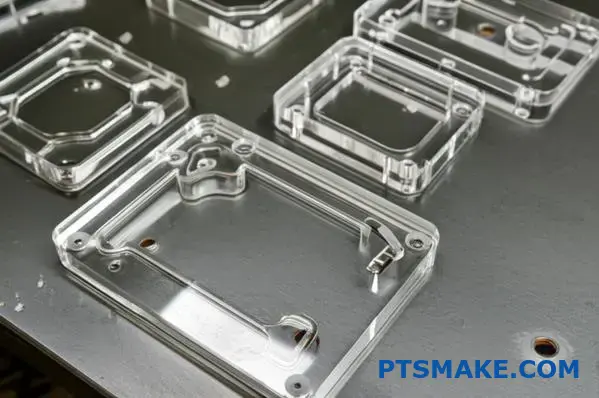

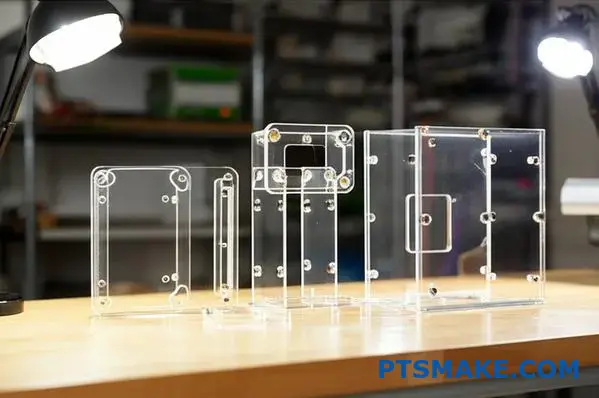

Electronics: Functional Housings and Panels

In the electronics industry, acrylic is valued for both its aesthetic and functional properties. It serves as an excellent electrical insulator, making it safe for enclosures and front panels on various devices. Engineers often use CNC machined acrylic for creating transparent housings for prototypes. This allows them to observe the internal components in action without disassembling the unit. The dimensional stability of acrylic ensures that precisely machined ports for cables, buttons, and ventilation slots align perfectly with the internal hardware. From custom computer cases for gaming enthusiasts to front panels on industrial control systems, acrylic provides a durable and professional-looking solution.

| Aspect | Retail Applications | Electronics Applications |

|---|---|---|

| Primary Goal | Visual appeal & product showcase | Functionality & component protection |

| Machining Focus | Intricate logos, polished edges | Precise cutouts, mounting holes |

| Common Finishes | Flame polishing, high gloss | Matte finish, clear |

| Key Benefit | Optical clarity & light transmission | Electrical insulation & durability |

From impact-resistant automotive headlights to sterile, precise components in medical labs, acrylic CNC machining proves its adaptability. We’ve explored how it creates visually stunning retail displays and functional electronic housings. Each sector leverages CNC machining’s ability to transform a simple acrylic sheet into a high-performance part, meeting unique demands for clarity, strength, and precision. This versatility makes it a cornerstone of modern manufacturing and a material we trust at PTSMAKE for demanding projects.

Design Considerations for Acrylic CNC Machined Parts?

Have you ever designed a beautiful acrylic part, only to see it crack during machining or fail unexpectedly? Its unique properties can quickly turn a great design into a failed prototype.

Successful acrylic CNC machining requires balancing your design with the material’s characteristics. This means carefully managing wall thickness, simplifying geometries to avoid stress concentrations, and defining practical tolerances, especially when optical clarity is a priority.

Managing Geometry and Structural Integrity

When working with acrylic, its brittleness is the single most important factor to consider during the design phase. Unlike more ductile plastics or metals, acrylic doesn’t bend or deform much before it fractures. This directly influences how you should approach part geometry.

Wall Thickness and Uniformity

A common mistake is designing walls that are too thin. Thin sections are not only fragile but also susceptible to vibration and chatter during the machining process, which can lead to micro-cracks. Based on projects we’ve handled at PTSMAKE, we recommend a minimum wall thickness of 1.5mm (0.060 inches) for most applications. More importantly, strive for uniform wall thickness throughout the part. Abrupt changes from thick to thin sections create internal stress points that become prime locations for failure. If thickness variations are unavoidable, use gradual transitions or fillets to ease the change.

Internal Corners and Stress Risers

Sharp internal corners are the natural enemy of acrylic. They act as stress concentrators, where mechanical forces build up and can easily initiate a crack. This phenomenon is known as notch sensitivity2. To prevent this, always design with generous inside corner radii. A good rule of thumb is to make the radius at least 50% of the adjacent wall thickness. For instance, if you have a 3mm wall, aim for an inside radius of at least 1.5mm. This simple change distributes stress over a larger area, drastically improving the part’s durability.

Here’s a quick guide we often share with our clients:

| Wall Thickness | Minimum Recommended Inside Radius |

|---|---|

| 1.5 mm | 0.75 mm |

| 3.0 mm | 1.5 mm |

| 6.0 mm | 3.0 mm |

| 12.0 mm | 6.0 mm |

Complexity and Machinability

While CNC machining offers incredible geometric freedom, overly complex designs can be problematic for acrylic. Features like deep, narrow pockets or tiny holes are difficult to machine without causing excessive heat buildup. Heat is a major issue as it can cause the acrylic to melt, gum up the cutting tool, and leave a poor surface finish. To optimize for machinability, try to keep pocket depths to no more than 3-4 times the tool diameter and ensure holes are large enough for effective chip evacuation.

Tolerances and Optical Properties

Beyond structural strength, many engineers choose acrylic for its exceptional optical clarity. However, achieving and maintaining this clarity through CNC machining requires specific design considerations related to tolerances and surface finishing. The level of precision you specify has a direct impact on both the manufacturing process and the final cost.

Defining Realistic Tolerances

Acrylic has a relatively high coefficient of thermal expansion. This means its dimensions can change noticeably with temperature fluctuations. When designing parts that need to fit together or interface with other components, you must account for this. Specify tolerances that are achievable and necessary, rather than defaulting to overly tight ones. For general mechanical parts, a tolerance of +/- 0.1mm (+/- 0.004 inches) is a reasonable starting point. If tighter tolerances are essential, discuss the part’s operating environment with your manufacturing partner so they can adjust their machining strategy accordingly. At PTSMAKE, we often advise clients on designing slip fits or clearance fits for acrylic assemblies to accommodate for this expansion.

Designing for Optical Clarity

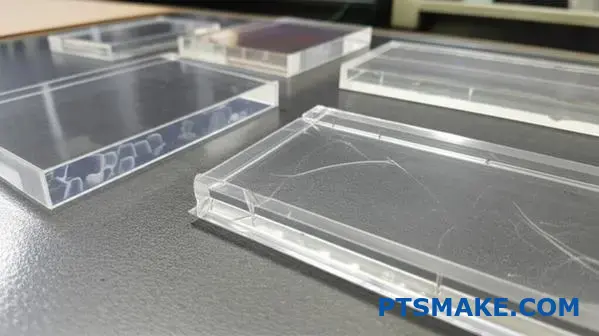

A raw machined acrylic surface will appear cloudy or matte, not transparent. Achieving that crystal-clear, glass-like finish requires post-processing, and your design can make this step easier or harder.

