Machining large parts brings unique challenges that can make or break your project timeline and budget. Standard CNC processes often fall short when dealing with oversized components, leading to precision issues, thermal distortion, and costly rework that delays critical production schedules.

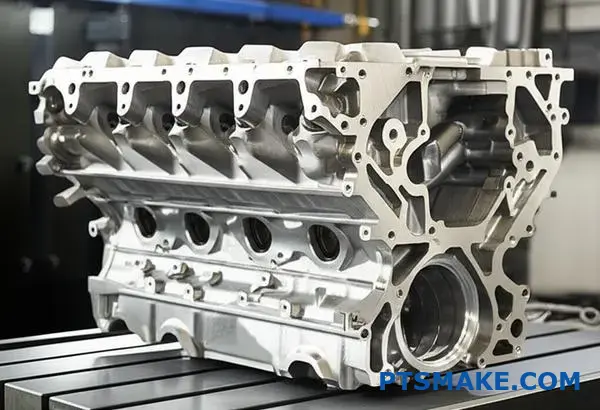

Large part CNC machining involves specialized equipment, advanced multi-axis techniques, and precise thermal management to manufacture oversized components with tight tolerances for industries like aerospace, defense, and oil & gas.

The complexity of large part machining goes far beyond simply scaling up standard processes. From material handling challenges to quality assurance requirements, each aspect demands careful consideration and specialized expertise. Understanding these factors helps you make informed decisions about your manufacturing strategy and partner selection. Let me walk you through the key industries, technical challenges, and innovative solutions that define successful large part CNC machining operations.

Industry-Specific Applications of Large Part CNC Machining.

Ever wondered how massive, mission-critical components for rockets or wind turbines are made with absolute precision? A single flaw in these giant parts could be catastrophic.

Large part CNC machining is the core manufacturing process for industries like aerospace, energy, and defense. It creates large-scale, high-precision components, from aircraft wings to turbine blades, ensuring the structural integrity, safety, and operational efficiency essential for these demanding sectors.

When we talk about large part CNC machining, it’s not just about the size. It’s about maintaining extreme precision over enormous surfaces and complex geometries. In past projects at PTSMAKE, we’ve found that industries with zero tolerance for error are the primary drivers of this technology. Two of the most demanding are aerospace and oil & gas.

Aerospace: Pushing the Boundaries of Precision

In the aerospace industry, every component’s weight and strength are critically important. There is simply no room for error when lives are at stake. Large part CNC machining is essential for manufacturing components that define an aircraft’s safety and performance.

Critical Components and Materials

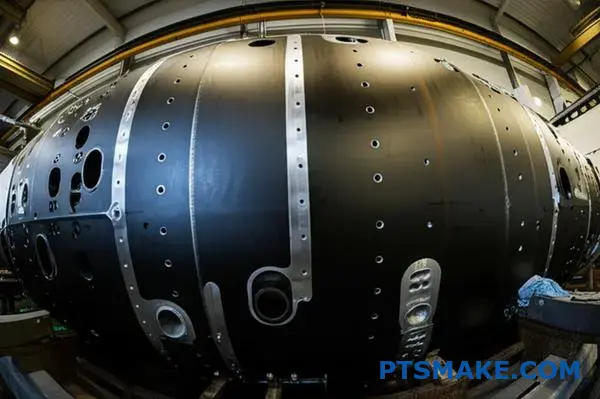

Think about key structural elements like wing spars, fuselage frames, and landing gear components. These are often machined from single, massive blocks of high-strength materials like titanium or aluminum alloys. This monolithic approach creates parts that are stronger and lighter than assemblies made from multiple smaller pieces. The goal is to eliminate potential failure points like joints or welds. Achieving the required tight tolerances across a part that might be several meters long is a significant engineering challenge. The machine tool’s volumetric accuracy1 becomes paramount in ensuring every feature is exactly where it needs to be.

Oil & Gas: Durability Under Extreme Pressure

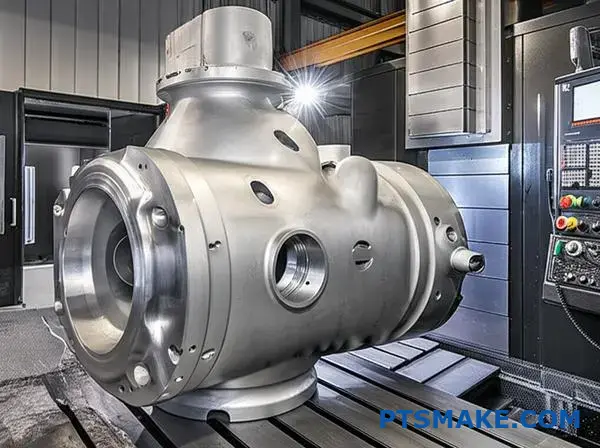

The oil and gas sector operates in some of the world’s harshest environments, from deep-sea drilling sites to remote desert rigs. The components used must withstand immense pressure, extreme temperatures, and corrosive materials. Failure is not an option, as it can lead to environmental disasters and massive financial losses.

Components That Withstand the Elements

Here, large part CNC machining is used to create robust components like blowout preventers (BOPs), large-scale valve bodies, and subsea equipment housings. These parts are often made from tough materials like stainless steel or nickel-based alloys such as Inconel. The precision of the machining ensures perfect seals and fits, which are essential for containing high-pressure fluids and gases safely.

| Industry | Key Component | Primary Material | Main Challenge |

|---|---|---|---|

| Aerospace | Wing Spar | Titanium / Aluminum Alloy | High strength-to-weight ratio |

| Oil & Gas | Blowout Preventer | Stainless Steel / Inconel | Corrosion and pressure resistance |

| Aerospace | Landing Gear | High-Strength Steel | Fatigue and impact resistance |

| Oil & Gas | Subsea Housing | Nickel-Based Alloy | Sealing and environmental durability |

Beyond aerospace and energy, the need for large, precisely machined parts is a common thread in other foundational industries. The principles of strength, reliability, and precision are just as critical in defense, transportation, and renewable energy, where large-scale machinery forms the backbone of our infrastructure and security.

Defense and Transportation: The Backbone of Mobility and Security

In both defense and heavy transportation, equipment must be built for extreme durability and long service life. The components are often large, heavy, and subjected to constant stress and vibration.

