Choosing the wrong aluminum finish can destroy your product’s professional image and increase production costs by 30%. Many engineers discover too late that their surface finish decision impacts everything from manufacturing complexity to end-user perception, leading to costly redesigns and delayed launches.

Brushed aluminum offers superior durability, cost-effectiveness, and aesthetic appeal compared to polished finishes, making it the preferred choice for industrial applications requiring both functional performance and premium visual quality.

This comprehensive guide covers everything from CNC machining considerations to industry-specific applications, helping you make informed decisions about brushed aluminum finishes for your next project.

What Every Engineer Must Know About Brushed Aluminum Finishes

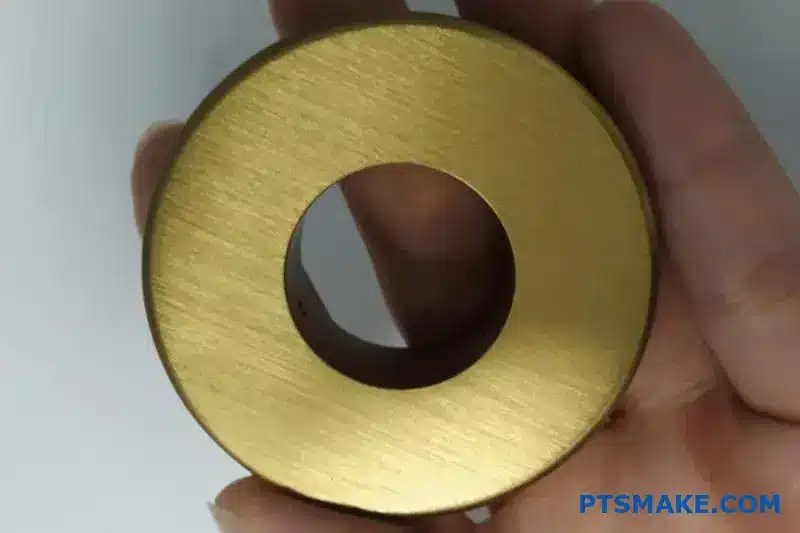

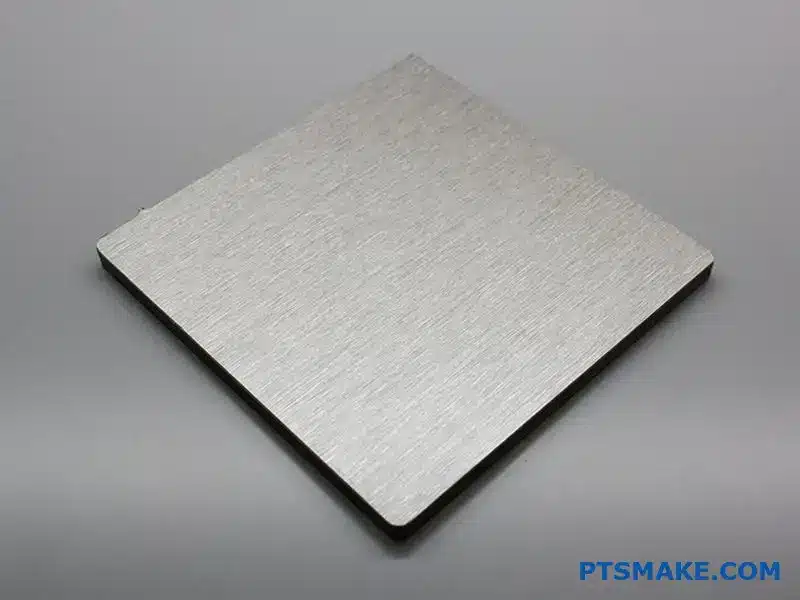

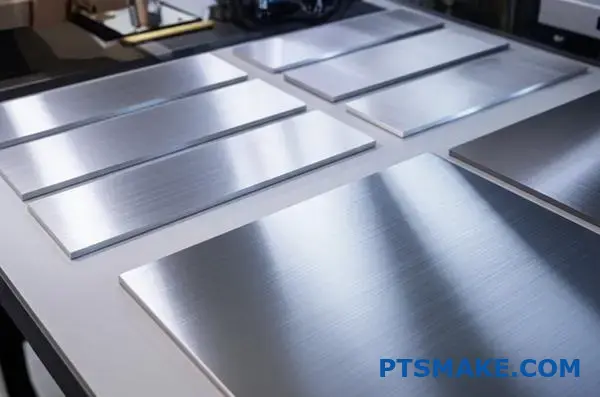

Brushed aluminum is a very common surface finish. You see it on everything from laptops to kitchen appliances. Its signature look comes from fine, parallel lines.

This gives the metal a distinctive satin texture.

The Brushing Process

This finish is created mechanically. An abrasive material, like a wire brush or belt, is used. It scours the aluminum surface in one direction. This creates the characteristic brushed pattern.

