Your CNC machined parts face constant wear, corrosion, and performance challenges in demanding industrial environments. Standard surface finishes often fail when parts need to maintain precision under heavy loads, chemical exposure, or high-friction conditions.

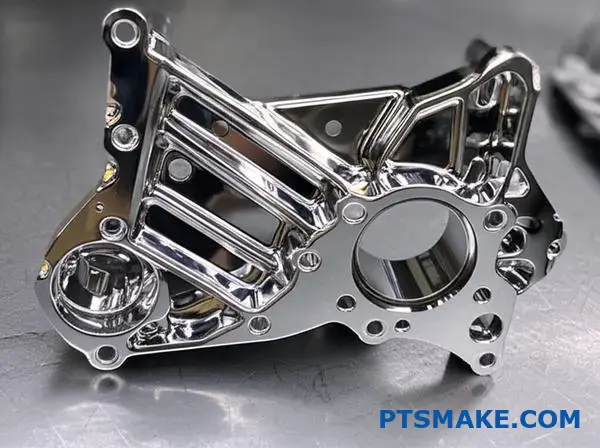

Chrome plating transforms CNC machined parts into durable, precision components that resist wear and corrosion while maintaining tight tolerances. This surface treatment extends part life, reduces maintenance costs, and delivers consistent performance across aerospace, automotive, hydraulic, and manufacturing applications.

This guide covers everything you need to know about chrome plating for precision parts. I’ll walk you through different plating types, material considerations, tolerance control, and how to choose the right approach for your specific application requirements.

Why Chrome Plating Enhances Performance-Critical Components

When designing performance-critical components, the base material is only half the story. The surface finish often determines a part’s true longevity and reliability. This is where performance surface treatments come into play.

The Core Benefits of Chrome Plating

Chrome plating for industrial parts offers a powerful trio of advantages. It creates a barrier that significantly enhances durability.

Superior Wear Resistance

The primary benefit is exceptional hardness. This layer protects components from friction and abrasion, extending their operational life.

Unmatched Corrosion Protection

Chrome is naturally resistant to oxidation. This makes it an ideal shield against moisture and corrosive agents.

| Feature | Unplated Component | Chrome Plated Component |

|---|---|---|

| Hardness | Moderate | Very High |

| Corrosion Risk | High | Very Low |

| Lifespan | Standard | Extended |

Beyond the Surface: Ensuring Long-Term Stability

The benefits of chrome plating go deeper than just protection. The process is critical for maintaining the component’s original design integrity over time, especially for parts we machine at PTSMAKE.

Maintaining Dimensional Accuracy

For high-precision parts, even microscopic changes can lead to failure. Hard chrome plating adds a thin, uniform layer that locks in the component’s dimensions. This prevents wear from altering critical tolerances during operation. Our tests show this stability is key in high-cycle machinery.

This process also helps manage thermal expansion. The coating acts as a stable barrier, which is essential for components operating at varying temperatures. In some applications, the presence of micro-cracks1 in the chrome layer can even improve performance. These tiny fissures can retain lubricants, further reducing friction on moving parts.

Plating Types for Industrial Applications

Different applications require different approaches. Understanding the distinction is vital for proper specification.

| Plating Type | Primary Use | Key Characteristic |

|---|---|---|

| Hard Chrome | Industrial Parts | Functional, High Hardness |

| Decorative Chrome | Automotive Trim | Aesthetic, Thin Layer |

| Black Chrome | Optical Tools | Reduced Reflectivity |

Chrome plating provides exceptional wear and corrosion resistance. It also ensures long-term dimensional stability, making it a vital performance surface treatment for industrial parts that require reliability and precision under demanding conditions.

The Complete Breakdown Of Chrome Plating Types

When we talk about chrome plating, it’s not a one-size-fits-all solution. The two main categories are hard chrome and decorative chrome. They serve entirely different purposes.

Hard chrome plating is all about function. It creates a durable, wear-resistant surface. Think of industrial parts that need to last.

Decorative chrome, on the other hand, is for aesthetics. It provides that classic, mirror-like finish you see on car bumpers or faucets.

Here is a quick overview:

| Plating Type | Primary Purpose | Key Feature |

|---|---|---|

| Hard Chrome | Engineering | Durability |

| Decorative Chrome | Aesthetics | Shine |

These differences are critical for engineers and designers.

Let’s dive deeper into what sets them apart. The application process is a major differentiator. Hard chrome plating is applied directly onto the base metal, often steel. This creates a strong bond and a very thick coating.

