Small-batch manufacturers face a tough choice: wait months for expensive tooling or compromise on precision with alternative methods. This gap between prototype and mass production creates delays, increases costs, and limits design flexibility when you need it most.

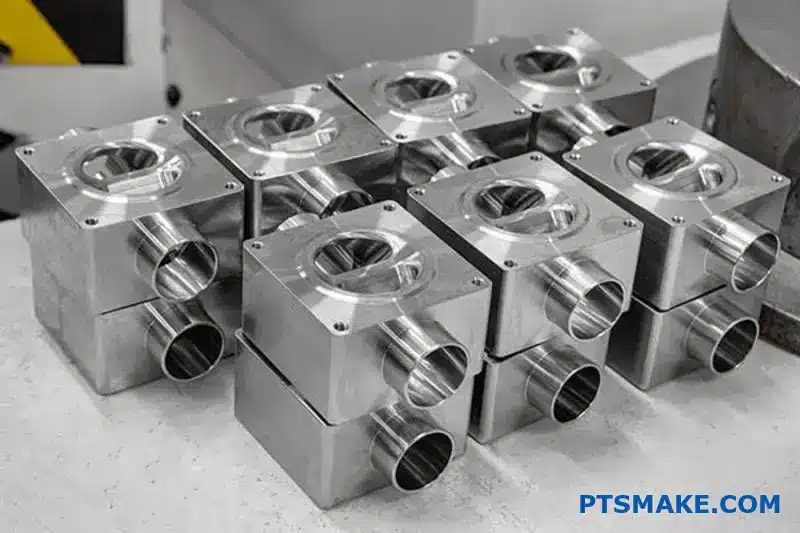

Low volume CNC machining bridges the gap between prototyping and mass production, delivering precision parts in quantities from 10 to 10,000 pieces with faster turnaround times and lower upfront costs than traditional manufacturing methods.

This manufacturing approach has transformed how companies bring products to market. At PTSMAKE, I’ve worked with clients who cut their product development cycles by 40% using low volume CNC for bridge production. The technology offers something unique: the precision of CNC machining without the high setup costs of mass production tooling. Whether you’re testing market demand, producing custom components, or managing seasonal products, understanding low volume CNC machining can give your business a competitive edge in today’s fast-moving markets.

Key Advantages of Low Volume CNC Machining for Modern Manufacturing?

Ever felt trapped by high tooling costs and long lead times for a small batch of custom parts, stalling your project’s momentum and innovative drive?

Low volume CNC machining offers unparalleled manufacturing flexibility, rapid turnaround, and cost-effectiveness for small batches. This method empowers businesses to accelerate design iterations, reduce time-to-market, minimize inventory risks, and swiftly adapt to market demands, becoming a cornerstone of modern product development.

The modern manufacturing landscape demands speed and agility. Gone are the days when a company could afford to spend months developing a single prototype or committing to a massive production run based on unproven assumptions. This is where low volume CNC machining truly shines, acting as a bridge between initial concepts and market-ready products. It fundamentally changes how we approach product development.

Unleashing True Manufacturing Flexibility

Unlike injection molding, which requires significant upfront investment in molds, CNC machining is a direct digital manufacturing process. Your CAD file is the only tool you need to get started. This "tool-less" nature provides incredible flexibility. If a design needs a minor tweak or a complete overhaul, you simply update the digital file. There are no costly mold modifications or write-offs. Furthermore, this flexibility extends to materials. At PTSMAKE, we frequently switch between machining aluminum for a lightweight prototype one day and PEEK for a high-performance end-use part the next, all using the same equipment. This ability to easily test different materials is invaluable during the R&D phase.

Accelerating Your Time-to-Market

In today’s competitive environment, speed is everything. Low volume production significantly shortens the product development cycle, allowing you to get your product into the hands of customers faster.

From Digital File to Physical Part

The process is remarkably streamlined. Once we receive a 3D model, our CAM software generates the toolpaths, and the machines can start cutting material within hours. This efficiency means you can have a functional prototype or a small batch of production-quality parts in your hands in a matter of days, not weeks or months. This rapid feedback loop is critical for validating designs and making informed decisions quickly.

The Cost-Effectiveness of Small Batches

One of the most significant barriers in traditional manufacturing is the economy of scale. It’s often not financially viable to produce a small quantity of parts. Low volume CNC machining flips this model on its head by eliminating the primary cost driver: tooling. Without the need for an expensive mold, the per-part cost remains reasonable even for a single unit. This pay-as-you-go approach minimizes financial risk and frees up capital that would otherwise be tied up in tooling and excess inventory. You can order exactly what you need, when you need it.

| Feature | Low Volume CNC Machining | Traditional Mass Production |

|---|---|---|

| Initial Tooling Cost | None / Very Low | High to Very High |

| Lead Time (First Article) | Days | Weeks or Months |

| Design Flexibility | High (Easily Modified) | Low (Costly to Change) |

| Ideal Batch Size | 1 – 10,000+ units | 10,000+ units |

The Freedom to Iterate and Innovate

Innovation rarely happens in a single step; it’s a process of continuous refinement. Low volume machining supports this iterative process perfectly. You can produce a first version, test it in a real-world application, gather feedback, and then machine an improved version. This cycle can be repeated quickly and affordably. It allows engineers to fail fast, learn, and arrive at an optimized design without breaking the budget. It also ensures that critical design elements, governed by standards like Geometric Dimensioning and Tolerancing (GD&T)[^1], are perfected before committing to larger-scale production.

Industries Leveraging Low Volume CNC Machining.

Have you ever needed a small batch of highly specialized parts, only to be quoted for mass production tooling? This often leaves innovative projects stuck before they can even begin.

Low volume CNC machining is a critical manufacturing process for industries like aerospace, automotive, medical, electronics, and industrial machinery. It enables rapid prototyping, custom part creation, and bridge production without the high costs of traditional mass manufacturing.

Low volume manufacturing isn’t a one-size-fits-all solution; its value is highly specific to the demands of each industry. Certain sectors thrive on its ability to deliver precision and speed without the commitment to large-scale tooling. Let’s look at a few where this impact is most profound.

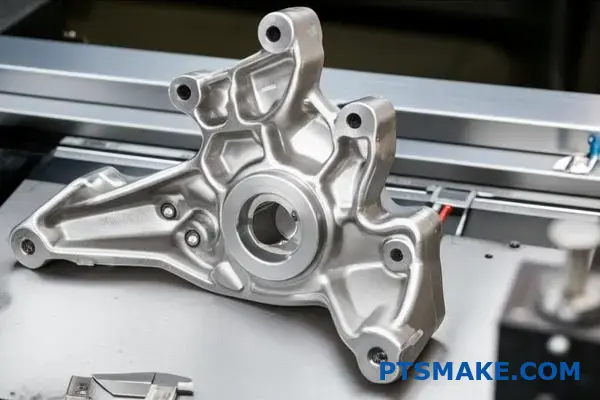

Aerospace and Defense

In aerospace, there is zero room for error. Every component, from a simple bracket to a complex turbine blade, must meet incredibly strict standards. Low volume CNC machining is essential here for several reasons. First, it’s perfect for creating prototypes of new designs that need rigorous testing. Second, it’s used for manufacturing jigs and fixtures that hold parts during assembly, which are often unique to a specific aircraft model.

