Many engineers struggle with stainless steel CNC machining projects that demand both precision and reliability. The challenge gets worse when you need parts that can withstand harsh environments while maintaining tight tolerances.

Stainless Steel CNC machining combines advanced manufacturing techniques with corrosion-resistant materials to produce high-precision components for medical, aerospace, automotive, and industrial applications, delivering superior durability and performance.

At PTSMAKE, I work with engineers who need reliable solutions for their most demanding projects. Stainless steel machining requires specific expertise in material selection, tooling strategies, and quality control. The right approach can make the difference between a part that meets specifications and one that exceeds performance expectations. This guide covers everything from material grades and surface finishing to overcoming common machining challenges and ensuring consistent quality.

Why Stainless Steel is the Preferred Choice for CNC Machining?

Have you ever specified a metal for a critical component, only to see it corrode or fail under pressure? This single choice can jeopardize an entire project, leading to costly redesigns and delays.

Stainless steel is the preferred choice for CNC machining due to its exceptional combination of corrosion resistance, high tensile strength, durability, and hygienic properties. This makes it an ideal material for producing reliable, long-lasting parts for demanding industries where performance cannot be compromised.

When selecting a material, engineers must balance performance, cost, and manufacturability. Stainless steel often emerges as the superior option, especially for parts that will face challenging operational environments. Its reputation isn’t just based on its shiny appearance; it’s built on a foundation of robust material science that translates directly into real-world advantages. The secret lies in its composition, primarily the inclusion of chromium, which forms a thin, invisible, and corrosion-resisting chromium oxide film on the surface. This process, known as passivation1, is self-healing; if the surface is scratched, the protective layer instantly reforms, preventing rust and degradation.

Unpacking the Core Properties

The value of stainless steel becomes clearer when we break down its primary characteristics, particularly in the context of CNC machining.

Superior Corrosion Resistance

Unlike carbon steel, which rusts easily when exposed to moisture, stainless steel remains inert in many corrosive environments. This includes exposure to water, chemicals, and acidic substances. In our projects at PTSMAKE, we’ve seen parts machined from 316L stainless steel perform flawlessly for years in marine applications, where saltwater would destroy other metals in months.

Exceptional Strength and Durability

Stainless steel offers an excellent strength-to-weight ratio. Certain grades can be heat-treated to achieve incredibly high tensile strengths, making them suitable for high-stress applications like aerospace components and industrial machinery parts. This inherent toughness also means it resists wear, dents, and scratches, ensuring the final part maintains its dimensional accuracy and integrity throughout its service life. This durability is a key factor when designing components that need to withstand significant mechanical stress.

Below is a simplified comparison based on our experience with common metals in CNC machining projects.

| Property | Stainless Steel (e.g., 304) | Aluminum (e.g., 6061) | Carbon Steel (e.g., 1018) |

|---|---|---|---|

| Corrosion Resistance | Excellent | Good (but can corrode) | Poor (requires coating) |

| Tensile Strength | High | Medium | Medium |

| Density | High | Low | High |

| Machinability | Fair to Good | Excellent | Good |

| Heat Resistance | Excellent | Fair | Good |

This table shows why stainless steel is often the go-to choice when durability and resistance are top priorities, even if it presents more challenges during the machining process itself.

The inherent properties of stainless steel translate into significant long-term value, which is a critical consideration for any project. While the initial material cost might be higher than that of, say, carbon steel, the total cost of ownership is often far lower. This is a point I always emphasize to clients who are focused solely on the upfront price per part. True cost-effectiveness includes maintenance, replacement frequency, and the cost of downtime caused by part failure.

The Long-Term Value in Demanding Industries

Different sectors leverage specific advantages of stainless steel, making it one of the most versatile materials available for high-precision manufacturing.

The Hygiene Factor: A Critical Requirement

For industries like medical, pharmaceutical, and food processing, hygiene is not just a feature—it’s a strict regulatory requirement. Stainless steel’s non-porous surface prevents bacteria from harboring and makes it incredibly easy to clean and sterilize. Grades like 316L are standard for surgical instruments, pharmaceutical vats, and food-grade machinery because they can withstand repeated, harsh sterilization cycles without degrading. When we handle a stainless steel CNC machining project for a medical device client, material traceability and surface finish are paramount to ensure patient safety.