Building for Strength and Reliability

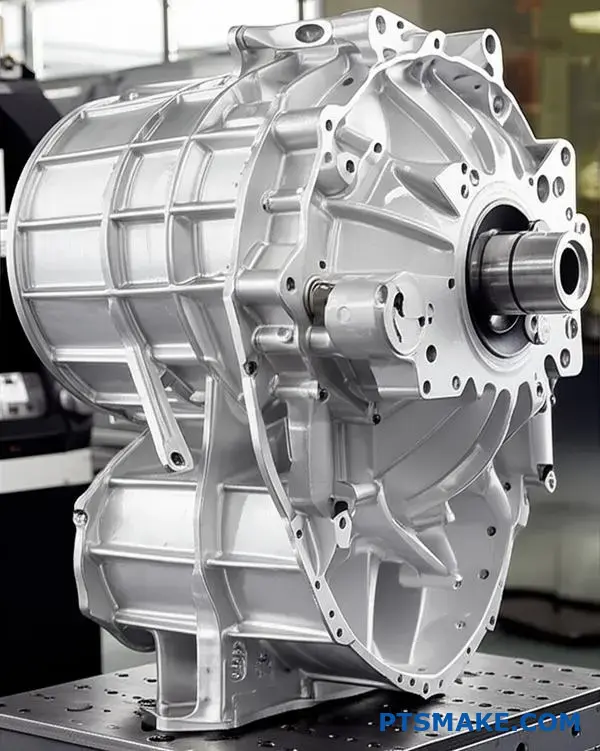

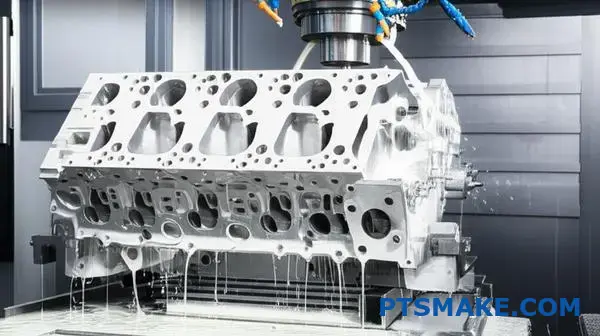

For defense applications, we see large part CNC machining used to produce monolithic hulls for armored vehicles or complex structural components for submarines. The precision ensures a perfect fit, which is critical for structural integrity and protection. Similarly, in transportation, massive engine blocks for locomotives, ships, and heavy-duty trucks are machined to exacting standards. This ensures efficiency and reliability over millions of miles. A small imprecision in a large engine block can lead to premature failure and costly downtime.

Renewable Energy: Machining a Sustainable Future

The shift to renewable energy sources has created a surge in demand for very large, high-precision components. Manufacturing parts for wind turbines and hydroelectric dams presents unique challenges due to their immense scale and the need for decades of reliable operation.

Components for a Greener Planet

At PTSMAKE, we’ve increasingly worked on projects in this sector. Wind turbines require massive components like hubs, main shafts, and gearbox housings. The hub, which connects the blades to the turbine, can be several meters in diameter and must be machined with incredible accuracy to ensure balance and aerodynamic efficiency. Any imbalance can lead to catastrophic failure. Similarly, the runners and gates for hydroelectric dams are enormous, complex parts that must be shaped perfectly to maximize energy generation and withstand the constant force of water.

| Industry | Example Component | Key Requirement | Impact of Failure |

|---|---|---|---|

| Defense | Armored Vehicle Hull | Ballistic Resistance | Compromised crew safety |

| Transportation | Locomotive Engine Block | High Endurance | Supply chain disruption |

| Renewable Energy | Wind Turbine Hub | Rotational Balance | Catastrophic structural failure |

| Renewable Energy | Hydroelectric Turbine Runner | Hydrodynamic Efficiency | Reduced power generation |

From aircraft flying at 30,000 feet to turbines harnessing wind power, large part CNC machining is the hidden engine driving modern industry. It enables the creation of massive, monolithic components where precision is non-negotiable. This technology is fundamental for ensuring safety in aerospace, durability in the oil and gas sector, and reliability in defense and renewable energy. The core challenge across all these fields remains the same: achieving tight tolerances and complex geometries on an enormous scale.

Material Challenges in Large Part CNC Machining.

Have you ever faced a project where the sheer size of the raw material completely changes the rules of machining? Handling a massive workpiece introduces unique challenges that standard processes simply can’t address, risking both delays and costly mistakes.

The primary material challenges in large part CNC machining stem from the workpiece’s size, weight, and internal stresses. These factors demand unique strategies for handling, clamping, and tool selection, especially with tough alloys like titanium or stainless steel, to prevent deformation and ensure precision.

The Weight and Size Dilemma

The most immediate challenge in large part CNC machining is managing the workpiece itself. We’re not talking about parts you can lift by hand. These often require overhead cranes and specialized rigging just to get them onto the machine bed. The sheer mass can cause the material to sag under its own weight, a phenomenon known as deflection. If not properly supported, this deflection can lead to inaccuracies that violate tight tolerances. Clamping is another hurdle. Applying enough force to secure a multi-ton block without distorting its shape is a delicate balancing act. At PTSMAKE, we often design custom fixtures for each large-scale project to provide robust support at critical points, ensuring the part remains stable throughout the entire machining cycle. This initial setup is arguably one of the most critical phases for success.

Internal Stresses and Material Stability

Large blocks of metal, whether forged, cast, or rolled, are not perfectly uniform. They harbor internal residual stress2 from their manufacturing process. As we machine away material, we release this stored energy, and the part can warp, twist, or bend in unpredictable ways. This is a huge problem when you’ve already invested hours of machine time. To counter this, a multi-stage machining process is often necessary. It might involve rough machining, followed by a stress-relieving heat treatment cycle, and then final finishing passes. This adds time and cost, but it’s essential for achieving dimensional stability. Ignoring these internal forces is a common pitfall that can turn a high-value workpiece into expensive scrap.

Key Material Properties and Their Impact

The choice of material dictates the entire machining strategy. Each alloy behaves differently under the cutter, especially at a large scale where heat has more time and space to build up. Understanding these properties is fundamental. Based on our project experience, here’s a quick breakdown of common materials used in large part manufacturing and their associated challenges.

| Material | Key Property | Machining Challenge |

|---|---|---|

| Titanium (Ti-6Al-4V) | High Strength-to-Weight, Poor Heat Conductor | Intense heat buildup at the tool, rapid wear |

| Stainless Steel (316L/17-4) | High Corrosion Resistance, Work Hardens | Material becomes harder as you cut it |

| Inconel 718 | Excellent High-Temperature Strength | Extreme tool wear, requires very slow speeds |

| Aluminum (7075/6061) | Lightweight, Good Machinability | Prone to distortion, thermal expansion issues |

Taming Tough Alloys in Large Formats

Machining difficult materials like titanium and superalloys is challenging on any scale, but for large parts, the problems are magnified. Long, continuous cuts generate immense heat, and because these materials are poor thermal conductors, that heat concentrates on the cutting tool, causing it to fail quickly. The strategy here revolves around effective heat management.

Heat Management is Everything

For a large titanium forging, for example, we can’t just rely on standard flood coolant. We use high-pressure coolant systems that blast jets of fluid directly at the cutting zone, extinguishing heat before it can damage the tool or workpiece. Tool selection is also critical. We use inserts with specific coatings, like Aluminum Titanium Nitride (AlTiN), which form a protective thermal barrier. We also carefully control cutting parameters—slowing down the spindle speed while maintaining a consistent feed rate helps reduce heat generation and allows for stable, predictable machining. It’s a slower process, but it’s the only way to ensure both tool longevity and part quality.

Strategies for Work-Hardening Materials

Stainless steels and alloys like Inconel have a tricky property: they get harder as you machine them. This is known as work hardening. If a cutting tool rubs against the surface instead of cleanly shearing the material, it hardens the spot it just touched, making the next pass even more difficult. This can lead to chatter, poor surface finish, and broken tools.

The "No-Dwell" Rule

The golden rule for these materials is to keep the tool constantly engaged and moving forward. We program our toolpaths to avoid dwelling in one spot. We use aggressive feed rates to stay underneath the previously hardened layer and cut into the softer material below. Techniques like trochoidal milling, where the tool takes a series of circular cuts instead of a straight line, are incredibly effective. This approach limits the tool’s engagement angle, which helps manage cutting forces and provides a "cooling" period as the tool completes each loop, significantly extending its life. In our work at PTSMAKE, adopting these advanced toolpaths has proven to cut down on tool consumption by a noticeable margin on large stainless steel components.

