UNC and UNF threads look similar, but choosing the wrong one can cause stripped threads, joint failures, or costly production delays. I’ve seen engineers struggle with this decision because the differences seem subtle, yet the consequences of getting it wrong are significant.

UNC (Unified National Coarse) threads have fewer threads per inch and are ideal for quick assembly and soft materials, while UNF (Unified National Fine) threads have more threads per inch and provide better strength and vibration resistance for precision applications.

This guide will walk you through the technical differences, practical applications, and decision-making process. You’ll learn how to select the right thread type based on material properties, assembly requirements, and performance needs. By the end, you’ll have a clear framework for making confident thread selections in any engineering project.

What is the Unified Thread Standard’s first principle?

The core principle of the Unified Thread Standard (UTS) is simple: interchangeability. It ensures a screw made in one factory will fit a nut from another.

The Problem Before Standardization

Imagine a world without it. Every manufacturer had their own thread designs. This created chaos and inefficiency. Parts simply did not fit together.

The Solution: A Common Language

UTS, documented in ASME B1.1, established a single set of rules. This standard guarantees compatibility across suppliers and industries. It was a revolutionary step for engineering.

| Before UTS | After UTS |

|---|---|

| Incompatible Parts | Universal Interchangeability |

| Custom Tooling | Standardized Tooling |

| High Costs & Waste | Efficiency & Reliability |

| Supply Chain Chaos | Streamlined Logistics |

Why Was a Standard So Critical?

The push for standardization gained urgency after World War II. Allied forces struggled with incompatible hardware. A bolt made in the USA often wouldn’t fit a nut made in the UK. This logistical nightmare cost time, resources, and even lives on the battlefield. It was clear that a shared system was essential for modern manufacturing and global cooperation.

The Birth of ASME B1.1

In response, the United States, United Kingdom, and Canada collaborated. They created the Unified Thread Standard. It defined a common system for screw threads, making replacement and repair straightforward.

Key Elements Defined

This standard specifies every critical detail of a thread. It dictates the thread form1, angles, diameters, and tolerances. This precision removes guesswork and ensures consistency. It’s the blueprint every manufacturer follows. The standard also details different series for specific uses, which brings up the common UNC vs UNF threads debate—one coarse, one fine, for different applications.

| Parameter | Specification in UTS |

|---|---|

| Thread Angle | 60 degrees |

| Crest Profile | Flat or rounded |

| Root Profile | Rounded |

| Pitch & Diameter | Defined combinations |

At PTSMAKE, our CNC machining processes rely on these exact specifications. Adhering to standards like ASME B1.1 is not optional; it is the foundation of the reliable, high-precision parts we deliver to our partners.

The Unified Thread Standard’s first principle is interchangeability. It was created to solve the historic problem of incompatible parts, establishing a universal language for screw threads that ensures components from different manufacturers fit and function together reliably.

How does geometry define a UNC thread fundamentally?

At its core, a UNC thread is defined by three simple geometric parameters. These elements work together to create its unique "coarse" profile. Understanding them is key.

The Building Blocks of a UNC Thread

First is the pitch, measured in Threads Per Inch (TPI). This dictates the distance between crests. Second is the 60° thread angle, a standard for Unified threads. Finally, we have the thread depth.

| Parameter | Standard Value | Role |

|---|---|---|

| Thread Angle | 60° | Creates the V-shape |

| Pitch (TPI) | Varies by diameter | Defines "coarseness" |

| Thread Form | Symmetrical | Ensures consistent engagement |

The large pitch, or low TPI, is what makes it coarse. This means fewer threads over a given length.

A Deeper Look at Coarse Geometry

The ‘coarse’ nature of a UNC thread is a direct result of its geometry. The lower TPI means each individual thread is larger and deeper compared to a fine thread like UNF. This design choice has significant mechanical implications.

A deeper thread provides stronger engagement per thread. This is because more material is in contact between the male and female parts. This robust design makes UNC threads more tolerant of minor damage and easier to assemble quickly without cross-threading.

Geometric Trade-offs

However, this geometry also means more material is removed during tapping. This can be a factor in thin-walled components. The effective mating size, known as the Pitch Diameter2, is crucial for fit. In past projects at PTSMAKE, we’ve seen how this dimension dictates the fastener’s strength and performance under load.

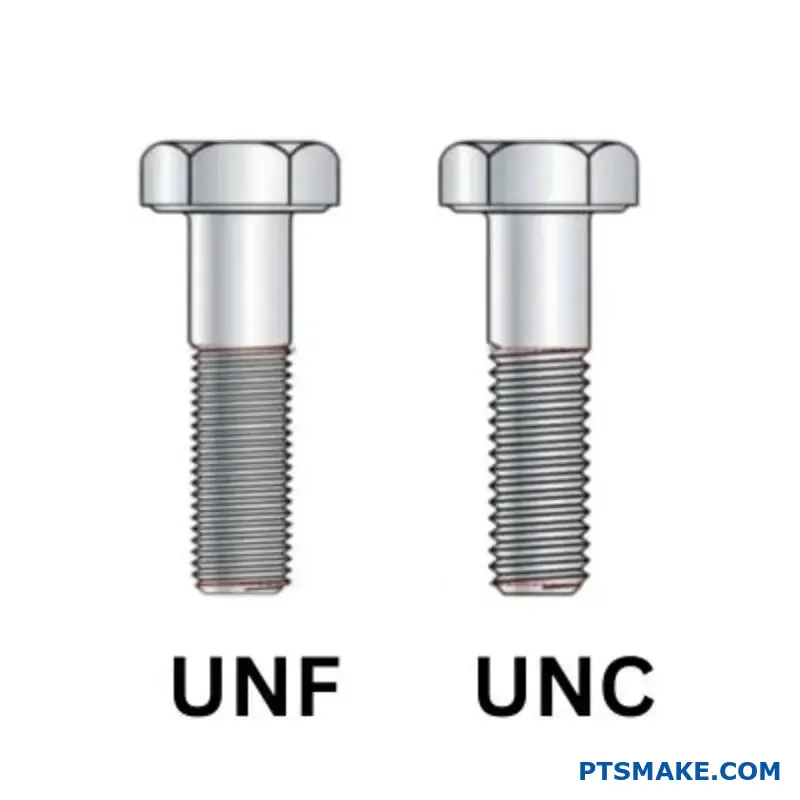

When considering UNC vs UNF threads, the geometric differences are clear.

| Feature | UNC (Coarse) | UNF (Fine) |

|---|---|---|

| Pitch (TPI) | Lower | Higher |

| Thread Depth | Deeper | Shallower |

| Helix Angle | Steeper | Finer |

| Assembly Speed | Faster | Slower |

This fundamental geometry makes UNC threads ideal for general-purpose fastening where strength and ease of use are paramount.