Key Characteristics

The result is both functional and stylish. It is a popular choice for many industrial aluminum finishes.

| Attribute | Description |

|---|---|

| Look | Satin, non-reflective |

| Feel | Textured, with fine lines |

| Effect | Hides minor surface defects |

Why It’s a Go-To for Industrial Design

Engineers choose brushed aluminum for several key reasons. It masterfully balances aesthetics with practicality. This makes it a highly versatile option for many applications.

Aesthetic Appeal

The finish offers a clean, modern, and high-tech appearance. It diffuses light, which reduces glare and hides fingerprints. This is a major advantage for consumer-facing products. The uniform lines create a sense of precision and quality.

Functional Advantages

Beyond looks, this finish is durable. The fine lines help conceal minor scratches and wear that occur over time. This extends the product’s aesthetic lifespan. Applying this finish to the aluminum substrate is also a cost-effective way to achieve a premium look without expensive plating or coating processes. At PTSMAKE, we often recommend it for parts that require a robust yet refined surface.

| Industry | Common Application | Primary Reason |

|---|---|---|

| Electronics | Laptop cases, audio equipment | Premium feel, hides fingerprints |

| Automotive | Interior trim, dashboard panels | Durability, modern style |

| Architecture | Wall panels, fixtures | Low maintenance, aesthetic consistency |

Brushed aluminum is a directional satin finish created through an abrasive process. It offers a modern aesthetic and functional durability, effectively hiding minor imperfections. This balance makes it a top choice for various industrial and consumer product applications.

Brushed Vs. Polished Aluminum: Which Finish Is Better For Your Product?

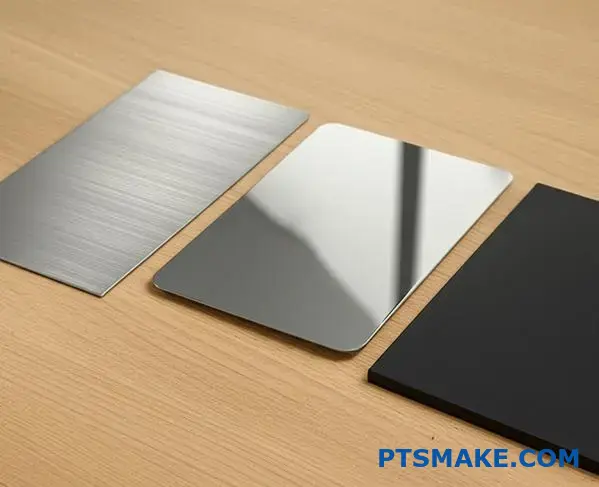

Choosing the right aluminum finish is a critical decision. It impacts your product’s look, feel, and performance. Both brushed and polished finishes have distinct advantages.

This choice often comes down to balancing aesthetics with practicality. Brushed aluminum offers a modern, subtle look. It’s also great at hiding minor imperfections. Polished aluminum provides a brilliant, mirror-like shine. It makes a strong visual statement. Let’s compare them directly.

| Feature | Brushed Aluminum | Polished Aluminum |

|---|---|---|

| Look | Satin, matte | Mirror-like, shiny |

| Feel | Textured | Smooth |

| Maintenance | Low | High |

Let’s dive deeper into the brushed aluminum vs polished aluminum debate. The best choice depends entirely on your product’s application and target market.

Durability and Maintenance

Brushed aluminum is a workhorse. Its fine, parallel lines are excellent at concealing fingerprints, smudges, and small scratches. This makes it ideal for high-touch surfaces. Think kitchen appliances or automotive trim. It requires minimal upkeep to look good.

Polished aluminum, on the other hand, is high-maintenance. Its reflective surface shows every fingerprint and scratch. It demands regular cleaning to maintain its pristine look. While beautiful, it’s less practical for items handled frequently. The polishing process itself can make the surface slightly more susceptible to showing wear. This is due to its flawless, uniform nature where any new mark stands out. This finish creates a visually anisotropic1 surface.

Cost and Production

From a manufacturing standpoint at PTSMAKE, a brushed finish is generally more cost-effective. The process is less labor-intensive. Polishing aluminum requires multiple stages of sanding and buffing. This increases labor and material costs, often significantly.

Common Use Cases

| Application | Recommended Finish | Why? |

|---|---|---|

| Consumer Electronics | Brushed Aluminum | Hides fingerprints, modern look |

| Architectural Trim | Brushed Aluminum | Low maintenance, elegant |

| Luxury Automotive Parts | Polished Aluminum | High-impact, premium feel |

| Decorative Items | Polished Aluminum | Creates a "wow" factor |

Ultimately, the decision between brushed and polished aluminum depends on your priorities. Brushed offers a practical, durable, and cost-effective solution with a modern aesthetic. Polished delivers a high-end, reflective look for products where visual impact is paramount.