Material selection for large parts goes far beyond its end-use properties; it directly impacts the entire manufacturing process. The inherent challenges of weight, internal stress, and thermal conductivity demand specialized solutions. For tough alloys like titanium or Inconel, effective strategies focusing on heat management and preventing work hardening are non-negotiable. By using high-pressure coolant, specific tool coatings, and advanced toolpaths, we can navigate these material hurdles to produce large, precise components that meet the most demanding specifications.

Precision and Tolerance Demands for Large Components.

Have you ever considered how a deviation smaller than a human hair on a massive component can cause a catastrophic system failure? The pressure to get it right is immense.

Achieving tight tolerances in large components is essential for functionality, safety, and integration. In large part CNC machining, precision ensures that parts fit perfectly, withstand operational stress, and perform reliably, especially in critical sectors where any failure can have severe consequences.

When we talk about large-scale components, precision isn’t just a quality metric; it’s a fundamental requirement for performance and safety. A slight inaccuracy can have a domino effect, causing misalignment, premature wear, or complete failure of an entire assembly. This is especially true in industries where the stakes are highest.

The Non-Negotiable Need for Precision

In the defense sector, a component for a submarine hull or an aerospace frame must meet exact specifications. A deviation of even a few microns could compromise structural integrity under extreme pressure or G-forces. Similarly, in the oil & gas industry, components for drilling equipment or pipelines operate under immense pressure and in harsh environments. A flange that doesn’t seal perfectly due to a tolerance error can lead to disastrous leaks. At PTSMAKE, we understand that for these applications, "close enough" is never an option. The functionality and safety of the final product depend entirely on the precision we achieve during the machining process.

Core Methods for Guaranteeing Accuracy

Achieving such high precision on large workpieces is a complex challenge that requires a combination of technology, strategy, and expertise. It’s not as simple as just scaling up the process for a smaller part.

Incremental Processing

Instead of trying to machine an entire feature at once, we often use an incremental approach. This involves machining a section of the part, stopping to measure and verify its accuracy, and then proceeding to the next section. This method helps manage heat buildup and internal stresses within the material, both of which can distort the workpiece and ruin tolerances. It’s a methodical process that ensures a stable and predictable outcome for any large part cnc machining project.

Advanced Measurement Systems

Verifying the dimensions of a large part requires specialized equipment. Traditional calipers and micrometers are often insufficient. We rely on advanced metrology3 tools to ensure our work meets the tightest specifications.

| Measurement System | Best Use Case for Large Parts | Key Advantage |

|---|---|---|

| Coordinate Measuring Machine (CMM) | Verifying complex internal geometries and final part inspection. | Extremely high accuracy and repeatability. |

| Laser Trackers | In-process measurement on the machine tool itself. | Portability and ability to measure very large volumes. |

| Structured Light Scanners | Capturing the complete surface geometry for comparison to CAD. | Speed and comprehensive data capture. |

These systems provide the data we need to make real-time adjustments and confirm that the final component is flawless.

Beyond the core methods, mastering precision in large-format machining involves overcoming significant physical and environmental challenges. A part that is several meters long behaves very differently on a machine bed than a small component. The interplay between the machine, the material, and the environment becomes much more pronounced.

Tackling the Physical Realities of Scale

Two of the biggest hurdles we consistently manage are thermal expansion and material stability. These factors can quietly sabotage the precision of a part if they are not properly controlled.

Managing Thermal Dynamics

The heat generated by the cutting process causes the workpiece and even the machine itself to expand. On a large part, this expansion can be substantial, easily pushing a feature out of tolerance. In our past projects, we’ve found that a multi-faceted approach works best. This includes using high-pressure coolant to dissipate heat at the cutting source, machining in a climate-controlled environment, and programming "cool-down" periods into the machining cycle to allow the part to normalize.

Ensuring Material Stability and Fixturing

The sheer weight of a large component can cause it to sag or deform under its own gravity, a phenomenon known as deflection. Proper support is critical. Designing a custom fixturing solution is often the first step in a large-scale project. The fixture must hold the part securely without introducing new stresses.

| Challenge | Mitigation Strategy at PTSMAKE | Expected Outcome |

|---|---|---|

| Part Deflection | Custom support fixtures, FEA simulation before machining. | Maintains geometric stability throughout the process. |

| Tool Wear & Vibration | Using specialized cutting tools, optimizing cutting speeds/feeds. | Consistent surface finish and dimensional accuracy. |

| Internal Material Stress | Stress-relieving heat treatments before final machining. | Prevents part from warping after being unclamped. |

The Indispensable Human Element

While advanced technology is crucial, it’s the skill of the machinist that brings everything together. An experienced machinist understands how to listen to the machine, read the subtle signs of tool wear, and make micro-adjustments on the fly. They can anticipate how a specific material will behave and adapt the machining strategy accordingly. In large part cnc machining, this hands-on expertise is irreplaceable. It’s the combination of advanced technology and our team’s deep experience that allows us to confidently deliver on the most demanding tolerance requirements.

In summary, achieving tight tolerances for large components is a fundamental requirement for ensuring safety and functionality in critical industries. Success depends on a strategic approach that includes incremental processing and the use of advanced measurement systems. Furthermore, overcoming physical challenges like thermal expansion and material deformation requires careful planning and robust strategies. Ultimately, the expertise of skilled machinists is what unites technology and technique to deliver the necessary precision on every single large-scale project.

Thermal Management and Cooling Strategies?

Ever had a massive workpiece warp from heat, turning a precision project into expensive scrap? It’s a frustrating reality when thermal management is overlooked in large part CNC machining.

Effective thermal management involves controlling heat generation and dissipation during large part CNC machining. Strategies include advanced coolants, strategic toolpaths, and controlled machining cycles to prevent thermal distortion and maintain dimensional accuracy, ensuring the final part meets strict specifications.

The Unseen Enemy: Heat in Large-Scale Machining

When you’re dealing with large part CNC machining, heat isn’t just a byproduct; it’s a primary obstacle. The sheer scale of the work amplifies the problem. Longer machining times, larger tool contact areas, and deeper cuts all contribute to a massive amount of thermal energy being pumped into the workpiece. Unlike smaller parts that can dissipate heat relatively quickly, a large block of metal acts like a heat sink, trapping thermal energy deep within its core. This trapped heat is where the real trouble begins. It doesn’t distribute evenly, creating temperature gradients that can compromise the entire project.

The material itself plays a huge role. In projects at PTSMAKE, we often work with materials like aluminum, which conducts heat well but also expands significantly, or titanium, which is a poor thermal conductor and concentrates intense heat right at the cutting edge. This concentration can lead to tool wear, work hardening, and a poor surface finish. The most significant threat, however, is thermal distortion. As different sections of the part heat and cool at different rates, the material expands and contracts unevenly. This movement, even if microscopic, can cause a perfectly machined part to warp, bow, or twist, throwing critical dimensions out of tolerance. A part that was perfectly accurate on the machine can become unusable once it cools to room temperature. This is why understanding a material’s thermal expansion coefficient4 is non-negotiable before the first cut is ever made.

Understanding the Impact of Uncontrolled Heat

The consequences of poor thermal management go beyond simple warping. Uneven temperature gradients create internal stresses within the material. These stresses can remain locked in the part long after machining is complete, potentially leading to premature failure or micro-cracking under operational loads. For critical components in the aerospace or automotive industries, this is an unacceptable risk. It’s not enough to just machine a part to the correct dimensions; we have to ensure its structural integrity is sound. Below is a simplified table showing how different materials react to heat during machining, which guides our strategy.

| Material | Thermal Conductivity (W/m·K) | Thermal Expansion (μm/m·°C) | Machining Heat Risk |

|---|---|---|---|

| Aluminum (6061) | ~167 | ~23.6 | High |

| Stainless Steel (304) | ~16.2 | ~17.2 | Very High |

| Titanium (Ti-6Al-4V) | ~6.7 | ~8.6 | Extreme |

| Invar | ~10 | ~1.2 | Low |

This table helps illustrate why a one-size-fits-all approach to cooling doesn’t work. Each material requires a tailored thermal management plan to counteract its inherent properties and ensure a successful outcome.