- Surface Finish Callouts: Specify the desired surface finish (Ra) on your drawings. This tells the machinist what tooling and cutting parameters to use. A smoother "as-machined" surface requires less effort in polishing.

- Accessibility for Polishing: Ensure the surfaces that need to be optically clear are accessible for polishing techniques like flame polishing or vapor polishing. Deep, enclosed cavities or intricate internal features are nearly impossible to polish effectively.

- Minimizing Tool Marks: The direction of tool paths will leave faint lines on the surface. If the direction of light transmission is critical (e.g., for a light pipe or lens), you can specify the direction of the final machining pass to align with the non-critical axis of the part.

This table illustrates how finishing requirements affect the process:

| Desired Finish | As-Machined Ra (Typical) | Post-Processing Required | Best For |

|---|---|---|---|

| Matte / Translucent | 1.6 – 3.2 μm | None | General mechanical parts, non-cosmetic covers |

| Semi-Gloss | 0.8 – 1.6 μm | Sanding and Buffing | Display cases, cosmetic panels |

| Optically Clear | < 0.8 μm | Sanding, Buffing, and Vapor/Flame Polish | Lenses, light pipes, windows, fluidics |

Designing for acrylic CNC machining is about respecting the material. By avoiding sharp internal corners, maintaining uniform wall thickness, and specifying practical tolerances, you can create robust parts. For optical applications, designing with post-processing in mind is critical. These considerations help prevent common failures like cracking and ensure the final part is both strong and aesthetically pleasing, aligning design intent with manufacturing reality.

Post-Processing Techniques for Acrylic CNC Parts?

Struggling to get that perfectly clear, polished look on your machined acrylic parts, leaving them looking cloudy and unfinished?

The solution lies in post-processing. Techniques like flame polishing, buffing, and laser engraving are essential for enhancing surface finish, improving optical clarity, and refining edge quality, transforming your parts from raw components to finished products.

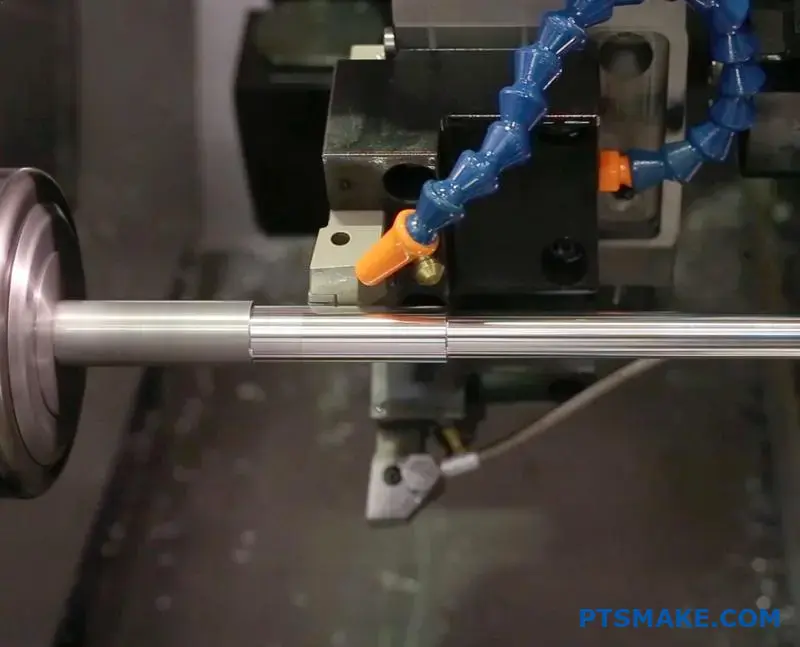

After the initial acrylic cnc machining process, the part’s surface is often left with a matte or frosted finish due to the marks left by the cutting tool. To achieve the crystal-clear appearance acrylic is known for, these marks must be removed. This is where post-processing becomes critical. The two most common methods for achieving a high-gloss finish are flame polishing and mechanical buffing. Each has its own distinct advantages and is suited for different applications.

Flame Polishing: A Rapid Path to Clarity

Flame polishing involves using a specialized torch that produces a hot, precise flame. When this flame is passed quickly and evenly over the surface of the machined acrylic, it momentarily melts the outermost layer. This melting action smooths out the microscopic surface asperities3 left by the CNC machine, resulting in a smooth, transparent, and glossy finish.

Key Considerations

This method is incredibly fast and effective, especially for complex geometries and hard-to-reach internal edges that would be impossible to polish mechanically. However, it is a technique that demands significant skill. If the flame is held too long or is too close, it can cause the acrylic to bubble, burn, or induce internal stress, which could lead to crazing later on. In our experience at PTSMAKE, we’ve found it’s best for aesthetic parts where optical perfection isn’t the primary goal.

Mechanical Buffing: The Gold Standard for Optical Quality

Mechanical buffing, or polishing, is a more labor-intensive but highly controlled process. It typically involves multiple stages, starting with sanding the machined surfaces with progressively finer grits of sandpaper to remove tool marks. After sanding, the part is moved to a buffing wheel treated with specialized polishing compounds. The wheel buffs the surface, physically abrading it to an exceptionally smooth and optically clear state.

When Buffing is Non-Negotiable

This method provides the highest level of surface quality and is the preferred choice for applications requiring superior optical clarity, such as lenses, light pipes, and high-end retail displays. Unlike flame polishing, it does not introduce thermal stress into the material.

| Feature | Flame Polishing | Mechanical Buffing |

|---|---|---|

| Speed | Very Fast | Slower, multi-step process |

| Best For | Complex shapes, outside edges | Flat surfaces, optical parts |

| Finish Quality | Good to excellent gloss | Superior, distortion-free clarity |

| Induced Stress | High risk if done incorrectly | Minimal to none |

| Skill Level | High skill and experience needed | Moderate skill, but labor-intensive |

Beyond achieving a basic clear finish, post-processing can also add intricate details and branding to your acrylic parts. Laser-based techniques, in particular, offer a high degree of precision and repeatability that manual methods can’t match. Choosing the right technique requires a careful balance between the desired aesthetic, functional requirements, and the project budget.

Laser Processing: Precision and Fine Detail

A CNC laser offers a versatile approach not just for cutting but also for finishing acrylic parts. It can be used in two primary ways for post-processing: edge polishing and engraving.

Laser Edge Polishing

When acrylic is cut with a finely tuned laser, the edge often comes out with a naturally flame-polished finish. This occurs because the laser’s heat melts the material as it cuts. This is an efficient way to get polished edges directly from the cutting process, ideal for signs, plaques, and decorative panels. It provides a clean, crisp finish without the manual labor of flame polishing or buffing.

Laser Engraving

For adding logos, text, part numbers, or intricate patterns, laser engraving is the superior method. The laser etches the surface with incredible precision, creating a frosted appearance that contrasts beautifully with the polished acrylic. This is invaluable for branding, serialization, or creating functional markings on your components. This process is highly automated, ensuring perfect consistency across a production run of acrylic cnc machining parts.

