Finding the right CNC machining partner in Perth can feel overwhelming. You’re dealing with tight deadlines, quality concerns, and the pressure to stay within budget while ensuring your parts meet exact specifications.

This complete guide covers everything you need to know about CNC machining in Perth, from evaluating suppliers and avoiding delays to managing complex projects and hidden costs effectively.

I’ve worked with manufacturing teams across Perth for over 15 years, and I understand the challenges you face when sourcing precision parts. This guide will walk you through proven strategies that help you make better decisions, reduce risks, and build reliable supplier relationships that deliver results every time.

Ultimate Checklist for Evaluating CNC Machining Services in Perth

Choosing the right partner for CNC machining services in Perth is a critical decision. A mistake here can lead to costly delays and quality failures. This guide provides a clear checklist. It will help you systematically evaluate potential suppliers.

I’ll focus on the essentials: quality standards, certifications, and technology. A thorough evaluation is the best way to reduce project risks. It ensures you find a reliable partner for your precision components.

Core Evaluation Areas

| Criteria | Importance | What It Means for You |

|---|---|---|

| Quality Standards | High | Ensures consistent, reliable parts. |

| Technology Level | High | Affects precision, speed, and cost. |

| Certifications | Medium | Verifies commitment to standards. |

A quality management system is more than a paper certificate. It shows a company’s daily commitment to excellence. When I evaluate CNC machining services, I look past the ISO 9001 certification. I ask specific questions about their process controls.

How do they maintain consistency across a large production run? This is where technology becomes crucial. Advanced CNC machines are powerful, but they require skilled operators and up-to-date software to perform at their best. Always ask about their CAD/CAM systems.

Also, check for material traceability. Knowing the origin and specifications of your raw materials is essential. This is especially true for demanding industries. A top-tier shop uses Statistical Process Control1 to monitor its processes in real-time. This approach prevents defects before they occur. It is a key indicator of a mature manufacturing partner when you evaluate CNC machining in Perth.

Key Technology Questions

| Technology Aspect | Key Question |

|---|---|

| Machinery | What types of CNC machines do you operate (3, 4, or 5-axis)? |

| Software | Which CAD/CAM software platforms are you proficient in? |

| Inspection | What metrology equipment (e.g., CMM) do you use for quality assurance? |

A structured evaluation of a CNC machining service in Perth is essential. By focusing on quality systems, certifications, and technology, you can mitigate risks. This ensures you partner with a supplier capable of delivering the precision and reliability your project demands.

How to Avoid Costly Delays with Your Perth CNC Machining Partner

Delivery delays are a common headache. They disrupt your production schedule and increase costs. The problem isn’t just one late part. It’s a chain reaction of missed deadlines.

However, you can prevent most delays. The key is proactive management. It starts with clear communication and realistic planning with your Perth CNC machining partner from day one. This simple shift ensures a smoother process.

The Proactive vs. Reactive Approach

| Proactive Management | Reactive Management |

|---|---|

| Sets clear milestones | Hopes for the best |

| Includes buffer time | Scrambles when issues arise |

| Vets supplier reliability | Deals with surprises |

Vetting for Reliability and Speed

To avoid CNC machining delays in Perth, you must verify your partner’s reliability. Don’t just take their word for it. Ask for their on-time delivery statistics. Also, ask for references from current clients in similar industries. A truly reliable CNC machining Perth partner will be transparent with this information.

At PTSMAKE, we encourage clients to ask these tough questions. It builds trust and sets expectations.

Key Questions for Potential Partners

| Category | Question |

|---|---|

| Capacity | What is your current machine availability? |

| Experience | Can you share case studies for similar parts? |

| Process | How do you communicate project status? |

| Contingency | What is your plan for unexpected issues? |

Planning for the Unexpected

Even the best plans can face issues. Material shortages or machine downtime can happen. That’s why building a buffer into your timeline is critical. This buffer isn’t just "extra time." It’s a strategic cushion that absorbs minor setbacks without derailing the entire project.

We also find that understanding a supplier’s lead time variability2 is crucial. Consistent delivery performance, even if slightly longer, is better than a supplier who is sometimes fast but often late. This predictability allows for much better planning. This approach is fundamental for fast delivery CNC machining in Perth.

Proactive management is essential to prevent costly delays. By setting clear timelines, thoroughly vetting your Perth CNC machining partner for reliability, and strategically planning for contingencies, you ensure your project stays on track for fast, on-time delivery.

The Complete Guide to Tight Tolerance CNC Machining in Perth

Why Tight Tolerances Are Non-Negotiable

In precision engineering, tolerances define success. For components in aerospace or medical devices, there is no room for error. Tight tolerances ensure parts fit perfectly and function reliably.