Proactive Cooling: More Than Just Spraying Coolant

Effective thermal management is an active, not passive, process. The standard flood coolant systems seen on many smaller machines are often inadequate for large part CNC machining. The sheer volume of the workpiece and the depth of the cuts can prevent the coolant from reaching the most critical area: the interface between the cutting tool and the material. To solve this, we rely on more advanced systems. High-pressure, through-spindle coolant is one of our most effective tools. This method delivers a concentrated, high-velocity jet of coolant directly through the tool to the cutting edge, blasting away chips and dissipating heat at its source. This prevents chips from being re-cut, which generates even more heat, and keeps the cutting zone at a stable temperature.

The type of coolant is just as important as the delivery method. At PTSMAKE, we work closely with our clients to select the right fluid—be it synthetic, semi-synthetic, or oil-based—to match the material and the operation. A good coolant does more than just cool; it lubricates the tool, reduces friction, and helps produce a better surface finish. It’s an integral part of the machining process, not an afterthought.

Smart Machining Strategies to Beat the Heat

Beyond the hardware, our programming and machining strategies are our first line of defense against thermal distortion. We can’t just press "start" and walk away.

Incremental Machining

For particularly sensitive parts, we use an incremental or "staged" machining approach. Instead of machining one area to completion, we machine a section, then move to a different area of the part to allow the first section to cool and stabilize. By rotating the machining zones, we prevent a large concentration of heat from building up in any single area. This method requires more complex programming but is invaluable for maintaining the dimensional stability of large, thin-walled, or complex components.

Timed Cooling Periods

In some of our past projects with clients, we’ve found success by programming planned pauses directly into the G-code. After a long or aggressive cutting operation, the machine will pause for a predetermined amount of time. This allows the entire workpiece to normalize in temperature, reducing the internal stresses caused by sharp temperature gradients. This simple but effective technique has saved countless parts from the scrap bin, especially those with extremely tight tolerance requirements.

| Cooling Strategy | Primary Mechanism | Best Suited For | Key Benefit |

|---|---|---|---|

| Flood Coolant | Convection/Evaporation | General Machining | Cost-effective, good chip removal |

| High-Pressure Coolant | Forced Convection | Deep pockets, drilling | Excellent chip evacuation, targeted cooling |

| Timed Pauses | Conduction/Radiation | Large parts, tight tolerances | Prevents cumulative heat buildup |

| Incremental Machining | Heat Localization Control | Thin-walled or complex parts | Minimizes overall part distortion |

Overlooking heat in large part CNC machining leads to costly thermal distortion and dimensional inaccuracies. The challenge stems from prolonged cutting and massive workpieces. By using smart cooling strategies like high-pressure coolants, timed pauses, and incremental machining, we control heat effectively. This proactive thermal management is crucial for maintaining part integrity and meeting the strict specifications required by our clients at PTSMAKE.

Multi-Axis Machining and Advanced Manufacturing Techniques?

Ever felt constrained by the limits of standard 3-axis machines when designing large, intricate components? This often forces costly redesigns and compromises, delaying your project and inflating the budget.

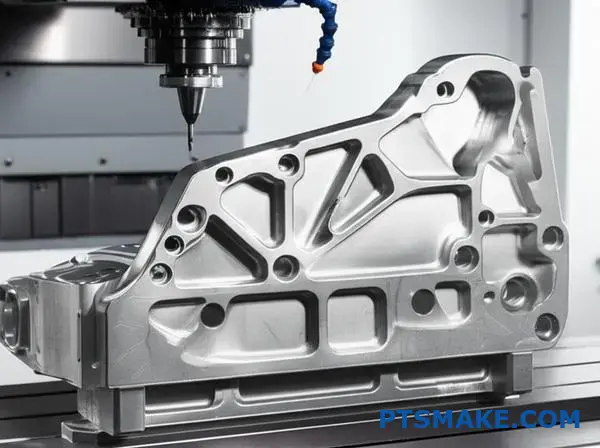

Multi-axis machining and advanced techniques like contour boring allow the creation of complex, large parts by moving the tool or workpiece on four or more axes simultaneously. This approach reduces manual repositioning, enhances precision, and makes it possible to machine geometries that standard machines simply cannot produce.

The Freedom of Multi-Axis Machining

When we talk about large part CNC machining, moving beyond the standard X, Y, and Z axes opens up a world of possibilities. This is where multi-axis machining comes in. It’s not just about adding more movement; it’s about fundamentally changing how we approach complex parts.

From 3-Axis to 5-Axis: An Evolution in Capability

Standard 3-axis machines move a cutting tool along three linear axes. They are workhorses for simpler parts but struggle with undercuts and complex curved surfaces. To machine different faces, the part must be manually unclamped, rotated, and re-clamped. Every setup introduces a risk of error, which can be disastrous for large, high-value components.

4-axis machining adds a rotational axis (the A-axis), allowing the workpiece to be turned during the process. This is great for cylindrical parts or for machining features around a central axis.

5-axis machining is the pinnacle for complexity. It adds a second rotational axis (the B or C axis), enabling the tool to approach the workpiece from virtually any angle. There are two main types:

- 3+2 Machining (Indexed 5-Axis): The machine orients the part to a specific angle, then performs 3-axis milling. It’s great for reducing setups on parts with features on multiple faces.

- Continuous 5-Axis Machining: All five axes move simultaneously, allowing for the creation of smooth, complex contours and organic shapes. The machine’s kinematics5 must be perfectly calibrated for this.

In our experience at PTSMAKE, moving a large aerospace component from a 3-axis to a 5-axis process can reduce the total machining time by up to 40% simply by eliminating setup changes.

Comparing Machining Axes

| Axis Configuration | Key Advantage | Common Applications | Complexity Level |

|---|---|---|---|

| 3-Axis | Simplicity, cost-effective | Flat parts, simple holes, basic profiles | Low |

| 4-Axis | Machining cylindrical features | Cams, shafts, propellers | Medium |

| 5-Axis | Complex geometries, fewer setups | Impellers, turbine blades, medical implants | High |

This multi-axis capability is what allows us to tackle monolithic designs for aerospace frames or intricate molds for the automotive industry without compromising the part’s structural integrity.

Specialized Techniques for Unique Challenges

Beyond adding axes, producing large and heavy parts often requires highly specialized manufacturing techniques that address specific geometric challenges. Two of the most critical are contour boring and deep hole drilling. These aren’t just scaled-up versions of standard operations; they are distinct processes demanding specialized tools and expertise.

Mastering Internal Geometries with Contour Boring

Imagine needing to machine a large, non-standard internal diameter or a complex tapered bore deep inside a massive valve body. Standard boring bars can’t handle this. Contour boring uses a specialized, often actuated tool that can follow a programmed path to create complex internal profiles. This is crucial for:

- Valve Bodies: Creating precise seating surfaces and flow paths.

- Engine Blocks: Machining cylinder bores with unique shapes for performance.

- Hydraulic Manifolds: Ensuring complex internal channels meet perfectly.