Minimizing Lifetime Maintenance Costs

Think about a part used in an offshore oil rig or a chemical processing plant. The cost to replace a failed component isn’t just the price of the part itself; it involves labor, equipment downtime, and potential safety risks. Because stainless steel resists corrosion and wear, parts made from it last significantly longer. This "set it and forget it" quality reduces the need for frequent inspections, repairs, or protective coatings that can chip or wear away. This reliability is why it’s a staple in infrastructure and heavy industry.

Consistent Performance in Extreme Environments

Stainless steel excels where other metals falter. Certain alloys maintain their strength at very high temperatures, making them suitable for engine components and exhaust systems. Conversely, austenitic grades become even tougher at cryogenic temperatures, which is why they are used in equipment for handling liquefied natural gas (LNG).

| Industry | Common Stainless Steel Grade | Key Reason for Selection |

|---|---|---|

| Medical Devices | 316L, 17-4 PH | Biocompatibility, Sterilizability |

| Aerospace | 15-5 PH, 304 | High Strength-to-Weight Ratio, Heat Resistance |

| Food & Beverage | 304, 316 | Hygienic Surface, Corrosion Resistance |

| Marine | 316L | Superior Saltwater Corrosion Resistance |

| Automotive | 409, 304 | Heat Resistance (Exhausts), Durability |

This demonstrates how specific grades are matched to industry needs, highlighting the material’s adaptability.

In summary, stainless steel’s popularity in CNC machining is well-earned. Its unique combination of corrosion resistance, high strength, durability, and hygienic properties makes it an unmatched choice for critical applications. While other materials may offer advantages in specific areas like weight or initial cost, stainless steel provides a holistic solution that guarantees long-term performance, reliability, and value, especially in environments where failure is not an option. It is a material that provides peace of mind.

Key Industries Leveraging Stainless Steel CNC Machining.

Have you ever wondered why stainless steel is the default choice for so many critical components? Is it just about looking clean, or is there a deeper, performance-driven reason that industries bet their reputations on it?

Stainless steel CNC machining is indispensable for sectors like medical, aerospace, food and beverage, and energy. Its unique blend of corrosion resistance, strength, hygiene, and heat tolerance makes it the only viable material for high-stakes applications where failure is simply not an option.

Stainless steel isn’t just one material; it’s a family of alloys, and each industry has its favorite for very specific reasons. The demands placed on a part for a surgical tool are completely different from those for an aircraft engine component. Understanding these nuances is key to successful manufacturing.

Medical and Healthcare

In the medical field, there is zero room for error. Materials must be non-reactive with human tissue, withstand repeated sterilization cycles, and maintain integrity. This is where stainless steel shines. Surgical instruments like scalpels, forceps, and retractors are typically machined from grades like 316L or 440C. They offer a sharp, durable edge and can be autoclaved countless times without degrading.

For implants, such as bone screws or joint replacements, the material choice is even more critical. The material must exhibit excellent Biocompatibility2 to prevent adverse reactions within the body. In past projects at PTSMAKE, we’ve worked with medical device companies to produce intricate implant components where the surface finish and material purity, achieved through precise stainless steel CNC machining, were paramount to the device’s success and patient safety.

Aerospace and Defense

The aerospace industry operates at the extremes of temperature, pressure, and stress. Components must be incredibly strong yet as light as possible. Precipitation-hardening stainless steels, like 17-4 PH, are often used. They provide the high strength-to-weight ratio needed for parts like landing gear components, engine mounts, and structural fasteners.

Here, corrosion resistance is not just about aesthetics; it’s about structural integrity. An aircraft part exposed to atmospheric moisture and de-icing fluids cannot afford to weaken over time. Precision CNC machining ensures these complex parts meet tight tolerances, which is essential for proper assembly and safe operation under immense physical loads.

Automotive Industry

While you might first think of the car’s shiny exhaust tip, stainless steel is a workhorse throughout the modern vehicle. Exhaust systems, including manifolds and catalytic converter components, are machined from heat-resistant grades to withstand extreme temperatures and corrosive gases. In our experience, material selection here directly impacts the longevity and performance of the emissions system.