This precision prevents premature wear and system failure. Achieving this level of accuracy is the core of high-precision CNC in Perth. It separates standard parts from high-performance components.

Below is a simple comparison of standard vs. tight tolerances.

| Feature (e.g., Hole Diameter) | Standard Tolerance (ISO 2768-m) | Tight Tolerance (Custom) |

|---|---|---|

| 10mm Steel Pin | ±0.1 mm | ±0.01 mm |

| 50mm Aluminum Block Length | ±0.3 mm | ±0.025 mm |

This showcases the demand for expert cnc machining perth services.

How Perth Suppliers Achieve Precision

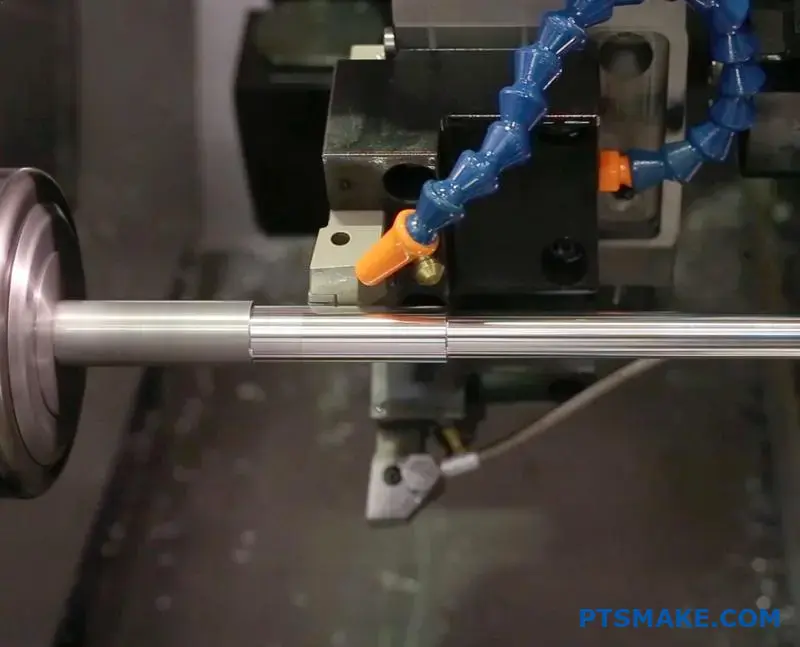

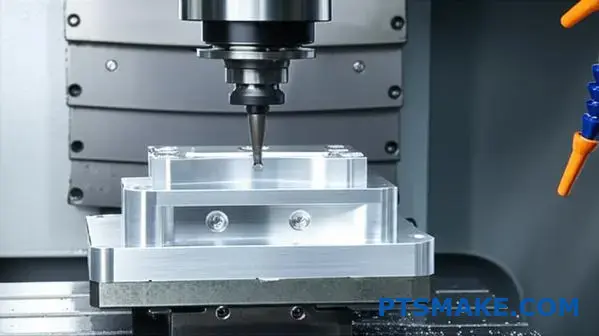

Achieving tight tolerances isn’t about one single action. It is a systematic process combining advanced technology, skilled operators, and a controlled environment. High-end multi-axis CNC machines provide the foundation for this precision.

However, the machine is only part of the equation. At PTSMAKE, we know that consistent quality control is crucial. This involves regular machine calibration and advanced inspection tools. It ensures that every part meets the exact specifications required by our clients.

Key Factors in Achieving Tight Tolerances

- Machine Capability: Using well-maintained, high-resolution CNC machines.

- Material Stability: Understanding how materials expand or contract with temperature.

- Cutting Tools: Selecting the correct tool and monitoring it for wear.

- Operator Skill: Experienced machinists who can adjust for minor variations.

The process of Metrology3 is central to verifying these outcomes. We use Coordinate Measuring Machines (CMMs) to confirm every dimension. This detailed verification is standard for any project involving tight tolerance CNC machining in Perth.

The table below outlines how these factors impact precision.

| Factor | Influence on Tolerance | Mitigation Strategy |

|---|---|---|

| Temperature Fluctuation | Material expansion/contraction | Climate-controlled workshop |

| Tool Wear | Gradual loss of accuracy | Automated tool monitoring |

| Machine Vibration | Surface finish imperfections | Rigid machine construction |

This disciplined approach ensures that CNC machining tolerances in Perth suppliers meet global standards.

Achieving tight tolerances requires advanced machinery, meticulous processes, and rigorous quality control. This combination ensures components function flawlessly in critical applications, making it a key focus for any high-precision CNC Perth supplier.