This technique removes the need for multiple tools and operations, ensuring a smooth, continuous internal surface with high accuracy. It’s a perfect example of how advanced manufacturing solves problems that are impossible with conventional methods.

Reaching New Depths with Deep Hole Drilling

Drilling a hole with a depth-to-diameter ratio greater than 10:1 is considered deep hole drilling. For large parts like landing gear components or long hydraulic cylinders, this ratio can be much higher. The main challenges are chip evacuation and delivering coolant to the cutting edge. Failure in either can cause tool breakage or a scrapped part—a very expensive mistake in large part CNC machining.

Specialized methods are used:

- Gun Drilling: Uses a single-flute drill with internal coolant channels that flush chips out through a V-shaped groove.

- BTA Drilling (Boring and Trepanning Association): Coolant is pumped around the outside of the tool, and chips are evacuated through the tool’s center. It’s faster and more effective for larger diameters.

At PTSMAKE, we’ve found that selecting the right deep hole drilling method can be the difference between a successful project and a failed one, especially when working with tough materials common in the energy and aerospace sectors.

| Technique | Depth-to-Diameter Ratio | Key Feature | Best For |

|---|---|---|---|

| Standard Drilling | < 10:1 | General purpose, simple | Standard holes in most parts |

| Gun Drilling | Up to 400:1 | High-pressure internal coolant | Small to medium diameter deep holes |

| Contour Boring | N/A | Creates complex internal profiles | Non-standard bores, valve seats |

These advanced techniques aren’t just about making parts; they’re about enabling better, more integrated designs that were previously considered unmanufacturable.

Multi-axis machining and advanced techniques are essential for overcoming the constraints of standard CNC machines. By moving beyond 3-axis limitations, we can produce large parts with complex geometries in fewer setups, enhancing accuracy and efficiency. Specialized methods like contour boring and deep hole drilling further expand these capabilities, allowing for the creation of intricate internal features and extreme depth-to-diameter ratios. These technologies are critical for pushing the boundaries of modern manufacturing in industries like aerospace and energy.

Quality Assurance and Inspection for Large CNC Parts?

Ever had a massive, expensive part fail inspection due to a tiny error discovered too late? The larger the component, the greater the financial and timeline risks from a single mistake.

Effective quality assurance for large CNC parts is a multi-stage process. It combines in-process inspection during manufacturing, final dimensional verification using advanced tools like CMMs, and non-destructive testing. This comprehensive approach guarantees that every feature meets specifications, ensuring the part’s integrity and performance.

Quality in large part CNC machining isn’t a final step; it’s a continuous process woven into every stage of production. A single flaw in a multi-ton component can lead to catastrophic failure, making a robust QA framework non-negotiable. It’s about building confidence and certainty from the raw material to the finished product. At PTSMAKE, we structure our quality assurance around three core pillars to mitigate risks and ensure absolute conformity.

The Three Pillars of Large Part QA

A successful quality strategy relies on catching potential issues at the earliest possible moment. Waiting until the end to inspect a part that took hundreds of hours to machine is a recipe for disaster. That’s why we break the process down.

In-Process Inspection: Catching Errors Early

In-process inspection is our first line of defense. We conduct checks at critical points during the machining cycle, not just at the end. For a large workpiece, this means verifying key features before the part is repositioned or moved to another machine. For instance, after a major milling operation, we might use portable CMM arms to check critical bore diameters and plane alignments. This proactive approach prevents small deviations from compounding into major, unfixable errors. It confirms that the setup is rigid, the tool wear is within limits, and the machine is performing as expected. Correcting an error mid-process is exponentially cheaper than scrapping a nearly-finished, high-value part.

Final Dimensional Verification: The Moment of Truth

Once all machining operations are complete, the part undergoes final dimensional verification. This is the comprehensive check against the customer’s CAD model and engineering drawings. For large parts, this presents unique logistical challenges related to handling and measurement. The science of Metrology6 is central here. We use large-gantry CMMs to meticulously measure hundreds, sometimes thousands, of points across the component. The goal is to create a detailed inspection report that confirms every dimension, tolerance, and geometric feature is within the specified limits. This report is the ultimate proof of conformity.

Non-Destructive Testing (NDT): Seeing What’s Beneath

Dimensional accuracy is only part of the story. The internal integrity of the material is just as important, especially for components subjected to high stress or fatigue. Non-Destructive Testing (NDT) methods allow us to inspect for subsurface flaws like cracks, voids, or inclusions without damaging the part.

| Inspection Type | Purpose | Timing | Common Methods |

|---|---|---|---|

| In-Process | Prevent error propagation | During machining cycles | Calipers, micrometers, portable CMMs |

| Final | Verify full compliance | After all machining is complete | Large CMMs, laser scanners |

| NDT | Ensure material integrity | Post-machining, before finishing | Ultrasonic, dye penetrant, magnetic particle |

By integrating these three pillars, we create a QA system that provides a complete picture of the part’s quality, both inside and out.

Inspecting large parts effectively requires more than just a good process; it demands sophisticated technology capable of handling immense scale while maintaining micron-level precision. The sheer size and weight of these components make traditional measurement techniques impractical or impossible. Over the years, we’ve invested heavily in specialized equipment to overcome these challenges and deliver the verifiable quality our clients in aerospace, automotive, and energy demand.

Advanced Inspection Technologies for Scale

Choosing the right inspection technology depends on the part’s geometry, tolerance requirements, and material. For large part CNC machining, two technologies stand out as the industry standards: Coordinate Measuring Machines (CMMs) and laser scanners.

Coordinate Measuring Machines (CMMs)

CMMs are the gold standard for dimensional inspection due to their incredible accuracy. A CMM uses a probe to touch discrete points on a part’s surface, recording their X, Y, and Z coordinates. For large components, this requires a gantry-style or bridge-style CMM with a measurement volume large enough to accommodate the entire workpiece. The primary challenge is the infrastructure—these machines require climate-controlled environments and massive, stable foundations to maintain their accuracy. At PTSMAKE, our large-format CMMs are the final arbiters of quality, providing the high-precision data needed to validate critical tolerances. While the process can be time-consuming, the resulting accuracy is unmatched for features like bore concentricity, flatness, and true position.

Laser Scanning and 3D Metrology

For parts with complex, free-form surfaces, laser scanning offers a powerful alternative. A laser scanner projects a line of light onto the surface and measures the shape’s geometry, quickly capturing millions of data points to create a "point cloud." This point cloud is then digitally overlaid onto the original CAD model to create a color-coded deviation map. This map instantly visualizes any areas that are out of tolerance, making it an excellent tool for qualifying complex curvatures on molds, turbine blades, or automotive body panels. Laser scanners are often more portable than CMMs, allowing for inspection directly on the machine tool bed in some cases.

| Technology | Accuracy | Speed | Best For |

|---|---|---|---|

| CMM | Very High (Micron-level) | Slower | High-precision geometric features (bores, planes) |

| Laser Scanner | High (Good for most uses) | Faster | Complex surfaces, reverse engineering, full-surface analysis |

The Critical Role of Documentation and Traceability

The inspection process doesn’t end when the measurements are taken. The data must be compiled into clear, comprehensive documentation that provides a complete history of the part. A quality part without a quality report is an incomplete delivery. Our documentation package typically includes:

- Material Certifications: Traceability back to the raw material supplier.

- Full Dimensional Inspection Report: A detailed list of all measured features against their nominal values and tolerances.

- NDT Reports: Certifications from any non-destructive tests performed.

- Certificate of Conformance (CoC): Our formal declaration that the part meets all customer requirements.

