CNC screw machining faces new challenges in 2025. Traditional methods struggle with complex geometries, sustainability demands, and tighter quality standards. Manual processes slow production and increase costs.

CNC screw machining in 2025 leverages multi-axis technology, AI-driven quality control, and sustainable practices to deliver precision fasteners for aerospace, medical, and electronics industries with enhanced efficiency and reduced environmental impact.

The manufacturing landscape has shifted dramatically. Companies need partners who understand these evolving requirements. At PTSMAKE, we’ve adapted our CNC machining capabilities to meet 2025’s precision demands. This guide covers seven critical areas that define modern screw machining success. You’ll discover how multi-axis technology unlocks complex designs, why sustainability drives profitability, and which quality control methods deliver consistent results.

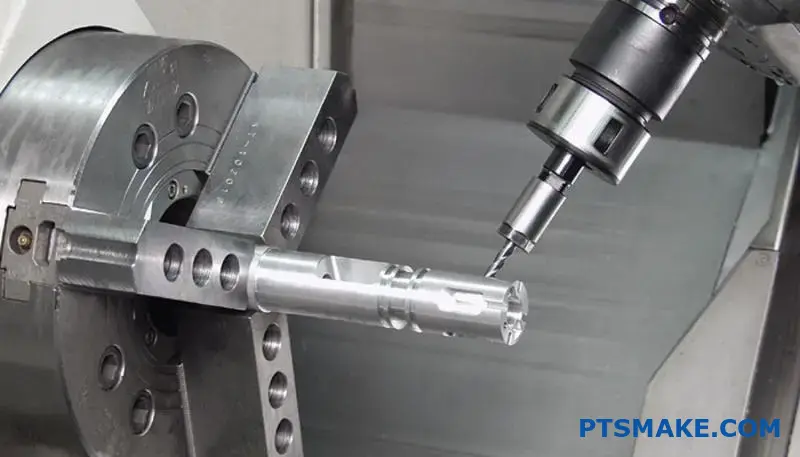

Multi-Axis Machining: Unlocking Complex Screw Geometries.

Have you ever designed a screw with complex threads or a unique head, only to find that traditional manufacturing methods couldn’t deliver? This often leads to design compromises or costly, inefficient processes.

Multi-axis machining solves this by using 4- or 5-axis CNC machines to cut complex geometries in a single setup. This approach unlocks intricate designs, enhances precision, and reduces production time, making it ideal for manufacturing advanced screws and fasteners.

The evolution from standard 3-axis to multi-axis CNC machining has fundamentally changed what’s possible in screw manufacturing. For years, 3-axis machines (moving along X, Y, and Z axes) were the standard. While effective for simple parts, they struggle with the complex geometries required in modern industries. Producing a screw with an undercut head or a variable-pitch thread on a 3-axis machine would require multiple fixtures and manual repositioning. Each new setup introduces a risk of misalignment, compromising the final part’s accuracy. This old method is not just slower; it’s a barrier to innovation.

The Shift to 4- and 5-Axis Machining

The introduction of 4-axis and 5-axis machines marked a significant leap forward. A 4-axis machine adds a rotational axis (the A-axis), allowing the workpiece to be turned during cutting. A 5-axis machine adds another rotational axis (the B or C-axis), enabling the cutting tool to approach the workpiece from virtually any angle. This capability is a game-changer for cnc screw machining. It means we can create features like helical flutes, off-center holes, and complex curved surfaces without ever unclamping the part.

How It Revolutionizes Screw Production

Simultaneous Tool Paths

The magic of 5-axis machining lies in its ability to perform simultaneous movements. The machine’s control unit calculates complex tool paths, moving all five axes in perfect harmony. This coordinated motion allows for the continuous cutting of smooth, contoured surfaces that are impossible with indexed positioning alone. In the past at PTSMAKE, we’ve seen how this technology turns a challenging design into a streamlined production run.

Accuracy Through Consolidation

By machining a complex screw in a single setup, we eliminate the compounded errors that come from re-fixturing a part. The machine’s internal kinematics1 ensures that every feature is perfectly aligned relative to the others. This single-setup approach, often called "done-in-one," is the key to achieving the tight tolerances demanded by our clients in the aerospace and medical fields.

| Feature | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

| Setups Required | Multiple | Single Setup ("Done-in-One") |

| Geometric Complexity | Limited to what’s accessible from one side | Near-limitless, including undercuts |

| Positional Accuracy | Lower due to re-fixturing errors | Highest level of precision |

| Cycle Time | Longer (includes setup time) | Shorter (no manual intervention) |

The theoretical benefits of multi-axis machining become tangible when applied to the specific challenges of high-stakes industries. It’s not just about making parts; it’s about enabling new technologies by producing components that were previously impossible to manufacture efficiently. In my experience, this is where the true value of advanced cnc screw machining is realized. From aerospace to medical devices, the demand for smaller, stronger, and more complex fasteners continues to grow.

Aerospace: Precision Under Pressure

In the aerospace industry, every component’s weight and reliability are critical. Fasteners are often made from tough alloys like Inconel or titanium, which are difficult to machine. Multi-axis machining allows us to create custom screws with specialized locking features, asymmetrical heads for tight spaces, and optimized thread profiles for maximum strength—all from a single block of material. This preserves the material’s grain structure and integrity, which is essential for parts that must withstand extreme vibration and temperature changes.