For example, a team might need just a dozen custom housings for a new avionics system. Creating a mold for this would be incredibly expensive and time-consuming. Instead, we can machine these parts directly from a block of aerospace-grade aluminum or titanium. This process ensures the parts have the required strength-to-weight ratio and can withstand extreme conditions. The materials used must have predictable performance under stress, and machining from a solid block of certified material guarantees this integrity. This method also allows for quick design iterations, which is a common need during the development phase. The ability to make small adjustments and produce a new batch of parts in days, not months, is invaluable. It’s a level of agility that traditional manufacturing simply can’t offer for small quantities. We often see projects that require a high degree of material biocompatibility1, a factor that machining handles exceptionally well by maintaining material purity.

Medical Device Manufacturing

The medical industry shares aerospace’s need for precision but adds the critical requirement of human safety. Low volume CNC machining is a cornerstone of medical device development. Think about surgical instruments, orthopedic implants, and components for diagnostic equipment. Many of these are produced in relatively small quantities.

Custom Implants

A patient might need a custom hip replacement or a specific bone plate tailored to their anatomy. It’s impossible to mass-produce these. Using CNC machining, we can take a patient’s CT scan data and create a 3D model, then machine a perfectly fitting implant from materials like titanium or PEEK. This level of personalization dramatically improves patient outcomes.

Prototyping and Testing

Before a new surgical tool is approved, it goes through numerous design changes. Engineers and surgeons need to physically hold and test different versions. Low volume CNC machining allows companies like ours at PTSMAKE to produce a handful of prototypes for them to evaluate. Based on their feedback, we can quickly refine the design and machine another set. This iterative process is essential for creating safe and effective medical devices.

| Industry | Common Materials | Key Requirement | Example Part |

|---|---|---|---|

| Aerospace | Titanium, Inconel, Aluminum 7075 | Extreme Strength-to-Weight Ratio | Avionics Housing |

| Medical | PEEK, Stainless Steel 316L, Titanium | Biocompatibility, Sterilizability | Surgical Guide |

Beyond the high-stakes worlds of aerospace and medicine, low volume CNC machining provides critical advantages to industries that balance innovation with market demands. These sectors rely on speed, customization, and the ability to pivot without incurring massive costs. This is where the flexibility of producing parts in smaller batches truly shines.

Automotive

The automotive industry, especially in the realms of high-performance vehicles, classic car restoration, and pre-production testing, heavily relies on low volume production. Automakers don’t just stamp out millions of identical cars; they are constantly innovating.

Performance and Aftermarket

Think about a team building a race car or a company developing an aftermarket supercharger kit. They need specialized components like custom brackets, unique intake manifolds, or lightweight suspension parts. These are not high-volume items. CNC machining allows them to produce a small run of these parts from high-strength aluminum or steel, test them on the track, and make adjustments. It’s the only feasible way to create these bespoke components.

Bridge to Production

When a major automaker is developing a new model, they create hundreds of pre-production vehicles for testing. These cars require thousands of parts that aren’t ready for mass-production tooling yet. Low volume CNC machining "bridges" this gap, supplying high-quality, functional parts that mimic the final product’s form and function until the assembly line is ready. In our experience at PTSMAKE, this is a crucial step that helps work out design kinks before millions are invested in production molds.

Consumer and Industrial Electronics

The electronics industry moves at lightning speed. A new product is often obsolete within a year. This rapid lifecycle makes low volume CNC machining an ideal partner for development and niche products. It’s all about creating custom enclosures, heatsinks, and mounting hardware for new devices. For instance, when a company develops a new server or a piece of scientific equipment, the initial run might only be a few hundred units. Machining the aluminum enclosures is far more cost-effective than investing in die-casting tools for such a small quantity. It also allows for a premium look and feel that you can’t get from other methods.

| Industry | CNC Application | Why It’s Critical |

|---|---|---|

| Automotive | Performance Parts | Enables customization and testing for niche markets. |

| Electronics | Custom Enclosures | Provides a high-end finish for low-volume products. |

| Industrial Machinery | Replacement Parts | Solves obsolescence for critical legacy equipment. |

Industrial Machinery

Finally, let’s consider industrial machinery. Factories run on complex equipment, and when a part breaks on an older machine, a replacement might no longer be available from the original manufacturer. This can shut down an entire production line. We’ve helped clients reverse-engineer and machine a single replacement gear or shaft, getting their equipment back online in days. This on-demand capability is also used to create custom components for automated systems, allowing factories to build unique machines tailored to their specific manufacturing process.

From aerospace to automotive, low volume CNC machining is the unsung hero that enables innovation and efficiency. It allows for the creation of precise, high-quality custom parts without the financial burden and time commitment of mass production tooling. This flexibility is critical for everything from prototyping new medical devices and building race cars to manufacturing niche electronics and keeping industrial machinery running smoothly. It empowers engineers to test, iterate, and bring specialized products to market faster.

Applications: From Prototyping to End-Use Parts.

Struggling to get high-quality, functional parts without the massive costs and commitment of full-scale production tooling? This critical gap can stall even the most innovative projects.

Low volume CNC machining is incredibly versatile, serving key roles from creating high-fidelity rapid prototypes to producing end-use custom components. It’s the ideal solution for bridge production, market testing, and manufacturing critical replacement or legacy parts for specialized equipment, streamlining the entire product lifecycle.

Low volume CNC machining is far more than just a single-step solution; it’s a strategic tool that adapts to different stages of the product development cycle. Its flexibility allows engineers and product designers to move seamlessly from concept validation to market-ready products. Let’s break down its primary applications.

Rapid Prototyping: Beyond Form and Fit

While 3D printing is excellent for initial concepts, CNC machining is the go-to for functional prototypes. Why? Because these prototypes are machined from solid blocks of production-grade materials, they possess the same mechanical properties, strength, and durability as the final part. This allows you to conduct real-world testing for stress, thermal resistance, and operational performance—tests that a 3D-printed model would likely fail. The precision of CNC also ensures that tolerances and surface finishes match the final design specifications, giving you an accurate representation of the end product. At PTSMAKE, we often see clients use these high-fidelity prototypes for investor demos or user testing, where functional reliability is non-negotiable. It allows for a level of validation that provides true confidence before committing to expensive tooling. This process reveals crucial insights into the part’s isotropy2 and how it will behave under stress.

Bridge Production: The Crucial Link

Bridge production is the critical manufacturing phase between prototyping and full-scale mass production. This is where low volume CNC machining truly shines. It serves as a "bridge" to get your product to market faster while final mass production tooling is still being prepared. This strategy is perfect for a few key scenarios:

- Market Testing: Launch your product to an early-adopter group to gather feedback before a full rollout.

