Finding the right copper casting manufacturer feels overwhelming when your project demands precision and reliability. You’re dealing with complex alloy selections, process decisions, and quality requirements that can make or break your component’s performance.

PTSMAKE specializes in custom copper casting with advanced sand casting, investment casting, and permanent mold processes. We deliver precision copper components from prototype to production, serving aerospace, automotive, electronics, and industrial equipment manufacturers with reliable quality and on-time delivery.

I’ve worked with many engineering teams who struggle with copper casting decisions. The technical complexity runs deep – from choosing between C83600 brass and C95400 aluminum bronze to selecting the right casting method for your geometry. This guide breaks down the essential knowledge you need to make informed decisions and work effectively with your casting supplier.

When to choose sand casting versus investment casting for copper alloys?

Choosing the right copper casting method is crucial. It impacts your part’s quality, cost, and lead time. Both sand casting and investment casting are popular for copper alloys.

However, they excel in different areas. The best choice depends entirely on your project’s specific needs.

We’ll compare them on practical criteria. This includes surface finish, dimensional accuracy, and tooling cost. Understanding these differences will help you make the right call for your copper components.

| Feature | Sand Casting | Investment Casting |

|---|---|---|

| Best For | Large Parts, Low Volume | Complex Parts, High Finish |

| Tooling Cost | Low | High |

| Surface Finish | Rough | Smooth |

Making the right selection starts by understanding the trade-offs. It’s not about a "better" process overall. It’s about finding the best fit for your specific copper alloy application.

Analyzing Core Production Factors

Let’s break down the critical factors that drive the decision. These elements influence your final part’s performance and budget. At PTSMAKE, we guide clients through these questions first.

Surface Finish and Dimensional Accuracy

Investment casting delivers a superior surface finish. This quality often reduces or eliminates the need for secondary machining. Sand casting, by nature, produces a rougher surface texture that may require post-processing.

Dimensional accuracy follows the same logic. Our tests show investment casting consistently holds tighter tolerances.

| Parameter | Sand Casting | Investment Casting |

|---|---|---|

| Surface Finish (Ra) | 12.5 – 25 µm | 1.6 – 3.2 µm |

| Typical Tolerance | ±0.8 mm | ±0.15 mm |

Balancing Cost, Volume, and Complexity

Sand casting tooling is simple and less expensive. This makes it ideal for prototypes and low-volume production runs. Investment casting requires complex, costly molds.

For high-volume runs, however, the higher tooling cost of investment casting is justified. It leads to lower per-part costs due to reduced labor and finishing. Complex parts with intricate details are also a clear win for investment casting. The sand-to-metal ratio1 is one of many variables we analyze in sand casting to optimize both quality and cost.

The choice between sand and investment casting for copper alloys is a strategic balance. You must weigh initial tooling costs against per-part costs, desired surface finish, and part complexity. Each project has a unique optimal solution.

What are the practical trade-offs between different copper casting alloys?

Choosing the right copper alloy involves balancing key properties. Let’s compare three common choices for copper casting projects. Each serves a different purpose in manufacturing.

We will focus on C83600, C95400, and C17200. These are alloys we frequently work with at PTSMAKE.

Their trade-offs in cost, strength, and castability are significant. Understanding them prevents costly mistakes in production. This knowledge is key for successful outcomes.