Medical Devices: The Scale of Innovation

The medical field requires incredible precision on a miniature scale. Think about a bone screw with a variable-pitch thread designed for better grip or a dental implant screw with a unique biocompatible surface finish. 5-axis CNC machines can produce these intricate features with exceptional accuracy and a superior surface finish in one operation. This is crucial, as any surface imperfection could compromise the part’s function or biocompatibility. At PTSMAKE, we’ve worked on projects where "done-in-one" machining was the only way to meet the stringent quality standards for surgical instruments.

Electronics: Miniaturization and Customization

As electronic devices get smaller and more powerful, the internal components become more densely packed. This drives a need for highly customized, miniature fasteners. Multi-axis machining enables the production of tiny, non-standard screws, such as those with unique drive types for security or integrated standoffs for board-to-board mounting. The ability to machine these complex forms efficiently makes it possible to design more compact and robust electronic products.

| Industry | Common Screw Application | Key Multi-Axis Advantage |

|---|---|---|

| Aerospace | Titanium locking fasteners, custom bolts | Machining tough alloys and complex heads in one setup |

| Medical | Bone screws, dental implant components | High precision for variable-pitch threads, superior finish |

| Electronics | Miniature captive screws, custom standoffs | Creating non-standard and micro-sized features |

Multi-axis machining revolutionizes screw and fastener production by overcoming the limitations of traditional methods. By enabling the creation of complex geometries in a single setup, it drastically improves accuracy, reduces lead times, and unlocks new design possibilities. This advanced approach to cnc screw machining is no longer a niche capability; it’s an essential tool for delivering the high-performance components required in critical industries like aerospace, medical, and electronics, where precision and reliability are paramount.

Describe the industry’s shift toward eco-friendly manufacturing.

Have you ever felt pressured to make your manufacturing more sustainable but worried about sacrificing performance or increasing costs? You’re not alone in facing this modern challenge.

The industry’s shift to eco-friendly manufacturing is driven by adopting energy-efficient CNC machines, using recyclable materials, and leveraging waste-minimizing software. These practices not only meet regulatory demands but also offer competitive advantages, enhancing efficiency and reducing operational costs in screw machining.

The push for sustainability isn’t just about public image; it’s about smart, long-term business strategy. In my 15+ years in precision manufacturing, I’ve seen this evolution firsthand. It’s moved from a "nice-to-have" to a core requirement for many of our partners. The change is most visible in two key areas: the machinery we use and the materials we choose.

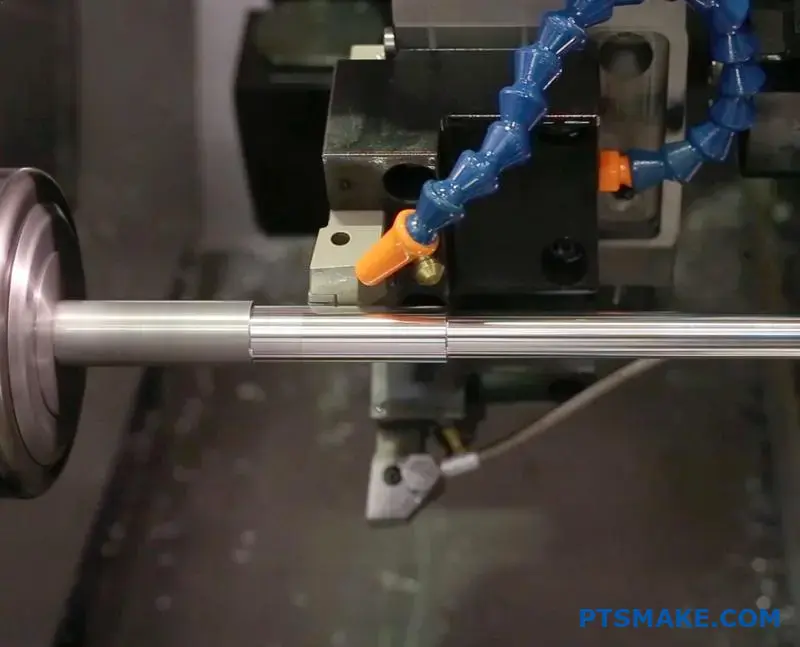

Embracing Energy-Efficient CNC Machines

The heart of any CNC screw machining operation is the machine itself. For decades, many machines relied on power-hungry hydraulic systems that ran constantly, consuming energy even when idle. The transition to modern, energy-efficient equipment has been a game-changer.

The Impact of Modern Servomotors

Today’s best-in-class CNC machines use electric servomotors. Unlike their hydraulic predecessors, these motors only draw significant power when they are actually moving an axis or the spindle. In one of our past projects at PTSMAKE, we found that upgrading a line of machines resulted in an energy consumption reduction of nearly 30%. This directly translates to lower operational costs, a saving we can pass on to our clients.