- First Production Run: Fulfill initial customer orders without waiting months for injection molds or other high-volume tools.

- Process Refinement: Use the low volume run to identify and fix any potential manufacturing issues before scaling up.

Here’s a simple comparison of production stages:

| Stage | Quantity | Cost Per Part | Lead Time |

|---|---|---|---|

| Prototyping | 1-50 | High | Short (Days) |

| Bridge Production | 50-10,000 | Moderate | Medium (Weeks) |

| Mass Production | 10,000+ | Low | Long (Months) |

This staged approach de-risks product launches and provides invaluable flexibility.

Beyond the development stages, low volume CNC machining holds its own as a primary manufacturing method for parts that will never be mass-produced. This capability is essential for specialized industries and for extending the life of valuable equipment. It’s about delivering precision and reliability exactly when and where it’s needed, without the constraints of high-volume economics.

Custom Components for Specialized Equipment

In industries like aerospace, medical devices, and robotics, "low volume" is often the standard volume. Components for a surgical robot, a satellite, or a piece of custom factory automation equipment are not needed in the millions. They are needed in dozens or hundreds, but with extreme precision and often from exotic, hard-to-machine materials like Titanium or PEEK. For these applications, low volume CNC machining is not a temporary step; it is the final production method. It provides the ability to create highly complex geometries and achieve tight tolerances that are impossible with other methods. This allows for continuous innovation and customization, as designs can be tweaked and improved for each new batch without incurring massive re-tooling costs. In our experience with clients in these advanced sectors, the ability to produce a small batch of mission-critical parts on demand is a significant competitive advantage.

Replacement and Legacy Parts: Keeping Machines Running

What happens when a critical component in a ten-year-old manufacturing line fails, and the original equipment manufacturer (OEM) no longer produces that part? This is a common and expensive problem. The choice is often between a complete, costly overhaul of the machinery or scrapping it entirely. Low volume CNC machining offers a third, more efficient solution. We can reverse-engineer the broken component from a physical sample or old drawings and machine an identical, or even improved, replacement part. This is a lifeline for businesses relying on legacy equipment. Creating a single gear or a custom bracket can save a company from hundreds of thousands of dollars in capital expenditure and prevent costly downtime.

| Aspect | OEM Part (If Available) | CNC Machined Legacy Part |

|---|---|---|

| Availability | Often discontinued | Made on demand |

| Lead Time | Can be months or infinite | Typically days or weeks |

| Material Options | Limited to original spec | Can be upgraded for better performance |

| Cost | Can be very high for old stock | Cost-effective for 1-100 units |

This on-demand manufacturing capability is indispensable for maintenance, repair, and operations (MRO) across countless industries.

In summary, low volume CNC machining is a uniquely adaptable manufacturing process. It’s not confined to a single stage but offers strategic value across the entire product lifecycle. From creating robust, functional prototypes for rigorous testing to bridging the gap to mass production, it accelerates development. Furthermore, it serves as the ideal production method for custom, high-precision components and as a vital solution for creating legacy parts, ensuring valuable equipment remains operational and productive for years to come.

Design Strategies for Cost-Effective Low Volume CNC Machining?

Struggling to balance intricate designs with your budget in low-volume production? Are complex features and expensive materials making your CNC machining costs spiral out of control?

To make low volume CNC machining cost-effective, focus on design for manufacturability (DFM). This means simplifying geometries, avoiding features that require multi-axis machining, and choosing materials that offer a good balance between performance and machinability. These strategies directly reduce machine time and setup complexity.

Optimize Your Part Design for Manufacturing

The most significant cost savings in low volume CNC machining happen at the design stage. A well-thought-out design that considers the manufacturing process can dramatically reduce expenses without compromising the part’s function. It’s about working smarter, not harder. In my experience, simple changes can lead to substantial savings.

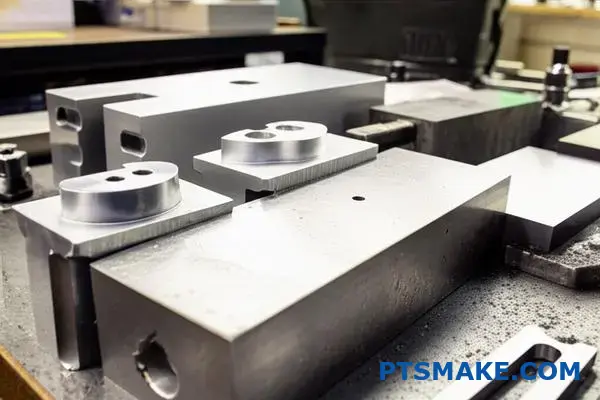

Simplify Geometry Whenever Possible

Every complex curve, sharp internal corner, and deep pocket adds machine time and potentially requires specialized tooling. Keeping the design as simple as its function allows is the first rule of cost reduction.

- Avoid Sharp Internal Corners: CNC tools are round, so they naturally create rounded internal corners. Achieving a perfectly sharp 90-degree internal corner is impossible with a standard end mill. It requires a secondary process like Electrical Discharge Machining (EDM), which significantly increases cost and lead time. Instead, design internal corners with a radius that is slightly larger than the cutting tool’s radius. A good rule of thumb is a radius of at least 1/3 of the cavity’s depth.

- Reduce Deep Pockets: Machining deep, narrow pockets is challenging. It requires long, thin tools that are prone to vibration and breakage, forcing the machine to run at slower speeds. This increases machining time. If a deep pocket is necessary, try to make it as wide as possible. A healthy length-to-diameter ratio for the tool (ideally under 4:1) ensures stability and faster material removal. Materials that are isotropic3 often behave more predictably during these operations, reducing the risk of tool failure.

The table below shows some common design choices and their more cost-effective alternatives.

| Costly Design Feature | Cost-Effective Alternative | Why It Saves Money |

|---|---|---|

| Sharp Internal Corners | Rounded Internal Corners | Eliminates the need for secondary processes like EDM. |

| Deep, Narrow Pockets | Wider, Shallower Pockets | Allows for more rigid tools and faster machining speeds. |

| Thin Walls | Thicker, More Robust Walls | Reduces vibration and the risk of part deformation. |

| Complex 3D Contours | 2.5D Features (prismatic) | Can be machined with simpler 3-axis setups. |

At PTSMAKE, we often collaborate with clients during the design phase. A quick review can often identify these small but impactful changes that optimize a part for low volume CNC machining.

Strategic Material Selection and Setup Reduction

Beyond pure geometry, the material you choose and how the part is set up on the machine are two other critical cost drivers. Smart decisions here can yield significant savings, especially when producing smaller quantities where setup costs are a larger portion of the total price.

Choose Materials that Balance Cost and Performance

The ideal material isn’t always the one with the highest performance specs. It’s the one that meets your application’s requirements while being as easy to machine as possible.