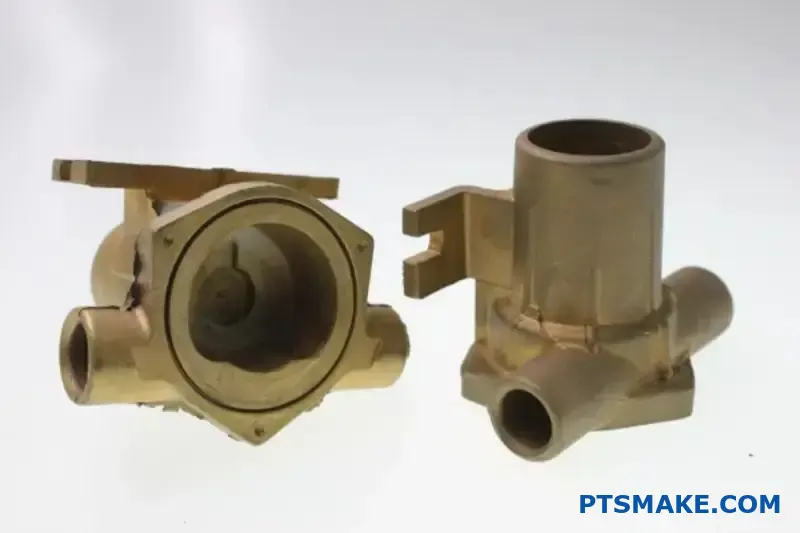

Let’s dig deeper into the practicalities. C83600 Leaded Red Brass is the workhorse. Its lead content improves machinability but can pose environmental concerns. It’s reliable for non-critical applications like valves and fittings.

C95400 Aluminum Bronze is a different beast. Its strength is impressive, often compared to steel. This alloy also has excellent resistance to galling2 under heavy loads. However, it can be more challenging to cast due to its aluminum oxide layer, which requires specialized foundry techniques.

C17200 Beryllium Copper is a premium choice. After heat treatment, its strength is unmatched among copper alloys. But this performance comes at a high cost. Handling beryllium dust also requires strict safety protocols, adding complexity to manufacturing.

Here is a quick comparison based on our project experience:

| Alloy | Key Advantage | Main Drawback | Typical Application |

|---|---|---|---|

| C83600 | Excellent castability, low cost | Lower strength, lead content | Plumbing, general hardware |

| C95400 | High strength, wear resistance | Difficult to cast/weld | Bearings, marine parts |

| C17200 | Highest strength, conductivity | High cost, safety concerns | Aerospace, electronics |

This table helps clients visualize the trade-offs quickly. The choice always depends on the specific engineering and budget requirements of the project.

Each copper alloy offers a distinct balance. Leaded Red Brass is cost-effective and easy to work with. Aluminum Bronze provides strength and wear resistance. Beryllium Copper delivers top-tier performance but at a premium cost and with added manufacturing complexity.

How are copper casting processes classified by mold material and purpose?

The main way to classify copper casting methods is by the mold type. We can split them into two fundamental groups. This initial choice sets the stage for cost, detail, and production speed.

Expendable Molds

These molds are used only once. After the metal solidifies, the mold is broken away to retrieve the part. This is ideal for complex geometries and prototypes.

Permanent Molds

As the name suggests, these molds are reusable. They are typically made from metal and can produce thousands of parts. This is the go-to for high-volume manufacturing.

| Mold Type | Reusability | Key Advantage |

|---|---|---|

| Expendable | Single-Use | Design Freedom |

| Permanent | Multi-Use | Production Speed |

Understanding this basic division is the first step in selecting the best casting process.

Let’s break down these categories further. Each sub-process offers unique trade-offs. Making the right choice early is something we always emphasize at PTSMAKE. It prevents costly redesigns later.

A Closer Look at Expendable Molds

These methods are known for their versatility.