Making the Right Choice for Your Application

Selecting the best post-processing method depends entirely on the part’s end-use. At PTSMAKE, we often walk clients through a simple decision-making process based on a few key factors.

| Desired Outcome | Recommended Primary Technique | Secondary Options |

|---|---|---|

| Maximum Optical Clarity | Mechanical Buffing | Vapor Polishing |

| Glossy Finish on Complex Shapes | Flame Polishing | Laser Edge Polishing |

| Adding Fine Details/Text | Laser Engraving | N/A |

| Cost-Effective General Finish | Flame Polishing | As-machined (if clarity not needed) |

Ultimately, the goal is to match the finishing technique to the application. For a simple protective cover, a quick flame polish might be sufficient. For a precision optical lens, a multi-stage mechanical buffing process is the only way to guarantee performance. Understanding these trade-offs ensures you don’t over-engineer—and overpay for—the finish on your acrylic parts.

The initial acrylic CNC machining is just the first step. Achieving the desired clarity and aesthetic relies heavily on post-processing. Techniques like flame polishing offer a fast, glossy finish for complex shapes, while mechanical buffing provides superior, distortion-free optical quality for precision applications. Additionally, laser engraving allows for intricate detailing and branding. Choosing the right method is a critical decision that balances appearance, function, and cost to transform a raw component into a high-quality finished product.

Troubleshooting Common Acrylic CNC Machining Issues.

Have you ever ruined a beautiful acrylic part with ugly cracks or melting right at the final pass? It’s a frustrating and costly setback that can derail your project timeline.

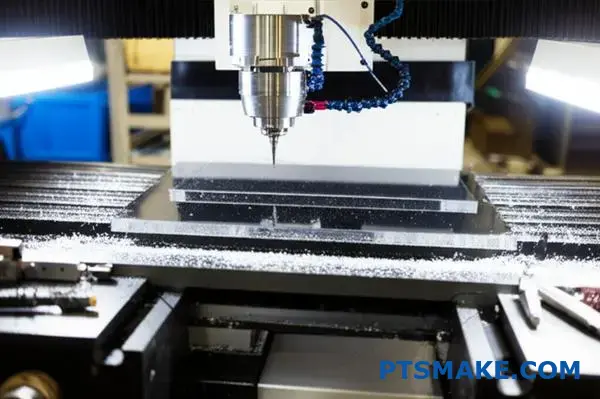

Successfully troubleshooting acrylic CNC machining involves controlling heat, using the right toolpaths, and applying proper workholding. Key issues like cracking, melting, and chipping can be solved by adjusting speeds, feeds, and cooling strategies to manage the material’s sensitivity.

Acrylic is a fantastic material, but it’s not as forgiving as aluminum or steel. Its unique properties demand a specific approach. When things go wrong, it’s usually due to a misunderstanding of how the material behaves under the stress of cutting. The most common failures I see are all related to two main culprits: heat and stress. Unlike metals that dissipate heat well, acrylic insulates it, causing heat to build up right at the cutting edge. This can quickly lead to problems that ruin the part’s aesthetic and structural integrity. Identifying the exact problem is the first step toward a solution.

Recognizing the Four Common Defects

Before you can fix an issue, you have to know what you’re looking at. In my experience, most defects in acrylic cnc machining fall into one of four categories. Each has a distinct look and a specific cause.

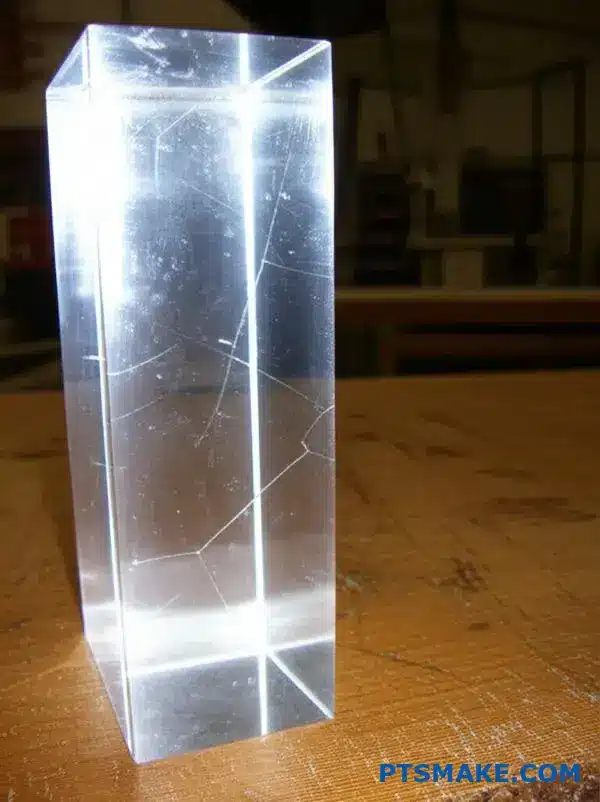

Stress Cracking and Crazing

These two are often confused, but they are different. Stress cracking results in deep, visible fractures, often starting from a sharp corner or a drilled hole. It’s caused by excessive mechanical stress, like over-tightening a clamp, or by chemical attack from incompatible fluids. Crazing, on the other hand, is a network of very fine, hair-like cracks on the surface. It looks like a frosted web and is almost always caused by a chemical reaction with improper coolants, cleaning agents, or even airborne vapors.

Melting and Chip Welding

This is perhaps the most common issue for beginners. You’ll see gummy, melted plastic building up on the tool and the workpiece, leaving a rough, distorted finish. This happens when the cutting tool generates more heat than the material can handle. The primary causes are using a dull tool, running the spindle speed (RPM) too high, or moving the tool too slowly (low feed rate). The high thermal expansion coefficient4 of acrylic means it swells significantly when heated, exacerbating the problem.

Chipping and Poor Edge Finish

Chipping results in jagged, broken edges, especially where the tool enters or exits the material. It’s a sign that the material is being fractured rather than sheared cleanly. This is often caused by using the wrong tool geometry—for instance, a tool with too many flutes—or by an overly aggressive feed rate that puts too much force on the material at once.

To make it simpler, here’s a quick reference table based on what we’ve seen in past projects at PTSMAKE.

| Defect | Visual Appearance | Primary Cause |

|---|---|---|

| Stress Cracking | Deep, visible fractures, often originating from a hole or edge. | Excessive mechanical or chemical stress. |

| Crazing | A network of tiny, hair-like cracks on the surface. | Chemical reaction with incompatible coolants or cleaners. |

| Melting | Gummy, melted plastic building up on the tool or workpiece. | Excessive heat from friction (high RPM/low feed rate). |

| Chipping | Jagged or broken edges, especially at entry/exit points. | Incorrect tool geometry or excessive cutting force. |

Knowing the problem is half the battle; implementing the right solutions is the other half. The key is to shift your mindset from simply cutting a part to managing the material’s environment throughout the process. A proactive strategy that addresses heat, stress, and chip evacuation before they become problems will save you time, material, and a lot of headaches. This is where experience and a methodical approach really pay off. At PTSMAKE, we’ve developed a set of best practices that form the foundation of our acrylic machining services, ensuring consistent, high-quality results for our clients.