Secrets to Sourcing High-Quality CNC Parts from Perth Suppliers

When you source CNC parts from Perth, the initial quote is only part of the story. The real cost appears when a part fails. Investing in quality upfront is the smartest financial decision. It saves you from expensive rework and delays.

The First Secret: Material Verification

Never assume the material is correct. Always ask for material certifications. Reputable suppliers provide these without hesitation. This is a key step in CNC machining quality control in Perth.

Why Certifications Matter

Without proof, you’re relying on trust alone. A simple mix-up in material grades can lead to catastrophic failures in the final product.

| Verification Method | Risk Level Without It | Cost Impact |

|---|---|---|

| Material Certificates | High | Potential for full recall |

| XRF Testing | Medium | Rework and testing costs |

| Hardness Testing | Medium-Low | Field failures, warranty claims |

The Second Secret: A Transparent Inspection Process

Quality isn’t just checked at the end. It’s built into every step. A top-tier Perth supplier should have a clear and documented quality control process. Ask to see it. This transparency builds trust.

You should understand their inspection points. This includes first-article inspection (FAI), in-process checks, and a final inspection report. This ensures consistency from the first part to the last. For any serious project involving cnc machining perth services, this is non-negotiable.

Key Inspection Stages

Effective quality control isn’t a single event. It’s a continuous process that ensures every specification is met. We rely on a system that tracks parts from raw material to final shipment, ensuring complete Material Traceability4 for every component produced.

This multi-stage approach catches potential issues early, which is far more cost-effective than finding a problem in a finished batch.

| Inspection Type | Purpose | When It’s Done |

|---|---|---|

| First Article Inspection | Verifies setup and tooling | Before the main production run |

| In-Process Inspection | Monitors consistency | During production |

| Final Inspection | Confirms all specs are met | Before shipping |

The Third Secret: Clear Testing Protocols

How will the part be tested? This needs to be defined before production starts. Discuss functional tests, pressure tests, or specific geometric checks. Agreeing on the testing methods and acceptance criteria prevents disputes later. A good supplier will help you define these protocols.

Ensuring high-quality CNC parts from Perth suppliers requires more than a purchase order. It demands upfront verification of materials, a transparent inspection process, and clearly defined testing protocols to prevent costly rework and ensure project success.

Top 10 Questions to Ask Before Hiring a CNC Machining Company in Perth

Finding the right CNC machining partner in Perth is critical. The right questions can separate a reliable supplier from a potential headache. I’ve prepared a list to guide your vetting process.

These questions help you assess their technical fit for your project. They also reveal their communication style and overall reliability. Asking them upfront ensures you hire a CNC machining Perth company that truly understands your needs. Let’s dive in.

Question 1: What are your machine capabilities and tolerances?

Understanding their equipment is fundamental. Do they have 3-axis, 4-axis, or 5-axis machines? This determines the complexity of parts they can produce efficiently. Also, ask for the specific tolerances they can consistently hold.

Question 2: Can you provide examples of past work?

Ask for case studies or photos of projects similar to yours. This is direct proof of their experience. It shows they’ve worked with your required materials, geometries, and industry standards before.

To make an informed decision, you need to dig deeper. Your goal is to build a partnership, not just place an order. A great CNC machining company in Perth will be transparent about their processes.

Organize your questions into three key areas. This ensures you cover all critical aspects of their operation before you commit. The right questions will clarify their expertise and process.

Assessing Technical Capabilities

Before discussing a quote, confirm their technical alignment. You must know if they can physically produce your part to spec. Misalignment here is a common source of project failure.

Their team’s proficiency with design specifications is crucial. Ask them: how do you interpret complex engineering drawings? Do your programmers and machinists fully understand systems like Geometric Dimensioning and Tolerancing (GD&T)5? This ensures design intent is not lost in production.

Below is a simple checklist for technical vetting:

| Capability Check | Ask About… | Why It Matters |

|---|---|---|

| Machinery | 3, 4, or 5-axis capabilities | Determines part complexity |

| Tolerances | Standard vs. achievable precision | Ensures parts meet functional needs |

| Materials | Experience with your specified metals/plastics | Reduces risk of material-related defects |

| Software | CAD/CAM software compatibility | Guarantees seamless file transfer |

Evaluating Experience and Communication

Experience goes beyond machinery. Ask about their quality management system (e.g., ISO 9001). A strong quality process reduces errors.

Finally, evaluate their communication protocol. A dedicated point of contact is essential for smooth project execution. Clear communication prevents costly misunderstandings down the line.

Asking targeted questions about capabilities, experience, and communication is vital. This structured approach helps you vet a CNC machining company in Perth thoroughly, ensuring they can meet your technical needs and function as a reliable partner for your business.