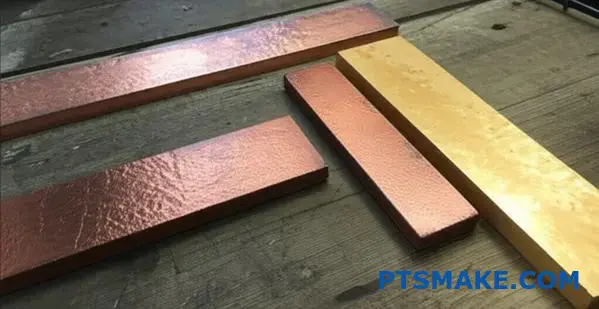

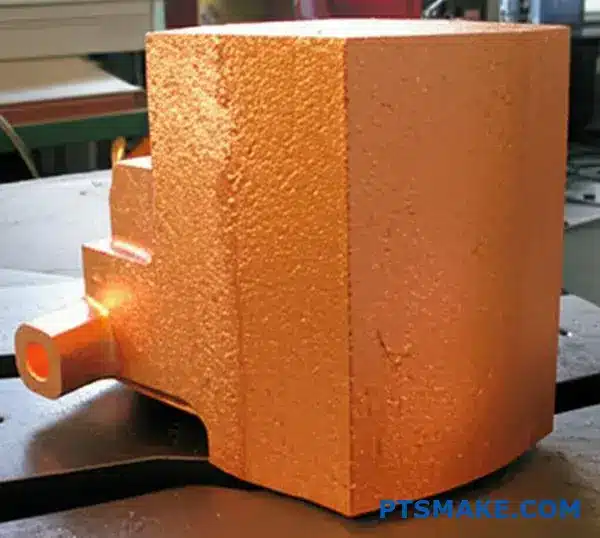

Sand Casting

This is a widely used copper casting process. A mold is formed from sand mixed with a binder. It’s excellent for large parts. However, its surface finish is rougher. The sand’s permeability3 is a key factor, as it allows gases to escape and prevents defects.

Shell Molding

This method uses a thin, hardened shell of sand and resin. It produces parts with a smoother finish and better dimensional accuracy than standard sand casting. It’s a great middle ground.

Investment Casting

Often called lost-wax casting, this process offers the highest precision. It’s perfect for creating highly intricate copper parts with excellent surface finishes. The trade-off is a higher per-unit cost.

A Closer Look at Permanent Molds

These are designed for efficiency in mass production.

Gravity Casting

Molten copper is poured into a reusable metal mold, filling it by gravity. This process yields good mechanical properties and is suitable for a wide range of copper alloys.

Die Casting

This involves injecting molten metal into a mold under high pressure. It is extremely fast but is less common for copper alloys due to their high melting temperatures, which can cause rapid mold wear.

| Process | Primary Benefit | Common Application |

|---|---|---|

| Sand Casting | Low tool cost | Large valves, impellers |

| Investment Casting | High detail | Small, intricate components |

| Gravity Casting | Good balance | Plumbing fittings, hardware |

Copper casting is not a one-size-fits-all solution. Each project has unique demands.

The main classification for copper casting hinges on expendable versus permanent molds. This choice directly impacts project cost, part complexity, and production volume. Selecting the right sub-process is critical for meeting specific design requirements for copper alloys.

What is the system for categorizing common copper casting defects?

To fix problems, you first need to understand them. A clear system is key. It helps us diagnose issues without guesswork.

In copper casting, we group defects into four main types. This structured approach helps us find the root cause faster. It prevents fixing the wrong thing.

Major Defect Categories

We classify defects based on their origin. This tells us where to look for the solution.

| Defect Category | Common Examples |

|---|---|

| Filling-Related | Misruns, Cold Shuts |

| Solidification-Related | Shrinkage, Hot Tears |

| Gas-Related | Porosity, Blowholes |

| Mold-Material-Related | Sand Inclusions, Scabs |

This framework is the foundation for effective troubleshooting.

A systematic approach transforms defect analysis. It moves from random fixes to targeted solutions. This is crucial for high-quality copper casting parts. At PTSMAKE, we rely on this logic to ensure every part meets specification. It’s about process control.

The Diagnostic Power of Categorization

Each category points to a different stage of the casting process. Is it a filling problem? We check gating design and pouring temperature. Is it a gas defect? We look at melt treatment and mold permeability.

This method helps distinguish between defects that look similar. For instance, gas porosity and shrinkage porosity can be confused. But their causes are completely different. Understanding the formation of interdendritic porosity4 is a perfect example of this deep analysis.