Intelligent Power Management

Modern machines also come with intelligent power management features. Think of it like the sleep mode on your computer. The machine can automatically power down non-essential components during short pauses and enter a deeper standby state during longer periods of inactivity. It’s a simple feature that makes a big difference over thousands of production hours.

| Feature | Traditional CNC Machine | Energy-Efficient CNC Machine |

|---|---|---|

| Drive System | Hydraulic Pumps (Constant) | Electric Servomotors (On-Demand) |

| Idle Power | High, constant power draw | Minimal, near-zero draw |

| Cooling Needs | Extensive and energy-intensive | Reduced and more efficient |

| Overall Efficiency | Lower | Up to 40% more efficient |

The Move Towards Sustainable Materials

Material selection is another critical component of sustainable manufacturing. We’re seeing a clear trend toward materials that are not only high-performance but also have a better environmental profile. This involves a complete Life Cycle Assessment2 to understand the environmental footprint from raw material extraction to disposal. Metals like aluminum, brass, and stainless steel are highly recyclable, meaning the scrap and chips from the machining process can be collected and reused, closing the loop on material usage. This focus on recyclability reduces landfill waste and decreases the demand for virgin raw materials.

Beyond hardware and materials, the digital tools we use play an enormous role in promoting sustainability. Advanced software allows us to optimize every step of the CNC screw machining process, drastically reducing waste before a single chip is cut. It’s about working smarter, not just harder.

The Role of Software in Minimizing Waste

The biggest source of waste in manufacturing is often inefficiency. Modern software directly tackles this problem, turning potential scrap into usable product and wasted time into productive output.

Optimizing Toolpaths with CAM Software

Computer-Aided Manufacturing (CAM) software has become incredibly sophisticated. Instead of basic, straight-line movements, today’s software can generate highly optimized toolpaths that maintain a constant tool engagement. This technique, known as high-efficiency milling (HEM), avoids sharp turns and sudden changes in load. The result? Faster cycle times, significantly longer tool life, and less energy consumed per part. Less tool wear means fewer tools are discarded, reducing another source of industrial waste.

Simulation and Virtual Prototyping

One of the most powerful features of modern software is the ability to run a complete virtual simulation of the machining process. Before we commit expensive material and machine time, we can see exactly how the tool will move and how the part will be created. This digital twin approach allows us to identify and correct potential collisions, inefficiencies, or programming errors in a risk-free environment. For us at PTSMAKE, this is a standard step for any complex part, ensuring we get it right the first time and virtually eliminating material scrap from setup errors.

| Aspect | Without Optimization | With Software Optimization |

|---|---|---|

| Material Scrap | Higher due to trial & error | Minimized via simulation |

| Cycle Time | Longer, more energy used | Reduced by efficient toolpaths |

| Tool Wear | Accelerated and unpredictable | Extended and consistent tool life |

| Coolant Usage | Higher, less precise | Optimized application, less waste |

Meeting Regulatory and Market Demands

This shift isn’t happening in a vacuum. It’s a direct response to both regulatory pressures and market expectations. Regulations like RoHS (Restriction of Hazardous Substances) and REACH in Europe dictate the materials that can be used in products. At the same time, end consumers are increasingly demanding environmentally responsible products. This pressure flows up the supply chain, making sustainability a key supplier qualification criterion. A client in the automotive sector recently came to us specifically because they needed a partner who could not only meet their tight tolerances but also document sustainable material sourcing and waste reduction practices for their annual corporate responsibility report.

The industry’s move toward eco-friendly manufacturing is a strategic evolution, not just a trend. By embracing energy-efficient CNC machines, sustainable materials, and intelligent software, screw machining operations can meet strict regulatory and market demands. This shift proves that sustainable practices are not a compromise on quality or cost; instead, they are a pathway to greater efficiency, reduced operational expenses, and a stronger competitive advantage in today’s environmentally conscious market.

Quality Control and Automated Inspection for Screw Machining.

Have you ever worried that a single, microscopic defect in a batch of thousands of parts could compromise your final product? That fear of inconsistency can be a major roadblock.

Automated inspection, which integrates image processing and AI, is revolutionizing quality control in CNC screw machining. These systems provide real-time defect detection and dimensional verification, drastically cutting scrap rates and ensuring every single part meets stringent specifications, far surpassing traditional manual checks.

The days of relying solely on manual measurements with calipers and micrometers are fading. While essential, these methods are slow and prone to human error, especially in high-volume production. In modern CNC screw machining, the goal isn’t just to make parts; it’s to make every part perfect. This is where automated inspection becomes a necessity, not a luxury. It represents a fundamental shift from reactive "spot-checking" to proactive, comprehensive quality assurance.

The Core of Automated Systems

Automated quality control is built on a foundation of sophisticated technologies working in unison. These systems are designed to operate at machine speed, providing insights that were previously impossible to gather.

High-Resolution Vision Systems

At the heart of many automated setups are high-resolution cameras and advanced lighting. These aren’t your standard cameras; they are industrial-grade vision systems designed to capture incredibly detailed images of components as they are produced. Software then analyzes these images pixel by pixel, comparing them against the original CAD file or a pre-approved "golden part." This process can instantly detect surface-level defects like scratches, burrs, incorrect finishes, or even subtle contamination that the human eye might miss. The system makes objective, repeatable decisions, removing any guesswork from the inspection process.