Practical Solutions for Flawless Acrylic Parts

Once you’ve identified the issue, you can apply a targeted solution. The goal is always to cut the acrylic cleanly without introducing excessive heat or stress.

Master Your Cooling and Chip Evacuation

Heat is the enemy. Your primary goal is to get it away from the cutting zone as quickly as possible. The best way to do this is with a steady stream of compressed air directed right at the tool tip. Air serves two purposes: it cools the tool and workpiece, and it blows chips out of the cut. Clogged chips are a major source of friction and heat. While flood coolants are common in metal machining, they can be risky with acrylic due to chemical compatibility issues that cause crazing. If you must use a liquid, always use one specifically formulated for plastics.

The Importance of Proper Fixturing and Handling

Mechanical stress from clamping is a leading cause of cracking. Never overtighten your vise or clamps. Instead, use fixtures that distribute pressure evenly across a larger surface area. We often use soft jaws or custom-milled fixtures to hold acrylic parts securely without inducing stress. Also, remember to handle the material carefully. Dropping a sheet or finished part can easily cause it to chip or crack. After machining, especially for parts with critical tolerances, we sometimes recommend an annealing process. This involves gently heating the part in an oven to a specific temperature and then slowly cooling it to relieve any internal stresses created during the machining process.

Optimizing Your Tools and Parameters

The right tool and cutting parameters make all the difference. For acrylic, you want a tool that shears the material, not one that plows through it.

Here’s a breakdown of effective strategies:

| Solution Area | Key Action | Benefit |

|---|---|---|

| Tool Selection | Use single-flute or two-flute "O-flute" cutters designed for plastics. | These provide excellent chip clearance, reducing heat buildup. |

| Speeds & Feeds | Use a moderate RPM and a relatively high feed rate. | The goal is to create a thick chip that carries heat away. A slow feed rate causes the tool to rub, generating friction and melting. |

| Workholding | Use soft jaws or dedicated fixtures that distribute clamping force. | This prevents the introduction of mechanical stress that leads to cracking. |

| Post-Processing | Anneal parts when necessary to relieve internal stresses. | Improves the part’s long-term stability and resistance to crazing. |

By focusing on these key areas, you can systematically eliminate the common problems associated with acrylic CNC machining and produce clean, visually stunning parts every time.

Troubleshooting common acrylic CNC machining issues boils down to managing heat and stress. Problems like cracking, crazing, melting, and chipping are not random; they are direct results of improper technique. By identifying the specific defect, you can apply targeted solutions. Mastering cooling strategies, using correct fixturing to avoid mechanical stress, and selecting the right tools and cutting parameters are essential for achieving a flawless finish. This proactive approach turns a challenging material into a predictable one.

Quality Assurance and Inspection for Acrylic CNC Components?

Ever received a batch of acrylic parts that looked perfect, only to find critical inconsistencies later? This hidden variation can easily derail entire projects and compromise your final product’s integrity.

Ensuring top quality for acrylic CNC components requires a multi-faceted approach. This includes precise dimensional inspection, rigorous surface clarity checks, and functional stress testing to guarantee every part meets stringent specifications and performs reliably.

Tailored Inspection Processes for Acrylic

When it comes to acrylic, standard quality checks aren’t enough. The material’s unique properties demand a specialized inspection process. At PTSMAKE, we’ve developed a detailed quality assurance protocol specifically for acrylic CNC machining to ensure every component we deliver is flawless.

Dimensional Inspection: Beyond the Basics

Checking dimensions on acrylic is more complex than with metals. Acrylic has a relatively high coefficient of thermal expansion, meaning its size can change with temperature. For high-precision parts, we conduct all measurements in a temperature-controlled environment using tools like Coordinate Measuring Machines (CMMs). For delicate, polished surfaces, we often use non-contact methods, such as optical comparators or vision systems. This prevents any risk of scratching the component while capturing precise measurements down to the micron level.

Surface Clarity and Optical Checks

For many applications, like lenses, light pipes, or display windows, the optical quality of acrylic is its most important feature. A simple visual check is just the starting point. We inspect components under specific, high-intensity lighting from multiple angles to identify any subtle haze, polish marks, or internal imperfections like voids. In our past projects with clients in the consumer electronics space, we have used spectrophotometers to verify light transmission percentages, ensuring the component meets the exact optical performance required by the design.

Stress Testing and Material Integrity

CNC machining, no matter how carefully done, can introduce internal stress into acrylic parts. This stress can lead to crazing or cracking over time, especially when exposed to chemicals or temperature changes. We use a technique involving polarized light to visualize these stress patterns. This method, known as photoelasticity5, allows us to see high-stress areas that are invisible to the naked eye. If significant stress is detected, we perform a post-machining annealing process to relieve it, greatly improving the part’s long-term durability and reliability.

Here is a quick overview of our primary inspection methods for acrylic components:

| Inspection Method | Key Focus for Acrylic | Common Tools Used |

|---|---|---|

| Dimensional Inspection | Accuracy, Tolerance, Warpage | CMM, Calipers, Optical Comparator |

| Surface Finish Check | Clarity, Scratches, Polishing Quality | Visual Inspection, Profilometer |

| Optical Properties | Light Transmission, Haze | Spectrophotometer, Hazemeter |

| Stress Analysis | Internal Stress from Machining | Polarized Light Inspection |

Ensuring Repeatability in Batch Production

A single perfect prototype is one thing; producing a thousand identical parts is another challenge entirely. For acrylic CNC machining, consistency across a production run is paramount, especially when these components are part of a larger assembly. Inconsistencies can halt an entire production line, leading to costly delays.

The Challenge of Consistency

Achieving repeatability with acrylic requires strict process control. Factors like ambient temperature, tool wear, and even minor variations between batches of raw acrylic sheeting can affect the final part. The first part might meet all specifications, but by the 500th part, tool wear could push a critical dimension out of tolerance. This is why a "set it and forget it" approach never works. We have to monitor the process continuously.

Process Control is Key

To combat these variables, we rely on Statistical Process Control (SPC). This involves monitoring key machining parameters in real-time and documenting every aspect of the setup, from the specific tool used to the precise feed rates and spindle speeds. By analyzing this data, we can anticipate and correct for trends before they result in a non-conforming part. At PTSMAKE, this meticulous documentation also means that when a client places a repeat order months or even years later, we can replicate the exact setup to produce identical components.

Adhering to Industry-Specific Standards

For components used in regulated industries, meeting general quality standards is not enough. The parts must comply with specific, stringent regulations to be considered safe and effective.

Medical Device Applications

In the medical field, quality is non-negotiable. Acrylic components used in medical devices often must adhere to ISO 13485 standards. This requires comprehensive documentation and traceability for every step of the manufacturing process. Furthermore, depending on the application, the material itself may need to be certified as biocompatible, often to USP Class VI standards, ensuring it won’t cause adverse reactions when in contact with the human body.