In essence, the UNC thread’s geometry—specifically its low TPI—dictates its coarse nature. This design leads to deeper, stronger threads that are easier to assemble, defining its fundamental mechanical properties and common applications.

How does geometry define a UNF thread fundamentally?

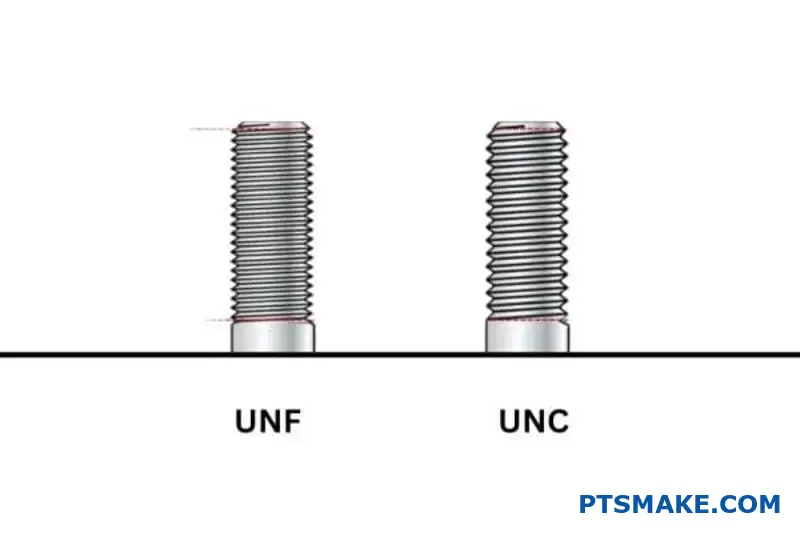

To understand UNF, we must compare it to its counterpart, the UNC (Unified Coarse) thread. The defining geometric difference is simple: the pitch.

For any given diameter, a UNF thread has a finer pitch. This means more threads per inch (TPI). This isn’t just a minor detail. It is the fundamental element that dictates its performance characteristics.

UNC vs. UNF: TPI at a Glance

Consider a common 1/4-inch fastener. The difference becomes immediately clear.

| Thread Standard | Diameter | Threads Per Inch (TPI) |

|---|---|---|

| UNC | 1/4" | 20 |

| UNF | 1/4" | 28 |

This single change in thread density is the source of all the functional distinctions between them.

This geometric shift from coarse to fine pitch creates a cascade of performance changes. The discussion of UNC vs UNF threads always comes back to this single factor.

How Pitch Dictates Performance

A finer pitch means the threads are closer together. This leads to shallower thread depth compared to a UNC thread of the same major diameter.

This results in a larger minor diameter. A larger minor diameter increases the bolt’s cross-sectional area. This directly boosts its ability to withstand pulling forces. The tensile stress area3 is subsequently greater.

In our past projects at PTSMAKE, we’ve found this gives UNF screws a strength advantage in tension and shear, which our tests confirm is around 10% higher.

The shallower angle of the finer threads also provides more resistance to loosening under vibration. It creates a tighter, more secure connection. It also allows for much finer adjustments in tensioning.

Performance Cascade from Finer Pitch

| Geometric Change | Resulting Performance Benefit |

|---|---|

| More Threads Per Inch | Finer adjustment control |

| Larger Minor Diameter | Higher tensile and shear strength |

| Shallower Thread Helixes | Increased resistance to vibrational loosening |

| Greater Thread Contact | Better load distribution, less stripping risk |

The key difference between UNC and UNF threads is pitch. This single geometric variation dictates strength, adjustment precision, and vibration resistance. This is why choosing the right thread is critical for application success.

Explain UNC vs. UNF using a simple analogy.

Imagine you’re pushing a cart up a ramp. This simple image is the key to understanding the difference between UNC and UNF threads.

The Steep Ramp: UNC Threads

UNC (Unified Coarse) threads are like a steep, short ramp. You get to the top faster with fewer turns. But, it’s also easier for the cart to roll back down if you let go.

The Gentle Slope: UNF Threads

UNF (Unified Fine) threads are a long, gentle slope. It takes more turns to reach the same height. However, the cart is far less likely to roll back. The connection is much more secure.

| Thread Type | Ramp Analogy | Key Feature |

|---|---|---|

| UNC | Steep Ramp | Fast Assembly |

| UNF | Shallow Ramp | High Security |

This core concept helps us select the right fastener for every project.

Why the Ramp’s Angle is Everything

The angle of the ramp changes the physics entirely. In threads, this "angle" is determined by the pitch—the distance between threads. A steeper pitch (UNC) provides less mechanical advantage.

This means it requires less turning force to tighten. But it also means it can loosen more easily under stress or vibration. A shallower pitch (UNF) offers greater mechanical advantage.

The Trade-off: Speed vs. Strength

With UNC threads, assembly is very fast. This makes them perfect for general applications where rapid production is a priority.

UNF threads take longer to fasten. However, they create a stronger and more reliable connection. The finer threads allow for greater tension and a more even distribution of preload4.

In our work at PTSMAKE, we often recommend UNF for critical components. This is especially true in the aerospace or automotive industries, where joint failure is not an option.

Here’s a breakdown of the trade-offs:

| Feature | UNC (Steep Ramp) | UNF (Shallow Ramp) |

|---|---|---|

| Assembly Speed | Faster | Slower |

| Vibration Resistance | Lower | Higher |

| Stripping Risk | Lower (deeper threads) | Higher (shallower threads) |

| Fine Adjustment | Less Precise | More Precise |

| Typical Use | General construction, quick assembly | Aerospace, automotive, high-stress applications |

Choosing the right thread is a fundamental step in our design for manufacturing process.