Conversely, decorative chrome plating is a much thinner layer. It almost always requires an undercoating of nickel or copper. This nickel layer provides the smoothness, reflectivity, and much of the corrosion resistance. The chrome layer on top is incredibly thin, primarily protecting the nickel from tarnishing.

The electroplating solution itself is also different. Both traditionally use a bath containing hexavalent chromium2, but the specific parameters are adjusted to achieve different results. Because of its thickness and direct application, hard chrome offers superior hardness and lubricity, making it ideal for industrial chrome coatings on pistons, cylinders, and molds.

Here’s a more detailed breakdown:

| Feature | Hard Chrome Plating | Decorative Chrome Plating |

|---|---|---|

| Thickness | Typically 20-100 µm | Typically 0.05-0.5 µm |

| Process | Applied directly to base metal | Requires nickel/copper underlayer |

| Durability | Extremely high wear resistance | Moderate corrosion resistance |

| Appearance | Matte to semi-bright | Mirror-like, reflective |

At PTSMAKE, we help clients select the right finish based on whether the part’s primary need is performance or appearance.

In short, the choice between hard and decorative chrome plating depends entirely on the application. Hard chrome is for industrial durability and function, while decorative chrome provides a brilliant, corrosion-resistant finish for consumer-facing products. The difference lies in thickness and process.

How To Choose The Right Chrome Plating For Your Application

Selecting the right chrome plating is crucial. It’s not just about a shiny finish. The choice directly impacts component performance and lifespan.

Engineers and procurement managers must weigh different factors. Functional needs often dictate the best type of chrome plating.

Hard Chrome vs. Decorative Chrome

The first decision is between hard and decorative chrome. Their properties are very different. Hard chrome is for function. Decorative chrome is for appearance.

| Feature | Hard Chrome Plating | Decorative Chrome Plating |

|---|---|---|

| Primary Goal | Functionality (Wear, Hardness) | Aesthetics (Shine, Appeal) |

| Thickness | Thicker (20-100 µm) | Thinner (0.05-0.5 µm) |

| Application | Industrial, Machinery | Automotive Trim, Fixtures |

This choice sets the foundation for your project’s success.

Choosing the correct chrome plating requires a deep dive into the application’s environment and operational demands. At PTSMAKE, we always start by asking about the part’s end-use. This determines everything.

Chrome Plating for Aerospace

In aerospace, performance is non-negotiable. Parts must withstand extreme conditions. This means chrome plating for aerospace focuses on corrosion resistance, hardness, and lubricity. It protects critical components like landing gear and actuators from failure. The plating must adhere perfectly to the base metal.

Automotive Chrome Finish

The automotive industry balances looks with durability. An automotive chrome finish must resist weather, road salt, and minor impacts. It’s applied to grilles, wheels, and trim. Here, a multi-layer system (copper-nickel-chrome) is common to ensure both a brilliant shine and robust protection. The process is key to longevity.

Machinery Wear Coatings

For industrial machinery, it’s all about wear resistance. Hard chrome is the standard for machinery wear coatings. It extends the life of pistons, rollers, and molds. The focus is on improving the tribological properties3 of the component. A thicker, precisely applied layer can significantly reduce downtime and maintenance costs. Our tests show it can increase part life by over 50%.

| Industry | Primary Requirement | Recommended Chrome Plating | Key Benefit |

|---|---|---|---|

| Aerospace | Corrosion Resistance | Hard Chrome (Thin Dense) | Component Reliability |

| Automotive | Aesthetics & Durability | Decorative Chrome | Longevity & Appearance |

| Machinery | Wear Resistance | Hard Chrome (Thick) | Extended Service Life |

Choosing the right chrome plating is a critical engineering decision. Aligning the plating type with the specific demands of aerospace, automotive, or industrial machinery ensures optimal performance, durability, and cost-effectiveness for every component.

Chrome Plating Vs. Alternative Surface Finishes: What You Need To Know

While chrome plating is a fantastic option, it’s not the only solution. The right choice depends entirely on your project’s specific needs. Let’s compare it with other popular finishes.

At PTSMAKE, we guide clients through this decision daily. We look at factors like environment, wear, and budget.