A Step-by-Step Guide to Maintaining Quality Consistency

Achieving consistent quality in CNC machined components isn’t magic. It is a result of a strict, repeatable system. Long-term partnerships are built on trust. That trust comes from knowing every part will be the same.

Here is a simple guide we follow.

Step 1: Implement Statistical Process Control (SPC)

We use SPC to monitor our production process in real-time. This helps us catch potential issues before they become defects. It’s about proactive control.

Step 2: Conduct Regular Audits

Regular internal and external audits are vital. They verify that our processes meet the required standards. This is a core part of our quality assurance in Perth.

Step 3: Standardize Everything

Standard Operating Procedures (SOPs) ensure every team member performs tasks the same way, every time. This removes variation and guarantees consistent results for every project.

Consistency is the foundation of trust in manufacturing. Simply inspecting parts at the end is not enough. A truly reliable partner builds quality into every step of the process. This commitment is what separates acceptable parts from exceptional ones.

The Proactive Approach to Quality

Reactive quality control, like final inspection, only catches mistakes after they’ve been made. This wastes time and materials. A proactive approach, however, prevents defects from happening in the first place. This is where tools like Statistical Process Control6 become essential for any serious Perth CNC machining service. It uses data to understand process capability and stability. This tells us if a process can consistently produce parts within specification.

Regular audits support this proactive mindset. They aren’t about blame. They are opportunities to refine and improve our systems.

| Method | Approach | Goal |

|---|---|---|

| Final Inspection | Reactive | Find defects in finished parts |

| In-Process Checks | Active | Find defects during production |

| SPC & Audits | Proactive | Prevent defects from occurring |

By focusing on proactive measures, we ensure that the quality of CNC machined components Perth clients receive is reliable from the first piece to the ten-thousandth. This is fundamental to building lasting partnerships.

A disciplined system combining proactive tools like SPC with regular process audits is non-negotiable. This approach doesn’t just catch errors—it prevents them, ensuring reliable, high-quality components and building the trust needed for strong, long-term partnerships.

The Ultimate Comparison: Local vs. International CNC Machining in Perth

Choosing a CNC machining partner is a major decision. For businesses in Perth, the choice often comes down to local versus international suppliers. This isn’t just about location.

It’s a strategic choice. It impacts your project’s cost, timeline, and logistics. Each option has clear benefits. The right choice depends entirely on your specific needs. Let’s break down this crucial CNC machining comparison for Perth companies.

Making the right sourcing decision requires a clear-eyed look at the trade-offs. There is no single "best" answer. A local Perth supplier might be perfect for a rapid prototype. An international partner might be better for a large production run.

It’s about aligning the supplier’s strengths with your project’s priorities. You need to consider more than just the price per part. You must factor in shipping, communication, and quality assurance. Overlooking these can lead to unexpected costs and delays.

A key factor for international sourcing is the total Landed Cost7. This includes not just the manufacturing price but also shipping, tariffs, and customs fees. At PTSMAKE, we help clients navigate these logistics smoothly.

This side-by-side comparison should clarify your decision.

CNC Machining Comparison: Perth Local vs. International

| Feature | Local CNC Machining Perth | International CNC Machining (e.g., China) |

|---|---|---|

| Cost | Higher unit prices. Fewer shipping costs. | Lower unit prices, especially at scale. |

| Lead Time | Very fast for prototypes and small batches. | Longer overall due to international shipping. |

| Communication | Simple. Same time zone and language. | Can involve time zone differences. |

| Logistics | Minimal. Local pickup or delivery. | Complex. Involves customs, freight, and duties. |

| Oversight | Easy to visit the facility for quality checks. | Relies on strong communication and trusted partners. |

This table shows the primary differences. Choosing a local supplier offers speed and simplicity. International options provide significant cost advantages for larger projects.

The choice between local and international CNC machining in Perth hinges on your project’s specific needs. Balance cost, speed, communication, and logistics to find the right partner for your goals. The best decision is an informed one.

Step-by-Step Guide to Managing CNC Machining Projects in Perth

Effectively managing CNC machining projects in Perth requires a clear framework. This structure turns a complex task into manageable steps. It ensures clarity from design to delivery.

A solid plan prevents delays and cost overruns. It aligns your team with the manufacturing partner. Below is a simple, chronological guide to follow.

The Core Project Phases

This framework breaks down the CNC machining process Perth relies on.

| Phase | Key Milestone | Best Practice |

|---|---|---|

| 1. Design | Finalized CAD Model | DFM Review |

| 2. Quoting | Approved Quote | Detailed Cost Breakdown |

| 3. Production | First Article Inspection | Regular Updates |

| 4. Delivery | Final QA Check | Secure Packaging |

This approach streamlines project flow. It makes managing CNC projects much easier.