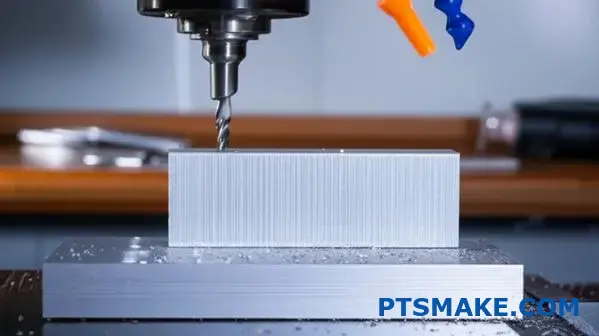

The Complete Guide To CNC Machining Brushed Aluminum Components

Machining brushed aluminum requires a specific approach. The pre-finished surface is the main consideration. Every step, from tool choice to feed rates, must protect this delicate finish. It’s a balance of precision and care.

Key Machining Techniques

Proper technique is crucial for success. High speeds and sharp tools are essential. This minimizes heat and prevents material from sticking to the tool, ensuring clean cuts on your aluminum CNC parts.

Tool Selection and Speeds

Choosing the right tool is the first step. Coated carbide end mills are often our go-to. The coating reduces friction.

| Tool Type | Recommended Speed | Key Benefit |

|---|---|---|

| Coated Carbide | High RPM | Reduces heat buildup |

| Diamond-Coated | Very High RPM | Excellent finish, long life |

| High-Speed Steel (HSS) | Moderate RPM | Cost-effective for roughing |

Proper speeds and feeds prevent damage to the brushed surface.

Achieving Tight Tolerances

Precision aluminum machining on brushed surfaces presents unique challenges. The texture can slightly affect measurements. We always account for this during programming and inspection. Secure, non-damaging workholding is non-negotiable.

Soft jaws or custom fixtures prevent scratches. These precautions ensure the final part meets both dimensional and aesthetic specifications. A common issue we manage is the Material Buildup Edge (BUE)2, which can ruin both the tool and the part.

Common Challenges and Solutions

Even with careful planning, issues can arise. Understanding these challenges helps in creating flawless brushed aluminum components. Based on our tests, proactive measures are always best.

| Challenge | Our Solution at PTSMAKE |

|---|---|

| Burr Formation | Use sharp tools; program a final deburring pass. |

| Surface Scratches | Use protective film or soft jaws during setup. |

| Heat Distortion | Employ high-quality coolants and optimized toolpaths. |

| Inconsistent Finish | Ensure consistent coolant flow and tool sharpness. |

These steps are part of our standard process for CNC machining brushed aluminum. They help us deliver consistent, high-quality parts every time. It’s about anticipating problems before they happen.

Mastering CNC machining for brushed aluminum involves precise techniques and careful setup. Understanding tolerances and proactively addressing challenges like burrs and surface protection is key to producing high-quality, aesthetically pleasing aluminum CNC parts that meet exact specifications.

How Brushed Aluminum Enhances Product Aesthetics In Consumer Applications

Brushed aluminum is a key element in modern product design. Its distinctive texture adds a premium feel that plastic cannot replicate. This finish transforms everyday items into sophisticated pieces.

The brushed aluminum design offers more than just looks. It also provides a durable, corrosion-resistant surface. This makes it a practical choice for many consumer products. We see it used everywhere.

This finish creates a unique visual effect by reflecting light along its parallel grain lines, enhancing the product’s form.

| Product Category | Primary Aesthetic Benefit |

|---|---|

| Electronics | Sleek, high-tech appearance |

| Home Appliances | Modern, clean, and durable look |

| Automotive | Luxurious and sporty interior feel |

The right aluminum surface aesthetics can define a product’s success. The application of brushed aluminum in consumer products varies, but the goal is always to elevate the user’s perception of quality and value.

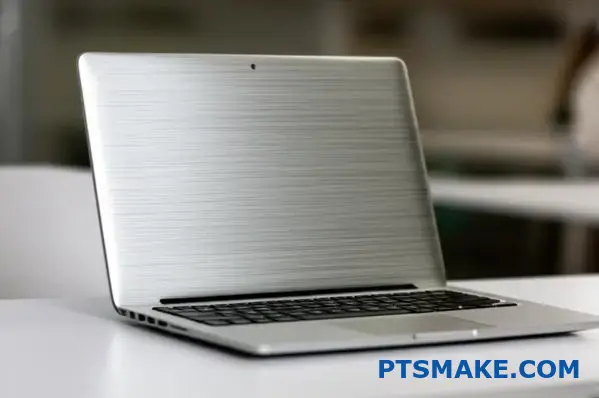

Enhancing Consumer Electronics

In electronics, this finish is iconic. Think of high-end laptops and smartphones. The brushed texture provides a tactile experience and a professional look. It also helps hide minor scratches and fingerprints.

This material choice is also functional. Aluminum is excellent for heat dissipation. This helps keep high-performance devices cool. We often assist clients in selecting the right alloy for both aesthetics and thermal management. The process often involves a surface treatment like anodization3 to add color and increase durability.

Upgrading Home Appliances

Brushed aluminum has transformed kitchen appliances. Stainless steel was once the standard, but brushed aluminum offers a softer, more modern appeal. It’s common on refrigerators, ovens, and microwaves.