Quick Finish Comparison

Each finish offers distinct advantages. Here is a quick overview to highlight their primary strengths.

| Finish | Primary Advantage |

|---|---|

| Chrome Plating | Hardness, Wear Resistance |

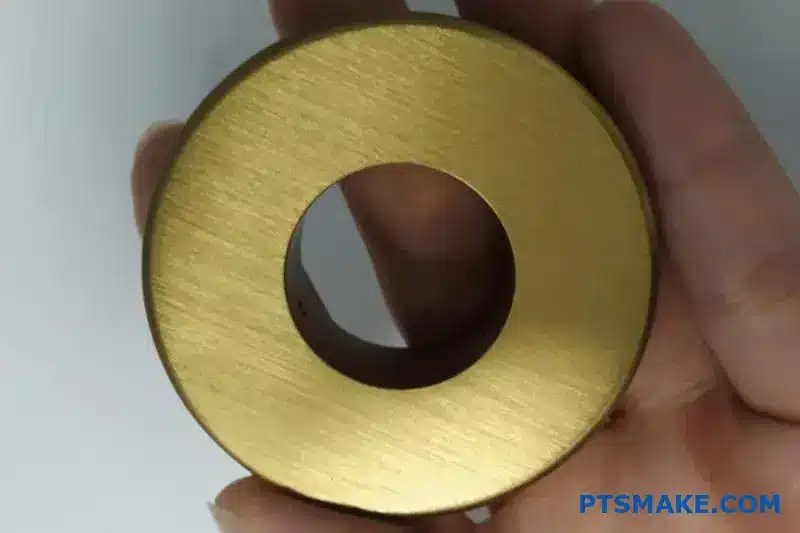

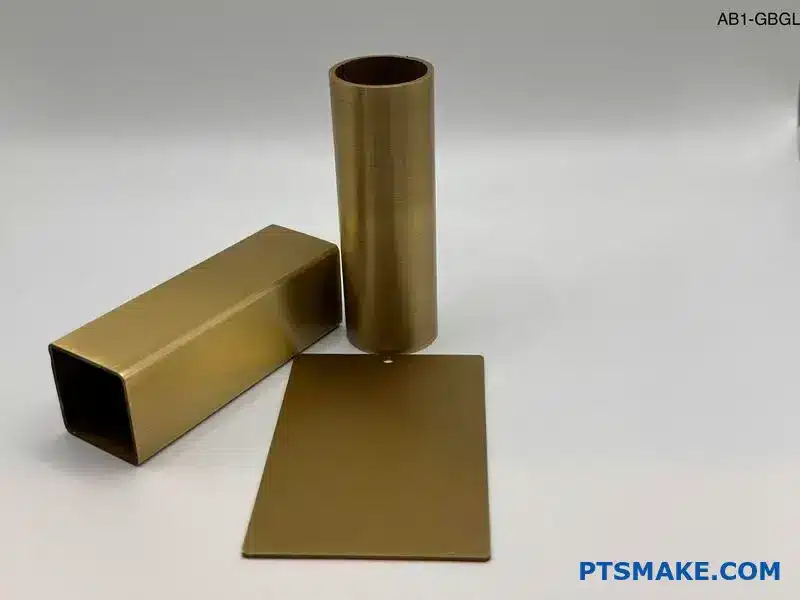

| Anodizing | Corrosion Resistance (Aluminum) |

| Nickel Plating | Cost-Effective Corrosion Resistance |

| Powder Coating | Durability, Color Variety |

This surface finish comparison is just the starting point.

Choosing the right metal finish is crucial for precision parts. It directly impacts performance, lifespan, and even the final cost of your product. A mismatched finish can lead to premature failure.

Chrome vs. Nickel Plating

The chrome vs nickel plating debate is common. Hard chrome is exceptionally hard and wear-resistant. It’s ideal for high-friction components. Nickel plating provides excellent corrosion resistance at a lower cost and often has a warmer, yellowish tint.

Other Functional Coatings

Anodizing is an electrochemical process for aluminum parts. It creates a durable, corrosion-resistant oxide layer. It’s not a coating, but an integral part of the metal itself.

Powder coating applies a dry powder that is then cured with heat. It creates a thick, durable finish available in many colors. However, it’s less suitable for parts with very tight tolerances.

Electroless nickel plating offers a key advantage: perfect uniformity. It deposits an even layer over the entire part, regardless of geometry. This is possible due to the autocatalytic reaction4 used in the process, making it ideal for complex metal finishing for precision parts.

| Feature | Chrome Plating | Nickel Plating | Anodizing (Aluminum) | Powder Coating |

|---|---|---|---|---|

| Hardness | Very High | Medium | High | Medium |

| Uniformity | Good | Good | Excellent | Fair |

| Substrates | Metals | Metals | Aluminum | Most Metals |

| Appearance | Bright, bluish | Bright, yellowish | Matte/Satin, Colors | Opaque, Colors |

Selecting the right surface finish balances performance, aesthetics, and cost. The final application of your part should always guide your decision, ensuring functionality and durability are prioritized. This choice is a critical step in the manufacturing process.