The ramp analogy makes the UNC vs. UNF choice clear. UNC is a steep, fast ramp for general use. UNF is a shallow, secure ramp for precision tasks. The right choice always depends on the application’s demand for speed versus security.

How are UNC/UNF organized within the UN thread series?

UNC and UNF are not standalone standards. They are the most popular members of a larger family: the Unified National (UN) thread series.

This system logically organizes threads based on their pitch, or threads per inch (TPI), for a given diameter.

The UN Thread Family

This classification helps engineers quickly select the right thread for a job. The system is straightforward: more threads per inch means a finer, more precise thread.

Below is a simple breakdown of the main series within this family.

| Series | Full Name | Primary Characteristic |

|---|---|---|

| UNC | Unified National Coarse | Rapid assembly, common use |

| UNF | Unified National Fine | Better torque tension, vibration resistance |

| UNEF | Unified National Extra Fine | Precision adjustment, thin-walled materials |

| UNJ | Unified National "J" Profile | High fatigue strength for aerospace |

This structure ensures a standardized option is available for nearly any mechanical application.

The logic behind this hierarchy is all about engineering trade-offs. There is no single "best" thread; the choice depends entirely on the application’s demands.

From Coarse to Aerospace

UNC threads are the workhorses. Their deeper, wider profile makes them fast to assemble and less prone to cross-threading. They are perfect for general construction and assembly where speed is key.

UNF threads provide a step up in precision. With more threads engaged over the same length, they create greater clamping force and resist loosening from vibration far better. This is why the UNC vs UNF threads discussion is vital in automotive and machinery design.

Specialized Fine Threads

UNEF takes this concept further. It’s used for precision instruments and applications needing very fine adjustment capabilities. However, these threads are more delicate and require careful handling.

The UNJ series is distinct. It was developed for aerospace, where fatigue failure can be catastrophic. It features a controlled root radius5 to reduce stress concentrations, a critical feature for bolts under extreme, cyclical loads. At PTSMAKE, we machine UNJ threads for our aerospace clients, where precision is non-negotiable.

| Feature | UNC | UNF | UNEF | UNJ |

|---|---|---|---|---|

| Assembly Speed | Highest | High | Moderate | Moderate |

| Vibration Resistance | Good | Better | Best | Excellent |

| Tensile Strength | Good | Better | Best | Highest |

| Primary Use | General Fastening | Automotive, Machinery | Instruments | Aerospace, Defense |

The UN thread series provides a clear hierarchy. UNC covers general use, while UNF and UNEF offer increasing precision. The specialized UNJ profile is engineered for high-stress aerospace applications, showcasing the system’s adaptability for critical performance requirements.

What do thread classes (1A/B, 2A/B, 3A/B) truly represent?

Choosing the right thread class is a practical decision. It directly impacts how easily parts assemble and how they perform under stress. Each class has a clear purpose.

This choice is a balance between function and budget. You must match the class to the application’s demands.

Application Breakdown

Below is a simple guide to their common uses.

| Class | Fit & Tolerance | Primary Application | Cost & Precision Trade-off |

|---|---|---|---|

| 1A/B | Loose Fit | Quick assembly, frequent disassembly, dirty environments. | Lowest Cost, Lowest Precision |

| 2A/B | Standard Fit | Most common industrial and commercial fasteners. | Moderate Cost, Standard Precision |

| 3A/B | Tight Fit | High-stress, safety-critical aerospace, automotive parts. | Highest Cost, Highest Precision |

This table shows the clear trade-offs.

Deeper Dive into Applications and Costs

Understanding the "why" behind each class prevents costly mistakes. It helps you avoid over-engineering or, worse, under-engineering a critical component.

Class 2A/B: The Industrial Workhorse

Class 2A/B is the default for a reason. It offers the best balance of precision, strength, and manufacturing cost. It’s the standard for the vast majority of commercial products. This applies to both UNC vs UNF threads in general hardware. We find it in everything from machinery to consumer electronics.

Class 3A/B: Precision Under Pressure

The jump to Class 3A/B is significant. This class has a tighter tolerance with a minimal allowance6. This ensures a secure, snug fit that resists vibration and fatigue.

But this precision comes at a price. Manufacturing requires more advanced tooling, slower machine cycles, and more intensive quality control. This increases production time and cost. It’s reserved for applications where failure is not an option.

Class 1A/B: Fit for Speed and Simplicity

Class 1A/B threads are designed for convenience. Their loose tolerances allow for rapid assembly and disassembly by hand. They can also accommodate dirt or debris without seizing. This makes them ideal for temporary fixtures or non-critical covers.

At PTSMAKE, we help clients select the most cost-effective class. We ensure the chosen thread meets performance needs without unnecessary expense.

Thread classes dictate a fastener’s fit, function, and final cost. Class 2A/B is the versatile industry standard. Class 1A/B suits rapid, loose-fit needs, while Class 3A/B is essential for high-precision, critical applications where performance justifies the higher expense.

How does UNC/UNF compare to the ISO Metric system?

The choice between Unified (UNC/UNF) and ISO Metric threads is fundamental in design. It impacts everything from manufacturing to global logistics. While they look similar, their core architectures are quite different.

Fundamental Unit Differences

UNC/UNF threads are based on the inch. In contrast, the ISO Metric system uses the millimeter. This basic difference is the source of all other distinctions.

Pitch Designation

How we measure the distance between threads also varies. This is a key point in the UNC vs UNF threads debate when comparing them to metric standards.

| System | Pitch Measurement | Example |

|---|---|---|

| UNC/UNF | Threads Per Inch (TPI) | 1/4"-20 (20 threads per inch) |

| ISO Metric | Distance between threads (mm) | M6x1.0 (1.0 mm between threads) |

A Surprising Similarity

Interestingly, both systems share the same 60° thread angle. This common feature defines the V-shape profile of the threads in both standards.

Global Manufacturing Implications

Choosing a thread system has significant global consequences. Your decision affects sourcing, compatibility, and market access. It is not just a technical choice; it is a strategic business decision.

For companies like us at PTSMAKE, navigating these standards is a daily task. We often advise clients on which system best suits their product’s intended market and supply chain.

A product designed with UNC threads for the US market may need a complete redesign to use Metric threads for sale in Europe. This lack of interchangeability7 between the systems creates real costs and logistical hurdles. It prevents the simple swapping of fasteners from one system to another.