Furthermore, critical sensor housings, fuel system components, and airbag inflators rely on the durability and reliability of stainless steel parts. It resists corrosion from road salt and environmental factors, ensuring safety systems function correctly throughout the vehicle’s life.

| Industry | Primary Requirement | Common Stainless Steel Grades | Example Application |

|---|---|---|---|

| Medical | Sterilizability, Biocompatibility | 316L, 420, 440C | Surgical Instruments, Implants |

| Aerospace | High Strength-to-Weight Ratio | 17-4 PH, 15-5 PH | Engine Components, Landing Gear |

| Automotive | Heat and Corrosion Resistance | 304, 409, 316 | Exhaust Systems, Sensor Housings |

Beyond the high-profile worlds of medicine and flight, stainless steel CNC machining is a silent enabler of industries we interact with every day. The demands are different, but the core reasons for choosing stainless steel—durability, resistance, and purity—remain the same.

Food and Beverage Processing

Hygiene is the top priority in the food and beverage industry. Equipment must be easily and thoroughly cleaned to prevent bacterial growth. Stainless steel, particularly grade 304, is the standard for everything from mixing tanks and conveyor systems to valves and fittings. Its non-porous surface leaves no place for microbes to hide.

The material’s resistance to corrosion from acidic foods and harsh cleaning chemicals ensures longevity and prevents contamination. At PTSMAKE, we’ve machined components for food processing lines where the smoothness of the surface finish was just as important as the dimensional accuracy to meet stringent food-grade standards.

Energy Sector

From oil rigs in the ocean to nuclear power plants, the energy sector demands components that can withstand some of the harshest conditions on Earth. Pressure vessels, turbine blades, and valve bodies are often machined from robust stainless steel grades. These parts must handle extreme pressures, high temperatures, and highly corrosive substances like hydrogen sulfide.

The reliability of a single valve can be critical to the safety and efficiency of an entire plant. The combination of strength and corrosion resistance offered by specialized stainless steel alloys makes them essential for these critical applications, ensuring equipment operates safely and for extended periods without failure.

Electronics and Consumer Goods

In the world of electronics, stainless steel provides both function and form. It is used to create durable and aesthetically pleasing enclosures for high-end smartphones, laptops, and smartwatches. Beyond looks, its properties are vital for performance. Stainless steel provides excellent structural rigidity, protecting delicate internal components.

It can also be used for EMI (electromagnetic interference) shielding, which is crucial for ensuring the proper function of sensitive electronics. For connectors and internal chassis, stainless steel CNC machining delivers the precision needed for tiny, complex parts that must fit together perfectly.

| Industry | Primary Requirement | Common Stainless Steel Grades | Example Application |

|---|---|---|---|

| Food & Beverage | Hygiene, Cleanability | 304, 316 | Processing Tanks, Conveyor Parts |

| Energy | Resistance to Pressure & Corrosion | Duplex, 316, 304 | Valves, Pressure Vessels |

| Electronics | Durability, Aesthetics, Shielding | 303, 304 | Enclosures, Connectors, Chassis |

From life-saving surgical tools to the systems that power our world, stainless steel CNC machining is the backbone of modern industry. Its versatility is unmatched, providing solutions where strength, corrosion resistance, and hygiene are critical. Key sectors like medical, aerospace, automotive, food, energy, and electronics depend on the reliability and precision that only machined stainless steel can offer. This reliance is built on the material’s proven ability to perform under the most demanding conditions imaginable.

Complex Part Production: Meeting Precision and Tolerance Demands.

Have you ever had a brilliant design compromised because of manufacturing limits? Are tight tolerances in complex stainless steel parts a constant challenge, forcing you to simplify your vision?