Understanding Tolerances And Thickness In Chrome Plating

Chrome plating is an additive process. It’s not just a paint; it is a layer of metal. This added material directly changes a part’s final dimensions.

For precision components, this is a critical detail. Ignoring the plating thickness can push a perfectly machined part out of its required tolerance.

The Impact of Plating Buildup

The amount of chrome added is known as the chrome plating thickness. This buildup occurs on all plated surfaces.

Here’s a simple example of how it affects a shaft’s diameter.

| Original Diameter | Plating Thickness (Per Side) | Final Diameter |

|---|---|---|

| 25.000 mm | 0.015 mm | 25.030 mm |

| 25.000 mm | 0.030 mm | 25.060 mm |

This shows why we must account for plating in the initial design phase.

The main challenge in chrome plating isn’t just the thickness, but its uniformity. Plating doesn’t build up evenly across a part’s surface.

The Problem with Uneven Buildup

Sharp external corners, edges, and holes tend to attract more chrome deposits. This happens because the electrical field is stronger in these areas during the plating process.

This unevenness contributes directly to tolerance stack-up. A part perfectly within machining tolerance can fail inspection after plating. We must consider both the machine tolerance and the plating tolerance together. The final dimensional control depends heavily on part geometry and the current density5 used in the plating bath.

Plating Dimensional Control Methods

At PTSMAKE, we manage this by collaborating closely on design and process control. You have two primary strategies for achieving plating dimensional control.

| Control Method | Description | Ideal Application |

|---|---|---|

| Pre-Plate Undersizing | Machining the part slightly smaller to compensate for the planned plating thickness. | Parts with simple geometry and standard plating needs. |

| Post-Plate Grinding | Plating the part slightly oversize, then grinding it down to the final, precise dimension. | Components requiring the highest precision and tight tolerances. |

Choosing the right method requires a clear understanding of the part’s function and cost targets. It’s a balance between precision and manufacturing efficiency.

Effective chrome plating dimensional control is all about planning. You must account for the added material during the design and machining stages. This proactive approach prevents tolerance failures and ensures your final component performs exactly as intended.

How Chrome Plating Impacts CNC Machined Part Performance

Chrome plating offers much more than a simple shiny finish. For CNC machined parts, it is a critical surface treatment that directly boosts performance.

This process creates an exceptionally smooth surface. This is key for reducing friction between moving components.

Key Performance Benefits

The hardness from chrome plating provides robust wear protection. This can dramatically extend the life of coated metal machined parts.

For load-bearing surfaces, this coating is essential. It enhances the part’s ability to withstand high pressure and stress without failing.

| Benefit | Impact on Performance |

|---|---|

| Surface Smoothness | Reduced Friction & Wear |

| Wear Protection | Increased Component Lifespan |

| Load-Bearing Capacity | Enhanced Durability Under Stress |

When we look deeper, the functional advantages of chrome plating become even clearer. It’s a strategic choice for engineers aiming for longevity and reliability in their designs. These benefits are especially prominent in hard chrome plating, which is designed for industrial use.

A Closer Look at Functional Gains

The extremely low coefficient of friction achieved with chrome is a major benefit. For components like hydraulic pistons or bearing shafts, this means less heat generation and smoother, more efficient operation. It’s one of the most effective surface finishes in CNC for this purpose.

Beyond a Simple Coating

The hardness of industrial hard chrome is truly impressive. It forms a protective barrier against both abrasion and corrosion, making chrome-plated CNC parts ideal for demanding environments. At PTSMAKE, we often recommend it for parts subjected to high cycles or harsh conditions.

The coating also helps distribute stress loads more evenly across a surface. This prevents premature failure from localized wear. Ensuring strong Substrate Adhesion6 is critical here, as it guarantees the coating remains intact under pressure. This is a core part of our quality assurance process.

| Feature | Hard Chrome Plating | Decorative Chrome Plating |

|---|---|---|

| Primary Purpose | Functional (Wear, Corrosion) | Aesthetic (Appearance) |

| Thickness | Thicker (20-100 µm) | Thinner (<1 µm) |

| Hardness (Vickers) | 850-1050 HV | 600-800 HV |

| Application | Pistons, Shafts, Molds | Faucets, Automotive Trim |

Chrome plating provides CNC parts with superior surface smoothness, wear protection, and load-bearing strength. These enhancements are not merely cosmetic; they are functional improvements that directly boost component durability and operational reliability, making it a valuable investment for high-performance applications.