Advanced Metrology

For verifying dimensional accuracy, we move beyond simple imaging. Non-contact metrology tools, such as laser scanners and structured-light projectors, are used to create a complete 3D digital map of the part. This technology is crucial for parts with complex geometries or extremely tight tolerances. Because there is no physical contact, there’s no risk of marring delicate surfaces or influencing the measurement. This level of analysis in our Machine Vision3 systems ensures that every feature—from thread pitch to hole diameter—is precisely within its specified tolerance range.

| Feature | Manual Inspection | Automated Inspection |

|---|---|---|

| Speed | Slow, creates bottlenecks | High-speed, in-line with production |

| Consistency | Subject to operator fatigue and error | Extremely high repeatability |

| Coverage | Typically sample-based | Can achieve 100% inspection |

| Data Logging | Manual and often inconsistent | Automatic, detailed, and traceable |

Integrating these technologies is one thing, but making them intelligent is what truly transforms the manufacturing floor. The real power of modern quality control comes from creating a real-time feedback loop where the inspection system communicates directly with the CNC machine, enabling a process that is not just automated but also self-correcting. This moves quality control from a final gate to an integrated part of the production process itself.

From Detection to Prevention

The ultimate goal of automated inspection is to prevent defects from ever occurring. By analyzing data in real-time, these systems can identify negative trends long before a part goes out of spec, turning the entire CNC screw machining operation into a proactive, data-driven environment.

The Power of the Feedback Loop

Imagine an inspection system detects that a critical diameter on a part is slowly drifting toward its upper tolerance limit. Instead of just flagging the part, it sends an alert directly to the CNC controller. The controller can then make a micro-adjustment to its tool offset, bringing the next part back to the center of the tolerance band. At PTSMAKE, we’ve implemented such closed-loop systems, and they have virtually eliminated scrap caused by tool wear. This process happens automatically within seconds, without any human intervention.

AI and Predictive Quality Control

This is where Artificial Intelligence (AI) and Machine Learning (ML) elevate the process. AI-driven systems don’t just follow pre-programmed rules; they learn from the data they collect. They can identify complex patterns that correlate with potential failures. For example, an AI might learn that a specific subtle change in surface texture, combined with a minor increase in spindle load, predicts that a cutting tool will fail within the next 100 cycles. It can then schedule a tool change during a planned stoppage, preventing the production of bad parts and avoiding unplanned downtime. This predictive capability is a game-changer for maintaining high standards in continuous production environments.

| Consequence | Without Real-Time Feedback | With Real-Time Feedback |

|---|---|---|

| Scrap Rate | Potentially high; an entire batch can be lost | Near-zero; only 1-2 parts lost before correction |

| Downtime | Unplanned, reactive, and disruptive | Planned and predictive |

| Process Control | Reactive adjustments based on past results | Proactive, self-correcting adjustments |

| Quality Focus | Finding and sorting bad parts | Preventing bad parts from being made |

Embracing automated inspection and AI is essential for modern CNC screw machining. This shift from manual, sample-based checks to intelligent, 100% in-line verification transforms quality control from a reactive measure into a proactive strategy. By integrating technologies like vision systems and creating real-time feedback loops, manufacturers can drastically reduce scrap, ensure unwavering dimensional accuracy, and maintain the highest quality standards. This isn’t just about catching defects; it’s about creating a process that prevents them.

Material Advancements for High-Performance Screws?

Have you ever had a critical screw fail under extreme heat or stress? It’s a frustrating setback that can compromise an entire assembly.

The solution lies in advanced materials. Innovations in alloys, ceramics, and coatings are pushing the boundaries of screw performance, offering superior wear resistance, heat tolerance, and overall strength for the most demanding applications.

When standard steel or stainless steel screws just won’t cut it, we turn to advanced alloys. These are not your everyday metals; they are engineered for exceptional performance under extreme conditions. In my experience at PTSMAKE, guiding clients through material selection is one of the most critical steps in ensuring a project’s success, especially for industries like aerospace and medical devices.

Superalloys: The Champions of High-Temperature Environments

Superalloys, often nickel-based like Inconel or cobalt-based, are designed to retain their strength at very high temperatures. A standard steel screw might lose its structural integrity past a few hundred degrees Celsius, but a screw made from Inconel 718 can perform reliably at temperatures approaching 700°C (1300°F). The challenge, however, is the cnc screw machining process itself. These materials are tough and abrasive, which means machining requires specialized tools, slower speeds, and precise cooling strategies to prevent tool wear and maintain tight tolerances. The properties of these materials can be highly anisotropic4, meaning they differ depending on the direction of measurement, adding another layer of complexity to the machining process.

Titanium Alloys: The Lightweight Powerhouses

Titanium alloys, such as Ti-6Al-4V, offer an incredible strength-to-weight ratio. They are about 40% lighter than steel but can be just as strong, making them ideal for aerospace and high-performance automotive applications where every gram matters. They also boast excellent corrosion resistance. Machining titanium requires a different approach than steel. It has low thermal conductivity, meaning heat builds up quickly at the cutting tool’s edge. This demands sharp tools, low cutting speeds, and high-pressure coolant to manage heat and prevent material galling.