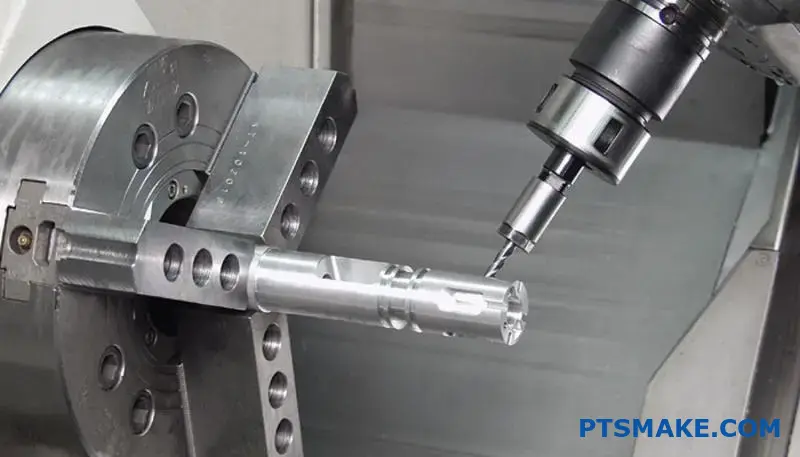

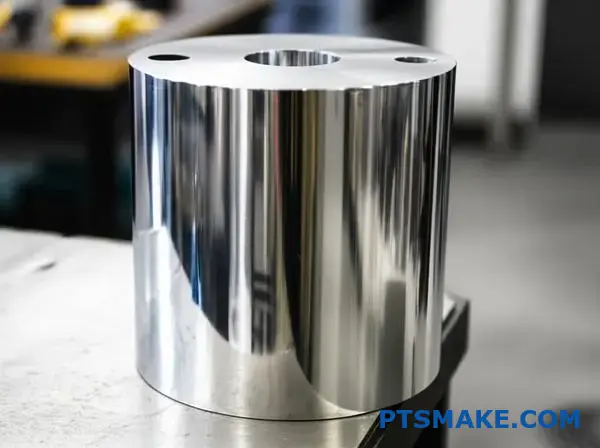

Stainless steel CNC machining enables complex parts with tight tolerances by using multi-axis machines and advanced CAD/CAM software. This process translates intricate digital designs into physical components with precision, which is essential for industries like aerospace, medical, and automotive.

Parts2:

Parts3:

Achieving both complexity and precision in stainless steel parts isn’t magic; it’s the result of carefully integrated technology. At the heart of this capability is the evolution from basic CNC machines to sophisticated multi-axis systems.

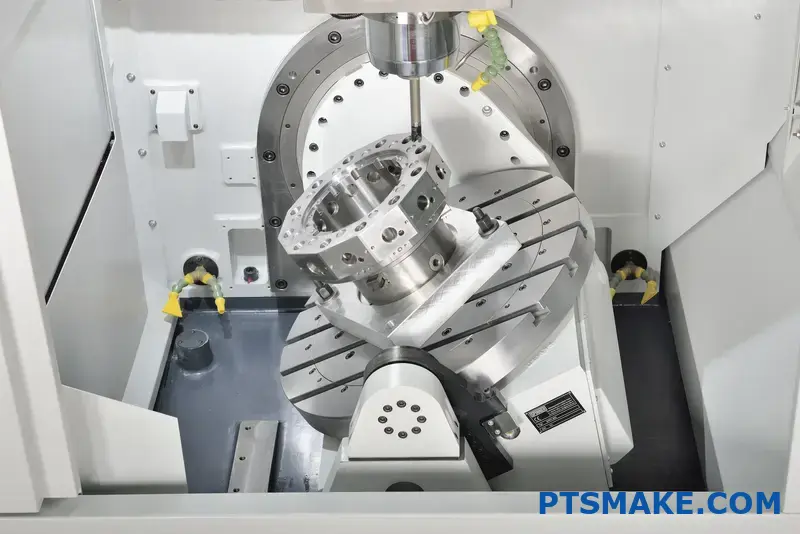

The Role of Multi-Axis Machining

Traditional CNC machines operate on three axes (X, Y, and Z), which is great for simpler parts. However, for complex geometries, this approach requires multiple setups. Each time a part is re-fixtured, there’s a risk of introducing small errors, which accumulate and can push a part out of tolerance. This is where 5-axis machining becomes a game-changer. By allowing the cutting tool and the workpiece to move simultaneously along five axes, a 5-axis machine can approach the part from almost any angle. This capability drastically reduces the number of setups needed, often down to a single one. This "done-in-one" approach is fundamental to maintaining tight tolerances on features with complex relationships to one another. The machine’s advanced kinematics3 are what allow for such fluid and precise movements, turning a complex digital model into a real-world object without losing fidelity.