This finish gives appliances a high-end feel. It resists smudges better than polished surfaces. This makes them easier to keep clean, a practical benefit for any household.

Key Benefits in Appliances

- Premium Look: Elevates the entire kitchen’s design.

- Durability: Resists scratches and corrosion effectively.

- Easy Maintenance: Less prone to showing fingerprints.

Refining Automotive Interiors

Car manufacturers use brushed aluminum to create a sense of luxury. You’ll find it on dashboards, center consoles, and door trims. It replaces plastic parts, giving the cabin a more premium and sporty feel. The specific grain direction is crucial for controlling reflections and enhancing the interior design flow.

Across electronics, appliances, and automotive interiors, brushed aluminum is not just a finish. It is a strategic design choice that adds tangible value, blending sophisticated aesthetics with practical durability and a premium user experience that we at PTSMAKE help deliver.

Why Tolerance Matters In Brushed Aluminum Machining Projects

In brushed aluminum projects, tolerance isn’t just a number. It defines how a part functions and its final cost. Tighter tolerances ensure better fit and performance.

However, this precision comes at a price.

Function vs. Cost

Achieving higher precision requires more machine time and advanced quality control. This directly impacts the budget for your precision aluminum parts.

| Tolerance Level | Functionality Impact | Cost Impact |

|---|---|---|

| Standard | Good for general use | Baseline |

| Tight | Critical for assembly | Higher |

| Very Tight | For high-performance | Significant |

You must balance the need for CNC part accuracy with your budget.

Tight Tolerances in Critical Industries

In sectors like aerospace and medical, tight brushed aluminum tolerances are non-negotiable. They are essential for safety and reliability.

Aerospace Applications

In aerospace, components are subjected to extreme stress and vibration. A brushed aluminum part with loose tolerances can lead to premature failure.

Perfect fits are crucial. They ensure structural integrity and prevent catastrophic outcomes. Even a minor deviation can compromise the entire assembly. This is often due to an accumulation of small errors, a concept known as tolerance stack-up4.

Medical Device Manufacturing

For medical instruments, precision is paramount. Surgical tools and diagnostic equipment demand flawless assembly. This ensures they function correctly during critical procedures.

Here, the cost of higher precision is justified by the need for patient safety and device efficacy.

| Industry | Tolerance Requirement | Justification |

|---|---|---|

| Aerospace | Extremely Tight | Safety, structural integrity, performance |

| Medical | Extremely Tight | Patient safety, device reliability, function |

| Automotive | Varies | Performance in critical systems, fit/finish |

| Electronics | Tight | Miniaturization, proper component fit |

At PTSMAKE, we guide our clients to find the right balance. We help you specify tolerances that meet functional needs without inflating costs unnecessarily.

Tighter tolerances are crucial for the function of brushed aluminum parts in industries like aerospace and medical. This increased precision ensures reliability and safety but also raises manufacturing costs due to the need for advanced CNC part accuracy and inspection.

How OEMs Use Brushed Aluminum To Reinforce Premium Brand Quality

Let’s look at real-world examples. Many leading brands use brushed aluminum in their flagship products. This is not a coincidence.

It is a deliberate choice for brushed aluminum branding. The material’s feel and look communicate quality before the device is even turned on. It suggests durability and precision engineering.

Why Material Perception Matters

The choice of material directly influences how customers perceive a product’s value. OEM aluminum parts play a key role in this.

| Material | Common Perception | Typical Use Case |

|---|---|---|

| Standard Plastic | Economical, functional | Budget consumer electronics |

| Brushed Aluminum | Premium, durable, modern | High-end laptops, audio |

| Polished Stainless Steel | Heavy, luxurious | Luxury watches, kitchen appliances |

We can see the impact of brushed aluminum across different industries. The decision to use it is a core part of product design and branding strategy for many successful companies. It’s about creating an experience that feels premium.

Case Study: Premium Consumer Electronics

High-end audio and computing brands often build their reputation on design. Think about premium laptops or speakers. The extensive use of brushed aluminum for the chassis is a key feature. This choice provides structural rigidity and excellent heat dissipation.

It also creates a sleek, minimalist aesthetic that customers associate with high performance. The finish is both visually appealing and practical, as it resists fingerprints and minor scratches. The process of Anodization5 is often used to add color and further increase surface hardness, creating a truly durable and beautiful product.

Case Study: Luxury Automotive Interiors

In the automotive world, perceived quality is everything. Luxury car manufacturers use OEM aluminum parts for interior trim. You can find brushed aluminum on dashboards, center consoles, and door panels.

This provides a cool, metallic touch that contrasts with leather or wood. It enhances the feeling of precision and modern luxury inside the cabin. These details help justify a higher price point and reinforce the brand’s premium status.

| Industry | Specific Application | Effect on Branding |

|---|---|---|

| Consumer Electronics | Laptop Enclosures | Signals durability and advanced technology. |

| Automotive | Interior Trim Accents | Reinforces a sense of precision and luxury. |

| Kitchen Appliances | Control Panels & Handles | Communicates reliability and a modern aesthetic. |

From electronics to automotive interiors, brushed aluminum is a powerful tool for brand reinforcement. The material’s tangible quality and sleek appearance help OEMs create products that not only perform well but also feel inherently premium to the consumer, strengthening brand loyalty.