From Diagnosis to Solution

By correctly identifying the defect’s group, we can trace its origin. This creates a clear path to the right solution. It saves time and materials.

| Root Cause Area | Defect Category | Potential Solution |

|---|---|---|

| Gating System Design | Filling-Related | Adjust runner size, increase pouring speed |

| Alloy Composition | Solidification-Related | Modify alloy, improve feeding system |

| Melt Handling | Gas-Related | Degas the molten metal properly |

| Mold Condition | Mold-Material-Related | Improve sand quality, use better coating |

This structured thinking prevents recurring issues. It builds a more reliable manufacturing process.

Categorizing copper casting defects is essential. Grouping them into filling, solidification, gas, and mold-related issues provides a clear diagnostic framework. This systematic method helps us quickly identify root causes and implement effective solutions for consistent quality.

How does part geometry dictate the optimal casting method selection?

Part geometry is the most critical factor. It’s the blueprint that tells us which casting method will work and which will fail.

Wall Thickness Challenges

Thin walls are difficult to fill completely. They cool too fast, risking defects. Thick sections, however, can cause shrinkage and porosity issues.

Complexity: Simple vs. Intricate

A simple block has few constraints. But a complex impeller with curved blades demands a process that can replicate fine details accurately.

| Feature | Simple Block | Complex Impeller |

|---|---|---|

| Geometry | Basic, solid | Intricate, thin-walled |

| Process | Sand Casting | Investment Casting |

| Cost | Low | High |

Beyond basic shape, specific geometric features narrow your choices even further. Each detail adds a constraint that points toward an ideal manufacturing path. At PTSMAKE, we analyze these details closely.

Internal Cavities and Cores

If your part has internal passages, you’ll need cores. Sand casting is excellent for this. It uses sand cores that are easily removed after casting. This method works well for hollow components.

Investment casting also handles complex internal shapes. It uses a wax pattern that gets melted out, leaving a cavity for the metal.

Tolerances and Surface Finish

How precise does your part need to be? Loose tolerances allow for simpler methods like sand casting. This method’s lower tooling cost is a benefit.

However, for tight tolerances and smooth finishes, die casting or investment casting are superior. These methods provide near-net-shape parts. This reduces the need for secondary machining. High-precision permeability5 of the mold material is a factor here.

Overall Size and Weight

Size matters greatly in casting. Very large parts, like engine blocks, are typically made with sand casting. The process is highly scalable.

Smaller, high-volume parts are perfect for die casting. This is common for materials like aluminum or zinc alloys. For specialized applications like high-conductivity copper casting, the geometry will again guide the choice between sand, investment, or another method.

Geometric features like wall thickness, cavities, tolerances, and size are decisive. They are not minor details. These factors directly guide the selection of the most efficient and reliable casting process for turning your design into a successful physical part.

What are the categories of post-casting finishing processes for copper?

Finishing a raw copper casting is a multi-stage process. Each stage serves a specific purpose. It moves the part from its rough state to a finished product.

We group these processes into key categories. This helps streamline production and ensures quality.

Fettling: The First Cleanup

Fettling removes excess material from the casting. This includes gates, risers, and flashing. It’s the essential first step after the part cools down.

Surface Treatment

Next, we treat the surface. This cleans the casting and prepares it for later steps. Processes like shot blasting create a uniform, clean finish.

| Stage | Purpose | Common Equipment |

|---|---|---|

| Fettling | Remove unwanted material | Saws, grinders, cutting tools |

| Surface Treatment | Clean and texturize surface | Shot or sand blasting machine |

After the initial cleanup, we move to refining the part’s properties and dimensions. Heat treatment and final machining are critical here. These stages determine the final performance and accuracy of the copper casting. At PTSMAKE, we carefully control these steps for every project.

Heat Treatment

Heat treatment alters the microstructure of copper alloys. This enhances their mechanical properties like strength and hardness. It’s not always required, but it is vital for high-performance applications.

Annealing

Annealing softens the copper. It improves ductility and relieves internal stresses created during casting. The part is heated to a specific temperature and then slowly cooled.