CAD/CAM Integration: The Digital Thread

The most advanced machine is useless without a clear set of instructions. This is where Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) integration is critical. The process starts with a 3D CAD model, the digital blueprint of the part. This model is then imported into CAM software, which generates the toolpaths—the exact G-code that the CNC machine will follow. A seamless integration between CAD and CAM is vital because it ensures that the design intent is perfectly translated into machine commands. At PTSMAKE, we’ve found that this tight digital thread minimizes the risk of data translation errors, which can be a hidden source of inaccuracies. It allows our programmers to simulate the entire machining process virtually, catching potential collisions and optimizing toolpaths for efficiency and surface finish before a single piece of stainless steel is cut.

Comparing 3-Axis and 5-Axis Machining

To better illustrate the difference, here’s a breakdown of how these technologies compare for stainless steel CNC machining:

| Feature | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

| Part Complexity | Best for prismatic, 2.5D parts | Ideal for complex curves, undercuts, and intricate geometries |

| Number of Setups | Multiple setups often required | Typically one or two setups ("done-in-one") |

| Accuracy | Good, but tolerance stacking can be an issue | Superior, as re-fixturing errors are eliminated |

| Tooling | Standard length tools | Can use shorter, more rigid tools for better surface finish |

| Cycle Time | Longer due to multiple setups | Faster for complex parts due to continuous machining |

This comparison makes it clear why 5-axis machining is the superior choice for producing the intricate stainless steel components required by today’s most demanding industries.

The theoretical capabilities of advanced CNC machining are impressive, but their true value is demonstrated in real-world applications. Certain industries rely heavily on the ability to produce complex stainless steel parts where failure is not an option.

Medical Devices: Precision for Human Health

In the medical field, components must be flawless. Think of surgical instruments, orthopedic implants, or parts for diagnostic equipment. These often feature complex, organic shapes that must be perfectly smooth and free of any microscopic burrs where bacteria could hide. Stainless steel is a common choice due to its corrosion resistance and biocompatibility. Using 5-axis CNC machining, we can create intricate features like bone screws with complex thread profiles or endoscopic tools with internal channels, all while holding tolerances measured in microns. Based on our experience with medical clients, the ability to achieve a superior surface finish directly from the machine reduces the need for extensive post-processing, which is both a cost and time saver.

Aerospace Assemblies: Lightweighting and Strength

Aerospace engineering is a constant balancing act between strength, weight, and performance. Stainless steel alloys are used in critical components like engine mounts, fuel system parts, and hydraulic fittings that must withstand extreme temperatures and pressures. CNC machining allows engineers to design parts with complex internal structures and thin walls to reduce weight without sacrificing structural integrity. For example, a single block of stainless steel can be machined into a complex valve body with intersecting fluid channels and mounting points. This monolithic design is far stronger than a component assembled from multiple pieces, and only advanced multi-axis machining can produce such a part efficiently and accurately.

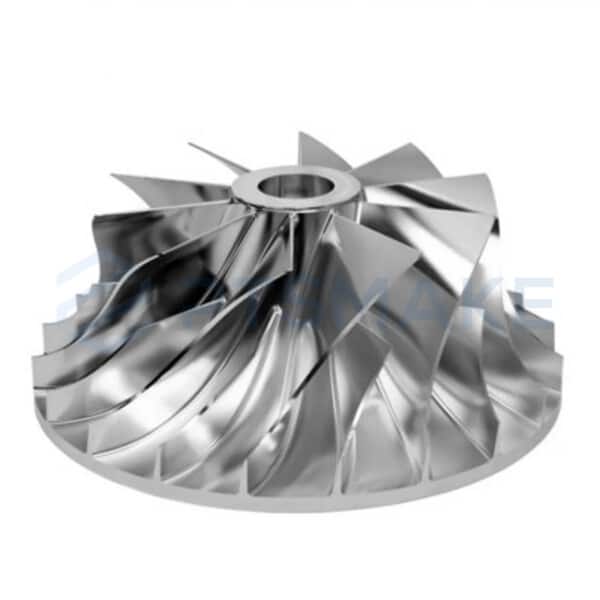

Automotive Parts: Durability Under Pressure

While the automotive industry is highly cost-sensitive, performance-critical components still demand the best manufacturing processes. Parts for high-performance engines, turbochargers, and fuel injection systems often have incredibly complex geometries designed to optimize fluid flow and withstand intense heat and vibration. Consider a turbocharger’s turbine wheel; its curved blades must be identical and perfectly balanced to function at over 100,000 RPM. Stainless steel CNC machining is the only practical way to produce such parts with the required repeatability and precision.

| Industry | Example Stainless Steel Part | Key Machining Challenge |

|---|---|---|

| Medical | Orthopedic Implant (e.g., hip stem) | Complex organic curves, superior surface finish |

| Aerospace | Hydraulic Manifold Block | Deep pockets, intersecting internal bores, thin walls |

| Automotive | Fuel Injector Nozzle | Micro-sized holes, intricate internal channels |

| Electronics | Heat Sink for a high-power device | High-density fins, complex mounting features |

These examples highlight how modern CNC technology isn’t just an option; it’s an essential enabler of innovation across a wide range of critical industries.