- Understand Machinability: Some materials are simply harder and more abrasive, which wears out tools faster and requires slower cutting speeds. For example, Aluminum 6061 is very easy to machine, while materials like Titanium or Inconel are extremely difficult and time-consuming. Based on our internal tests, switching from a hard-to-machine steel to a high-performance aluminum can sometimes cut machining time by over 50% for the same geometry.

- Consider Plastic Options: Don’t overlook engineering-grade plastics. Materials like Delrin (POM), PEEK, and Nylon can often replace metal in low-stress applications. They are lightweight, corrosion-resistant, and typically much faster and cheaper to machine.

Here’s a quick comparison of some common materials used in low volume manufacturing:

| Material | Relative Cost | Machinability | Common Applications |

|---|---|---|---|

| Aluminum 6061 | Low | Excellent | Prototypes, structural components, housings |

| Stainless Steel 304 | Medium | Fair | Medical devices, food processing parts |

| Delrin (POM) | Low | Excellent | Gears, bearings, high-wear parts |

| PEEK | High | Good | Aerospace, high-temp applications |

Minimize Setups and Fixturing

Every time a part has to be removed and repositioned in the CNC machine, it costs time and introduces a potential for error. This is known as a "setup."

- Design for Single-Setup Machining: If possible, try to design your part so all features can be machined from one or two directions (e.g., top and bottom). This allows the part to be completed in a single setup on a 3-axis or 5-axis machine. Avoid placing critical features on multiple, oddly angled faces that require custom fixtures and multiple setups.

- Standardize Hole Sizes: Using standard drill and tap sizes eliminates the need for tool changes or custom tooling. Consolidating to fewer hole sizes means the machine can complete all similar operations without stopping, which streamlines the process for any low volume CNC machining project.

Effective design for low volume CNC machining is a game of strategic choices. By simplifying your part’s geometry, such as rounding internal corners and avoiding deep pockets, you reduce machine time. Selecting materials based on machinability, not just performance, further cuts costs. Finally, designing parts that can be made in a single machine setup minimizes labor and potential for error. These DFM principles are key to making small-batch production both affordable and efficient.

Material Selection and Its Impact on Low Volume CNC Projects.

Ever chosen a material that seemed perfect on paper, only to face unexpected machining costs or part failures? This common misstep can derail your entire low volume CNC project.

Choosing the right material involves balancing performance, machinability, and cost. For low volume CNC machining, this decision directly impacts lead times and final part quality, making a strategic material selection process essential for project success.

Beyond the Basics: Exploring Composites and Specialty Alloys

While aluminum and standard plastics are workhorses, many projects require materials with more specific properties. This is where composites and specialty alloys come into play. Composites like G-10/FR-4 and Carbon Fiber offer incredible strength-to-weight ratios, making them ideal for applications where every gram counts. However, they are not machined like metals. Their abrasive nature can lead to rapid tool wear, and there is a constant risk of delamination if the machining parameters are not perfect. Unlike metals, which are isotropic, composites exhibit anisotropy4, meaning their mechanical properties differ along different axes. This must be accounted for in the part design and machining setup.

The Machinability Factor in Exotic Materials

Specialty alloys such as Titanium and Inconel present their own set of challenges. These materials are chosen for their exceptional strength, heat resistance, and corrosion resistance. But these same properties make them notoriously difficult to machine. They generate high heat during cutting and have a tendency to work-harden, which drastically increases cycle times and tool wear. For a low volume cnc machining project, this can significantly impact the cost per part. Successfully working with these materials requires specialized tooling, robust machinery, and, most importantly, deep process knowledge. In our experience at PTSMAKE, a project using Titanium can require three to four times the machine time compared to one using aluminum.

Cost vs. Performance Trade-off

Making the right choice often comes down to a clear understanding of the trade-offs. The following table provides a simplified comparison to guide your decision-making.

| Material | Key Property | Relative Machinability (1=Easy) | Relative Material Cost | Best For |

|---|---|---|---|---|

| Aluminum 6061 | Excellent strength-to-weight | 1 | $ | General prototypes, structural parts |

| G-10/FR-4 | High electrical insulation | 4 | $$ | Insulators, PCB stiffeners, jigs |

| Titanium (Grade 5) | Superior strength, corrosion resistance | 7 | $$$$ | Aerospace, medical implants |

Matching Materials to Industry Demands

The theoretical properties of a material are only useful when applied correctly to a real-world problem. The best material choice is always tied to the specific application and its industry standards. An engineer designing a consumer electronic enclosure has very different priorities from one designing a surgical instrument. Over the years, we’ve helped clients navigate these specific requirements, ensuring the final part not only meets the print but also performs reliably in its intended environment. It’s about moving from a general material list to a curated selection that guarantees success.

Aerospace and Defense

In this sector, performance is non-negotiable. Materials must be lightweight, incredibly strong, and able to withstand extreme temperatures and corrosive environments.

- Aluminum 7075: Offers a strength comparable to many steels but at a fraction of the weight.

- Titanium (Grade 5, 6Al-4V): Provides an unbeatable combination of high strength, low weight, and excellent corrosion resistance.

- PEEK: A high-performance polymer used for its mechanical strength, low outgassing properties, and resistance to harsh chemicals.

Medical Devices

The medical industry prioritizes biocompatibility, the ability to withstand sterilization, and complete material traceability. Parts that come into contact with the human body must be made from materials that are proven to be safe.

- Stainless Steel (316L): Widely used for surgical tools and instruments due to its excellent corrosion resistance and cleanability.

- Titanium: The preferred material for implants like bone screws and joint replacements because it is biocompatible and osseointegrates well.

- Medical-Grade Polymers (PEEK, Radel): These materials are often used for device housings and trial implants, as they can be repeatedly sterilized and are radiolucent (transparent to X-rays).

Application-Specific Material Selection

This table shows how requirements drive material choice across different fields.

| Industry | Common Materials | Key Requirement | Example Application |

|---|---|---|---|

| Aerospace | Aluminum 7075, Titanium, PEEK | High strength-to-weight, Temp. resistance | Structural brackets, engine components |

| Medical | Stainless Steel 316L, Titanium, Radel | Biocompatibility, Sterilizability | Surgical tools, implants, device housings |

| Robotics | Aluminum 6061, Delrin, Steel 1018 | Durability, Wear resistance, Cost | Robotic arms, gears, mounting plates |

Material selection for low volume CNC machining is a critical decision that balances performance needs with practical constraints like cost and machinability. Moving beyond standard materials to composites or specialty alloys can provide significant advantages but requires expertise to manage machining challenges. Ultimately, the best choice is driven by the specific demands of the industry, whether it’s the high strength-to-weight ratios needed in aerospace or the biocompatibility required for medical devices, ensuring the final part is perfectly suited for its purpose.

Quality Assurance and Inspection in Small Batch CNC Machining.