Successful CNC project management in Perth hinges on detail and communication. A structured process removes guesswork and builds trust between you and your supplier. It’s about creating a predictable path to a high-quality finished part.

From Design to Delivery

The initial step is a Design for Manufacturability (DFM) review. We at PTSMAKE always perform this check. It helps identify potential issues before any metal is cut. This simple step can save significant time and money. It ensures the design is optimized for efficiency.

Clear specifications are also critical. Using a system like Geometric Dimensioning and Tolerancing (GD&T)8 leaves no room for error. It is the precise language of engineering. It ensures every feature on your part meets exact requirements.

Communication Best Practices

Consistent communication is the backbone of successful CNC project management. It prevents surprises and keeps everyone aligned.

| Communication Type | Frequency | Purpose |

|---|---|---|

| Kick-off Meeting | Once | Align on goals and timeline |

| Progress Updates | Weekly | Share status and address issues |

| Milestone Review | Per Milestone | Confirm key stages are complete |

| Final Sign-off | At Delivery | Formal project acceptance |

This proactive communication strategy is a core part of the CNC machining process Perth businesses should adopt for better outcomes.

A structured framework from design to delivery is essential. Clear milestones and consistent communication simplify the entire CNC machining process. This approach minimizes risks and ensures your Perth project is completed successfully, on time, and within budget.

Critical Factors for Choosing a Reliable CNC Machining Partner in Perth

Finding the right CNC machining partner in Perth is critical. Your project’s success hinges on their reliability. It’s more than just getting parts made.

It’s about trust in their process.

I focus on three core factors. These are reputation, technical skill, and customer support. A reliable partner excels in all three areas. This ensures your project stays on track.

Reputation as a Foundation

A good reputation is earned over time. Look for consistent positive feedback. Check for industry certifications and client testimonials.

Technical Expertise Matters

Expertise guarantees quality. A skilled team understands materials and complex designs. They use the right tools for the job.

The Role of Customer Support

Strong support means clear communication. Your partner should be responsive and proactive. They help solve problems before they escalate.

Key Reliability Indicators

| Factor | What to Look For | Red Flags |

|---|---|---|

| Reputation | Long-standing business, ISO 9001 | Poor online reviews, no case studies |

| Expertise | Advanced machinery, skilled engineers | Outdated equipment, limited material knowledge |

| Support | Proactive updates, dedicated contact | Slow responses, communication barriers |

When you choose a CNC machining partner in Perth, you’re investing in a relationship. A truly reliable one acts as an extension of your own team, safeguarding your project’s outcome.

Diving Deeper into Technical Prowess

Technical expertise is non-negotiable. It’s the difference between a part that works and one that fails. Look for a partner who offers Design for Manufacturability (DFM) feedback. This saves time and money.

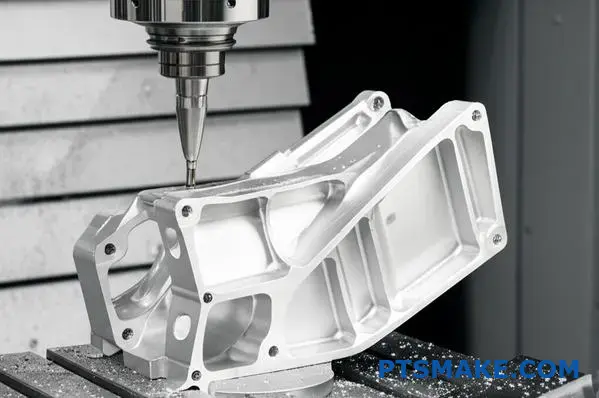

Their engineers should understand the nuances of different materials. They must be proficient in advanced techniques. This includes multi-axis machining for complex geometries.

At PTSMAKE, our process includes a thorough DFM review. This helps us catch potential issues early. We ensure every design is optimized for production. This deep understanding of Geometric Dimensioning and Tolerancing9 is fundamental. It guarantees parts meet exact specifications.

The True Value of Proactive Support

Excellent customer support is about more than answering emails. A reliable CNC machining partner offers transparency. They provide regular updates without you having to ask.

Think about it. When a potential issue arises, do they hide it or call you with a solution? Proactive problem-solving is a key sign of a trustworthy partner. It shows they are committed to your success.