Solutionizing

Some copper alloys benefit from solutionizing6. This involves heating the alloy to dissolve alloying elements into a solid solution. Rapid cooling then traps these elements. This process prepares the alloy for age hardening, which significantly boosts its strength.

Final Machining

Final machining is where we achieve the precise dimensions and tight tolerances required by the design. Using CNC machines, we create the final shape, threads, and features with high accuracy.

| Process Stage | Specific Method | Objective |

|---|---|---|

| Heat Treatment | Annealing | Increase ductility, relieve stress |

| Heat Treatment | Solutionizing | Prepare for age hardening |

| Final Machining | CNC Milling/Turning | Achieve final part dimensions |

Post-casting finishing involves four key stages: fettling, surface treatment, heat treatment, and final machining. This systematic approach transforms a raw casting into a precise, functional component that meets all specifications and ensures reliable performance in its final application.

How do permanent mold and die casting differ for copper?

Copper’s high melting point is the single most important factor. It dictates the entire approach for copper casting. This fundamental property creates a clear divide between permanent mold and die casting.

The choice of method directly impacts mold material, pressure, and production speed. Understanding these differences is crucial for any project involving cast copper components. Below is a quick comparison of these key differentiators.

| Feature | Permanent Mold Casting | Die Casting |

|---|---|---|

| Pressure | Gravity-fed | High pressure injection |

| Mold Material | Iron, Steel | Refractory Metals |

| Production Rate | Lower | Higher |

| Tooling Cost | Moderate | Very High |

The primary challenge for die casting copper is its melting point of over 1080°C (1984°F). Standard die casting tool steels, such as H13, cannot withstand this extreme temperature for long. They quickly lose hardness and develop cracks.

This rapid degradation is a classic case of material failure. The intense and repeated heat cycles cause severe thermal fatigue7 in the mold steel. In our past projects at PTSMAKE, we’ve seen standard dies become unusable after very few cycles with high-temperature copper alloys.

The Mold Material Dilemma

To overcome this, copper die casting requires molds made from refractory metals. Materials like molybdenum and tungsten are necessary because their melting points are much higher. This is the only viable solution for high-volume production.

However, these materials are incredibly expensive and difficult to machine. This drives the tooling cost up substantially compared to permanent mold casting or die casting for aluminum or zinc.

Pressure, Rate, and Complexity

Permanent mold casting uses gravity, putting far less stress on the mold. This allows for the use of more conventional and affordable mold materials, making it suitable for smaller production runs.

Die casting, on the other hand, uses immense pressure to fill the mold cavity. This enables the creation of complex parts with thin walls but also adds to the extreme stress on the already costly refractory molds.

| Aspect | Permanent Mold for Copper | Die Casting for Copper |

|---|---|---|

| Typical Part Size | Small to large | Small to medium |

| Complexity | Simple to moderate | High, thin walls possible |

| Main Challenge | Slower cycle times | Extreme mold wear & cost |

The main differences are driven by copper’s heat. Die casting is faster and produces complex parts but demands expensive refractory metal molds. Permanent mold casting is slower and simpler, offering a more cost-effective tooling solution for lower volumes.

What is the structure of a typical copper casting quality standard?

Let’s examine a typical standard, like ASTM B824 for copper alloys. It provides a clear roadmap. This ensures everyone—from the foundry to the end-user—is on the same page.

It is not just a document. It is a shared language for quality.

Key Sections of a Standard

A well-structured standard covers all critical aspects of production. This removes guesswork and prevents disputes. Below is a common structure you’ll find.

| Section | Purpose |

|---|---|

| Scope | Defines the alloy and casting types covered. |

| Composition | Lists required chemical element percentages. |

| Mechanical | Specifies strength and hardness requirements. |

| Defects | Sets limits for visual and internal flaws. |

| Certification | Outlines necessary documentation. |

A Deeper Look into the Standard’s Framework

Understanding each section is key to successful sourcing. It helps you specify exactly what you need for your application. At PTSMAKE, we use these standards daily. They are the foundation of every high-quality copper casting we produce.