Will Brushed Aluminum Corrode Over Time? Industry-Specific Insights

The corrosion resistance of brushed aluminum is not absolute. It heavily depends on the specific industry and environment it serves.

Different sectors expose aluminum to unique corrosive agents. What works in a sterile medical setting will fail in the harsh marine world.

Industry-Specific Corrosion Challenges

Understanding these environments is key to preventing brushed aluminum corrosion. Each has its own set of rules and risks.

For example, aerospace demands resistance to extreme temperature shifts. The medical field requires materials that withstand harsh sterilization.

| Industry | Primary Corrosive Threats | Common Aluminum Alloys |

|---|---|---|

| Medical | Sterilization chemicals, bodily fluids | 6061, 7075 |

| Marine | Saltwater spray, high humidity | 5052, 5083 |

| Aerospace | Atmospheric moisture, de-icing fluids, temperature extremes | 2024, 7075 |

This shows why a one-size-fits-all approach to corrosion-resistant aluminum is not effective.

To combat these threats, we must employ specific mitigation tactics. It starts with choosing the right alloy. For marine applications, we always recommend the 5xxx series. It has excellent resistance to saltwater. In contrast, aerospace often requires the high strength of the 7xxx series.

Surface treatments are the next critical layer of defense. Anodizing is a common choice. It creates a hard, protective oxide layer. This is especially vital in aerospace and medical devices. It boosts both corrosion and wear resistance.

Effective Mitigation Strategies

We also consider specialized coatings. Powder coating provides a durable barrier against moisture and chemicals. For the most demanding environments, proprietary coatings can offer tailored protection. At PTSMAKE, we guide clients through these choices. We ensure the final part performs as intended for its entire lifecycle.

A frequent issue we address is galvanic corrosion6. This occurs when aluminum contacts a more noble metal in the presence of an electrolyte, like saltwater. Proper design, using insulators or compatible materials, is the only way to prevent this type of failure.

| Mitigation Tactic | Best For | Key Benefit |

|---|---|---|

| Alloy Selection | All Industries | Foundation of corrosion resistance. |

| Anodizing | Aerospace, Medical | Hard, durable protective layer. |

| Powder Coating | Marine, Industrial | Thick barrier against chemicals/moisture. |

| Proper Design | Marine, Aerospace | Prevents galvanic corrosion failures. |

Choosing the right combination of alloy and protection is crucial for performance.

Brushed aluminum’s durability is conditional. While inherently resistant, its environment dictates its fate. By selecting the right alloy and applying industry-specific surface treatments, we ensure long-term performance and prevent premature corrosion, a core part of our manufacturing philosophy.

Brushed Aluminum For Medical Devices: What Engineers Must Consider

When selecting brushed aluminum for medical use, engineers face strict rules. The material must meet high standards for safety and performance. This is non-negotiable in the medical field.

Cleanliness and Biocompatibility

The brushed finish, while aesthetic, can pose cleaning challenges. Its grooves can trap contaminants. So, proper sealing and finishing are critical. We must ensure the surface is non-toxic and safe for patient contact.

Sterilization and Finish Durability

Medical devices undergo repeated sterilization. This process can degrade some materials. Engineers must choose a finish that withstands harsh sterilization methods without corroding or leaching.

| Sterilization Method | Effect on Brushed Aluminum | Recommendation |

|---|---|---|

| Autoclave (Steam) | Minimal risk if properly sealed | Highly Recommended |

| Ethylene Oxide (EtO) | Generally safe | Recommended |

| Gamma Radiation | Can cause discoloration | Use with caution |

Choosing the right medical grade aluminum is just the first step. The brushed finish adds another layer of complexity. At PTSMAKE, we focus on surface integrity from the start. A poorly executed finish can create micro-crevices. These can harbor bacteria.

Overcoming Surface Challenges

To counter this, we often recommend post-treatment processes. Anodizing is a common choice. It seals the aluminum’s porous surface. This creates a harder, more corrosion-resistant, and easier-to-clean layer. This process is essential for ensuring true biocompatibility7.

The specific alloy also matters greatly. Some alloys respond better to finishing and sterilization than others. After running tests with our clients, we’ve found that 6061-T6 is a versatile option. However, 7075-T6 offers superior strength when needed.

Alloy Selection for Medical Use

| Aluminum Alloy | Key Properties | Common Medical Use |

|---|---|---|

| 6061-T6 | Good corrosion resistance, weldability | Surgical instruments, device casings |

| 7075-T6 | High strength-to-weight ratio | Orthopedic devices, structural parts |

| 5052 | Excellent corrosion resistance in saltwater | Housings for marine medical equipment |

Ultimately, the goal is a surface that is both functional and impeccably safe. The brushed aluminum must maintain its integrity through its entire service life.