Here is a quick comparison of these advanced alloys:

| Material | Key Properties | Ideal Applications | Machining Challenge |

|---|---|---|---|

| Inconel 718 | High-temperature strength, corrosion resistance | Jet engines, gas turbines, nuclear reactors | High work hardening, intense tool wear |

| Titanium (Ti-6Al-4V) | High strength-to-weight ratio, biocompatible | Aerospace components, medical implants | Low thermal conductivity, tendency to gall |

| MP35N | Ultra-high strength, corrosion resistance | Medical devices, marine hardware, racing | Extremely tough, requires rigid machine setup |

Selecting the right alloy is a trade-off between performance requirements and manufacturing costs. The expertise in cnc screw machining these exotic materials is what separates a reliable parts supplier from the rest.

Beyond engineering the entire screw from an advanced alloy, we can significantly enhance the performance of conventional materials using specialized coatings and even ceramics. This approach often provides a cost-effective solution for improving surface properties like hardness and friction without changing the core material of the screw.

Surface Coatings: An Armor for Your Screws

Coatings are micro-thin layers applied to the surface of a screw to boost its performance. The base screw might be made from a familiar material like stainless steel, but the coating gives it superpowers. This is a common strategy we use in projects where only the surface of the component faces extreme wear or corrosive elements.

Common High-Performance Coatings

- Titanium Nitride (TiN): This is a classic. You’ll recognize it by its gold color. It increases surface hardness and provides excellent lubricity, reducing friction in dynamic applications.

- Diamond-Like Carbon (DLC): As the name suggests, DLC coatings are incredibly hard and slick. They create a surface with a very low coefficient of friction, perfect for components in high-wear, sliding applications.

- Aluminum Titanium Nitride (AlTiN): This coating offers superior high-temperature performance compared to TiN. It forms a protective layer of aluminum oxide at high temperatures, making it ideal for screws used in high-speed machinery or engines.

The table below outlines the primary benefits of each coating:

| Coating Type | Primary Benefit | Common Color | Max Operating Temp. |

|---|---|---|---|

| Titanium Nitride (TiN) | General-purpose wear resistance, lubricity | Gold | ~600°C (1100°F) |

| DLC | Extreme hardness, lowest friction | Black/Gray | ~350°C (660°F) |

| AlTiN | High-temperature wear resistance | Violet/Black | ~900°C (1650°F) |

The Rise of Engineering Ceramics

For the most extreme applications, we sometimes look to screws made entirely of engineering ceramics like Zirconia or Silicon Nitride. These materials are exceptionally hard, chemically inert, and can withstand incredibly high temperatures. They are also excellent electrical insulators. However, their brittleness makes them unsuitable for applications with high-impact loads. The cnc screw machining of ceramics is more akin to grinding than cutting, requiring diamond-tipped tools and highly specialized equipment to achieve the necessary precision without causing micro-fractures. It’s a niche but growing area for specialty fasteners.

In essence, the days of relying solely on standard steel are over for high-performance applications. Whether through advanced superalloys like Inconel, lightweight powerhouses like titanium, or innovative surface coatings like DLC, material science has unlocked new levels of performance. Understanding these options is key to designing and manufacturing screws that won’t fail when it matters most. Successful cnc screw machining of these materials requires deep expertise to balance performance, cost, and manufacturability.

Industry Applications: CNC Screw Machining Across Sectors.

Have you ever wondered how industries from automotive to aerospace achieve such high standards of reliability? Their success often hinges on the tiniest, most precise components, where a single failure is not an option.

CNC screw machining is the cornerstone technology that makes this possible. Its ability to produce highly customized, ultra-precise screws from a vast range of materials allows it to meet the unique and demanding specifications of virtually any high-stakes industry.

The versatility of CNC screw machining truly comes to life when you look at its application in different sectors. Each industry presents a unique set of challenges, from withstanding extreme temperatures to ensuring biocompatibility, and the screws used are engineered to meet these specific demands head-on. In past projects at PTSMAKE, we’ve seen these differences firsthand.

The Automotive Sector: Durability Meets Volume

In the automotive world, it’s a game of balance. Manufacturers need components that are incredibly durable and reliable, yet they must be produced in massive quantities to keep assembly lines moving.

- Engine Components: Screws and bolts used inside an engine must withstand constant vibration, high temperatures, and corrosive fluids. We often use high-strength steel alloys and specialized coatings to prevent failure.

- Safety Systems: For critical systems like airbags and braking, there is zero tolerance for error. These screws undergo rigorous testing and require complete traceability from raw material to final part. The precision of cnc screw machining ensures every single piece meets the exact specifications.

- Chassis and Body: These fasteners need to provide structural integrity while also being cost-effective. Self-tapping and thread-forming screws are common, designed for rapid assembly into metal and plastic parts.

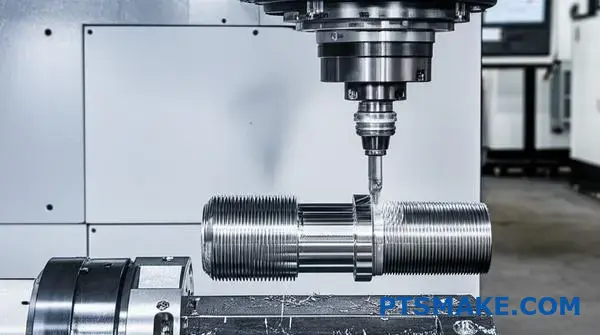

The Aerospace Sector: Where Precision is Paramount

Aerospace is arguably the most demanding industry for any component. The consequences of failure are catastrophic, so every part, no matter how small, must be perfect.