Have you ever worried that the quality of your tenth part won’t match the perfection of the first? This inconsistency can derail entire projects, especially with tight deadlines and smaller order quantities.

Rigorous quality assurance in small batch CNC machining is a systematic process. It uses advanced inspection, detailed documentation, and full traceability to guarantee that every part, from first to last, consistently meets precise specifications and industry standards, preventing costly rework and delays.

The Foundation of Trust: Why QA Matters in Small Batches

In mass production, a few defective parts might be statistically acceptable. However, in low volume CNC machining, every single component is critical. Often, these parts are for final assembly, prototyping validation, or specialized equipment where one failure can be catastrophic. There is simply no room for error. A robust quality assurance process isn’t just about catching mistakes; it’s about preventing them from happening in the first place. It builds a foundation of trust between you and your manufacturing partner. At PTSMAKE, we view QA as an integral part of the production process, not a final gate. This mindset ensures that from the moment we receive your CAD file, quality is the primary driver of every decision. This proactive approach is essential for delivering consistent, reliable parts batch after batch.

Advanced Tools for Uncompromising Precision

Visual checks and calipers have their place, but for the complex geometries and tight tolerances required today, they are not enough. We rely on advanced inspection technology to get a complete and accurate picture of each part.

- Coordinate Measuring Machines (CMMs): These are the gold standard for dimensional inspection. A CMM uses a probe to touch points on a part, recording X, Y, and Z coordinates with incredible accuracy. This data is then compared directly against your original CAD model to verify every feature. It’s how we ensure that a bore is perfectly concentric or a plane is truly flat.

- Laser Scanners and Optical Systems: For parts with complex, organic surfaces, a CMM can be slow. Laser scanners capture millions of data points in seconds, creating a detailed 3D map of the surface. This is perfect for verifying contoured shapes and ensuring there are no surface deviations.

These tools provide objective, repeatable data, removing any guesswork from the inspection process. Our commitment to using this technology means you can be confident that your parts adhere to even the most stringent Geometric Dimensioning and Tolerancing (GD&T)5 callouts.

Inspection Equipment Comparison

| Tool | Best For | Key Advantage | Limitation |

|---|---|---|---|

| CMM | High-precision prismatic parts, tight tolerances | Unmatched accuracy and repeatability | Slower for complex, freeform surfaces |

| Laser Scanner | Complex surfaces, reverse engineering | Speed and high-density data capture | Slightly less accurate than touch-probe CMMs |

| Calipers/Micrometers | Quick spot-checks, basic dimensions | Portability and ease of use | Operator-dependent, limited to simple features |

Documentation and Traceability: The Quality Paper Trail

A perfect part is useless without the documentation to prove it. For many industries, especially aerospace, medical, and automotive, traceability is not a luxury—it’s a requirement. This is where a disciplined approach to documentation becomes critical. It creates a complete history for every part we produce. This commitment to transparency is a core part of how we operate at PTSMAKE. We believe that providing you with a clear and comprehensive quality record is just as important as delivering the physical part itself. This paper trail provides peace of mind and simplifies your own internal quality control and assembly processes.

Building a Traceable System

Traceability starts long before the CNC machine is turned on. It’s a chain of information that follows the part through its entire lifecycle.

- Material Certification: It begins with the raw material. We ensure every bar stock or plate comes with a certificate from the mill, verifying its composition and properties (e.g., 6061-T6 Aluminum, 316 Stainless Steel). This document is linked to your project.

- First Article Inspection (FAI): Before running the full batch, we produce and meticulously inspect the first part. The FAI report is a comprehensive document that checks every single dimension, feature, and note on your print. We share this with you for approval, ensuring we’re perfectly aligned before proceeding.

- In-Process Checks: Quality isn’t just a final step. Our operators perform regular checks throughout the

low volume cnc machiningrun. This helps catch any potential issues, like tool wear, before they lead to out-of-spec parts. - Final Inspection Report: Every part in the batch undergoes a final inspection. The results are compiled into a final report, providing a complete record of the part’s adherence to your specifications.

Meeting Demanding Industry Standards

Different industries have different quality requirements. A part for a consumer electronic device has different needs than a component for a surgical robot. A key part of our service is understanding and adhering to these specific standards.

| Industry | Common Standard | Key QA Requirement |

|---|---|---|

| Aerospace | AS9100 | Full traceability, FAI reports, material certs |

| Medical Devices | ISO 13485 | Process validation, risk management, sterile handling |

| Automotive | IATF 16949 | Statistical Process Control (SPC), PPAP documentation |

| General | ISO 9001 | Consistent processes, customer focus, continuous improvement |

By having robust systems in place, we can readily adapt our quality control plan to meet the specific needs of your project, ensuring compliance and performance no matter the application.

In small batch CNC machining, you can’t afford inconsistency. Rigorous quality assurance, driven by advanced inspection tools like CMMs and laser scanners, is essential. This process isn’t just about final inspection; it’s about creating a traceable system through meticulous documentation, from material certification to First Article Inspection reports. This ensures every part in a small batch is identical and meets the demanding standards of industries like aerospace and medical, providing the reliability your project depends on.

Innovative Technologies Enhancing Low Volume CNC Machining?

Have you ever found your designs compromised by the limitations of traditional CNC methods? Are complex geometries and tight deadlines making your low volume production runs a constant challenge?

Innovative technologies like multi-axis machining, high-speed cutting, and digital workflows are revolutionizing low volume CNC machining. They dramatically boost precision, handle complex geometries effortlessly, and accelerate production, making small batches more efficient and cost-effective than ever before.

The perception that cutting-edge technology is only for mass production is outdated. For low volume CNC machining, these advancements are not just beneficial; they are game-changers. They directly address the core challenges of small-batch manufacturing: setup time, cost-per-part, and the flexibility to produce complex designs without committing to large quantities. Let’s break down the most impactful technologies.

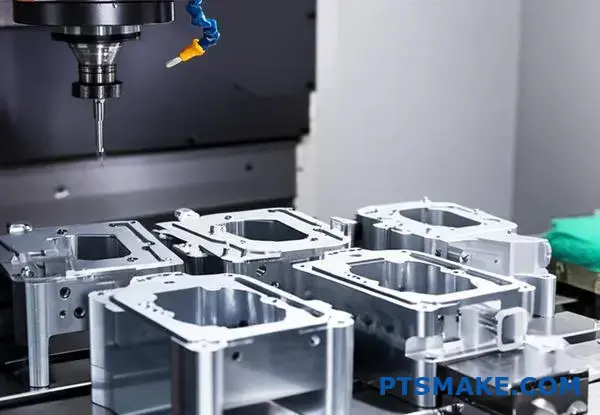

Multi-Axis Machining: Beyond Three Dimensions

The leap from traditional 3-axis to 5-axis machining is one of the most significant advancements. Instead of re-fixturing a part multiple times to access different faces—a process that introduces time, cost, and potential for error—a 5-axis machine can approach the workpiece from five different directions in a single setup.