For medical applications, brushed aluminum’s success depends on the right alloy, surface treatment, and finishing process. These factors ensure the final component is clean, safe, and durable enough to withstand repeated sterilization cycles and patient contact.

Bulk Ordering Brushed Aluminum Parts Without Sacrificing Precision

Scaling from a perfect prototype to mass production is a critical step. For brushed aluminum, this transition is especially challenging. The unique aesthetic of the finish demands exceptional consistency.

How do you maintain that precision across thousands of units?

From One to Many

A successful scale-up relies on a robust plan. It’s about translating the quality of a single piece into a repeatable, high-volume process. This is a common challenge in brushed aluminum volume production.

| Phase | Primary Goal | Key Challenge |

|---|---|---|

| Prototype | Design Validation | Proving function and finish. |

| Production | Quality Consistency | Replicating the finish at scale. |

This shift requires a different mindset and a detailed approach with your manufacturing partner.

The journey from a single prototype to mass production aluminum parts begins with one key item: the "golden sample." This approved prototype becomes the benchmark against which all subsequent parts are measured.

Defining Production Standards

We work with clients to create a detailed Production Part Approval Process (PPAP). This isn’t just paperwork. It’s a comprehensive plan that locks in every variable. It documents the material, tooling, and specific finishing steps.

This ensures the 1000th part is identical to the first.

Communication and Specification

Clear technical drawings are essential. Ambiguity leads to inconsistency, especially in high-volume orders. That’s why precise Geometric Dimensioning and Tolerancing (GD&T)8 is fundamental for any serious production run. It removes guesswork.

Validating the Process

Before launching full-scale production, we perform rigorous validation. We confirm material consistency from our suppliers. We also lock in the specific parameters for the brushing process—speed, pressure, and grit.

| Quality Check | Prototype | Mass Production |

|---|---|---|

| First Article Inspection | The prototype itself | First parts off the line |

| Material Certificate | Verified for the batch | Verified for every new batch |

| In-Process Checks | Informal checks | Scheduled, documented checks |

| Final Inspection | 100% of parts | Statistical sampling (AQL) |

This structured approach, which we refine at PTSMAKE, ensures that quality control is built into the process, not just checked at the end.

Scaling brushed aluminum production from a prototype requires a disciplined strategy. Success depends on clear documentation, rigorous process validation, and a close partnership with your supplier to ensure consistency and precision are maintained throughout the entire run.

The Secret Behind Consistency In Brushed Aluminum Surface Appearance

Achieving a uniform brushed aluminum finish is a challenge. The most common issue I see is inconsistent brushing direction. This small detail can ruin the look of a final product.

Proper control over the process is essential. Without it, you get a finish that looks messy and unprofessional. This directly impacts the perceived quality of your part. Experienced shops know how to prevent this.

Why Direction Matters

The direction of the brush lines must be perfectly parallel. Any deviation creates visible flaws. This is especially true on large surfaces where inconsistencies stand out.

| Defect Type | Description | Common Cause |

|---|---|---|

| Swirl Marks | Circular or random scratches | Improper tool path or manual error |

| Uneven Lines | Brush lines are not straight | Unstable workpiece or worn tooling |

| Directional Shift | Lines change angle across the part | Fixture movement or programming error |

This level of control is what separates an average supplier from a great one. It is a core part of ensuring aluminum surface uniformity.

At PTSMAKE, we focus heavily on process control to guarantee brushed aluminum consistency. Preventing inconsistent brushing direction starts long before the part hits the machine. It begins with robust fixture design.

Securing the Part

The workpiece must be completely immobile during the brushing process. Even microscopic shifts can alter the brush path. We design custom fixtures that clamp the part securely without damaging its surface. This ensures the brush follows the programmed path exactly.

Tooling and Programming

The right tool and path are critical. We use specialized abrasive brushes maintained to strict standards. Worn-out tools are a primary cause of poor finishes.

Our CNC programmers define precise, linear toolpaths. These paths ensure the brush moves in one consistent direction across the entire surface. This eliminates the variables that lead to swirls or shifts. The material’s surface develops a specific directional reflectivity, a property related to its Anisotropy9. This is key to a premium look.

| Technique | Purpose | Benefit |

|---|---|---|

| Custom Fixturing | Prevents part movement | Guarantees straight brush lines |

| CNC-Controlled Path | Ensures consistent direction | Eliminates manual errors and swirls |

| Tool Maintenance | Maintains abrasive quality | Prevents uneven or dull finishes |

Consistent brushing direction isn’t an accident. It’s the result of careful planning, precise programming, and secure workholding. These steps are essential for achieving flawless aluminum surface uniformity and a high-quality brushed aluminum appearance.

How Brushed Aluminum Impacts RF Signal And Electronics Enclosures

Brushed aluminum is a top choice for electronic enclosures. This is due to its excellent electrical properties. It provides strong RF shielding. This protects sensitive internal components.

Its surface conductivity is also key. Proper grounding paths are essential for safety and performance. We ensure these properties are optimized.