- Lightweighting: Every gram counts. We frequently machine screws from advanced materials like titanium and high-grade aluminum alloys to achieve a high strength-to-weight ratio.

- Extreme Tolerances: Aerospace components require some of the tightest tolerances in manufacturing. CNC screw machines are essential for creating complex thread profiles and head designs that fit perfectly and distribute stress correctly.

- Surface Integrity: To enhance fatigue resistance and prevent corrosion, many aerospace screws receive specialized surface treatments like Anodizing5. This process creates a protective oxide layer that is integral to the part itself.

Here’s a quick comparison of the primary demands in these two sectors:

| Feature | Automotive Industry | Aerospace Industry |

|---|---|---|

| Primary Driver | Cost-effective reliability at scale | Absolute safety and performance |

| Material Focus | High-strength steel, coated alloys | Titanium, aluminum alloys, superalloys |

| Key Requirement | Vibration and heat resistance | High strength-to-weight ratio |

| Production Volume | Very High | Low to Medium |

While automotive and aerospace push the boundaries of strength and durability, other industries present entirely different, yet equally complex, challenges. The electronics and medical fields, for instance, demand precision on a microscopic scale and materials that can safely interact with the human body.

The Electronics Industry: The World of Miniaturization

As electronic devices get smaller and more powerful, so must their components. CNC screw machining is critical for producing the microscopic fasteners that hold our modern world together.

- Micro-Screws: Think about the tiny screws inside your smartphone or laptop. These are often just a millimeter or two in length and are produced by specialized CNC screw machines capable of incredible precision.

- Material Properties: In electronics, materials are often chosen for their electrical properties. We use non-magnetic materials like stainless steel, brass, or even PEEK to avoid interference with sensitive electronic components.

- Custom Heads: To fit into compact designs and accommodate automated assembly, many electronic screws have unique head designs, such as low-profile Torx or custom pentalobe heads.

The Medical Device Sector: Biocompatibility and Sterilization

In the medical field, components must not only be precise but also safe for human contact. This introduces a new layer of material and manufacturing constraints.

- Biocompatible Materials: For implants and surgical tools, we exclusively use materials like medical-grade titanium and stainless steel, or polymers like PEEK, which do not react with the human body.

- Flawless Surface Finish: Medical screws require an exceptionally smooth surface finish to prevent bacterial growth and ensure they can be properly sterilized. CNC machining provides the control needed to achieve this.

- Traceability: Every medical component must be fully traceable back to its raw material batch. Our quality systems at PTSMAKE are designed to provide this documentation, ensuring compliance and patient safety.

Here’s how these industries differ in their component requirements:

| Industry | Primary Requirement | Common Screw Types | Common Materials |

|---|---|---|---|

| Electronics | Miniaturization, Non-magnetic | Micro-screws, Phillips, Torx | Stainless Steel, Brass |

| Medical Devices | Biocompatibility, Sterilizability | Bone screws, Dental implant screws | Titanium, PEEK, 316L Stainless Steel |

| Energy | Corrosion Resistance, High Strength | Hex bolts, Stud bolts | Inconel, Monel, Duplex Steel |

The energy sector, particularly oil and gas, also relies heavily on custom cnc screw machining for fasteners that can withstand some of the harshest environments on earth, from deep-sea pressures to corrosive chemicals.

From the high-volume production lines of the automotive industry to the sterile environments of medical device manufacturing, CNC screw machining proves its value. Its core strengths—precision, material flexibility, and customization—are not just beneficial; they are essential. This adaptability allows engineers in aerospace, electronics, and energy to design and build reliable products that meet the strictest performance, safety, and regulatory standards. The tiny screw, often overlooked, is a testament to advanced manufacturing’s critical role across all sectors.

Digital Integration: CAD/CAM and Edge Computing in Screw Production.

Ever felt the frustration of a design looking perfect on screen, only to be bogged down by errors and delays once it hits the machine shop? Are you tired of the disconnect between design and production?

The seamless integration of CAD/CAM software with edge computing fundamentally transforms CNC screw machining. It creates a unified digital thread from design to finished part, dramatically speeding up prototyping, minimizing human error, and ensuring flawless data transfer for unparalleled precision and efficiency.

The journey from a digital concept to a physical screw used to be fragmented. Designers would create a model in CAD (Computer-Aided Design) software, then hand it off to a machinist. That machinist would then manually program the CNC machine, a process ripe for interpretation errors. This gap between design and manufacturing often led to costly mistakes and delays. Today, integrated CAD/CAM (Computer-Aided Manufacturing) systems bridge this gap, creating a seamless workflow that has become the standard in modern precision manufacturing.

From Blueprint to G-Code: The CAD/CAM Connection

At its core, CAD/CAM integration means the design software and the manufacturing software talk to each other. When a design for a custom screw is finalized in the CAD environment, the CAM module takes over. It analyzes the 3D model’s geometry and generates the optimal toolpaths—the exact route the cutting tool will take. This process also determines critical parameters like cutting speed, feed rate, and tool selection.

The CAM system then performs a crucial step known as post-processing6. This converts the generic toolpath data into a specific G-code program that the target CNC machine can understand. Each machine has its own dialect, and the post-processor acts as the perfect translator. This automation eliminates the manual programming errors that were once a major source of production issues. In our projects at PTSMAKE, this direct link has drastically reduced the time from design approval to the first article inspection.