The Truth About Chrome Plating On Aluminum And Stainless Steel

Non-ferrous materials present unique chrome plating challenges. Unlike steel, aluminum and stainless steel have passive oxide layers.

These layers prevent direct adhesion. Getting chrome to stick requires specialized pre-treatment. Without it, the plating will peel or blister.

The Adhesion Problem

Chrome plating aluminum parts is notoriously difficult. A tough, invisible oxide layer forms instantly on aluminum when exposed to air. This layer must be removed completely for proper adhesion.

Common Failure Points

| Material | Primary Challenge | Consequence of Failure |

|---|---|---|

| Aluminum | Instant Oxide Layer | Peeling, Blistering |

| Stainless Steel | Passive Chromium Oxide | Poor Adhesion, Flaking |

This is why proper surface preparation is not just a step; it is the most critical part of nonferrous plating.

The main hurdle with non-ferrous metals is chemistry. Their surfaces are fundamentally different from ferrous metals like carbon steel. They are designed to resist corrosion, which ironically also resists plating.

Overcoming Surface Passivity

For stainless steel, the challenge is its chromium content. This element creates a passive, non-reactive surface layer. To achieve strong adhesion for chrome on stainless steel, this layer needs special activation, usually with a strong acid strike.

For aluminum, the solution is more complex. After cleaning, the part goes through a specific pre-treatment. A common and effective method we use at PTSMAKE is a double zincate process7. This deposits a thin layer of zinc, which acts as a better bonding surface for subsequent copper, nickel, and chrome layers.

Simplified Pre-Treatment Flow

| Step | Aluminum | Stainless Steel |

|---|---|---|

| 1 | Alkaline Clean | Alkaline Clean |

| 2 | Deoxidize / Etch | Acid Activation (e.g., Woods Nickel Strike) |

| 3 | Zincate Immersion | Rinse |

| 4 | Copper / Nickel Underplate | Nickel Underplate |

| 5 | Chrome Plating | Chrome Plating |

Without these specific underplating and activation steps, any attempt at chrome plating aluminum parts or stainless steel will almost certainly fail quality checks. The bond will simply be too weak for any practical application. We learned this through rigorous testing and collaboration with clients.

Chrome plating non-ferrous metals is challenging due to their natural oxide layers. Success depends entirely on specific pre-treatment processes, like the zincate process for aluminum and acid activation for stainless steel, to ensure a strong, durable bond for the chrome finish.

Can Chrome Plating Deliver Both Precision And Aesthetic Appeal?

The conversation around chrome plating often splits into two camps. One focuses on its tough, functional benefits. The other praises its brilliant, decorative finish. But what if you need both?

This is a common requirement in B2B industries. Many components must perform reliably while also looking the part. This is where functional decorative plating shines. It merges durability with design.

Aesthetic Chrome for Industrial Parts

Consider parts that are visible to the end-user. They need to look premium and trustworthy. At the same time, they must withstand wear, corrosion, and environmental stress. This dual demand is not an exception; it is often the rule.

| Industry | Functional Need | Aesthetic Need |

|---|---|---|

| Medical Devices | Biocompatibility, Sterilizability | Clean, professional look |

| Automotive | Corrosion Resistance, Wear | High-gloss, premium finish |

| Electronics | EMI Shielding, Durability | Sleek, modern appearance |

This balance requires a deep understanding of the chrome plating process. It’s not just about applying a shiny coat.

Many think achieving both function and beauty is a compromise. They assume you have to sacrifice some hardness for a better shine, or vice-versa. This is a misconception rooted in outdated practices. Modern chrome plating techniques have evolved significantly.

At PTSMAKE, we manage projects where both aspects are critical. The key lies in controlling the entire process with precision. This starts with substrate preparation and ends with final quality control. Each step impacts both performance and appearance.

The Science of a Dual-Purpose Finish

To achieve a successful dual-purpose finish, we focus on the plating bath chemistry and electrical parameters. Minor adjustments here can dramatically alter the outcome. For example, controlling current density influences the crystalline structure of the chrome layer.

This directly affects its hardness and luster. A poorly controlled process can lead to a finish that is either brittle or dull. It can also fail prematurely under mechanical stress or due to environmental factors like tribocorrosion8.