The Single-Setup Advantage

For low volume projects, setup time is a major cost driver. Multi-axis machining consolidates operations, drastically cutting down this non-productive time. This means we can produce intricate parts, like a complex medical device housing or an aerospace component with contoured surfaces, much more efficiently. It minimizes the risk of tolerance stacking errors that can occur with each new setup. In our experience at PTSMAKE, this approach is key to delivering high-precision parts on tight schedules.

Unlocking Geometric Freedom

With 5-axis capabilities, designers are no longer constrained by the limitations of 3-axis machining. Undercuts, deep pockets, and complex curves become feasible without needing specialized fixtures or multiple operations. This opens the door to more innovative and optimized part designs, which is crucial for prototyping and specialized equipment where performance is paramount. We find that better Toolpath optimization6 is a direct result of having more axes of movement.

The table below contrasts the two approaches for small-batch runs:

| Feature | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

| Setup Time | High (multiple setups required) | Low (single setup for most parts) |

| Part Complexity | Limited to simpler geometries | Ideal for complex, contoured surfaces |

| Accuracy | Good, but risk of error with each setup | Excellent, high-precision and repeatability |

| Ideal Batch Size | Best for simpler, larger quantity runs | Perfect for low volume, high-complexity |

High-Speed Cutting (HSC) for Speed and Quality

High-Speed Cutting isn’t just about moving faster; it’s a different manufacturing philosophy. It utilizes extremely high spindle speeds and specially designed tools to make lighter, faster cuts. The chips carry away most of the heat, protecting both the tool and the workpiece from thermal stress.

This technique delivers a superior surface finish that often eliminates the need for secondary polishing operations, saving both time and money—a significant benefit in low volume production where every minute counts.

Beyond the physical machines on the shop floor, the digital infrastructure supporting them is equally transformative. A seamless digital workflow is the backbone of modern, efficient low volume CNC machining. It connects every stage of the process, from initial design to final inspection, minimizing friction and eliminating data loss.

The Power of a Digital Thread

The concept of a "digital thread" means that a single, consistent stream of data flows from the initial CAD model through to the final manufactured part. This integrated approach has profound implications for speed and accuracy.

Integrated CAD/CAM Systems

Modern CAD/CAM software is no longer a set of disconnected tools. Today’s platforms allow us to program toolpaths directly from the 3D design model. When a design is updated, the toolpaths can be regenerated automatically, ensuring the machine is always working from the latest revision. This tight integration is invaluable in prototyping, where we often work with clients on several design iterations. It allows us to provide feedback quickly and move from design to a physical part in a matter of days.

Simulation and Digital Twins

Before we cut any metal, we run the entire machining process in a virtual environment. Using digital twin technology, we create a virtual replica of the CNC machine and the workpiece. This allows us to:

- Verify Toolpaths: We can detect potential collisions between the tool, workpiece, and fixtures, preventing costly machine crashes and scrapped parts.

- Optimize Cycle Times: We can experiment with different cutting strategies virtually to find the most efficient approach without wasting machine time.

- Predict Part Quality: Advanced simulation can even predict the final surface finish and dimensional accuracy, ensuring the part meets specifications before production begins.

This "first-time-right" approach is essential for low volume CNC machining, where there is no economy of scale to absorb the cost of errors.

Here’s a look at how a digital workflow streamlines the process:

| Stage | Technology Used | Benefit for Low Volume |

|---|---|---|

| Design | 3D CAD Software | Rapid iteration and design for manufacturability (DFM). |

| Programming | Integrated CAM Software | Automatic toolpath generation, reducing programming time. |

| Simulation | Digital Twin / Verification Software | Error prevention, process optimization, zero physical waste. |

| Machining | Smart CNC Controllers | Real-time monitoring and adaptive control for consistency. |

| Inspection | CMM with CAD Data | Automated verification against the original design model. |

By embracing this digital ecosystem, we transform low volume production from a series of discrete steps into a fluid, data-driven process.

Ultimately, technologies like multi-axis machining, high-speed cutting, and integrated digital workflows are not just incremental improvements. They fundamentally change the economics and capabilities of low volume CNC machining. They empower us to produce highly complex parts with greater precision, speed, and cost-effectiveness than ever before. For engineers and designers, this means more creative freedom and a faster path from concept to reality, turning innovative ideas into tangible, high-quality components without the barrier of large production commitments.

Comparing Low Volume CNC Machining to Alternative Manufacturing Methods?

Struggling to choose the right manufacturing method for your small batch? Feeling overwhelmed by the options and their trade-offs in cost, speed, and quality?

Low volume CNC machining offers superior material choice and precision. In contrast, 3D printing excels in speed for complex prototypes, while low volume injection molding becomes cost-effective for slightly larger batches, each with distinct advantages and limitations.

When deciding on a manufacturing process for a small batch of parts, the choice often comes down to a few key players: CNC machining, 3D printing (additive manufacturing), and low volume injection molding. Each method has its place, and understanding their core differences is critical to making a cost-effective and technically sound decision. The best choice is rarely obvious and depends entirely on your project’s specific requirements.

Head-to-Head Comparison: Key Metrics

Let’s break down how these three methods stack up against each other based on the most important factors. In our experience at PTSMAKE, these are the criteria that most frequently guide our clients’ decisions.

Cost Structure

The cost dynamics vary significantly. CNC machining has minimal setup costs beyond programming, making it economical for single parts up to several hundred. 3D printing has almost no setup cost, but the per-part material and machine time can be high. Injection molding requires a significant upfront investment in a mold, but the per-part cost is extremely low once the mold is made. This makes it suitable for quantities where the tooling cost can be amortized effectively.

Material Selection and Properties

This is where low volume CNC machining truly shines. It can work with a vast range of production-grade metals and plastics, delivering parts with isotropic material properties, meaning they have uniform strength in all directions. 3D printing offers a growing list of polymers and some metals, but parts often have Anisotropic7 properties due to the layer-by-layer process, making them weaker along certain axes. Injection molding supports a massive library of thermoplastics, offering excellent material properties for the final part.

Here is a simplified breakdown based on our internal project data:

| Feature | Low Volume CNC Machining | 3D Printing (FDM/SLA) | Low Volume Injection Molding |

|---|---|---|---|

| Tooling Cost | Low to None | None | High |

| Per-Part Cost | Medium (Stable) | High (Decreases slightly) | Very Low |

| Lead Time | Fast (Days) | Very Fast (Hours to Days) | Moderate (Weeks due to tooling) |

| Materials | Wide (Metals, Plastics) | Moderate (Mainly Plastics) | Wide (Thermoplastics) |

| Complexity | High (with limitations) | Very High (complex internal) | Moderate (requires draft angles) |

| Tolerances | Very High | Low to Medium | High |

This table provides a quick reference, but the nuances of each project can shift the balance. For example, a highly complex part that is impossible to mold might be a perfect candidate for 3D printing, even if the material properties aren’t ideal for end-use.