Strategic System Choice

The best choice depends on your primary market. A focus on North America often favors UNC/UNF. However, for global distribution, the ISO Metric system is almost always the more practical choice.

| Factor | UNC/UNF System | ISO Metric System |

|---|---|---|

| Primary Market | North America | Global (especially Europe, Asia) |

| Component Sourcing | Easiest in the USA | Widely available worldwide |

| Global Compatibility | Limited | High |

This consideration is crucial for anyone involved in product design, from engineers to procurement managers.

Choosing between UNC/UNF and ISO Metric systems involves trade-offs. The core differences in unit and pitch measurement create global compatibility challenges, despite the shared 60° thread angle. Your target market should guide this critical design decision.

How does material dictate the UNC vs UNF choice?

Choosing the right thread is a critical engineering decision. The material of your component is the primary guide in this choice.

It directly influences the joint’s strength and longevity. Let’s break it down.

A Quick Decision Guide

To simplify the UNC vs UNF threads selection, we can use a basic matrix. This approach helps us match the material to the optimal thread type quickly.

Material Grouping

We categorize materials into three main groups based on their hardness and ductility.

| Material Group | Common Examples | Recommended Thread |

|---|---|---|

| Soft | Aluminum, Brass, Plastics | UNC |

| General | Low-Carbon Steel | UNC or UNF |

| Hard | Alloy Steels, Titanium | UNF |

This table serves as a reliable starting point for most applications.

Let’s delve deeper into the "why" behind these recommendations. The logic is rooted in fundamental mechanical principles: resistance to stripping and the fastener’s inherent strength.

UNC Threads for Softer Materials

When working with materials like aluminum, brass, or even some plastics, the primary risk is thread stripping. The material itself is the weak link.

UNC’s coarser, deeper threads engage more material. This wider thread profile creates a stronger hold within the softer base material. It effectively distributes the load and prevents the threads from pulling out.

In past projects at PTSMAKE, we’ve seen this prevent costly failures in aluminum housings and plastic enclosures.

UNF Threads for Harder Materials

For high-strength materials like alloy steels or titanium, stripping the internal thread is much less likely. Here, the focus shifts to maximizing the fastener’s strength.

UNF threads have a slightly larger minor diameter. This provides a greater tensile stress area8, making the bolt or screw itself stronger under tension.

The fine pitch of UNF threads also allows for more precise tension adjustments, which is vital in high-performance aerospace and automotive applications.

Reasoning Summary

This table clarifies the core reasoning for each material type.

| Material Type | Primary Concern | Optimal Choice & Reason |

|---|---|---|

| Soft | Internal thread stripping | UNC: Deeper threads provide superior grip and stripping resistance. |

| Hard | Fastener fracture (tensile strength) | UNF: Larger core diameter increases fastener strength and allows fine adjustments. |

Material hardness is the key determinant. Soft materials need UNC’s robust grip to prevent stripping. Hard materials leverage UNF’s design for higher fastener strength and precision clamping, ensuring a secure and reliable joint.

How do you select between UNC and UNF for assembly speed?

When assembly speed is your top priority, the choice is simple. The fewer rotations a fastener needs, the faster it can be installed.

UNC threads have a coarser pitch. This means fewer turns are needed to fully engage the fastener. This is a huge advantage in high-volume production.

A Simple Decision Rule

For speed, choose UNC. The time savings add up quickly. This simple rule helps reduce assembly time and labor costs significantly.

Time vs. Rotations

Let’s compare a common size. The difference in rotations directly impacts total assembly time.

| Thread Type | Threads Per Inch (TPI) for 1/4" | Advantage for Speed |

|---|---|---|

| UNC | 20 | Fewer Rotations |

| UNF | 28 | More Rotations |

This table clearly shows UNC requires less turning. This translates directly to faster assembly.

Cost Analysis: Time is Money

In manufacturing, every second counts. The direct relationship between assembly time and cost is undeniable. Faster assembly means lower labor costs and higher output.

For a large production run, saving just one second per fastener can lead to hours of saved labor. This has a massive impact on the project’s bottom line.

High-Volume Production Impact

In past projects at PTSMAKE, especially with automated assembly lines, this choice becomes critical. UNC threads reduce the cycle time for each unit.

This reduction improves the overall efficiency of the production line. A faster line can produce more units per day. This boosts throughput without adding machinery or personnel. Based on our client collaborations, this decision directly impacts Takt time9.

Calculating the Savings

Consider the cumulative effect. Small time savings on each part become significant when multiplied by thousands or millions of units.

| Factor | UNC Threads | UNF Threads |

|---|---|---|

| Assembly Time/Unit | Faster | Slower |

| Labor Cost/Unit | Lower | Higher |

| Total Throughput | Higher | Lower |

| Ideal Application | High-volume, fast assembly | Precision, high-strength |

Choosing the right thread in the design phase is a key cost-saving strategy. We often guide our partners to make this choice early to maximize efficiency.

For high-volume manufacturing where speed is crucial, UNC threads are the superior choice. Their coarser pitch allows for faster assembly, directly reducing labor costs and increasing production throughput. This small detail has a large financial impact on large-scale projects.

How do you select between UNC/UNF for vibration resistance?

When vibration is a key factor, the choice matters. For applications with significant shaking or thermal changes, UNF threads often win.

Their finer pitch provides a smaller helix angle. This creates more friction and resistance to loosening.

This design also allows for more precise tensioning. You can achieve a higher, more reliable clamping force. Think of it as having more control over how tight the connection is.

| Feature | UNC (Coarse) | UNF (Fine) | Vibration Impact |

|---|---|---|---|

| Helix Angle | Larger | Smaller | Smaller angle resists loosening |

| Preload | Good | Higher | Higher preload means a tighter joint |

| Adjustment | Standard | Finer | More precise tension control |

A Clear Methodology for Selection

In high-vibration environments, your fastener choice is critical. A simple methodology can guide you in the UNC vs UNF threads debate. Start by analyzing the operational forces.

1. Assess Environmental Loads

First, quantify the vibration and thermal cycling. Is it constant, low-frequency shaking? Or is it high-frequency, intermittent shock? Severe conditions demand a more robust solution. UNF’s design provides superior resistance here.