Here is how we approach the balancing act:

| Plating Parameter | Impact on Function | Impact on Aesthetics |

|---|---|---|

| Layer Thickness | Increases wear resistance | Can obscure fine details |

| Current Density | Affects hardness & adhesion | Influences brightness |

| Bath Temperature | Modifies grain structure | Impacts finish uniformity |

Functional decorative plating is not a one-size-fits-all solution. It requires a custom approach for each application, ensuring that the final part meets precise engineering and design specifications without compromise.

Dual-purpose chrome plating successfully merges functional durability with high-end aesthetics. By precisely controlling the plating process, we deliver parts that perform under stress and meet the visual standards required in demanding B2B industries like automotive, medical, and electronics.

Hard Chrome Plating For Hydraulic, Pneumatic, And Cylindrical Parts

In hydraulic and pneumatic systems, performance is everything. Components are constantly moving under high pressure and stress. This is where hard chrome plating truly shines.

It provides a durable, low-friction surface. This is essential for parts like pistons, rods, and cylinders. The smooth finish reduces seal wear and prevents fluid leaks.

Key Applications

Hard chrome plating extends the life of critical parts. It ensures they operate smoothly and efficiently for longer periods. This reduces downtime and maintenance costs.

Hydraulic and Pneumatic Components

We often recommend hydraulic chrome plating for parts that face intense, repetitive motion. The hard surface prevents galling and seizure under load.

| Component | Primary Benefit | Common Issue Without Plating |

|---|---|---|

| Chrome Piston Rods | Wear Resistance | Scoring, Seal Damage |

| Hydraulic Cylinders | Low Friction | High Energy Loss, Stick-Slip |

| Pneumatic Pistons | Corrosion Resistance | Rust, Air Leaks |

| Valve Spools | Smooth Operation | Sticking, Inconsistent Flow |

This treatment is a standard for high-performance chrome piston rods.

The value of hard chrome plating goes beyond just a shiny surface. The metallurgical bond it creates is incredibly strong. It becomes an integral part of the component itself, not just a coating.

Performance Characteristics

The key is the combination of hardness and a low coefficient of friction. This dual benefit is why a cylinder chrome finish is the preferred choice for so many demanding applications. It ensures parts slide smoothly with minimal resistance.

This finish also possesses a network of microscopic fissures. This pattern of micro-cracking9 is a unique feature. It acts as a reservoir for lubricants, ensuring consistent oil retention on the surface. This dramatically improves performance under pressure.

Typical Properties of Hard Chrome Finish

A proper hydraulic chrome plating process results in specific, measurable improvements. We have verified these enhancements through client application studies.

| Property | Typical Value/Range | Impact on Performance |

|---|---|---|

| Hardness | 68-72 HRC | Resists abrasion and scoring |

| Thickness | 0.0005" – 0.020" | Customizable for wear life |

| Friction Coefficient | ~0.15 (with steel) | Reduces operational energy |

| Corrosion Resistance | Excellent (in non-acidic) | Protects base metal from rust |

At PTSMAKE, we guide our partners in selecting the optimal plating thickness. This ensures the component meets its expected service life without unnecessary cost. The finish must match the operational environment perfectly.

Hard chrome plating provides a durable, low-friction surface essential for hydraulic and pneumatic parts. Its unique properties, including hardness and lubricant retention, significantly extend the life and improve the performance of components like chrome piston rods and cylinders.

Controlling Chrome Plating Build-Up On Complex Geometries

Plating complex parts is a true test of a chrome plating process. Irregular shapes with holes, sharp corners, and deep recesses present unique challenges.

High-current areas, like edges, tend to build up too much chrome. Low-current areas, such as internal corners, receive too little.

This unevenness can compromise both function and appearance. The goal is achieving consistent thickness across the entire surface. This requires careful planning and specialized techniques. Standard methods often fail here.

The Crucial Role of Fixturing

Properly fixturing chrome surfaces is the first step to success. A generic rack won’t work for complex parts. We design custom fixtures at PTSMAKE for each unique project.

These fixtures hold the part in the optimal orientation. This ensures the best possible current flow from the anodes to all surfaces of the component.

Balancing with Anodes and Shields

For truly difficult geometries, fixturing alone isn’t enough. We use auxiliary anodes and shields to manage the plating process. This is the core of chrome buildup balancing.

Shields, or "robbers," are placed near high-current-density areas. They divert some of the electrical current, preventing excessive buildup on sharp edges.