Beyond the core metrics, the best manufacturing choice is often dictated by the specific application or the stage of product development. A method that is perfect for a proof-of-concept prototype is likely not the right choice for a pre-production run. Let’s explore some common scenarios to see how these processes fit different needs.

Application-Specific Scenarios

Understanding the ideal use case for each method helps clarify the decision-making process. It’s not just about specs on a sheet; it’s about what you need the part to do.

Best for Functional Prototypes and Testing

When you need a prototype that mimics the strength, feel, and performance of a final production part, low volume CNC machining is often the superior choice. Because it uses real production materials, you can perform rigorous functional tests, like stress analysis or fit checks, with confidence. While 3D printing is faster for checking form and fit, its material limitations can be a drawback for functional testing. We frequently recommend CNC for clients who need to validate a design with a part that behaves exactly as the mass-produced version will.

Best for Speed and Geometric Complexity

For initial design iterations, especially those with incredibly complex internal geometries or organic shapes, 3D printing is unmatched. It can produce parts in a matter of hours, directly from a CAD file, without any tooling or complex setup. This allows engineers to quickly identify design flaws and iterate rapidly. However, if the part requires tight tolerances or a smooth surface finish, post-processing will be necessary, which adds time and cost.

Best for Bridge Production and Market Testing

Low volume injection molding is the ideal "bridge" between prototyping and full-scale production. When you need a few hundred to several thousand parts to test the market, validate your manufacturing process, or fulfill initial orders, molding provides production-quality parts at a scalable cost. The initial tooling investment is higher than CNC, but the low per-part price makes it economical for these quantities. At PTSMAKE, we often use CNC machining to create initial prototypes before a client commits to the higher cost of an injection mold, ensuring the design is perfected first. This hybrid approach de-risks the entire process.

Choosing between low volume CNC machining, 3D printing, and injection molding requires a clear understanding of your project’s goals. While CNC offers unmatched material selection and precision for functional parts, 3D printing provides incredible speed for complex early-stage prototypes. Injection molding stands as the most cost-effective solution for slightly larger batches intended for market testing or initial production runs. The optimal choice is always a balance of cost, lead time, material requirements, and application.

Selecting the Right Low Volume CNC Machining Partner.

Have you ever picked a machining partner based on a low quote, only to face endless delays and parts that don’t meet spec? Are you worried that the wrong choice for your next project could derail your entire timeline?

To select the right partner for low volume CNC machining, you must look beyond the price. A thorough evaluation of their technical capabilities, relevant industry experience, certified quality systems, communication practices, and genuine flexibility is crucial for a successful and reliable manufacturing partnership.

Choosing a partner is one of the most critical decisions you’ll make for your project’s success. It’s not just about finding a supplier; it’s about finding an extension of your own team. The right partner can provide invaluable feedback, prevent costly errors, and ensure your components are delivered on time and to your exact specifications. Let’s break down the key criteria to evaluate.

Technical Capabilities: Look Beyond the Machine List

A long list of 3-axis and 5-axis machines on a website looks impressive, but it doesn’t tell the whole story. True technical capability is a combination of hardware, software, and human expertise. When evaluating a potential partner, dig deeper into these areas:

- Advanced Software and Programming: Do they use modern CAM software? Proficient programming is essential for complex geometries and efficient toolpaths, which directly impacts the quality and cost of your parts, especially in low volume production where setup time is a significant factor.

- Inspection and Metrology: How do they verify their work? Look for well-calibrated inspection equipment like Coordinate Measuring Machines (CMMs), optical comparators, and surface roughness testers. A commitment to metrology is a commitment to quality. Their expertise in applying principles like Geometric Dimensioning and Tolerancing8 is a clear indicator of their technical depth.

- Material Expertise: A partner should have documented experience working with the specific materials you require, whether it’s standard aluminum and steel or more exotic alloys like Inconel or titanium. Ask them about past projects involving similar materials.

At PTSMAKE, we’ve found that this combination of advanced technology and skilled engineers is what truly enables us to tackle complex low volume CNC machining projects effectively.

Quality Certifications: Your Assurance of Consistency

Certifications are not just pieces of paper; they are proof of a company’s commitment to established, repeatable processes. They provide a framework for quality management that ensures consistency from the first part to the last.

| Certification | What It Means for Your Project |

|---|---|

| ISO 9001:2015 | The partner has a robust Quality Management System (QMS). This means documented processes, clear accountability, and a focus on continuous improvement and customer satisfaction. |

| AS9100 | This is the standard for the aerospace industry. It includes all of ISO 9001’s requirements plus additional criteria for safety, quality, and risk management specific to aviation and defense. |

| ISO 13485 | Essential for medical device manufacturing. It signifies that the partner follows strict risk management and traceability protocols required for medical-grade components. |

When you see these certifications, you can be more confident that the supplier takes quality seriously. They have been audited by a third party and have proven their processes are reliable.

Beyond the hardware and certifications, the human element of a partnership is what often determines success or failure. How a supplier communicates and adapts to your needs can make all the difference, particularly in the dynamic environment of product development and low volume production.

Communication: The Foundation of a Strong Partnership

Poor communication is a major pain point I’ve seen ruin projects. Vague updates, slow responses, and language barriers can lead to misunderstandings, mistakes, and missed deadlines. Excellent communication is a non-negotiable trait for a long-term partner.

Key Communication Indicators:

- Dedicated Point of Contact: Are you assigned a specific project manager or engineer who understands your project? Dealing with a single person who is accountable and knowledgeable prevents information from getting lost.

- Proactive Feedback: A great partner doesn’t just take your CAD file and make parts. They provide Design for Manufacturability (DFM) feedback. They’ll suggest minor tweaks that could improve part quality, reduce costs, or speed up production. This collaborative approach is a sign of a true expert.

- Clarity and Transparency: They should provide clear, regular updates on your project’s status. If a problem arises, they should inform you immediately with a proposed solution, not wait until the delivery date has passed.

Flexibility: The Litmus Test for Low Volume Specialists

Low volume manufacturing is inherently different from mass production. Designs evolve, requirements change, and schedules shift. A partner who specializes in this area must be built for flexibility. A rigid, high-volume-focused shop will struggle with the demands of short-run projects.

How to Gauge Flexibility:

- Ask "What If" Scenarios: During the quoting process, ask hypothetical questions. "What is your process if we need to change a critical dimension after the order is placed?" or "How would you handle a request to expedite half of the order?" Their answers will reveal their processes and attitude toward change.

- Review Their Change Order Process: Do they have a clear, fair, and efficient process for handling design changes? It should be straightforward and transparent, outlining any impact on cost and lead time.

- Inquire About Prototyping: A company that excels at rapid prototyping is often very flexible. They are used to quick turnarounds and iterative design, which is the same mindset needed for successful low volume cnc machining. In our experience at PTSMAKE, embracing this flexibility allows us to support clients throughout their entire product development lifecycle, from a single prototype to short-run production.