2. Evaluate Clamping Force Needs

Next, determine the required clamping force, or preload10. This is the tension that holds the joint together. UNF threads allow for finer torque adjustments.

This precision is crucial. Our internal tests show UNF fasteners can achieve up to 10% higher preload than UNC fasteners for the same material and diameter. This creates a much more secure joint.

| Application Factor | Recommendation | Rationale |

|---|---|---|

| High Vibration | UNF | Smaller helix angle resists loosening. |

| Thermal Cycling | UNF | Maintains tension better during expansion/contraction. |

| High Preload Required | UNF | Finer adjustments achieve higher, more accurate clamping force. |

| Frequent Reassembly | UNC | Less prone to cross-threading and galling. |

3. Consider Material and Size

Finally, think about the fastener’s material and size. Softer materials can be stripped by fine threads. Smaller diameter fasteners benefit more from the increased thread engagement of UNF.

For critical applications at PTSMAKE, we almost always recommend UNF threads. This ensures the joint remains secure under stress.

For applications with high vibration, UNF threads are superior. Their finer pitch allows for higher preload and finer tension adjustments, creating a more secure joint that resists loosening much more effectively than UNC threads.

How do you specify a threaded fastener on an engineering drawing?

A clear drawing callout is everything. It removes guesswork for your manufacturing partner. It is the single source of truth for the part.

The Anatomy of a Perfect Callout

Getting it right means specifying every detail. This prevents costly errors and delays. We use a checklist to ensure nothing is missed.

Here is a quick overview of what to include. Each element plays a critical role in defining the fastener.

| Element | Example |

|---|---|

| Nominal Size & TPI | 1/4"-20 |

| Series | UNC |

| Class of Fit | 2A (External) |

| Standard | ASME B1.1 |

| Material | 316 Stainless Steel |

| Finish | Passivate per ASTM A967 |

This structured approach ensures clarity.

Breaking Down the Callout Details

Each part of the callout has a specific job. The nominal size (e.g., 1/4") is the major diameter. Threads per inch (TPI) defines the thread density.

Then comes the thread series. This is where you specify UNC (Unified Coarse) or UNF (Unified Fine). Choosing between UNC vs UNF threads depends on the application. UNC is common and resists stripping. UNF offers finer adjustment and higher strength.

Fit, Material, and Finish

The class of fit11 dictates the tolerance between mating threads. A ‘2A’ (external) or ‘2B’ (internal) is standard for commercial products. A ‘3A/3B’ offers a tighter fit for high-precision applications. This detail is crucial for performance.

Material and finish specifications are equally important. You must state the exact material, like "Alloy Steel." Also include any required hardness (e.g., Rockwell C 38-42).

Finally, specify any coatings. This could be zinc plating for corrosion resistance or a black oxide finish for appearance. At PTSMAKE, we always cross-reference these details to avoid ambiguity.

| Class | Description | Application |

|---|---|---|

| 1A/1B | Loose fit, easy assembly | Quick assembly/disassembly |

| 2A/2B | Standard commercial fit | General purpose |

| 3A/3B | Tight fit, high accuracy | Aerospace, precision machinery |

A complete fastener callout is non-negotiable. This checklist ensures your design intent is perfectly communicated to your manufacturing partner. Including every detail, from size to finish, guarantees you get the right part every single time.

How do you choose a thread for tapping into brittle material?

When tapping into brittle materials, the choice between UNC vs UNF threads is critical. We consistently recommend UNC (Unified Coarse) threads for materials like cast iron or hard plastics.

The reasoning is straightforward. UNC threads have a coarser pitch and deeper profile. This design helps distribute stress more evenly across the material. It significantly lowers the risk of causing cracks or chips during the tapping process, ensuring part integrity.

| Feature | UNC (Coarse) | UNF (Fine) |

|---|---|---|

| Stress | Lower Concentration | Higher Concentration |

| Risk of Cracking | Lower | Higher |

| Best For | Brittle Materials | Ductile Materials |

| Tapping Speed | Faster | Slower |

The Mechanics of Threading Brittle Materials

Brittle materials like ceramics, cast iron, or thermoset plastics have very low ductility. This means they fracture under stress with little to no plastic deformation. Tapping creates immense localized stress, making thread choice vital.

Why Coarse Threads Excel

A UNC thread’s larger and deeper profile provides a greater cross-sectional area at the root of the thread. This design element is key to spreading out the load.

In contrast, UNF (Unified Fine) threads have shallower, more closely spaced grooves. These sharper notches can cause a significant stress concentration12, a major concern in brittle materials. Each sharp root acts as a potential starting point for a crack.

In past projects at PTSMAKE, especially with glass-filled plastics, using UNC threads has proven essential. It prevents micro-fractures that could lead to catastrophic failure under operational load.

| Thread Type | Root Radius | Stress Distribution | Failure Mode in Brittle Material |

|---|---|---|---|

| UNC | Larger | More Even | Less Likely to Initiate Crack |

| UNF | Sharper | Concentrated at Root | High Risk of Crack Initiation |

For brittle materials, the best practice is clear. UNC threads offer a more robust and reliable fastening solution by minimizing stress concentration and reducing the likelihood of cracking during and after the tapping operation. This choice ensures the component’s structural integrity.

How do you mitigate thread stripping in soft materials?

Thread stripping in soft materials like aluminum or plastics is a common frustration. It can ruin a perfectly good part. But you can prevent it. The key is to maximize the thread’s holding power.

Start with the Right Thread Type

The first line of defense is choosing the correct thread. In the UNC vs UNF threads debate for soft materials, UNC is the clear winner. Its deeper, coarser threads provide a larger surface for engagement.

| Feature | UNC (Coarse) | UNF (Fine) |

|---|---|---|

| Thread Depth | Deeper | Shallower |

| Shear Area | Larger | Smaller |

| Best For | Soft Materials | Hard Materials |

This increased contact area helps distribute the load more effectively. It significantly reduces the risk of threads pulling out.

Beyond Thread Choice: Additional Strategies

While choosing UNC threads is a great start, other methods provide extra security. We often combine these techniques at PTSMAKE for robust designs in soft materials. Each approach has its place depending on the application’s demands.