Chemical Composition

This section is precise. It details the exact percentages for copper, tin, zinc, and other elements. Deviating from this recipe can drastically alter the final part’s performance and properties.

Mechanical Property Testing

Here, the standard defines the material’s strength. It mandates tests for tensile strength, yield strength, and elongation. These tests confirm the casting can withstand the mechanical stresses of its intended use.

Permissible Defects

No casting is perfect. This section sets realistic limits. It covers visual flaws like surface porosity. It also addresses internal issues. Standards define acceptable levels for these flaws, often using radiographic standards8 for internal soundness.

This table shows a simplified comparison.

| Defect Type | Inspection Method | Example Criteria |

|---|---|---|

| Surface Porosity | Visual Inspection | Max number of pores per square inch. |

| Internal Shrinkage | Radiographic (X-ray) | ASTM E446 reference radiographs. |

| Cracks | Visual, Dye Penetrant | No visible cracks are allowed. |

Certification and Documentation

Finally, this part requires proof. The manufacturer must provide a certificate. This document confirms the copper casting meets all specified chemical and mechanical requirements, ensuring full traceability.

Standards like ASTM provide a comprehensive blueprint. They define everything from chemical makeup to testing protocols and acceptable defects. This structure ensures that every copper casting part meets the exact engineering requirements for reliability and performance in demanding applications.

How do you select the optimal heat treatment for a casting?

Choosing the right heat treatment for a copper casting is crucial. It’s not just about heating and cooling. It is about unlocking the specific properties your application demands. Different copper alloys respond very differently.

A Quick Decision Guide

For common copper alloys, the goal dictates the process. Whether you need to soften the material or significantly increase its strength, there’s a specific thermal path to follow.

| Alloy Family | Primary Goal | Recommended Heat Treatment |

|---|---|---|

| Pure Copper / Brasses | Relieve stress, improve ductility | Annealing (Stress Relief) |

| Bronzes (e.g., Tin Bronze) | Improve toughness, reduce hardness | Annealing |

| Beryllium Copper (BeCu) | Maximize strength and hardness | Solution Treatment + Aging |

| Chromium Copper | Enhance conductivity and strength | Solution Treatment + Aging |

This guide helps simplify the initial selection.

Understanding the Key Processes

Each heat treatment process serves a unique metallurgical purpose. Incorrect application can ruin a perfectly good casting. Let’s break down the most common methods we use at PTSMAKE for copper alloys.

Annealing for Stress Relief

Annealing is essentially a softening process. We heat the copper casting to a specific temperature and hold it there. This allows the internal crystal structure to realign, which relieves stresses built up during casting or machining.

The primary benefits are:

- Improved ductility and formability.

- Reduced risk of stress-corrosion cracking.

- A more stable and uniform material.

Solution Treatment and Aging

This two-step process is reserved for precipitation-hardenable9 alloys, like Beryllium Copper (BeCu). It is how we achieve remarkable strength from these materials.

Step 1: Solution Treatment

First, we heat the casting to a high temperature. This dissolves the hardening elements (like beryllium) evenly into the copper, creating a solid solution. Then, we rapidly quench it to lock that structure in place.

Step 2: Aging (Precipitation Hardening)

Next, the casting is reheated to a lower temperature for a set time. This allows the dissolved elements to precipitate out as very fine, hard particles within the metal’s grain structure. These particles act as obstacles to dislocation movement, dramatically increasing the alloy’s strength and hardness.

Selecting the right heat treatment for a copper casting is key. Annealing enhances ductility by relieving stress. For high-strength alloys like BeCu, a two-step solution treatment and aging process is necessary to achieve peak mechanical properties for demanding applications.