Impact of Customer Support on Projects

| Support Level | Communication Style | Project Outcome |

|---|---|---|

| Excellent | Proactive, Transparent, Solution-Oriented | On-time delivery, meets specs, low stress |

| Poor | Reactive, Vague, Blame-Oriented | Delays, quality issues, high frustration |

Choosing a reliable CNC machining partner in Perth means evaluating these factors together. They form the foundation of a successful manufacturing partnership.

A reliable CNC machining partner combines a solid reputation, deep technical knowledge, and excellent customer support. This trifecta is essential for ensuring your project’s success and achieving high-quality results without costly delays or communication issues.

How to Reduce Lead Times with Efficient CNC Machining in Perth

In Perth’s competitive market, speed is crucial. Reducing CNC machining lead times directly boosts your time-to-market.

This isn’t about rushing. It’s about working smarter from the very beginning. We focus on two key areas: design optimization and supplier collaboration.

Simple changes in these areas yield significant results. This approach helps deliver parts faster without compromising on quality.

| Tactic | Potential Time Saving |

|---|---|

| Simplified Geometry | 15-20% |

| Standardized Materials | 10-15% |

| Early Supplier Input | 20-30% |

Optimizing Your Design for Speed

Effective design is the foundation for efficient CNC machining in Perth. Small adjustments during the design phase can prevent major delays during production. It is the most direct way to reduce lead times.

Simplify Your Geometry

Complex designs mean more machine time. They often require custom tooling, which adds days or even weeks to your timeline. Small adjustments can make a big impact. Increasing internal corner radii, for example, allows for faster machining.

Standardize Components and Materials

Using common materials and standard components is a smart move. Your supplier likely has them in stock, which eliminates sourcing delays. We often guide clients towards materials that meet performance needs and are readily available.

The Power of Supplier Collaboration

Treat your supplier as a partner, not just a vendor. Early and clear communication is essential for any fast CNC machining Perth project.

Involve Your Partner Early

Don’t just send a finished CAD file and wait. Discuss your project with your CNC machining partner during the design phase. At PTSMAKE, we provide input that makes parts easier and faster to produce.

This includes providing clear drawings. Precise specifications using systems like Geometric Dimensioning and Tolerancing (GD&T)10 are crucial. When we get clear specs early, setup time is drastically reduced, preventing costly redesigns later.

To reduce lead times for CNC machining in Perth, focus on two things. First, optimize your design for manufacturability. Second, collaborate closely with your supplier from the beginning. This strategic partnership is the fastest path from design to finished part.

The Hidden Costs of CNC Machining in Perth and How to Avoid Them

The initial quote for your CNC machining project in Perth is just the starting point. Hidden costs often appear later, disrupting your budget. These surprises usually come from tooling changes and rework.

Understanding these potential expenses upfront is the best defence. It helps you plan better and avoid unexpected budget increases. Let’s break down where these costs hide.

Common Unforeseen Costs

Tooling wear isn’t always factored into the initial price. Rework from minor design flaws can also add up quickly. Awareness is the first step to control.

| Hidden Cost | Primary Cause |

|---|---|

| Tooling Replacement | Abrasive materials or complex geometries wearing tools faster than expected. |

| Rework & Revisions | Unclear technical drawings or minor design misinterpretations. |

| Setup Time Increase | Last-minute design changes requiring new fixture setups. |

These factors can inflate your final invoice if not managed proactively.

Beyond the obvious, some costs are deeply embedded in the machining process. Proactive communication and detailed planning are your best strategies to mitigate them. It’s about creating a partnership with your machining shop.

Deeper Dive into Cost Drivers

Tooling costs can escalate with hard-to-machine materials. For instance, materials like Inconel or Titanium cause rapid tool wear. This means more frequent tool changes, which add both time and direct costs to the project. We advise clients on material selection to balance performance with manufacturability. This is a key part of achieving CNC machining cost savings in Perth.

Rework is another major financial drain. It often stems from small ambiguities in the design files. An unclear tolerance or a missing fillet callout can lead to parts that don’t pass inspection. This is where subtle issues like tolerance creep11 can emerge during a production run, causing entire batches to fail quality control.

Strategies to Avoid Hidden Costs

To avoid CNC machining costs in Perth, a detailed Design for Manufacturability (DFM) review is essential. At PTSMAKE, we conduct this review before any machining begins.

| Problem Area | Mitigation Strategy |

|---|---|

| Ambiguous Drawings | Mandatory pre-production meeting to clarify all specifications. |

| Rapid Tool Wear | Material consultation and selecting the optimal cutting tools and parameters. |

| Mid-production Changes | A clear change order process with transparent cost impact analysis. |

This process ensures everyone is aligned, significantly reducing the risk of expensive rework later.