Auxiliary anodes are placed near recessed areas. They provide a localized current source, ensuring these spots get adequate chrome coverage. The precise management of the current density distribution10 is critical for a uniform finish.

Here’s a breakdown of how these tools impact results:

| Technique | High-Current Areas (Edges) | Low-Current Areas (Recesses) | Overall Uniformity |

|---|---|---|---|

| Standard Racking | Excessive Buildup | Insufficient Plating | Poor |

| Custom Fixture | Moderate Buildup | Improved Plating | Fair |

| Fixture with Shields/Anodes | Controlled Buildup | Sufficient Plating | Excellent |

After collaborating with our clients on some very intricate parts, we found this combined approach gives the most reliable outcomes for plating complex parts.

Controlling chrome plating on complex geometries is a precise science. It relies on strategic fixturing and the targeted use of auxiliary anodes and shields. These tools help manipulate electric current to ensure a uniform, high-quality finish across the entire part.

Expert Tips On Chrome Plating Prototypes Vs. Production Volume

Scaling chrome plating from prototype to production involves more than just increasing numbers. The entire approach changes.

For prototype chrome parts, speed is often the priority. The goal is a visual and functional sample.

When scaling chrome projects, consistency and cost-per-unit become the main drivers. This shift impacts everything.

Key Differences at a Glance

| Factor | Prototyping | Production Volume |

|---|---|---|

| Primary Goal | Speed, proof-of-concept | Consistency, cost-efficiency |

| Tooling | Simple, often manual | Custom, automated racks |

| Cost Model | High per-unit cost | Lower per-unit cost |

| Lead Time | Faster setup, shorter runs | Longer setup, faster per unit |

A Deeper Dive into Plating Techniques

When we handle low volume plating tips for clients, the conversation is very different from a mass production inquiry. The techniques must adapt.

Tooling and Fixturing

For a single prototype, we might use a simple, adjustable wire jig. It’s quick and effective for one part. This approach is not scalable.

For production, we design and build custom plating racks. These racks hold dozens or hundreds of parts. They ensure every part is oriented identically to the anode. This guarantees uniform plating thickness.

Process Control and Consistency

In prototyping, an operator can manually adjust a part’s position for better coverage. This hands-on approach is impractical for thousands of units.

Production relies on process automation and strict parameter control. We focus on the bath chemistry, temperature, and current density. Consistent results depend on the stability of these factors. This is where the throwing power11 of the plating solution becomes critical.

| Aspect | Prototype Chrome Plating | Production Chrome Plating |

|---|---|---|

| Fixturing | Manual, temporary jigs | Custom-designed racks |

| Consistency | Operator dependent | Process dependent |

| Quality Check | 100% manual inspection | Statistical Process Control (SPC) |

| Bath Maint. | Less critical | Highly critical |

Scaling chrome plating from a prototype to production requires a strategic shift. You must re-evaluate cost structures, lead times, and technical methods. Prototyping prioritizes speed and flexibility, while production demands efficiency, consistency, and optimized tooling for success.

How To Partner With A Full-Service CNC + Chrome Plating Supplier

Choosing a supplier that handles both CNC machining and chrome plating under one roof is a strategic decision. This approach is often called vertical integration. It offers powerful benefits for your project.

Why a One-Stop Shop Wins

A ‘one-stop metal finishing’ partner simplifies everything. You get faster turnarounds and clearer communication. There is no need to manage multiple vendors.

The process becomes much more efficient.

Single vs. Multi-Vendor Approach

| Feature | Single Supplier | Multiple Suppliers |

|---|---|---|

| Lead Time | Reduced | Extended |

| Accountability | Single Point | Diffused |

| Logistics | Simplified | Complex |

| Quality Control | Consistent | Variable |

This consolidation is a key advantage for any project requiring precision parts with a durable, high-quality finish. It streamlines your entire workflow.

Working with a single ‘chrome machining supplier’ who also manages plating fundamentally changes project dynamics. The most significant advantage is single-vendor accountability.

Eliminating the Blame Game

When machining and plating are separate, problems can lead to finger-pointing. The plater might blame poor surface preparation, while the machinist blames the plating process. With a ‘CNC plus chrome plating’ partner like PTSMAKE, one team owns the entire result. This ensures a focus on solutions, not excuses.

This integrated approach also dramatically cuts down on lead times.