Ultimately, selecting the right partner for low volume CNC machining goes far beyond a simple cost comparison. It requires a holistic assessment of their technical prowess, proven industry experience, and commitment to quality systems. Equally important are the "soft skills" of the partnership: clear communication and a willingness to adapt to changes. By using these criteria, you can find a reliable supplier who acts as a true extension of your team, ensuring your project’s success.

Cost Drivers and Pricing Models in Low Volume CNC Machining?

Have you ever received two CNC machining quotes for the same part that were worlds apart? It can be confusing to understand what truly drives the final price, leaving you unsure if you’re getting a fair deal.

The primary cost drivers in low volume CNC machining are setup time, material choice, part complexity, and batch size. Pricing models typically include per-part, per-batch, or project-based structures, and obtaining transparent quotes hinges on providing a detailed Request for Quote (RFQ).

Understanding what goes into a quote is the first step toward controlling your budget. The price isn’t arbitrary; it’s a direct reflection of the resources required to transform your design into a physical part. Let’s break down the core factors that every machine shop, including us at PTSMAKE, considers when preparing a quote for your project.

The Anatomy of a CNC Machining Quote

The final price is a sum of several key components. While they all interact, thinking of them separately can clarify where your money is going.

Setup Time: The Initial Hurdle

For low volume CNC machining, setup costs are often the most significant part of the bill. Unlike mass production where this cost is spread over thousands of units, in small batches, it’s divided among just a few. Setup includes everything that happens before the first chip is cut:

- CAM Programming: A programmer translates your CAD model into instructions (G-code) for the CNC machine. Complex parts require more programming time.

- Tooling & Fixturing: The right cutting tools must be selected, loaded, and calibrated. Often, custom fixtures are needed to hold the workpiece securely and accurately, which adds to the initial cost. The process of spreading these one-time costs over the number of parts produced is a form of amortization9.

Material Selection: Cost and Machinability

The raw material cost is straightforward, but it’s only half the story. The material’s machinability plays a massive role. Some materials are simply harder and more time-consuming to cut than others.

| Material | Relative Raw Cost | Machinability | Impact on Machining Time |

|---|---|---|---|

| Aluminum 6061 | Low | Excellent | Fast, less tool wear |

| Stainless Steel 304 | Medium | Moderate | Slower, more tool wear |

| Titanium | High | Difficult | Very slow, significant tool wear |

As you can see, choosing a hard-to-machine material like Titanium can increase machining time and tool replacement costs, significantly raising the price per part, even if the raw material cost difference isn’t extreme.

Part Complexity and Tolerances

The more complex your part, the more it will cost. Complexity isn’t just about the overall shape; it’s driven by specific features:

- Number of Operations: Does the part need to be milled, then turned, then drilled? Each machine change adds setup and handling time.

- Tight Tolerances: Holding a tolerance of ±0.005" is standard. Requiring ±0.001" demands more precise machines, slower cutting speeds, and more frequent inspections, all of which increase cost.

- Surface Finish: A standard machined finish is the most cost-effective. Requiring smoother finishes (e.g., through grinding or polishing) adds secondary processing steps and costs.

Once you understand the cost drivers, you can better interpret the pricing models that suppliers use. Different models suit different project types, and knowing the difference helps you compare apples to apples when evaluating quotes. It’s about finding a structure that aligns with your project’s specific needs and budget.

Decoding Pricing Models for Better Budgeting

Machine shops typically use one of three main pricing models. In our work with clients at PTSMAKE, we help them understand which model best fits their project to ensure clarity and avoid surprises.

Common Pricing Structures

Each model has its place, and a good supplier will be transparent about how they’ve structured their quote.

| Pricing Model | Best For | How It Works | Key Consideration |

|---|---|---|---|

| Per-Part Pricing | Prototypes, very small runs (1-10 units) | All setup, material, and labor costs are bundled into the price of a single unit. | The price per part is high but straightforward. Good for one-offs. |

| Per-Batch Pricing | Typical low-volume runs (10-500 units) | A single price is quoted for the entire batch. This price includes one setup charge plus the material and machining cost for all parts. | Offers a lower per-part cost than the per-part model. Allows for clear cost comparison at different quantities. |

| Project-Based Pricing | Complex projects with multiple components, assembly | A single price covers all manufacturing, assembly, and management for an entire project. | Ideal for complete solutions but requires a very detailed scope of work to be accurate. |

Tips for Obtaining Transparent and Competitive Quotes

Getting a quote that is both fair and easy to understand requires you to provide the right information upfront. A detailed RFQ is your best tool.

Provide a Complete Technical Package

The more information you give, the more accurate the quote will be. A great RFQ always includes:

- 3D CAD Files: STEP or IGES files are standard.

- 2D Drawings: Call out critical dimensions, tolerances, surface finishes, and specific materials.

- Quantity: Specify the exact number of parts needed. It’s also helpful to ask for price breaks at different quantities (e.g., 50, 100, 250 units) to see how the per-part cost changes.

- Material & Finish Specifications: Be precise. Instead of "aluminum," specify "Aluminum 6061-T6, anodized clear."

Communicate Your Priorities

In my experience, the most successful projects happen when the client and the shop are aligned. Let your supplier know what matters most. Is the deadline non-negotiable? Is hitting a specific target cost the top priority? This context allows a partner like PTSMAKE to suggest alternative materials or minor design tweaks (DFM) that can save you money without compromising function. A transparent supplier should be willing to provide a basic cost breakdown, helping you see where the money is going and making the quote easy to understand.

Understanding the cost drivers and pricing models in low volume CNC machining demystifies the quoting process. Key factors like setup time, material choice, and part complexity directly influence the final price. By providing a detailed RFQ that includes complete technical files and clear priorities, you empower your manufacturing partner to deliver a transparent and competitive quote. This knowledge allows you to better manage budgets and make informed decisions, ensuring you get the best value for your project.

Unlock CNC Precision—Get Your Low Volume Quote with PTSMAKE

Ready to shorten lead times, minimize risk, and achieve precision with low volume CNC machining? Contact PTSMAKE now for a fast, reliable quote tailored to your custom manufacturing needs. Discover the flexibility and expertise trusted by industry leaders—send your inquiry today!

Understand how a material interacts with the human body to ensure device safety and effectiveness. ↩

Learn why uniform material strength is critical for the performance and reliability of your functional prototypes. ↩

Explore why materials with uniform properties in all directions machine more predictably. ↩

Understand this key material property to avoid unexpected part failures and optimize your design for composite materials. ↩

Understand this symbolic language to better define and inspect your part’s critical features and tolerances. ↩

Discover how advanced toolpath strategies can reduce cycle times and improve surface finish on your CNC parts. ↩

Understand how material grain affects part strength and performance. ↩

Click to understand how this symbolic language ensures your design intent is perfectly translated into a physical part. ↩

Learn more about how one-time setup costs are distributed across production units. ↩