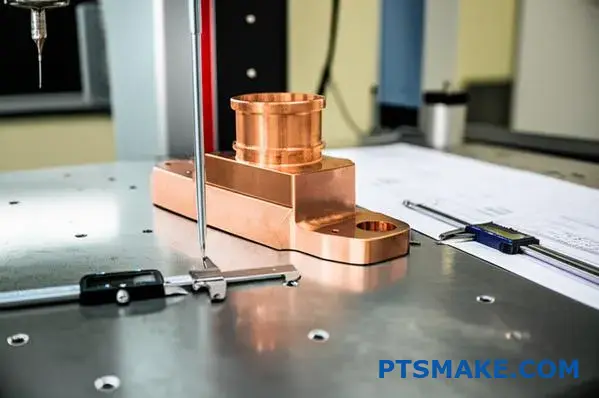

What is the methodical approach to dimensional inspection of a casting?

A robust Quality Assurance (QA) procedure is the foundation for reliable dimensional inspection. It’s more than just measuring; it’s a system. This ensures every casting meets the required specifications.

The Core QA Framework

We begin by selecting the right measurement tools. Then, we identify all critical dimensions from the engineering drawing. This systematic process minimizes errors and guarantees consistency.

Essential Steps in QA

| Step | Description | Primary Goal |

|---|---|---|

| Tool Selection | Choose from Calipers, CMMs, etc. | Match tool to tolerance |

| Define Dimensions | Identify critical features on drawing. | Ensure part functionality |

| Create Protocol | Standardize the measurement process. | Achieve repeatability |

| Document Results | Record all data systematically. | Enable process control |

This structured method is vital for all parts. It’s especially important for complex components like a copper casting with tight tolerances.

Selecting the Right Measurement Tools

The choice of inspection tool depends entirely on the part’s complexity and tolerance requirements. For quick, simple checks, digital calipers or micrometers are often sufficient.

However, for castings with intricate geometries or very tight tolerances, a Coordinate Measuring Machine (CMM) is indispensable. A CMM provides highly accurate 3D data points, offering a complete picture of the part’s dimensions. At PTSMAKE, we always match the inspection tool to the specific demands of the project.

From Drawing to Protocol

The engineering drawing is our single source of truth. We meticulously review it to identify critical-to-function dimensions and their associated tolerances. These are the features that directly impact how the casting will perform in its final assembly.

Based on these critical features, we establish a formal measurement protocol. This document is a step-by-step guide for our quality inspectors. It details how, where, and in what sequence to measure the part. This detailed process is part of a larger field called metrology10.

The Importance of Documentation

Every measurement is carefully recorded. This data creates more than just a simple pass/fail report. It feeds into a continuous improvement loop. We use these results to monitor the stability of our casting process and provide actionable feedback.

A systematic QA procedure is key for dimensional inspection. It involves selecting the right tools, defining critical tolerances from drawings, and following a strict measurement protocol. Documentation completes the process, ensuring consistent quality and control for every casting produced.

Partner with PTSMAKE for Expert Copper Casting Solutions

Ready to take your copper casting project to the next level? Contact PTSMAKE for a fast, detailed quote—our team specializes in precision solutions tailored to your requirements. Ensure quality, reliability, and competitive pricing. Send your inquiry now and make your sourcing more efficient with PTSMAKE!

Learn more about this key parameter affecting sand casting quality and cost. ↩

Learn how material properties can prevent surface damage and component failure in high-load applications. ↩

Discover how mold characteristics directly affect the final quality and integrity of your cast copper parts. ↩

Understand the microstructural details of how this common porosity type forms and how to prevent it. ↩

Learn how this property is crucial for preventing gas defects and ensuring a high-quality casting. ↩

Understand how this thermal process enhances the strength and performance of specific copper alloys for demanding applications. ↩

Learn how repeated heating and cooling cycles cause material failure in casting molds. ↩

Understand how X-ray inspection finds hidden flaws to guarantee the structural integrity of your cast parts. ↩

Discover the metallurgical science behind how these specialized alloys achieve superior strength. ↩

Explore this link to understand the fundamental principles of measurement science and its importance in manufacturing. ↩