The Benefits of a Unified Digital Workflow

The impact of this integration on cnc screw machining is immediate and significant. Version control becomes straightforward, as any change in the CAD model can be quickly updated in the CAM program, ensuring the machine is always working from the latest design. This tight loop is invaluable for rapid prototyping and iterative design processes.

| Aspect | Traditional Workflow | Integrated CAD/CAM Workflow |

|---|---|---|

| Data Transfer | Manual (e.g., 2D drawings, separate files) | Automated, direct from CAD to CAM |

| Programming | Manual G-code programming | Automated toolpath generation |

| Error Potential | High (human interpretation, data entry) | Low (minimized human intervention) |

| Prototyping Speed | Slow, multiple manual steps | Fast, streamlined updates |

This digital continuity means we can simulate the entire machining process before a single piece of metal is cut. We can detect potential collisions, optimize toolpaths for efficiency, and get a precise estimate of cycle times.

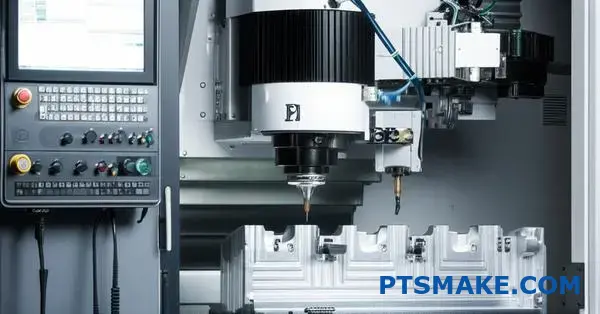

While CAD/CAM integration creates a powerful digital thread, edge computing takes it a step further by bringing data processing and decision-making right to the factory floor. Instead of sending vast amounts of data from a CNC machine to a distant cloud server for analysis, edge computing processes it locally, either on the machine itself or on a nearby server. This shift from centralized to decentralized processing is a game-changer for high-speed, high-precision operations like cnc screw machining.

Edge Computing: The Smart Brain on the Factory Floor

Think of edge computing as giving each CNC machine its own localized intelligence. It equips the machine with the ability to analyze its own performance and environment in real-time, making instantaneous adjustments that were previously impossible. This is achieved by placing sensors on the machine to monitor variables like vibration, temperature, and tool wear.

Real-Time Process Optimization

Imagine a CNC machine turning a complex screw. An edge device can analyze acoustic and vibration data to detect the first signs of tool chatter. Before the chatter can affect the surface finish or dimensional accuracy, the system can automatically adjust the spindle speed or feed rate to mitigate the issue. This real-time feedback loop ensures every single screw meets the exact specifications. Our tests show that this can improve tool life by up to 20% and reduce scrap rates significantly.

Enhancing Reliability and Throughput

Edge computing isn’t just about in-process adjustments; it’s also a powerful tool for predictive maintenance and overall efficiency. By continuously monitoring the health of machine components, it can predict failures before they happen, allowing us to schedule maintenance during planned downtime.

| Edge Computing Feature | Description | Impact on Screw Production |

|---|---|---|

| Low-Latency Processing | Data is analyzed locally, eliminating network delays. | Instantaneous adjustments to machining parameters. |

| Predictive Maintenance | Algorithms analyze sensor data to predict component failure. | Reduced machine downtime and maintenance costs. |

| Enhanced Data Security | Sensitive design data stays on the local network. | Lower risk of IP theft or data breaches. |

| On-the-fly Analytics | Performance data is used for immediate process improvements. | Consistent quality and optimized cycle times. |

By combining a seamless CAD/CAM workflow with the on-the-ground intelligence of edge computing, we create a highly responsive and resilient manufacturing environment. This is how we consistently deliver high-precision screws on schedule.

Struggling with a slow and error-prone design-to-production process? The integration of CAD/CAM software and edge computing creates a direct digital link from your design to the finished screw. This unified workflow eliminates manual programming errors, accelerates prototyping, and uses real-time data to optimize the cnc screw machining process. The result is unparalleled speed, precision, and reliability, ensuring your parts are made right the first time, every time.

Cost Optimization Strategies for CNC Screw Machining?

Are your project budgets shrinking while production costs for precision parts seem to climb ever higher? Does balancing quality with cost feel like an impossible tightrope walk?

Optimizing CNC screw machining costs involves a strategic blend of efficient material usage, process automation, batch optimization, and data-driven decisions. By focusing on these key areas, you can significantly reduce expenses without compromising the quality or integrity of your final components.

Controlling costs in any manufacturing process, especially a precision-driven one like CNC screw machining, requires a proactive and holistic approach. It’s not about cutting corners; it’s about working smarter. At PTSMAKE, we partner with our clients from the very beginning, often starting with the design phase itself, to build cost-efficiency into the DNA of a part.

Design for Manufacturability (DFM)

The biggest cost savings often happen before a single piece of metal is cut. Applying DFM principles is crucial.

Simplifying Geometries

Complex features drive up machining time and tooling costs. We often ask clients: is that intricate curve or ultra-tight internal corner absolutely essential for the part’s function? Sometimes, a minor design tweak that doesn’t affect performance can reduce machining cycles by a noticeable percentage, leading to direct savings. In past projects, simplifying a non-critical internal radius has cut cycle time by up to 15%.