Automotive Applications

For the automotive industry, components like light covers, interior lenses, and dashboard displays must meet standards like IATF 16949. The quality assurance process for these parts includes tests for UV resistance, impact strength, and the ability to withstand extreme temperature cycles without cracking or crazing. The focus is on long-term durability and safety, ensuring the part performs reliably for the vehicle’s entire lifespan.

Quality assurance for acrylic CNC machining goes far beyond simple measurements. It requires specialized inspection processes that account for the material’s unique optical and physical properties, including surface clarity and internal stress. For batch production, rigorous process control is the only way to achieve true consistency. Furthermore, for critical applications in sectors like medical and automotive, strict adherence to industry-specific standards like ISO 13485 is essential to guarantee not just precision, but also safety and long-term reliability.

Environmental and Durability Benefits of CNC-Machined Acrylic?

Struggling to find a material that won’t yellow, crack, or fail in harsh outdoor conditions? Are you concerned that your high-traffic components will quickly show wear and tear, leading to costly replacements?

CNC-machined acrylic is an excellent solution. It offers exceptional durability due to its inherent resistance to UV light, weathering, and impact. This makes it a reliable, long-lasting choice for both demanding outdoor and high-traffic indoor applications, outperforming many traditional materials.

Unmatched Resistance to UV Light and Weathering

One of the standout features of acrylic is its incredible ability to withstand the elements. When you’re designing parts for outdoor signage, architectural glazing, or marine applications, you need a material that won’t degrade after a few seasons. This is where acrylic truly shines. Unlike many other plastics that become brittle and discolored when exposed to sunlight, acrylic maintains its structural integrity and clarity for years.

Resisting Solar Radiation

The primary reason for this resilience is acrylic’s molecular structure, which is inherently resistant to ultraviolet (UV) radiation. In past projects at PTSMAKE, we’ve seen components made from other plastics fail because UV rays broke down their polymer chains. This process, known as photodegradation6, leads to the yellowing and weakening you often see in lesser-quality materials. Acrylic, however, can filter out damaging UV radiation without being affected itself. Based on our tests, high-quality cast acrylic can maintain over 90% of its light transmission properties even after a decade of outdoor exposure, ensuring long-term aesthetic appeal and performance.

Performance in Varied Climates

Beyond sunlight, acrylic holds up extremely well against other weather conditions. It has very low water absorption, so it won’t swell, warp, or lose its strength in humid or rainy environments. It’s also stable across a wide temperature range, making it suitable for applications from hot, arid deserts to cold, damp climates. When we work on an acrylic CNC machining project, we know the final part will be just as reliable in Florida’s humidity as it is in Arizona’s dry heat.

The table below shows a simplified comparison of how acrylic stands up to common environmental stressors compared to other plastics.

| Feature | Acrylic (PMMA) | Polycarbonate (PC) | PVC |

|---|---|---|---|

| UV Resistance | Excellent | Good (often coated) | Poor (requires stabilizers) |

| Clarity Retention | Excellent | Fair (can yellow) | Poor |

| Water Absorption | Very Low | Low | Low |

| Weatherability | Excellent | Good | Fair |

This inherent durability means fewer replacements, lower maintenance costs, and a more reliable end product for our clients.

Superior Impact Strength and Recyclability

While weather resistance is crucial, a material’s ability to withstand physical stress is equally important, especially in public-facing or high-traffic areas. This is another area where CNC-machined acrylic proves its value, offering a compelling alternative to materials like glass and even other robust plastics like polycarbonate.

Acrylic vs. Glass: A Clear Winner in Safety

The most obvious comparison is between acrylic and glass. Acrylic has significantly higher impact resistance—up to 17 times that of standard glass. When it does fail under extreme force, it fractures into large, dull-edged pieces rather than shattering into dangerous shards. This makes it the ideal choice for safety glazing, protective barriers, and display cases where public safety is a concern. At PTSMAKE, we often recommend acrylic for projects like machine guards and retail displays for this very reason. It provides the clarity of glass without the associated risk.

Acrylic vs. Polycarbonate: A Trade-off

Polycarbonate is known for its incredible impact strength, which is even higher than acrylic’s. However, the choice isn’t always straightforward. Polycarbonate is softer and scratches more easily, and it lacks the inherent UV resistance of acrylic, often requiring a special protective coating that can wear off over time. Acrylic, on the other hand, offers better optical clarity, a harder surface that resists scratches better, and superior weatherability. The decision often comes down to the specific application needs.

Here’s a quick comparison to help guide material selection:

| Property | Acrylic (PMMA) | Polycarbonate (PC) | Glass |

|---|---|---|---|

| Impact Strength | High (17x Glass) | Very High (250x Glass) | Low |

| Scratch Resistance | Good | Fair | Excellent |

| Optical Clarity | 92% | ~88% | ~90% |

| Weight | Low | Low | High |

Long-Term Performance and Sustainability

From an environmental standpoint, acrylic’s longevity is a major benefit. Because parts last longer, the need for manufacturing replacements is reduced, saving energy and resources. Furthermore, acrylic is a thermoplastic, meaning it can be melted down and reformed without significant degradation. While the recycling infrastructure for acrylic isn’t as widespread as for materials like PET, it is fully recyclable. Scraps from the acrylic CNC machining process can be collected and reprocessed, reducing industrial waste and contributing to a more circular economy. This combination of durability and recyclability makes acrylic a responsible choice for forward-thinking projects.

CNC-machined acrylic stands out as a highly durable material. Its innate resistance to UV radiation and weathering ensures long-term clarity and structural integrity in outdoor applications. Compared to glass, it offers far superior impact strength and safety. While polycarbonate is tougher, acrylic provides better optical clarity and scratch resistance. This blend of properties, combined with its recyclability, makes acrylic a reliable and sustainable choice for a wide range of demanding projects.

Customization and Prototyping with Acrylic CNC Machining?

Have you ever waited weeks for a prototype, only for it to fail the first fit test? This cycle of delays and redesigns can seriously derail a project’s timeline and budget.

Acrylic CNC machining provides a fast, cost-effective, and highly accurate solution for creating custom parts and functional prototypes. It allows designers to quickly iterate from a digital model to a physical part for fit testing, visual validation, and even low-volume production.

When a project demands speed without sacrificing precision, acrylic CNC machining becomes an essential tool for prototyping. The ability to move directly from a CAD file to a physical part is a game-changer, dramatically shortening the development cycle. Unlike methods that require molds or complex setups, machining acrylic is a direct process, meaning a design conceived in the morning can often be a physical part in your hands by the afternoon.

The True Value of a High-Fidelity Prototype

A prototype isn’t just a rough model; it’s the first physical representation of your design intent. It must be accurate. CNC machining delivers on this by holding tight tolerances, ensuring that the part you test is a true reflection of the final product’s dimensions. This is critical for fit and form validation, especially in complex assemblies where every micron matters. The optical clarity of acrylic offers a unique advantage here, allowing engineers to see how internal components interact without disassembling the unit. This visual access is invaluable for diagnosing clearance issues or validating fluid dynamics in microfluidic devices. The material’s Isotropic7 nature also ensures that its mechanical properties are uniform, providing predictable performance during functional testing.