Increase Engagement Length

A simple yet effective method is to increase the thread’s length of engagement. A longer screw or a deeper tapped hole gives more threads to share the load. A general rule is to have the engagement length be at least 1.5 to 2 times the screw’s diameter. This ensures the fastener’s tensile strength is the limiting factor, not the soft material’s Shear Area13.

Use Threaded Inserts

For high-load applications, threaded inserts are the best solution. These components, like Helicoils, are made from a stronger material, such as stainless steel. You install them into a larger, tapped hole in the soft material. This creates strong, durable steel threads inside the softer parent material.

| Mitigation Method | Primary Benefit | Best Use Case |

|---|---|---|

| Increase Engagement | Simple, no extra parts | Moderate load, sufficient material depth |

| Threaded Inserts | Maximum strength & repairability | High load, frequent assembly/disassembly |

This approach effectively distributes the clamping force over a much larger area. It makes the connection incredibly resistant to stripping.

To prevent thread stripping in soft materials, start by using UNC threads. For added security, increase the engagement length or use threaded inserts like Helicoils. These methods distribute the load, creating a stronger and more reliable connection for your parts.

How do you select a thread for high tensile strength applications?

When selecting a thread for high-tensile applications, the choice is crucial. It often comes down to UNC vs UNF threads.

UNF threads generally offer a slight strength advantage. This is because they have a larger tensile stress area for the same bolt diameter.

However, the bolt is only one part of the equation. You must also consider the material of the internal thread. The interaction between them determines the joint’s true strength. For pure high-strength bolting, UNF is usually the preferred choice.

Why UNF is Often Stronger

For the same material and nominal diameter, a UNF bolt is slightly stronger in tension. This is due to its larger tensile stress area14. This is the effective area of the bolt that resists being pulled apart.

The finer pitch of UNF threads also provides better resistance to loosening under vibration. This is a critical factor in many high-performance applications.

Considering the Mating Material

The choice isn’t always simple. The material you are threading into plays a huge role. If you are creating threads in a softer material, like aluminum, a coarser UNC thread can be better. It provides more material engagement and reduces the risk of stripping.

In our projects at PTSMAKE, we’ve seen this firsthand. A high-strength UNF bolt can easily strip the threads in a softer block, compromising the entire assembly.

For high-strength steel-on-steel connections, UNF is almost always the superior choice. It offers higher strength and more precise tension adjustments due to its fine pitch.

Here’s a quick guide to help decide between UNC vs UNF threads:

| Factor | Choose UNF (Fine) | Choose UNC (Coarse) |

|---|---|---|

| Primary Goal | Maximum tensile strength | General purpose, fast assembly |

| Mating Material | High-strength steel | Softer materials (aluminum, plastic) |

| Vibration | High vibration environments | Low to moderate vibration |

| Adjustment | Requires precise tension control | Standard applications |

For high-tensile strength, UNF threads are generally preferred due to their larger stress area and better vibration resistance. However, the mating material is a critical factor. Coarser UNC threads may be necessary for softer materials to prevent stripping.

How do you design a joint to resist cross-threading?

Practical design choices are your first defense. Selecting the right thread type is a critical step.

Choosing the Right Thread

For applications involving manual assembly, I often recommend UNC (Unified National Coarse) threads. Their design is inherently more forgiving.

The larger pitch makes starting the fastener much easier. This reduces the chances of misalignment that leads to cross-threading.

UNC vs. UNF: A Quick Look

Here’s a simple breakdown from our experience at PTSMAKE. It shows why UNC is often preferred for ease of assembly.

| Thread Type | Cross-Threading Risk | Assembly Speed |

|---|---|---|

| UNC | Lower | Faster |

| UNF | Higher | Slower |

This makes UNC ideal for parts that are frequently disassembled and reassembled.

When we dive deeper into the design, the debate often comes down to UNC vs UNF threads. Each has a specific purpose, and choosing correctly is key to a robust design. This is a common discussion I have with clients to prevent future assembly issues.

The Case for UNC Threads

UNC threads feature a larger, coarser thread pitch15. This design choice is not accidental. It provides a wider "entry lane" for the male and female threads to engage properly.

This makes them less susceptible to damage from dirt or minor debris. For on-site assembly or maintenance, this is a significant advantage. The threads are simply more robust and easier to handle.

When to Consider UNF Threads

UNF (Unified National Fine) threads have their place. Their finer pitch provides greater tensile stress area. They also allow for more precise adjustments.

However, this precision comes at a cost. The fine threads require much more careful alignment during assembly. They are more easily damaged and far more prone to cross-threading if not handled correctly. In past projects, we’ve specified UNF for high-vibration environments where self-loosening is a major concern.

Application-Specific Thread Selection

Based on our tests, here’s how we typically guide the selection process:

| Application Factor | Recommended Thread | Rationale |

|---|---|---|

| Frequent Assembly/Disassembly | UNC | Lower risk of cross-threading damage. |

| High-Vibration Environment | UNF | Higher resistance to loosening. |

| High Tensile Strength Needed | UNF | Greater stress area for the same diameter. |

| Manual Assembly Priority | UNC | Easier and faster to start correctly. |

Choosing the right thread type, like UNC for manual assembly, is a fundamental design decision to prevent cross-threading. The thread’s pitch directly impacts ease of use and resistance to misalignment, making it a critical factor for reliable joints.

Analyze a high-performance engine head bolt failure.

Synthesizing multiple concepts is key to understanding bolt failure. A single cause is rare. Instead, failures often result from a combination of factors.

Three potential failure modes are most common. Each has a distinct root cause and signature.

Primary Failure Modes

We must consider tensile failure from over-torquing. Also, fatigue failure from cyclic loading is a major concern. Finally, thread stripping can occur due to material or design issues.

| Failure Mode | Primary Cause |

|---|---|

| Tensile Failure | Excessive installation torque |

| Fatigue Failure | Repeated stress cycles |

| Thread Stripping | Material incompatibility or damage |

This multi-faceted view helps us build a more robust solution.

To prevent these failures, we must analyze the entire system. This includes the bolt’s design, material, and coating. It’s not just about one element.

Mitigating Risks with Advanced Design

A fine, rolled-root thread like the UNJF standard is a great starting point. Unlike standard cut threads, rolled threads are formed under pressure. This process cold-works the material, increasing its strength and fatigue resistance.