Understanding Surface Properties

The brushing process can slightly alter the surface. This change can impact electrical contact points.

| Property | Raw Aluminum | Brushed Aluminum |

|---|---|---|

| RF Shielding | Excellent | Excellent |

| Conductivity | High | High (check contact) |

| Grounding | Simple | Requires attention |

This makes brushed aluminum RF shielding very effective.

When designing aluminum electronic enclosures, we focus on shielding effectiveness. Aluminum naturally forms a non-conductive oxide layer. The brushing process doesn’t remove this benefit. It creates a great material for a Faraday cage10.

Grounding and Conductivity

Effective grounding is critical. The brushed texture can create microscopic peaks and valleys. This can affect the surface area available for electrical contact points.

We often recommend specific connection points. These areas may need masking before finishing. This ensures a direct, low-resistance path to the ground.

Anodization’s Role

Anodizing after brushing creates a durable, non-conductive surface. This is great for aesthetics and corrosion resistance. But it electrically insulates the enclosure.

For proper grounding, specific areas must be masked before anodization. Our tests show this is the best way to maintain electrical continuity.

| Feature | Design Consideration | PTSMAKE Solution |

|---|---|---|

| Grounding Point | Non-conductive finish | Pre-finishing masking |

| EMI Gasket | Clean contact surface | Controlled surface prep |

| Fastener Contact | Direct metal-to-metal | Use of serrated washers |

These small details are vital for performance.

Brushed aluminum is excellent for RF shielding in electronic enclosures. However, its surface treatment and grounding paths require careful engineering. Masking before anodizing is crucial for maintaining electrical continuity and ensuring optimal device performance and safety.

Customizing Brushed Aluminum Textures To Match Product Identity

A brushed aluminum finish is more than a surface treatment. It is a core element of your product’s identity.

The right brushed aluminum texture options can define your product. They convey messages of durability, elegance, or innovation.

Grit level and brush pattern are your main tools. Each choice shapes how customers perceive the final product. Let’s explore how.

| Grit Level | Visual Effect | Common Application |

|---|---|---|

| Coarse | Deep, visible lines | Industrial equipment |

| Medium | Balanced texture | Consumer electronics |

| Fine | Subtle, soft sheen | Luxury goods |

Fine-Tuning with Grit Selection

Choosing the right grit is fundamental to achieving your desired look. A lower grit number, like 120, creates deeper, more aggressive lines. This finish is excellent for products intended to look rugged or industrial.

Conversely, a higher grit, such as 320 or 400, produces a much finer texture. The lines are softer, creating a smooth, sophisticated sheen. This approach is ideal for premium electronics or automotive decorative trim. The difference significantly alters light reflection and tactile feel.

The Impact of Brush Patterns

The direction and style of the brush pattern are just as critical for a custom aluminum finish. The pattern guides the viewer’s eye and establishes the product’s character. A linear pattern is the most common, offering a clean, modern look suitable for large surfaces.

| Brush Pattern | Brand Identity/Feel | Example Product |

|---|---|---|

| Linear | Modern, clean, directional | Laptop casing, kitchen appliance |

| Circular | Precision, focused, dynamic | Watch dial, control knob |

| Cross-Hatch | Industrial, textured, robust | Tooling, heavy-duty panels |

Circular brushing creates a dynamic, sunburst effect. It’s perfect for drawing attention to a central point like a logo or knob. Cross-hatch patterns provide a more complex, textured appearance, adding a sense of durability. The brushing process creates a directional grain. This results in a unique visual effect known as Anisotropy11, where light reflects differently depending on the viewing angle.

Selecting the right grit and pattern is a core design decision. It aligns your product’s physical form with its brand identity. A thoughtful custom aluminum finish communicates quality and attention to detail before a user even touches it.

Brushed Aluminum In Robotics: Benefits For Functional Aesthetics

Brushed aluminum is a popular choice in robotics. It strikes a balance between professional looks and practical durability.

Many designs use this material. From collaborative robot arms to autonomous mobile robots, the finish signals quality and precision.

Striking the Right Balance

The key is aligning design goals with budget. A robotics aluminum enclosure needs to protect internal components. It must also look good.

Brushed aluminum achieves both. The finish hides minor scratches and wear, which is common in industrial settings.

Examples in the Field

Consider these common applications. Each has different priorities, but brushed aluminum often fits.

| Robot Type | Primary Benefit of Brushed Aluminum |

|---|---|

| Collaborative Robots | Professional look, durability in shared workspaces |

| Autonomous Mobile Robots | Scratch resistance, lightweight for efficiency |

| Consumer Robots | Premium feel, aesthetic appeal |

| Lab Automation | Easy to clean, resistant to chemicals |

This material offers a cost-effective solution. It delivers a premium aesthetic without the high cost of more exotic materials.

When evaluating materials for a robotics aluminum enclosure, cost is a major factor. The conversation always includes durability and design intent. Brushed aluminum often emerges as the clear winner.

Cost vs. Durability Analysis

The initial cost for a machined brushed aluminum part may be higher than molded plastic. However, its longevity provides a better return on investment over the product’s life.