Unexpected costs like tooling and rework can derail a project’s budget. Proactive communication, detailed design reviews, and a clear understanding of material properties are essential for effective cost management in CNC machining projects.

Best Practices for Communicating with Perth CNC Machining Vendors

Effective communication with your CNC machining vendor is more than just sending an email. It requires a clear, agreed-upon protocol. This ensures everyone is on the same page.

Clear protocols prevent misunderstandings. They reduce errors and keep your project on schedule. Good communication is the foundation of successful vendor management in Perth.

Let’s explore some best practices with real-world scenarios.

Initial RFQ and Quoting

When you request a quote, provide comprehensive information. This includes 3D CAD files, 2D drawings with tolerances, material specifications, and desired quantity. A vague request leads to a vague quote.

Mid-Project Design Changes

If a design change is needed, document it formally. An email should be followed by an updated drawing and a formal change order request. This avoids confusion and potential rework.

To truly improve how you communicate with CNC vendors in Perth, you need to establish protocols before the project even starts. It’s about creating a predictable and clear framework for all interactions. This moves your partnership from reactive to proactive.

Establish a Single Point of Contact

Assign a dedicated project manager on your side and request the same from your vendor. This prevents mixed messages and ensures accountability. All official communication should flow through these two individuals. This simple step is crucial for effective CNC machining communication in Perth.

Use a Centralized Documentation System

Relying on scattered emails is a recipe for disaster. Use a shared folder (like Dropbox or Google Drive) for all project files. This includes drawings, purchase orders, and meeting notes. Every revision should have a clear version number and date.

At critical stages, a formal sign-off process is essential. This step, sometimes called a Tollgate Review12, ensures both parties agree on the progress and next steps before committing more resources.

Here is a simple comparison:

| Scenario | Ineffective Communication | Best Practice Protocol |

|---|---|---|

| Material Change | A quick phone call to the shop floor. | Formal email to the project manager, followed by an updated PO. |

| Progress Check | Random emails asking "how’s it going?" | Scheduled weekly 15-minute check-in call with a shared agenda. |

| Quality Issue | A frustrated email with a blurry photo. | A detailed non-conformance report with clear photos and measurements. |

By implementing these protocols, you build a system of clarity. This system protects both you and your CNC machining Perth partner from costly errors.

Establishing clear communication protocols is not about adding bureaucracy. It’s about creating a reliable system that minimizes risk, prevents costly mistakes, and builds a stronger, more efficient partnership with your Perth CNC machining vendor.

Essential Tips for Prototyping with CNC Machining in Perth

Prototyping is a critical step in product development. It allows you to test form, fit, and function before committing to mass production.

Effective CNC prototyping in Perth reduces risks. It helps you find and fix design flaws early. This saves significant time and money down the line.

Key Prototyping Considerations

Here are my essential tips. We’ll cover material selection, iteration planning, and cost control for your projects. These principles are key to success.

| Factor | Early-Stage Prototype | Late-Stage Prototype |

|---|---|---|

| Goal | Validate concept, basic fit | Test function, pre-production |

| Material | Lower-cost, easy to machine | Production-intent material |

| Tolerance | Looser | Tighter, close to final spec |

| Cost | Low | Higher |

Effective prototyping is more than just making a part. It’s a strategic process. Getting it right ensures a smoother transition to the final product. Let’s break down some key tips for CNC prototyping Perth.

Smart Material Selection for Prototypes

Choosing the right material is crucial. For early-stage models, you don’t always need the final production material. A lower-cost alternative that mimics key properties often works well.

This approach validates the design without high upfront costs. For instance, using Aluminum 6061 instead of a more expensive steel alloy can be a smart move for initial functional tests.

| Material | Common Use Case | Key Benefit |

|---|---|---|

| ABS Plastic | Form and fit testing | Low cost, easy to machine |

| Aluminum 6061 | Functional prototypes | Good strength-to-weight ratio |

| Stainless Steel | Pre-production validation | High strength, corrosion resistant |

Strategic Iteration and Cost Management

Plan for multiple iterations from the start. Each prototype should have a clear goal. This avoids trying to perfect everything in one go, which is often inefficient.

For early prototypes, simplify the design. Focus only on the critical features you need to test. This reduces machining time and cost. Applying principles of Design for Manufacturability (DFM)13 early on is a powerful cost-control strategy we use at PTSMAKE. This is one of the most vital tips for CNC prototyping Perth projects.

Successful prototype CNC machining in Perth relies on smart planning. By carefully selecting materials, planning iterations, and designing for cost-effectiveness, you de-risk your project. This approach paves a clear and efficient path from concept to production-ready part.