This documentation provides our clients with total confidence and traceability, which is essential for regulated industries and critical applications. It is our tangible commitment to the quality we promise.

Ultimately, quality assurance in large part CNC machining is about risk mitigation. A multi-stage approach, combining in-process checks with final verification and NDT, is crucial. Leveraging advanced technologies like large-format CMMs and laser scanners overcomes the unique challenges posed by size and scale. However, the process is only complete with thorough documentation, which provides the traceability and proof of conformity that our partners rely on. This comprehensive strategy ensures that every massive component we produce is dependably precise.

Logistics and Handling of Oversized Machined Components.

Have you ever seen a perfectly machined large component get damaged in the final step of delivery? This last mile can easily undo weeks of meticulous work, turning a manufacturing success into a costly failure.

Successful handling of oversized machined components demands a comprehensive logistics strategy. This includes using specialized transport, custom fixtures, and coordinated lifting with equipment like cranes. Meticulous planning is essential to ensure the component arrives safely, on time, and damage-free, preserving its precision and value.

The Blueprint: Pre-Movement Planning and Risk Assessment

The biggest mistake in large part CNC machining logistics is treating it as an afterthought. At PTSMAKE, the logistics plan begins the moment we quote a project. A successful delivery isn’t about luck; it’s about a detailed blueprint that anticipates challenges before they arise. This involves more than just booking a truck. We conduct a thorough analysis of the component’s journey from our facility to its final destination. This includes mapping the route to identify potential obstacles like low bridges, narrow roads, or weight-restricted zones.

We also assess the loading and unloading capabilities at both ends. Do we have the overhead crane capacity? Does the client’s site have adequate access for a heavy-haul truck and the necessary equipment to receive the part? Answering these questions early prevents costly delays and dangerous situations. Creating a detailed handling document is standard practice for us. This document outlines every step, from the initial lift off the machine to the final placement, ensuring everyone involved understands the specific requirements and safety protocols for that unique component.

Specialized Equipment: The Right Tools for the Job

Moving a multi-ton, precision-machined part is not a job for a standard forklift. It requires a suite of specialized equipment carefully selected based on the component’s weight, dimensions, and geometry.

Lifting and Moving Solutions

The primary tools are heavy-duty cranes and high-capacity forklifts. For in-facility movement, we rely on overhead gantry cranes that can safely lift and position components with extreme accuracy. For transport, this might involve coordinating with mobile crane services at both the shipping and receiving locations. A critical safety factor we always implement is ensuring the lifting equipment’s capacity is significantly higher than the part’s weight, typically by at least 25%, to provide a robust safety margin.

Custom Fixtures and Crating

Standard pallets and crates are completely inadequate for oversized, irregularly shaped parts. Each large component requires a custom-designed solution. We build custom wooden or welded steel cradles and fixtures directly from the part’s CAD model. These supports are engineered to distribute the part’s weight evenly, protect sensitive surfaces, and secure it against movement and vibration during transit. Proper use of dunnage7 is also crucial to cushion the part and absorb shocks.

Here is a simplified checklist we use as a starting point for our logistics planning:

| Planning Stage | Key Consideration | Primary Responsibility |

|---|---|---|

| Initial Assessment | Verify final weight and center of gravity. | Engineering & QA |

| Route Survey | Identify and clear transport route obstacles. | Logistics Partner |

| Packaging Design | Engineer custom cradle and crating solution. | Packaging Team |

| Equipment Scheduling | Reserve cranes, trucks, and personnel. | Project Manager |

| Documentation | Prepare handling instructions and shipping docs. | Administration |

Execution: Best Practices for Transport and Storage

With a solid plan and the right equipment, the focus shifts to flawless execution. The actual process of moving, transporting, and storing the component is where attention to detail prevents catastrophic failures. It’s a coordinated effort that relies on expertise and constant communication.

The Transportation Phase in Action

Loading a large machined part is a slow, deliberate process managed by certified riggers. They ensure that lifting straps are placed at designated, structurally sound points to avoid stress or damage. Once on the transport vehicle, the custom crate is securely fastened using heavy-duty chains and binders to prevent any shifting. In past projects at PTSMAKE, we’ve found that using trucks with air-ride suspension provides a smoother journey, significantly reducing the G-forces exerted on the component. Throughout the transit, we often utilize GPS tracking with shock and tilt sensors. This technology provides real-time data, allowing us to monitor the component’s condition and gives our clients peace of mind.

Secure Storage and Environmental Controls

Not every component goes directly from the truck to the assembly line. If storage is required, it must be handled with the same level of care. An oversized part cannot simply be left on a loading dock. We ensure it is stored in a climate-controlled environment to protect it from humidity, temperature fluctuations, and contaminants that could lead to corrosion or warping. The component should remain in its custom cradle, elevated off the floor, and covered with a protective tarp. This maintains its integrity and ensures it’s in perfect condition when the client is ready for installation.

A comparison between standard and specialized handling highlights the difference in care:

| Feature | Standard Freight Handling | Specialized Large Part Handling |

|---|---|---|

| Support | Generic pallets or boxing | Custom-engineered cradles |

| Equipment | Standard forklifts, pallet jacks | Overhead cranes, air-ride trucks |

| Securing | Plastic wrap, basic straps | Heavy-duty chains, custom bracing |

| Monitoring | Basic tracking number | GPS with shock/tilt sensors |

| Environment | Open-air or general warehousing | Climate-controlled storage |

This specialized approach is non-negotiable for high-value, large part CNC machining. The goal is to make the logistics process a seamless, invisible extension of the precision manufacturing that preceded it.

Logistics for oversized machined parts is not an afterthought but a critical phase of the manufacturing process. It requires meticulous pre-planning, from route surveys to designing custom fixtures. Utilizing specialized equipment like cranes and air-ride trucks is essential for safe handling. By implementing best practices for crating, transportation, and storage, we ensure that the precision and value engineered into the component are protected until it reaches its final destination, preventing costly damage and delays.

Cost Factors and Economic Impact of Large Part CNC Machining.

Have you ever looked at a quote for a large machined component and wondered what truly drives the final price? The numbers can often seem daunting, leaving you to question the overall economic feasibility.

The cost of large part CNC machining is primarily driven by four key areas: raw material, machine time, skilled labor, and logistics. However, leveraging economies of scale, process optimization, and automation are powerful strategies to mitigate these expenses and enhance your project’s profitability.

Understanding the cost structure of large part CNC machining is the first step toward optimizing your budget. Unlike smaller components, every factor is magnified. It’s not just about more material; it’s a completely different scale of operational complexity. At PTSMAKE, we break down these costs to give our partners full transparency, ensuring there are no surprises.

Material Costs: The Heavy Foundation

The sheer volume of material required for a large part is the most obvious cost driver. A large billet of aerospace-grade aluminum or stainless steel represents a significant upfront investment before a single chip is cut. Furthermore, the buy-to-fly ratio—the weight of the raw material versus the weight of the final part—is critical. Inefficient machining strategies can turn a large portion of that expensive billet into low-value scrap, directly impacting your bottom line.

Machine Time: The Premium on Size

Larger parts require larger machines, and these machines come with higher hourly rates. A 5-axis gantry mill capable of handling a multi-ton workpiece is a massive capital investment. The cost of that investment, along with its significant power consumption and maintenance needs, is factored into its operating rate through a process of amortization8 over its lifespan. Additionally, setup and programming times are substantially longer. Securing, aligning, and calibrating a massive workpiece can take hours, all of which is billable machine time.