Our clients at PTSMAKE often find that aluminum’s strength reduces repair and replacement costs. This is a critical factor for robots deployed in demanding environments.

The Finishing Touch

The brushing process itself is just one step. Further treatments can enhance durability. For example, Anodization12 creates a harder, corrosion-resistant surface. This adds a protective layer without hiding the brushed texture. It’s a process we frequently manage.

Below is a simple cost consideration breakdown.

| Cost Factor | Impact of Brushed Aluminum |

|---|---|

| Raw Material | Moderate |

| Machining Time | Varies with complexity |

| Finishing Process | Adds to unit cost, but boosts durability |

| Long-term Value | High, due to low maintenance and high durability |

Ultimately, choosing brushed aluminum in robots is a strategic decision. It aligns production cost with the need for a durable, high-quality product that performs reliably for years.

Brushed aluminum offers a smart blend of durability, aesthetics, and manageable costs for robotic enclosures. This makes it a practical choice for developers aiming for a premium yet functional design without overspending on materials or long-term maintenance.

Should You Switch To Brushed Aluminum? Materials Comparison With Steel And Plastics

Choosing the right material is a critical decision. It impacts cost, performance, and user perception. Many clients ask about brushed aluminum vs stainless steel or plastic.

To simplify this, I’ve created a direct comparison. This matrix focuses on key factors for B2B applications. It’s a quick guide to help you decide.

Side-by-Side Material Matrix

| Feature | Brushed Aluminum | Stainless Steel (304) | Plastic (ABS) |

|---|---|---|---|

| Aesthetics | Premium, modern | Classic, industrial | Versatile, colorful |

| Weight | Lightweight | Heavy | Very Lightweight |

| Durability | Good, can scratch | Excellent, corrosion-resistant | Good, impact-resistant |

| Cost | Moderate | High | Low |

| Machinability | Excellent | Moderate | Excellent |

This table shows a clear trade-off. Brushed aluminum often hits a sweet spot. It offers a premium feel without the weight or cost of steel.

The matrix provides a high-level view. However, the best choice often depends on the specific product environment and its intended use. Let’s dig deeper into practical scenarios.

Application-Specific Showdown

For consumer electronics, aesthetics and weight are key. Here, the brushed aluminum vs plastic debate is common. Brushed aluminum provides a premium feel that plastics often cannot replicate. This justifies its higher cost.

In industrial settings, durability is paramount. The discussion shifts to brushed aluminum vs stainless steel. While steel is tougher, aluminum’s corrosion resistance and lower weight can be decisive for certain components.

The surface finish of brushed aluminum creates properties that are anisotropic13. This means its visual appearance can change depending on the viewing angle and light source, adding a dynamic quality.

B2B Use Case Comparison

| Use Case | Best Fit: Brushed Aluminum | Best Fit: Stainless Steel | Best Fit: Plastic |

|---|---|---|---|

| Front Panels | Yes (Light & Premium) | Sometimes (Heavy Duty) | Yes (Low Cost) |

| Enclosures | Yes (Heat Dissipation) | Yes (Harsh Environments) | Yes (Cost-Sensitive) |

| Structural Parts | No (Less Strength) | Yes (High Strength) | No (Low Rigidity) |

| Decorative Trim | Yes (Aesthetic) | Yes (High-End Look) | Yes (Color Options) |

At PTSMAKE, we guide clients through these trade-offs daily. We ensure the material not only meets specs but also aligns with the product’s market position and budget. The choice is never just about the raw material.

Choosing between brushed aluminum, stainless steel, and plastic involves weighing aesthetics, weight, durability, and cost. Your specific B2B application and priorities will determine the ideal material, with brushed aluminum offering a balanced, premium option for many designs.

Unlock Premium Brushed Aluminum Solutions with PTSMAKE Today

Ready to elevate your next project with high-precision brushed aluminum parts? Contact PTSMAKE for a fast, personalized quote. Our expert team guarantees accuracy, consistency, and on-time delivery—no compromises. Send your RFQ now and discover why industry leaders trust PTSMAKE for all their CNC machining needs!

Understand how a material’s surface texture affects its visual properties from different angles. ↩

Learn how this phenomenon affects tool life and surface finish in precision aluminum machining. ↩

Learn about this electrochemical process that enhances aluminum’s durability. ↩

Learn how individual part tolerances can accumulate and affect the final assembly’s fit and function. ↩

Learn more about this electrochemical process that enhances aluminum’s durability and appearance. ↩

Learn how dissimilar metals can accelerate brushed aluminum corrosion and how to prevent it. ↩

Learn more about material properties for medical-grade manufacturing. ↩

Learn how these symbols ensure your design intent is perfectly translated into the final part. ↩

Learn how this directional property impacts the visual quality of metal finishes. ↩

Learn how the principles of RF shielding are applied to protect sensitive electronics in enclosures. ↩

Learn how this optical property can be leveraged in your product design for unique visual effects. ↩

Discover how this electrochemical process enhances durability and appearance. ↩

Discover how this directional property impacts material performance and visual appeal. ↩