From Visual Models to Functional Tests

The applications for acrylic prototypes span the entire product development lifecycle. Early-stage models are perfect for marketing presentations or securing investor buy-in, thanks to their professional, polished appearance. As the design matures, these same parts can be used for rigorous functional testing.

Here’s a quick comparison of prototyping methods we often discuss with clients at PTSMAKE:

| Feature | CNC Machined Acrylic | 3D Printing (FDM/SLA) | Injection Molding (Prototype Tool) |

|---|---|---|---|

| Speed | Very Fast (Hours) | Fast (Hours to Days) | Slow (Weeks) |

| Accuracy | High | Moderate to High | Very High |

| Material Strength | Good | Varies (Often Lower) | Excellent |

| Surface Finish | Excellent | Varies (Layer Lines) | Excellent |

| Cost (per part) | Moderate | Low | High (Tooling Cost) |

This shows that for a balance of speed, accuracy, and material properties that closely mimic production plastics, acrylic CNC machining often hits the sweet spot.

Beyond single-unit prototypes, acrylic CNC machining excels in customization and serves as a bridge to low-volume manufacturing. This flexibility is crucial for projects that require unique parts or for companies testing a new product in the market before committing to the massive capital expense of production tooling. It allows for an agile manufacturing approach where designs can be refined based on real-world feedback without incurring significant costs or delays.

The Economics of On-Demand Customization

One of the most significant advantages of CNC machining is the absence of tooling costs. For injection molding, the steel mold is the largest upfront investment, making it impractical for producing just a handful of parts. With CNC, the "tooling" is the digital program. Need to adjust a hole diameter by 0.5mm? That’s a simple code change that takes minutes. In molding, that same change could mean days or weeks of mold rework and significant expense. This makes acrylic CNC machining the ideal choice for creating custom jigs, fixtures, one-off scientific apparatus, and bespoke electronic enclosures. At PTSMAKE, we frequently produce custom mounting brackets and alignment guides for clients in the robotics and automation sectors, where each machine might require a slightly different setup.

Scaling from One to One Thousand

While perfect for one-offs, CNC machining is also economically viable for low-volume production runs, typically from a few dozen to several thousand units. The process is highly repeatable, ensuring that the thousandth part is identical to the first. This "bridge" capability allows businesses to launch a product and generate revenue while their high-volume production molds are being manufactured.

Consider the cost-per-part trade-off:

| Quantity | CNC Machining Cost Per Part | Injection Molding Cost Per Part | Notes |

|---|---|---|---|

| 10 | Low | Very High | CNC is the clear winner. |

| 100 | Low-Moderate | High | CNC remains more cost-effective. |

| 1,000 | Moderate | Moderate | Crossover point approaching. |

| 10,000+ | High | Low | Injection molding is more economical. |

This illustrates how CNC machining fills a critical gap, enabling innovation and market entry without the financial risks associated with mass production tooling. It empowers engineers to create exactly what they need, exactly when they need it.

In summary, acrylic CNC machining is a powerful asset for modern product development. It offers unmatched speed and precision for rapid prototyping, allowing for thorough fit, form, and functional testing with high-fidelity models. Furthermore, its flexibility and cost-effectiveness make it the ideal solution for creating custom parts and supporting low-volume production runs. By eliminating the need for expensive tooling, it empowers engineers to innovate freely, iterate quickly, and bring products to market faster.

Optical Applications: Lenses, Light Pipes, and Diffusers?

Have you ever designed a product where perfect light transmission was critical, only to be let down by hazy or flawed components? Are you finding it difficult to balance optical clarity with material durability and cost?

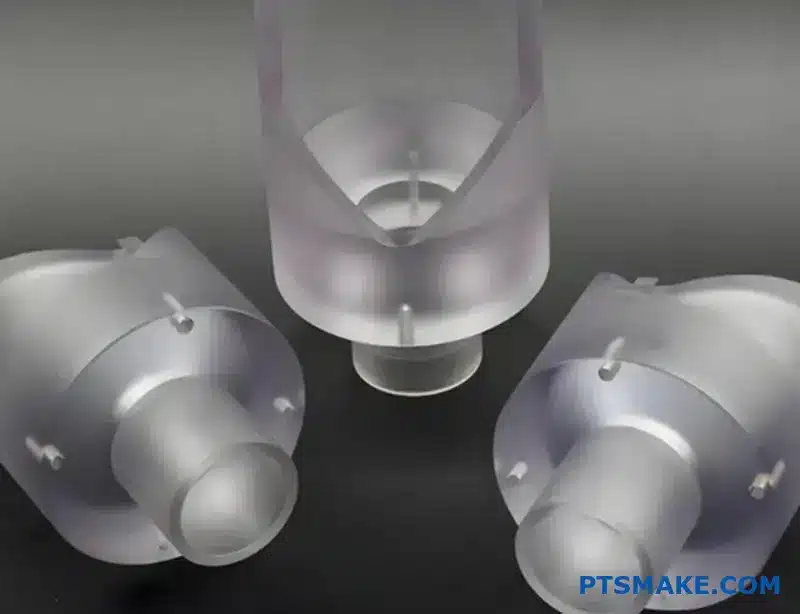

Acrylic is a premier material for optical applications like lenses, light pipes, and diffusers due to its outstanding clarity, light weight, and impact resistance. Precision acrylic CNC machining is the key to manufacturing these components with the exact geometries and flawless surface finishes required for optimal performance.

When it comes to optical components, glass has long been the traditional choice. However, acrylic, specifically PMMA, has emerged as a powerful alternative, especially when intricate shapes and durability are required. Its unique combination of properties makes it an ideal candidate for a wide range of applications where light management is crucial. At PTSMAKE, we’ve helped numerous clients in the automotive, medical, and lighting industries leverage acrylic for its optical superiority.

The Versatility of Acrylic in Optical Design

The primary reason engineers turn to acrylic is its exceptional optical clarity. With a light transmittance of up to 92%, it outperforms many types of glass and other transparent plastics. This clarity is essential for components designed to guide, focus, or diffuse light efficiently.

Crafting Lenses with Precision

Acrylic lenses are used in everything from simple magnifying glasses to complex lighting systems. The success of a lens depends entirely on the precision of its curvature. Using 5-axis CNC machining, we can create aspheric and other complex lens profiles that would be difficult or costly to produce through molding or grinding glass. This process allows for rapid prototyping and design iteration, which is invaluable during product development.