Labor and Expertise: The Human Factor

Operating large-format CNC machines is not a job for a novice. It requires highly skilled and experienced machinists who can manage complex setups, monitor long machining cycles, and troubleshoot potential issues on high-value parts. Often, the setup and handling of these components require a team, not just a single operator, adding to the labor costs. Their expertise is essential to prevent costly errors that could scrap the entire workpiece.

Logistics and Overhead: The Hidden Multipliers

Simply moving a large workpiece around the shop floor requires specialized equipment like overhead cranes or heavy-duty forklifts. Once the part is complete, shipping is another major consideration. It often requires custom crating, freight shipping, and specialized logistics, all of which add to the final cost.

A simple comparison highlights the exponential increase in costs:

| Cost Factor | Standard Part (e.g., 6" x 6") | Large Part (e.g., 6′ x 6′) |

|---|---|---|

| Material Cost | Manageable | Substantial Investment |

| Machine Rate | Standard | Premium |

| Setup Time | Minutes | Hours, potentially a full shift |

| Handling Needs | Manual / Cart | Overhead Crane / Forklift |

| Shipping Method | Standard Parcel | Freight / Custom Crate |

While the cost drivers may seem intimidating, they are not insurmountable. The key is to shift from simply accepting the costs to strategically managing them. This is where a partnership with an experienced manufacturer like PTSMAKE provides a significant economic advantage. We focus not just on machining a part, but on engineering a cost-effective production process from start to finish. This holistic view is what transforms a high-cost component into a profitable asset for your company.

Unlocking Economies of Scale

One of the most effective ways to reduce per-unit cost is through volume. The significant initial costs of programming and setup are fixed whether you produce one part or one hundred. By spreading these fixed costs over a larger production run, the cost attributed to each individual part decreases dramatically. In past projects at PTSMAKE, we’ve seen per-unit costs drop by a considerable percentage when moving from a prototype run to low-volume production, purely by leveraging economies of scale. Furthermore, larger production runs allow for bulk purchasing of raw materials, often at a discounted rate.

The Power of Process Optimization and Automation

This is where technical expertise truly impacts the bottom line.

Smart Automation

Automation isn’t just for small parts. Modern large-format machines can be equipped with pallet changers and robotic systems that can run "lights-out," or unattended, for extended periods. This drastically reduces the labor cost per part and maximizes the use of the high-value machine asset.

Advanced CAM Strategies

Optimizing toolpaths within the CAM software is a critical step. Our engineers focus on strategies like high-efficiency milling (HEM) to reduce cycle times, extend tool life, and improve surface finish. A well-optimized program can shave hours off a machining cycle, resulting in direct and substantial cost savings.

The Broader Economic Impact

The benefits of efficient large part CNC machining extend far beyond the part itself.

Accelerating Time-to-Market

By consolidating multiple smaller, welded components into a single large machined part, you can eliminate entire assembly steps and their associated labor, inspection, and lead times. This simplification enables a much faster turnaround from design to a market-ready product, giving you a crucial competitive advantage.

Enabling High-Volume Production

Previously, the high cost of large part machining might have made certain product designs economically unviable for mass production. Through strategic optimization, we can make high-volume production of these large, complex components a reality, opening up new possibilities for your product lines and overall profitability.

| Strategy | Primary Cost Reduction Area | Impact on Profitability |

|---|---|---|

| Economies of Scale | Setup & Material Costs | Lowers per-unit cost, increasing margin on larger orders. |

| CAM Optimization | Machine Time & Tool Wear | Reduces operational expenses, increases machine capacity. |

| Smart Automation | Labor & Machine Downtime | Boosts productivity and enables 24/7 operation. |

| Design for Manufacturability (DFM) | Material Waste & Machining Time | Simplifies production, lowering overall project costs from the start. |

Ultimately, understanding the key cost drivers in large part CNC machining—materials, machine time, labor, and logistics—is fundamental. By actively applying strategies like economies of scale, process optimization, and smart automation, these high costs can be effectively managed. This transforms large-scale machining from a significant expense into a strategic capability, enabling faster turnarounds and higher production volumes that directly enhance your company’s profitability and market position.

Selecting the Right CNC Machining Partner for Large Parts?

Ever chosen a supplier for a critical large part, only to face delays and quality issues that put your entire project at risk?

Selecting the right partner for large part CNC machining involves a thorough evaluation of their equipment, proven experience with similar-scale projects, quality certifications like ISO 9001, and transparent communication protocols. These factors are crucial for ensuring your project’s success from start to finish.

When you’re dealing with large, expensive, and mission-critical components, you can’t afford to get your choice of manufacturing partner wrong. The selection process needs to be more rigorous than just comparing quotes. It’s about finding a team that becomes an extension of your own, one that understands the unique challenges of large part CNC machining. Let’s break down the essential criteria you should be evaluating.

Scrutinizing Equipment and Capabilities

The most obvious starting point is the machinery itself, but you need to look deeper than just the size of the machine bed.

Beyond the Machine’s Size

A shop might have a large-format machine, but does it have the necessary specifications for your job? For heavy-duty materials common in large parts, you need a machine with high spindle power and torque to handle aggressive material removal rates without sacrificing surface finish. The machine’s structural rigidity is also paramount; any flex or vibration during machining will be amplified across a large surface, leading to inaccuracies. Furthermore, consider the machine’s kinematic accuracy9, as this fundamentally determines its ability to hold tight tolerances over long travel distances. 5-axis capabilities are often a necessity for machining complex geometries on large workpieces in a single setup, reducing both time and the potential for error.

Ancillary Equipment and Infrastructure

The machining process doesn’t end when the cutting tool stops. How will the partner handle your large part? Look for a facility equipped with essential support infrastructure. This includes:

- Heavy-Lifting Equipment: Overhead cranes or gantry systems with sufficient capacity are non-negotiable for safely loading and unloading large, heavy workpieces.

- Large-Scale Metrology: How will they verify the part’s accuracy? They need large Coordinate Measuring Machines (CMMs), laser trackers, or portable measuring arms capable of inspecting your part’s full dimensions.

- Facility Layout: The shop floor should be organized and spacious enough to accommodate large parts at every stage, from raw material receiving to final inspection and shipping, without creating bottlenecks.

Experience and Proven Track Record

A partner’s past performance is the best indicator of future success. You want a team that has already navigated the challenges you’re about to present them with.

Ask for Relevant Case Studies

Don’t be afraid to ask for specific examples of past work. A truly experienced partner in large part CNC machining will be proud to share case studies. Look for projects that are similar to yours in terms of:

- Size and Weight: Have they handled parts of a comparable scale?

- Material: Do they have deep experience with your specified material, whether it’s aluminum, steel, titanium, or an exotic alloy?

- Complexity and Tolerances: Can they show examples of parts with similar geometric complexity and tight tolerance requirements?

In our experience at PTSMAKE, sharing these past successes helps build trust and gives our clients the confidence that we can deliver.

Beyond the hardware and a portfolio of past work, the "softer" aspects of a potential partner—their processes, certifications, and communication style—are what truly separate a mere supplier from a strategic partner. These elements are critical for a smooth and successful project, especially when dealing with the complexities of large components.

Certifications and Quality Management Systems

Certifications aren’t just pieces of paper; they are evidence of a company’s commitment to quality, consistency, and continuous improvement. They prove that a robust system is in place to manage every aspect of the manufacturing process.

The ISO 9001 Baseline

At a minimum, any potential partner should be ISO 9001 certified. This international standard ensures the company has a well-documented Quality Management System (QMS). It means they have defined processes for everything from quoting and order entry to material traceability, process control, inspection, and corrective actions. It’s your assurance that they don’t just get it right by chance, but by design.