The rounded root of the UNJF thread design is crucial. It helps distribute load more evenly across the threads. This significantly reduces stress concentration16 at the thread root, a common point of failure.

Material and Coating Synergy

Choosing the right material is just as important. In our experience at PTSMAKE, materials like H-11 tool steel or similar alloys offer superior tensile strength. This directly counters the risk of failure from over-torquing.

A performance coating, such as molybdenum disulfide, provides necessary lubrication. This ensures accurate torque readings and prevents thread galling, which can lead to stripping. The debate of UNC vs UNF threads also matters; finer threads like UNF or UNJF offer better tension control.

| Mitigation Strategy | Target Failure Mode |

|---|---|

| UNJF Rolled Threads | Fatigue Failure, Tensile Failure |

| High-Strength Alloy | Tensile Failure, Thread Stripping |

| Lubricant Coating | Thread Stripping, Tensile Failure |

Combining UNJF rolled threads with a high-strength alloy and a performance coating creates a robust system. This approach addresses tensile failure, fatigue, and thread stripping, ensuring the bolt can withstand the engine’s harsh demands.

Design the fastening system for a satellite’s vibrating component.

Designing for a satellite means zero room for error. Components face constant vibration. A single loose fastener can cause catastrophic failure. This is a true zero-maintenance environment.

So, how do we ensure absolute joint integrity? The answer lies in the details. We must select the right threads, fit, and locking mechanisms.

Our approach focuses on UNJF threads. They offer superior fatigue resistance. We combine this with a precise Class 3 fit to eliminate any play.

| Feature | Specification | Rationale |

|---|---|---|

| Thread Type | UNJF | Enhanced fatigue life |

| Fit Class | Class 3 | Minimal play, maximum stability |

| Environment | High Vibration | Zero-failure tolerance |

Why UNJF Threads are Non-Negotiable

When discussing fastener selection, UNJF threads are the clear choice for this application.

Unlike standard UNC vs UNF threads, UNJF features a controlled root radius. This small design change dramatically reduces stress concentration at the thread root, a common point of failure.

This is critical for preventing crack initiation under cyclic loading. The material’s ability to withstand repeated stress cycles, its fatigue resistance17, is significantly enhanced. In past projects at PTSMAKE, we have seen this make a crucial difference.

The Importance of a Class 3 Fit

Next, we specify a Class 3 fit. This is the tightest standard tolerance class. It ensures minimal play between the bolt and nut threads. This tight fit maximizes surface contact, distributing the load more evenly and preventing micro-movements that lead to loosening.

Layering Locking Mechanisms

At PTSMAKE, we don’t stop there. Redundancy is key in aerospace. We incorporate multiple locking features to guarantee the joint’s integrity.

| Locking Method | Description | Application |

|---|---|---|

| Safety Wire | A physical wire threaded through fastener heads, preventing rotation. | Critical fasteners, visual confirmation of security. |

| Locking Patch | A pre-applied adhesive on threads that adds friction. | Secondary locking, prevents vibrational loosening. |

Torqueing: The Final Lock-In

Finally, a rigorous torqueing procedure is executed. Each fastener is tightened to a precise value using a calibrated torque wrench. An independent inspector then verifies the torque. This two-step process ensures every joint is perfectly secured.

In summary, securing a satellite’s component is about system design. The combination of UNJF threads, a Class 3 fit, layered locking features, and a verified torqueing protocol creates a fastener system built for extreme reliability and zero maintenance.

When would you intentionally violate a standard rule of thumb?

Rules of thumb are vital. They are our baselines for safe and effective design. But true expertise means knowing when a rule can be broken.

Consider the debate of UNC vs UNF threads. The standard rule says use UNF for high-vibration environments.

However, we sometimes intentionally choose UNC threads for these exact applications. This expert-level exception can lead to a superior final product when executed correctly. It’s about a systems-based approach.

| Thread Type | Standard Application | Key Feature |

|---|---|---|

| UNF | High-Vibration | Fine Pitch |

| UNC | General Purpose | Coarse Pitch |

The System-Based Justification

Why choose a coarse UNC thread against vibration? The answer lies beyond the fastener itself. It involves the entire assembly.

Material and Assembly Considerations

In past projects at PTSMAKE, we’ve faced this with soft housing materials like aluminum. Fine UNF threads can easily strip or cross-thread during assembly. This risk is higher during rapid production or field maintenance.

A robust UNC thread is less prone to this kind of damage. Its deeper, coarser threads provide more resistance to stripping. This simplifies assembly and reduces costly errors. The risk of galling18 is also a factor we consider with certain material combinations.

The Role of Locking Mechanisms

The key is adding a robust locking mechanism. This transforms the fastener into a secure system. It compensates for the UNC thread’s lower inherent vibration resistance. We aren’t just choosing a thread; we are designing a complete joint.

Here are some options we frequently use:

| Locking Mechanism | How It Works | Best For |

|---|---|---|

| Locking Washers | Use tension or friction to prevent loosening. | High-vibration mechanical assemblies. |

| Thread Adhesives | Fill gaps between threads, curing to lock them. | Sealing against leaks and preventing vibration. |

| Nylon Inserts | Deform around threads to create a tight grip. | Applications requiring frequent adjustments. |

By adding a component like a Nord-Lock washer or a thread-locking adhesive, we engineer a solution. The ease of assembly and stripping resistance of the UNC thread is combined with the security of a locking feature.

This is a calculated trade-off. It prioritizes manufacturing efficiency and long-term serviceability. The choice solves a bigger problem than just vibration.

Choosing a UNC thread for high-vibration areas is a calculated risk. When paired with the right locking system, it becomes a smart engineering decision that prioritizes assembly robustness and material integrity over a single, isolated rule of thumb.

Develop a personal ‘decision tree’ for UNC vs UNF selection.

Theory is good, but action is better. Let’s turn knowledge into a practical tool. A personal decision tree helps you make the right choice quickly.

It removes guesswork from the UNC vs UNF threads debate. You simply answer a series of questions about your project.