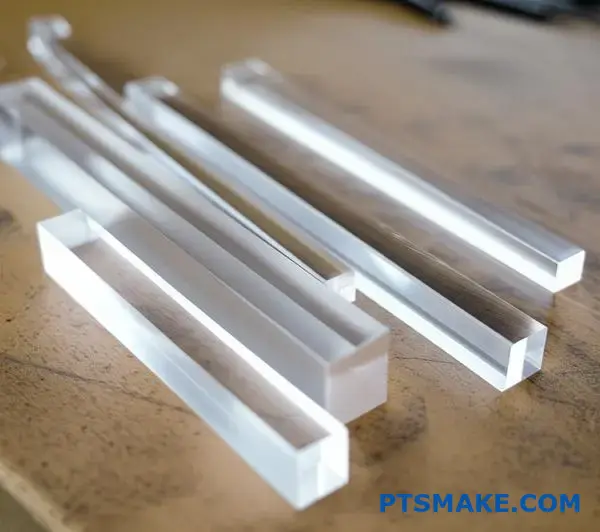

Illuminating with Light Pipes

Light pipes are essentially optical waveguides, designed to transmit light from a source, like an LED, to a specific location with minimal loss. You see them every day in automotive dashboard indicators, consumer electronics status lights, and medical device displays. The key to an effective light pipe is an incredibly smooth surface finish. Any imperfection can cause light to scatter and escape, diminishing the brightness at the output. This is where the quality of the acrylic cnc machining process becomes paramount. We focus on specialized tooling and cutting parameters to achieve a near-polished surface directly from the machine, minimizing the need for extensive secondary finishing. The refractive index8 of the material is also a critical factor in how efficiently light is guided through total internal reflection.

| Feature | Acrylic (PMMA) | Polycarbonate (PC) | Glass |

|---|---|---|---|

| Clarity (Transmittance) | ~92% | ~88% | 90-99% |

| Impact Resistance | Good | Excellent | Poor |

| Weight | Low | Low | High |

| Machinability | Excellent | Good | Poor |

| UV Resistance | Good (can be enhanced) | Poor (yellows) | Excellent |

Beyond the material’s inherent properties, the manufacturing process itself dictates the final performance of an optical component. The journey from a block of raw acrylic to a flawless lens or light pipe is one of meticulous control and precision. It’s not just about cutting a shape; it’s about preserving the material’s optical integrity throughout every step.

Machining Techniques for Flawless Optical Surfaces

Achieving a glass-like finish on acrylic requires more than just a standard CNC program. It’s a specialized skill that combines the right tools, techniques, and an understanding of how the material behaves under stress.

Tool Selection and Cutting Parameters

The secret to minimizing tool marks starts with the cutting tool itself. For optical acrylic parts, we use diamond-tipped or specially coated carbide tools with extremely sharp cutting edges. The geometry of the tool is also critical. High-helix cutters designed for plastics help evacuate chips efficiently, preventing them from melting and re-adhering to the surface. We pair these tools with high spindle speeds and carefully calculated feed rates. Moving too slowly can generate excess heat and melt the acrylic, while moving too quickly can cause chatter and leave a poor finish. It’s a delicate balance that our machinists have perfected through years of experience on projects at PTSMAKE.

The Importance of Post-Processing

While our machining process gets us remarkably close, achieving true optical perfection often requires a final touch. Two common methods for acrylic are vapor polishing and flame polishing.

- Vapor Polishing: This technique involves exposing the machined part to a chemical vapor that slightly melts the surface, causing it to flow and smooth out microscopic tool marks. It’s excellent for achieving a uniform, crystal-clear finish on complex geometries.

- Flame Polishing: Here, a specialized torch with a precise flame is passed quickly over the surface. The intense heat momentarily melts the acrylic, and surface tension pulls it into a perfectly smooth finish. This method requires significant skill to avoid overheating or burning the part.

Both methods, when executed properly, can elevate a precisely machined part to a truly optical-grade component ready for integration into high-performance assemblies in the medical or automotive sectors.

In summary, acrylic is a powerful material for optical applications, offering a compelling blend of clarity, durability, and design freedom. Success hinges on a deep understanding of both the material and the manufacturing process. By leveraging precision acrylic cnc machining with specialized tooling and combining it with expert post-processing techniques like vapor or flame polishing, we can create high-performance lenses, light pipes, and diffusers that meet the stringent demands of industries like automotive, medical, and high-end lighting.

Material Properties and Selection Criteria for Acrylic CNC Projects.

Have you ever picked an acrylic for its looks, only to have it crack during machining or yellow after a few months? Choosing the wrong grade can quickly turn a great design into a costly mistake.

To select the right acrylic, you must match its core properties—tensile strength, UV stability, and hardness—to your project’s demands. The key decision is between cast acrylic for its superior machinability and optical quality, or extruded acrylic for its tighter thickness tolerance and lower cost.

Understanding the fundamental properties of acrylic, or Poly(methyl methacrylate)9, is the first step toward a successful CNC project. These characteristics dictate how the material behaves not just during machining but also in its final application. Let’s break down the most critical ones.

Key Mechanical Properties: Strength and Hardness

When we talk about strength, we often refer to tensile strength—the material’s ability to resist being pulled apart. For acrylic parts that will bear loads or be assembled with fasteners, this is a vital metric. A higher tensile strength means the part is less likely to fracture under stress. Hardness, on the other hand, measures its resistance to surface scratching and indentation. This is crucial for applications like retail displays, protective screens, or any part that will be handled frequently. A material with poor hardness will show wear quickly, diminishing its aesthetic appeal.

Environmental Resistance: UV Stability

One of acrylic’s most popular uses is in signage and outdoor applications, making UV stability a non-negotiable property. Unprotected acrylic will yellow and become brittle when exposed to prolonged sunlight. However, many grades are now manufactured with UV inhibitors that significantly slow this degradation process. When sourcing material for an outdoor project, always verify its UV resistance rating on the technical datasheet to ensure long-term clarity and durability.

Machinability: The Defining Factor

For any CNC project, machinability is paramount. This property describes how easily a material can be cut, drilled, and milled without melting, chipping, or cracking. It’s not a single metric but a combination of factors, including the material’s melting point, internal stress, and chip formation characteristics. Poor machinability leads to rough surface finishes, gummed-up tools, and internal stress fractures that can cause the part to fail later. This is often the biggest differentiator between various acrylic grades.

Here’s a simplified comparison of what to look for:

| Property | Why It Matters for CNC Machining | Ideal Characteristic |

|---|---|---|

| Tensile Strength | Resistance to fracture from clamping or mechanical stress. | High |

| Hardness (Rockwell) | Prevents surface scratching during handling and use. | High (e.g., M90-M100) |

| UV Stability | Ensures long-term clarity for outdoor or high-light parts. | UV-Inhibited Grade |

| Machinability | Determines ease of cutting, surface finish, and tool life. | Low internal stress, clean chip formation |

Once you understand the key properties, the next step is to choose the right type of acrylic. The decision almost always comes down to two main options: cast and extruded. While they look similar, their manufacturing processes create vastly different internal structures, which directly impacts their performance in acrylic CNC machining.