Standardizing Tolerances

Applying a blanket tight tolerance across an entire part is a common and costly mistake. Only critical features need high precision. By relaxing tolerances on non-functional surfaces, you reduce machine time, lower the scrap rate, and decrease the need for secondary finishing operations. This simple change can make a huge difference in the overall cost per part.

Mastering Material Usage

Material is a primary cost driver in cnc screw machining. How you select and use it matters immensely.

Choosing the Right Material

It’s tempting to over-spec a material "just in case." However, using a high-cost alloy when a more standard, cost-effective metal would suffice adds unnecessary expense. We help clients evaluate the functional requirements—strength, corrosion resistance, weight—and match them to the most economical material that meets all specifications. Understanding the tribology7 between the material and cutting tool is also key to optimizing tool life.

The following table shows a basic comparison of common materials, balancing cost against machinability, which directly impacts cycle time.

| Material | Relative Cost Index | Machinability Rating (100 = Best) | Key Considerations |

|---|---|---|---|

| Aluminum 6061 | 1.2x | 90 | Excellent machinability, good strength-to-weight. |

| Brass 360 | 1.8x | 100 | The benchmark for machinability; fast cycles. |

| Stainless Steel 303 | 2.5x | 75 | Good corrosion resistance, fairly machinable. |

| Stainless Steel 316 | 3.0x | 45 | Superior corrosion resistance, but much slower to machine. |

| Titanium | 8.0x | 20 | High strength, low weight, but challenging and costly to machine. |

Beyond design and materials, optimizing the actual shop floor operations is where consistent, long-term savings are realized. It’s about efficiency in motion, minimizing waste in every form—be it time, material, or energy. This is where data becomes an invaluable asset, transforming guesswork into precise, actionable intelligence.

Optimizing Machine and Process Efficiency

A machine that isn’t cutting is a machine that’s losing money. The goal is to maximize chip-making time.

Minimizing Machine Downtime

Unplanned downtime is a profit killer. It halts production, creates bottlenecks, and can delay entire projects. After research with our clients, we found that a robust preventive maintenance schedule is non-negotiable. Regularly inspecting spindles, checking fluid levels, and monitoring tool wear prevents catastrophic failures. Furthermore, using data analytics to predict when a component might fail allows for scheduled maintenance during non-productive hours, maximizing uptime.

Optimizing Batch Sizes

Finding the sweet spot for production run size is a careful balancing act. Large batches can lower the per-piece setup cost, but also tie up capital in inventory. Small batches offer flexibility but can be inefficient due to frequent changeovers. We use historical production data to help determine the Economic Order Quantity (EOQ) for each part, ensuring we run batches that are large enough for efficiency but small enough to remain lean and responsive to changing demand.

The Role of Automation and Data

In modern CNC screw machining, technology is the ultimate lever for cost optimization.

Process Automation

Simple, repetitive tasks are prime candidates for automation. Using bar feeders and robotic arms to load and unload parts can allow a machine to run unattended for extended periods, even lights-out. This dramatically increases machine utilization and frees up skilled operators to focus on more complex tasks like quality control and programming. This single step can boost output without a proportional increase in labor costs.

The table below illustrates how automation can impact cost per part.

| Metric | Manual Loading | Automated Loading | Impact |

|---|---|---|---|

| Machine Utilization | 60-70% | 90-95% | ~30% increase in productive time |

| Labor per Part | High | Low | Significant reduction in direct labor cost |

| Consistency | Variable | High | Lower scrap rates, better quality |

| Setup Time | Moderate | Low (with quick-change systems) | Faster changeovers between jobs |

By integrating these operational strategies, you move from simply making parts to manufacturing them intelligently. Each decision is backed by data, and each process is refined for maximum efficiency, ensuring your cnc screw machining is as cost-effective as possible.

True cost optimization in CNC screw machining isn’t a one-time fix but a continuous process. It begins with intelligent design and material selection to prevent unnecessary expenses from the start. This proactive approach is then supported by highly efficient shop floor practices, focusing on maximizing machine uptime and running optimal batch sizes. By leveraging automation and data-driven insights, you can refine every aspect of production, turning your manufacturing process into a lean, cost-effective, and highly reliable operation.

Take CNC Screw Machining Further with PTSMAKE Today

Ready to elevate your CNC screw machining projects? Contact PTSMAKE for a rapid, detailed quote and experience next-generation precision, sustainability, and efficiency. Discover how our expertise in multi-axis machining, smart inspection, and innovative materials can transform your supply chain—start your inquiry now!

Understand how the machine’s core motion system dictates the final accuracy of your parts. ↩

Understand the full environmental impact of your material choices from start to finish with this detailed guide. ↩

Learn how this technology goes beyond simple cameras to enable intelligent, automated decision-making in manufacturing. ↩

Learn more about how a material’s directional properties can impact CNC machining strategies and part performance. ↩

See how this surface treatment adds durability and corrosion resistance for mission-critical parts. ↩

Learn how this critical step translates universal CAM instructions into the unique language your specific CNC machine understands. ↩

Understand how friction and wear science can help you select better tools and coolants, extending tool life. ↩