Starting with the Core Question

Your first question should always be about the main constraint. What is the most critical factor for this specific application?

| Constraint | Initial Thought |

|---|---|

| High Vibration | Fine threads might be better. |

| Fast Assembly | Coarse threads are faster. |

| Soft Material | Coarse threads have more grip. |

Building Your Logic

Each answer leads to another question. This flow guides you to the most logical and reliable thread choice for your design.

Making the Decision Tree Your Own

The goal is to create a repeatable process. This tool internalizes the complex factors of thread selection. It makes your design process more efficient and less prone to errors. You’re not just guessing; you’re making an informed engineering decision every single time.

This decision-making framework is something we use at PTSMAKE. It helps our engineers align with client needs quickly, ensuring the selected fasteners meet all performance criteria. It’s a simple but powerful method.

Key Decision Points

Consider the following branching questions for your tree. These address the most common scenarios we encounter in CNC machining and injection molding projects.

- Vibration Level: Is the environment static or dynamic?

- Material Hardness: Are you working with aluminum or hardened steel?

- Assembly Speed: Is this for mass production or a one-off prototype?

- Tensile Load: What is the required clamping force?

The interaction between these factors is key. For example, a high-vibration application in a soft material presents a unique challenge. This is where a fine thread’s resistance to loosening must be weighed against a coarse thread’s resistance to stripping.

Understanding the Tensile Stress Area19 is crucial here. It directly impacts the fastener’s load-bearing capacity.

| Scenario | Primary Factor | Secondary Factor | Recommended Thread |

|---|---|---|---|

| Aerospace Engine Mount | High Vibration | High Strength | UNF |

| Furniture Assembly | Fast Assembly | Soft Wood | UNC |

| Precision Instrument | Fine Adjustment | Hard Steel | UNF |

| General Construction | Cost & Speed | Common Materials | UNC |

This structured approach ensures you consistently choose the optimal thread. It moves the UNC vs UNF threads selection from a simple preference to a calculated engineering decision based on application demands.

A personal decision tree turns complex engineering principles into a simple, step-by-step flowchart. This tool streamlines the UNC vs UNF threads selection process, ensuring consistent, reliable choices based on specific application constraints like vibration, material, and assembly requirements.

Can a 3D printed polymer thread behave like a metal one?

The short answer is no. But they can be functional with smart design. We can’t expect a polymer to have the same strength as steel.

The key is understanding the limitations. Polymer threads are inherently weaker. Their performance depends heavily on the printing process and design choices.

Key Material Differences

Let’s compare them directly. The differences are quite clear when you look at the material properties.

| Feature | Metal Threads | 3D Printed Polymer Threads |

|---|---|---|

| Strength | High | Low to Moderate |

| Creep | Negligible | Significant under load |

| Layer Adhesion | N/A (Solid) | A critical weak point |

| Precision | Very High | Variable |

This comparison shows why a direct substitution is rarely a good idea. We must design for the material.

Compensating for Polymer Weaknesses

We can’t change the material’s nature. But we can change our design approach. It starts with accepting the core limitations of 3D printing for mechanical parts like threads.

Understanding the Weak Points

Three main issues plague printed threads: layer adhesion, creep, and overall low strength. The bond between printed layers is always weaker than the material itself. This makes the part anisotropic20. The layers can separate under shear stress, which is common in threads.

Creep is another major concern. Over time, a loaded polymer thread will deform permanently. This can cause the connection to loosen and fail, especially under constant tension. This is something we rarely worry about with metal fasteners.

Why Coarser is Better: UNC vs UNF Threads

This is why coarser threads are a must. Fine threads like UNF have shallow profiles and thin features. They are very prone to stripping. Their small size makes layer adhesion failures more likely.

Coarser threads, like UNC, are much more robust. In past projects at PTSMAKE, we’ve found that UNC threads provide a better solution. They have deeper profiles and more material engagement. This helps distribute the load over a larger area, compensating for the polymer’s lower strength.

| Thread Type | Suitability for 3D Printing | Reason |

|---|---|---|

| UNF (Fine) | Poor | Small features, high risk of layer shear |

| UNC (Coarse) | Good | Deeper engagement, better load distribution |

| Custom Profile | Excellent | Can be optimized for layer lines & strength |

In some cases, we even design custom thread profiles. These are specifically made to maximize strength for 3D printed applications.

3D printed polymer threads have weaknesses like poor layer adhesion and creep. To create reliable parts, we must compensate through smart design, primarily by using coarser threads like UNC, which better distribute stress and reduce the risk of failure.

Unlock Precision Thread Solutions with PTSMAKE Today!

Ready to optimize your next project with expert advice on UNC vs UNF threads? Contact PTSMAKE for a fast, customized machining or molding quote. Our engineering team delivers reliable, high-precision threaded parts—on time, every time. Submit your inquiry now and let us exceed your expectations!

Discover the precise geometry defining a screw thread, ensuring it functions perfectly with mating components. ↩

Understand this critical dimension for ensuring proper thread fit and strength. ↩

Understand this key concept to calculate a bolt’s true strength and prevent fastener failure. ↩

Discover how achieving correct preload is crucial for the integrity and safety of bolted joints. ↩

Discover how this root design feature significantly enhances fastener fatigue life in demanding applications. ↩

Learn how this intentional design gap is crucial for thread fit and interchangeability. ↩

Learn how this principle impacts part compatibility and reduces global manufacturing costs. ↩

Understand how this critical area affects a fastener’s load-bearing capacity and overall joint integrity. ↩

Learn how this metric helps streamline manufacturing cycle times and meet customer demand. ↩

Learn more about how preload is critical for joint integrity and preventing fastener failure. ↩

Discover more about thread tolerance and how it impacts fastener performance in precision applications. ↩

Learn more about how stress points can lead to material failure in engineering design. ↩

Learn how this critical geometric feature impacts thread strength and failure. ↩

Understand how this critical area is calculated and its direct impact on bolt strength. ↩

Understand how thread pitch affects fastener strength, grip, and resistance to vibration. ↩

Learn how stress distribution is critical for the longevity of mechanical components. ↩

Explore this link to understand how material properties and design influence component lifespan under cyclic loads. ↩

Understand how this thread damage occurs and learn the best strategies to avoid it. ↩

Understand how this crucial measurement determines a fastener’s ultimate strength and reliability in your application. ↩

Understand how material properties change with direction, crucial for designing strong 3D printed parts. ↩