Cast vs. Extruded Acrylic: The Core Decision

The difference begins at creation. Cast acrylic is made by pouring liquid monomer into a mold, where it polymerizes. This creates a material with very little internal stress and a higher molecular weight. Extruded acrylic is made by pushing acrylic pellets through a die, which is a more economical process but introduces internal stress. This fundamental difference is why they behave so differently on a CNC machine.

| Feature | Cast Acrylic | Extruded Acrylic |

|---|---|---|

| Manufacturing | Monomer poured into a mold | Pellets pushed through a die |

| Internal Stress | Very low | Higher |

| Thickness Tolerance | Less consistent (+/- 10%) | Very consistent (+/- 3%) |

| Machinability | Excellent; chips cleanly | Fair; prone to melting/gumming |

| Chemical Resistance | Superior | Good |

| Laser Cutting/Engraving | Excellent; produces a frosted edge | Good; produces a flamed edge |

| Cost | Higher | Lower |

How to Use a Technical Datasheet (TDS)

Never rely on assumptions. The technical datasheet is your source of truth. When evaluating a material, look for standardized test results, often listed under ASTM or ISO codes. For example, ASTM D638 measures tensile properties, while ASTM D785 indicates Rockwell hardness. These documents provide the objective data needed to compare materials. At PTSMAKE, we always cross-reference a client’s design requirements with the material’s TDS to prevent costly mismatches. If a part requires tight-tolerance tapped holes and a crystal-clear finish, the TDS will point us toward a specific grade of cast acrylic. For a large run of simple, flat covers where cost is the main driver, the data might support using extruded acrylic. This data-driven approach removes guesswork and ensures the final part performs exactly as intended.

Selecting the right acrylic is a critical step in any CNC machining project. Success hinges on matching material properties like tensile strength, hardness, and UV stability with your application’s needs. The primary choice between cast and extruded acrylic comes down to a trade-off: cast offers superior machinability and optical clarity, making it ideal for complex parts, while extruded provides better thickness consistency and a lower cost, suiting simpler, high-volume applications. Always consult the technical datasheet to make an informed decision.

Cost Efficiency and Production Scalability with CNC Acrylic Machining?

Struggling to control costs as your acrylic part orders increase? Worried that scaling up production will lead to inconsistent quality and higher defect rates?

CNC acrylic machining is the solution. It boosts cost-efficiency by automating processes, minimizing material waste, and reducing labor needs. This technology allows for seamless scalability from single prototypes to high-volume production, ensuring every single part meets the same exact quality standards.

CNC machining isn’t just about cutting acrylic; it’s a strategic approach to manufacturing that directly impacts your bottom line. The efficiency gains are rooted in how the technology fundamentally operates. By translating a digital design directly into machine instructions, we remove many of the variable and costly steps associated with traditional fabrication methods.

How CNC Machining Drives Down Costs

The primary cost drivers in any manufacturing project are materials, labor, and time. CNC machining addresses all three with remarkable efficiency.

Automation and Labor Reduction

A single skilled technician can supervise multiple CNC machines running simultaneously. Once a program is loaded and the material is set, the machine operates autonomously. This contrasts sharply with manual methods that require constant, skilled human intervention for each part. At PTSMAKE, this automation allows us to run production for extended periods, even lights-out, drastically reducing the labor cost allocated to each component.

Material Optimization Through Precision

Scrap material is a hidden cost that can quickly add up. CNC systems use sophisticated software to plan cuts in a way that maximizes the number of parts from a single sheet of acrylic. This process, often involving advanced Toolpath Optimization10, ensures the cutting head travels the most efficient route, minimizing waste. Based on our internal tests, this can reduce material waste by up to 20% compared to less precise methods.

A cost comparison highlights these advantages:

| Factor | Manual Fabrication | CNC Acrylic Machining |

|---|---|---|

| Labor Cost | High (Requires constant skilled labor) | Low (One operator for multiple machines) |

| Material Waste | Moderate to High | Low (Optimized cutting paths) |

| Setup Time | Varies per part | High for first part, zero for subsequent |

| Consistency | Operator-dependent | Extremely High (Machine-controlled) |

| Cost Per Part | Decreases slowly with volume | Decreases significantly with volume |

This table clearly shows that while the initial setup for a CNC job might take time, the per-part cost drops dramatically as production scales, making it highly cost-effective for both small and large runs.

Beyond direct cost savings, the scalability offered by CNC machining provides a critical competitive advantage. The ability to move from a small batch of prototypes to a full-scale production run without re-engineering the entire process is invaluable. This agility allows businesses to respond quickly to market demands without being penalized by prohibitive manufacturing costs or quality control issues.

Seamless Scaling from a Single Part to Mass Production

The real power of acrylic CNC machining lies in its perfect replicability. The digital CAD file is the master blueprint, and the CNC machine is the perfect executor, time and time again.

The Scalability Framework

Whether you need ten parts for a prototype test or ten thousand for a product launch, the process is fundamentally the same. The same G-code that produced the first perfect part will produce the ten-thousandth perfect part. This creates a predictable and reliable production pathway. In our experience working with clients, this removes the uncertainty often associated with scaling manufacturing operations. They can confidently place larger orders knowing the quality will not deviate.

Maintaining Quality at High Volumes

Human error is a natural variable in manual processes. Fatigue, distraction, and minor inconsistencies can lead to parts that fall outside of tolerance. CNC machining eliminates this variable. The machine doesn’t get tired or make mistakes. It executes the programmed instructions with micron-level precision every single time. This ensures that every component in a high-volume run is functionally and dimensionally identical to the last.

Here’s how CNC supports different production volumes:

| Production Stage | Key Challenge | How CNC Machining Solves It |

|---|---|---|

| Prototyping (1-50 units) | Speed & Design Iteration | Fast turnaround from digital file; easy to modify designs. |

| Low-Volume (50-1,000 units) | Balancing Cost & Quality | Automation keeps per-part costs down without tooling investment. |

| High-Volume (1,000+ units) | Consistency & Throughput | Machines can run 24/7, producing identical parts without failure. |

This adaptability makes CNC machining a versatile solution for businesses at any stage of growth, from startups testing a new concept to established companies launching products globally.

CNC acrylic machining is a powerful strategy for achieving both cost efficiency and production scalability. By leveraging automation and precision, it minimizes labor and material costs, making it financially viable for any project size. More importantly, its digital foundation ensures that quality remains exceptionally high and consistent, whether producing a single prototype or tens of thousands of units. This reliability gives engineers and procurement managers confidence that their production can scale without compromising their design integrity.

Partner with PTSMAKE for Superior Acrylic CNC Machining Results

Ready to unlock precision, quality, and cost efficiency for your acrylic CNC machining projects? Contact PTSMAKE today for a fast, competitive quote—our expert team delivers consistent, high-quality results, from prototyping to production, tailored to your business needs. Let’s drive your innovations forward—send us your inquiry now!

Click here to understand the core chemical properties that make this material so versatile for CNC machining. ↩

Understand how material stress concentration leads to failure and how to design around it effectively. ↩

Understand how these microscopic surface peaks and valleys impact light reflection and the overall clarity of your acrylic parts. ↩

Understand how this property impacts material behavior during machining to prevent heat-related defects. ↩

Learn more about how this optical method reveals hidden stress in transparent materials before they cause component failure. ↩

Understand the science of how materials break down under light and why acrylic is built to last. ↩

Learn why this material property is critical for ensuring your prototype performs as expected under stress. ↩

Learn more about how this critical property affects light behavior and material selection for your optical designs. ↩

Learn more about the chemical structure of PMMA and how it influences its unique material properties for machining. ↩

Learn more about how optimizing machine movements can reduce machining time and improve the surface finish of your parts. ↩