How to Handle Complex Geometries with Perth CNC Machining Experts

Handling intricate designs is a major challenge in our field. It requires more than just good equipment. Expertise in handling complex geometries CNC Perth is essential for success.

The Digital Bridge: CAD/CAM Integration

We start with a solid digital foundation. CAD/CAM software translates complex designs into precise machine instructions. This integration is crucial for accuracy and repeatability on every project.

Machining Approaches

| Method | Complexity Level | Primary Use |

|---|---|---|

| 3-Axis CNC | Low to Medium | Prismatic Parts |

| 5-Axis CNC | High | Contoured Surfaces |

This advanced approach ensures every detail of the digital model is perfectly replicated in the physical part.

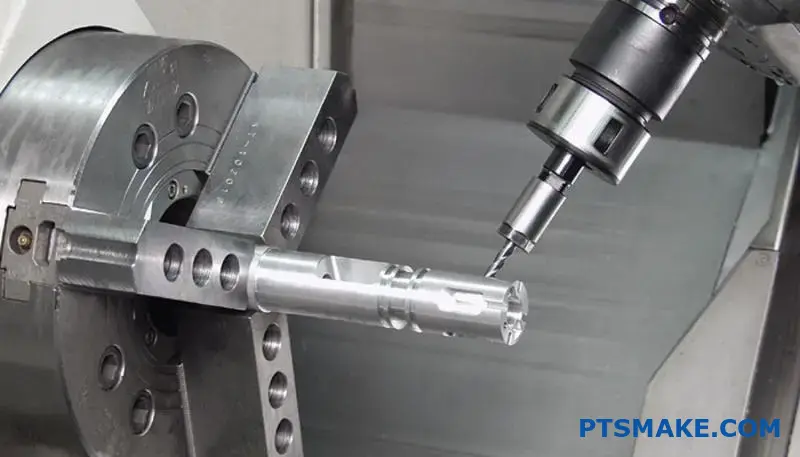

Unleashing Multi-Axis Capabilities

For truly complex parts, we rely on multi-axis CNC machines. These machines move a tool or part on four or five axes simultaneously. This is a game-changer for CNC machining complex parts Perth.

Unlike traditional 3-axis machines, 5-axis systems can approach a workpiece from any direction. This capability eliminates the need for multiple setups. Fewer setups mean higher accuracy and faster cycle times for our clients.

Key Advantages of Multi-Axis CNC

| Feature | Benefit for Complex Geometries |

|---|---|

| Simultaneous Motion | Machines undercuts and angled features in one go. |

| Single Setup | Reduces tolerance stack-up and human error. |

| Shorter Tools | Allows higher cutting speeds and better surface finish. |

| Optimized toolpath14 | Creates smoother, more efficient cutting motions. |

At PTSMAKE, our expertise in multi-axis CNC Perth allows us to tackle designs that others find impossible. We program the machine to follow the most efficient path. This precision is fundamental to our cnc machining perth services. We ensure the final part perfectly matches the client’s CAD model.

In summary, machining complex geometries demands a blend of advanced technology and deep expertise. Seamless CAD/CAM integration and the strategic use of multi-axis CNC systems are essential for achieving precision, efficiency, and superior quality in every part we produce.

Get Reliable CNC Machining in Perth—Partner With PTSMAKE Now!

Ready to secure precision CNC machining solutions in Perth? Contact PTSMAKE for an immediate quote and experience our next-generation quality, on-time delivery, and expert support from prototype to production. Let us exceed your expectations and eliminate your CNC manufacturing worries—submit your inquiry now!

Learn how SPC uses data to improve manufacturing quality and reduce costs in our detailed guide. ↩

Learn how this key metric can help you predict and manage your project timelines more effectively. ↩

Learn about the science of measurement and its role in quality assurance. ↩

Learn how this ensures your parts meet regulatory standards and quality benchmarks from raw stock to finished product. ↩

Learn how this symbolic language ensures your design intent is perfectly translated into a physical part. ↩

Explore how this data-driven method ensures quality from the very first part to the last. ↩

Learn how to calculate the true cost of importing your CNC machined parts. ↩

Understand how this engineering standard ensures your parts meet exact specifications and quality. ↩

Understand how this system ensures your design intent is perfectly translated into a physical part. ↩

Understand how GD&T can eliminate ambiguity, leading to faster and more accurate manufacturing. ↩

Discover how managing this factor is crucial for maintaining part consistency and avoiding budget overruns. ↩

Learn how formal project gates can improve project outcomes and prevent budget overruns in manufacturing. ↩

Learn how DFM principles optimize designs for efficient manufacturing and lower production costs. ↩

Learn how optimizing the cutter’s path can significantly reduce your machining costs and improve part quality. ↩