Industry-Specific Certifications

If your project is for a regulated industry, look for relevant certifications. For example, AS9100 is critical for aerospace components, while IATF 16949 is the standard for the automotive industry. These certifications demonstrate that the partner understands the stringent documentation, traceability, and quality requirements specific to your field. They speak the same language of compliance and risk management that you do.

Evaluating Communication and Project Support

For a long and complex large part machining project, clear and consistent communication is the glue that holds everything together.

The Value of a Dedicated Contact

Find out how they manage projects. Will you have a single point of contact, like a dedicated project manager or engineer? Having one person who understands your project inside and out is invaluable. It prevents things from getting lost in translation between departments and ensures you get timely, accurate updates. This is a core part of our philosophy at PTSMAKE; we want to make the process simple and transparent for our clients.

Turnaround Time and Transparency

Be wary of partners who promise unrealistically fast turnaround times for large parts. A credible partner will provide a detailed and realistic project timeline that accounts for material procurement, programming, machine setup, machining time, finishing processes, and quality inspection. Ask them to walk you through their production schedule. Transparency here is a sign of an experienced and trustworthy partner.

A simple evaluation matrix can help you compare potential partners objectively:

| Criterion | What to Look For | Red Flags |

|---|---|---|

| Experience | Case studies of similar size/material parts | Vague answers, no relevant examples |

| Equipment | Large-format 5-axis CNC, CMMs, cranes | Outdated machines, no inspection tools |

| Certifications | ISO 9001, AS9100 (if applicable) | No certifications, messy shop floor |

| Communication | Dedicated project manager, clear updates | Slow responses, multiple contacts |

Choosing the right partner for large part CNC machining goes beyond just machine size. It requires a thorough review of their real-world experience, support equipment, quality systems, and communication protocols. A deep evaluation of these key criteria ensures you find a reliable partner capable of handling the unique challenges of large-scale projects. This diligence upfront is the best way to guarantee your complex components are delivered on time and to your exact specifications.

Case Studies: Success Stories in Large Part CNC Machining?

Ever wondered how theoretical precision translates into real-world success for massive components? Or faced a project where the sheer scale seemed to defy the required accuracy?

Success stories in large part CNC machining highlight how expert partners overcome complex challenges like material stability and tight tolerances on massive scales. These real-world examples from aerospace to energy demonstrate tangible results, from reduced assembly times to enhanced component performance, proving the value of strategic planning.

Theory is one thing, but execution is where the real challenges in large part CNC machining emerge. Seeing how these challenges are met in practice provides the most valuable lessons. In our work at PTSMAKE, we’ve collaborated with clients on projects where success hinged on overcoming immense technical hurdles. Let’s look at a couple of examples.

The Challenge: Uncompromising Aerospace Tolerances

An aerospace client approached us with a project for a structural wing rib machined from a large billet of 7075 aluminum. The part was over 3 meters long, with thin walls and deep pockets. The primary challenges were preventing material warping during machining and maintaining the strict geometric tolerances required for aircraft assembly. The raw material alone represented a significant investment, so there was no room for error.

Our Solution: A Multi-Stage Machining Strategy

We developed a comprehensive strategy that went beyond just programming a toolpath. First, we used a 5-axis machining center to minimize setups, as each re-fixturing introduces potential error. The core of our solution was a multi-stage machining process. We started with a roughing phase to remove the bulk of the material, leaving a consistent layer. Then, the part underwent a controlled stress-relieving heat treatment. This step was crucial for stabilizing the material. After stabilization, we performed semi-finishing and final finishing passes with high-speed tools to achieve the required surface finish and dimensional accuracy. We also designed and built custom fixtures with multiple support points to prevent vibration and deflection during machining. The machine’s volumetric accuracy10 was calibrated specifically for this job to ensure precision across its entire travel.

| Aspect | Initial Challenge | Implemented Solution |

|---|---|---|

| Material Stability | High risk of warping in 7075 aluminum | Multi-stage machining with intermediate stress relief |

| Tolerance Control | Tight GD&T over a 3-meter length | 5-axis machining, custom fixturing, in-process probing |

| Process Risk | High cost of material scrap | Detailed simulation and verification before machining |

The result was a component that met all specifications perfectly. It integrated seamlessly into the client’s assembly, reducing their fit-up time and ensuring the structural integrity of the wing assembly.

Success in large part manufacturing isn’t limited to aerospace. The principles of meticulous planning and process control apply across all industries, from industrial machinery to automotive tooling. Each sector brings its own unique set of material and geometric challenges.

The Challenge: Precision and Stability for a Large Machine Base

Another memorable project involved manufacturing a large machine base for a semiconductor equipment company. The component was a massive casting of gray cast iron, serving as the foundation for a high-precision lithography system. The key requirements were exceptional flatness across the top surface (within a few microns over 2 meters) and parallelism between multiple mounting points. The sheer weight and size of the workpiece made handling and machining incredibly difficult.

Our Approach: A Fusion of Technology and Process Control

To tackle this, we utilized one of our large gantry mills. The first step was to create a detailed plan for lifting and securing the workpiece on the machine bed without introducing any stress or distortion. We used laser trackers to verify the initial setup and alignment before making the first cut. The machining process itself was carefully sequenced to manage thermal expansion. We used through-spindle coolant to keep the cutting zone at a stable temperature. After the primary surfaces were milled, the part was left to normalize for 24 hours on the machine before we took the final, light finishing passes. This patient approach ensured the material was stable and the final geometry was true.

| Metric | Project Goal | Achieved Result |

|---|---|---|

| Surface Flatness | < 10 µm over 2000 mm | 7 µm over 2000 mm |

| Parallelism | < 15 µm between mounting planes | 11 µm between mounting planes |

| Production Lead Time | 6 weeks | 5.5 weeks |

The outcome was a machine base that exceeded the client’s stringent specifications. This precision at the foundational level was critical for the overall accuracy of their equipment, enabling them to produce next-generation microchips. It proved that for large part CNC machining, patience and process are just as important as the power of the machine itself.

These case studies show that success in large part CNC machining is about more than just having large equipment. It’s about a holistic approach that combines strategic planning, material science, advanced technology, and deep expertise. From aerospace components requiring minimal weight and maximum strength to massive industrial bases needing absolute stability, the right partner transforms complex challenges into tangible results. This ultimately delivers value through improved performance, reliability, and faster integration into the final product.

Get Your Large Part CNC Machining Quote with PTSMAKE Today!

Ready to achieve unmatched precision and reliability for your large part CNC machining needs? Partner with PTSMAKE—your next-generation precision manufacturing expert. Contact us now for a fast, tailored quote and discover how we help you streamline production, reduce delays, and guarantee top-tier quality.

Understand how this crucial metric ensures precision across the entire working volume of a large machine tool. ↩

Understand how this internal force affects machining precision and part stability. ↩

Explore Metrology, the science of measurement, to see how it underpins all high-precision manufacturing. ↩

Understand how this material property dictates the risk of distortion and why it’s critical for material selection. ↩

Learn about the principles of machine motion to better optimize your designs for manufacturability. ↩

Understand the science of measurement and how it impacts the precision and reliability of your CNC machined parts. ↩

Discover why the right material choice here is critical for protecting your high-value components during transit. ↩

Learn how this key accounting principle affects your machining quotes and project budget planning. ↩

Click to understand how this machine-tool characteristic directly impacts the precision and quality of your large machined parts. ↩

Understand why this factor is crucial for ensuring precision across the entire surface of your large components. ↩