The True Cost of Multiple Vendors

We’ve seen that eliminating transit time between a machinist and a plater can shorten a project timeline by days, sometimes even weeks. This is a direct result of improved synergistic efficiency12.

Here are some hidden complexities you avoid:

| Hidden Cost | Description |

|---|---|

| Transit Delays | Shipping parts between facilities adds time and risk. |

| Scheduling Conflicts | Aligning schedules of two different companies is difficult. |

| Quality Mismatches | Inconsistent communication on surface finish requirements. |

| Admin Overhead | Managing two sets of POs, invoices, and contacts. |

Choosing a fully integrated partner for services like chrome plating ensures that the part is designed and machined with the final finish in mind from the very start.

Choosing a vertically integrated partner for CNC and chrome plating streamlines production. It reduces lead times and establishes single-vendor accountability, eliminating coordination headaches and simplifying your supply chain for a better final product.

Your Chrome Plating Questions—Answered By Industrial Experts

Making the right decision on chrome plating requires clear, technical answers. Decision-makers often ask about the core differences and applications. This FAQ provides expert chrome advice.

We will address the most common inquiries I receive. This section offers direct answers to guide your component design and material selection process.

Hard Chrome vs. Decorative Chrome

What sets them apart? Hard chrome is for function. Decorative chrome is for appearance. Both offer corrosion protection, but their primary purposes differ significantly.

Key Distinctions

| Feature | Hard Chrome Plating | Decorative Chrome Plating |

|---|---|---|

| Purpose | Wear resistance, durability | Aesthetics, corrosion resistance |

| Thickness | Thicker (20-100 µm) | Thinner (0.05-0.5 µm) |

| Appearance | Matte to semi-bright | Bright, mirror-like |

| Underlayers | Applied directly | Requires nickel/copper |

Many engineers ask for technical chrome coating help, especially regarding material compatibility and potential issues. Let’s dive deeper into some of these complex topics.

Can All Metals Be Chrome Plated?

The short answer is no. Success depends heavily on the base material. Proper surface preparation is critical for adhesion and a quality finish. Some metals require special intermediate layers.

For example, aluminum is challenging. It needs a zincate process before plating. Stainless steel can also be difficult due to its natural passive layer.

What Causes Plating Failure?

Failures like peeling or flaking usually trace back to preparation. Inadequate cleaning or poor activation of the substrate are common culprits. Another cause is internal stress within the chrome layer itself.

After working with our clients, we’ve found that controlling bath chemistry is also vital. Impurities or incorrect concentrations can compromise the entire process. This can lead to a weak bond between the substrate and the coating, often requiring complete rework of the part. Understanding the role of passivation13 on certain substrates is key.

Common Substrates and Plating Suitability

| Substrate Material | Suitability | Key Considerations |

|---|---|---|

| Steel (Low Carbon) | Excellent | Straightforward process. |

| Stainless Steel | Good | Requires specific activation step. |

| Aluminum | Fair | Needs a zincate undercoat. |

| Copper Alloys | Excellent | Often used as an underlayer. |

This FAQ addresses critical technical questions on chrome plating, comparing hard and decorative types and exploring key factors like material suitability and common causes of failure. It offers expert guidance to ensure optimal results for your components.

Unlock Precision Chrome Plating Solutions With PTSMAKE Today

Ready to elevate your CNC machined parts with advanced chrome plating? Partner with PTSMAKE for rapid quoting, expert technical advice, and seamless project execution—from prototype to production. Contact us now to get a fast, tailored quotation and experience precision manufacturing you can trust!

Discover how controlled surface properties can enhance lubricant retention and overall part performance. ↩

Understand the properties and safety considerations of this key chemical used in traditional chrome plating processes. ↩

Understand how friction and wear data can predict the service life and reliability of your parts. ↩

Learn the science behind this plating method that provides uniform coverage without an electrical current. ↩

Learn how this electrical principle directly impacts the uniformity and quality of your chrome plated finish. ↩

Understand how the bond between coating and material impacts the durability of your CNC machined parts. ↩

Discover the chemical details of this essential process for successfully plating aluminum. ↩

Learn how the combined effects of mechanical wear and corrosion can impact part performance. ↩

Understand the unique surface properties of hard chrome that improve lubrication and component life. ↩

Learn how electric current flow impacts plating quality and how to control it for superior results. ↩

Learn how this property affects plating uniformity on complex parts and impacts your project’s quality. ↩

Discover how process synergy can cut hidden costs and improve project delivery schedules. ↩

Learn how this chemical treatment affects plating adhesion on specific alloys. ↩