Ultimately, producing complex stainless steel parts with tight tolerances relies on a combination of technology and expertise. Multi-axis CNC machining minimizes setup errors, while strong CAD/CAM integration ensures design fidelity. This powerful pairing makes it possible to manufacture the intricate, high-performance components demanded by critical industries like medical, aerospace, and automotive. It transforms a complex digital design into a precise physical reality, enabling innovation that was once considered impossible to manufacture.

Material Grades: Selecting the Right Stainless Steel for Each Application?

Ever felt overwhelmed by the sheer number of stainless steel grades available? Choosing the wrong one can easily compromise your part’s integrity and inflate your manufacturing costs.

Selecting the right stainless steel involves matching the grade’s unique properties—like 303’s machinability or 316L’s corrosion resistance—to your application’s functional and environmental demands. This critical decision is the foundation of successful stainless steel CNC machining, ensuring both performance and cost-effectiveness.

When we talk about stainless steel CNC machining, not all grades are created equal. The choice you make here directly impacts machining time, tool life, cost, and the final part’s performance. Let’s break down some of the most common grades we handle at PTSMAKE.

The Workhorse Grades: 303 & 304 Stainless Steel

These are two of the most popular grades in the Austenitic4 family, but they serve different purposes. Think of them as cousins with distinct personalities.

303 Stainless Steel: The Machinability Champion

If your top priority is ease of machining, 303 is your go-to. It’s often called a "free-machining" grade because it contains sulfur, which helps break up the chips during cutting. This small addition dramatically improves machinability, reduces tool wear, and can lower the overall cost of CNC machining. However, this benefit comes with a trade-off: the sulfur content slightly reduces its corrosion resistance and makes it unsuitable for welding.

- Best for: Shafts, gears, fittings, and complex parts where intricate machining is the primary challenge.

- Avoid if: The part requires welding or will be exposed to highly corrosive environments, especially marine or chemical settings.

304 Stainless Steel: The All-Rounder

304 is the most versatile and widely used stainless steel. It offers a great balance of corrosion resistance, formability, and strength. While not as easy to machine as 303, its superior corrosion resistance and weldability make it suitable for a vast range of applications. The "L" in 304L stands for low carbon, which improves weldability by minimizing carbide precipitation at the weld seams.

Here’s a quick comparison based on our experience:

| Feature | 303 Stainless Steel | 304/304L Stainless Steel |

|---|---|---|

| Machinability | Excellent | Good |

| Corrosion Resistance | Good | Excellent |

| Weldability | Poor | Excellent |

| Cost | Slightly higher (material) | Slightly lower (material) |

| Typical Use | Intricate, machined parts | Food equipment, architectural |

Choosing between them often comes down to a simple question: is machinability more critical than corrosion resistance and weldability? If the part is complex, 303 might save you on machining costs. If it needs to withstand the elements or be welded, 304/304L is the safer bet.

Moving beyond the common workhorses, let’s look at grades designed for more demanding environments. When a project requires superior corrosion resistance or exceptional strength, we turn to specialized materials like 316 and 17-4PH stainless steel. These are premium grades, and understanding their specific advantages is crucial for high-performance applications.

The High-Performance Grades: 316 & 17-4PH

When general-purpose grades like 304 won’t cut it, you need to step up. These two grades offer solutions for environments where failure is not an option.

316/316L Stainless Steel: The Corrosion Fighter

Think of 316 as 304’s tougher, more resilient sibling. The key difference is the addition of molybdenum, which significantly enhances its resistance to corrosion, especially from chlorides and other industrial solvents. This makes it the standard for marine applications, medical implants, and food processing equipment where harsh cleaning chemicals are used. Like 304L, 316L has a lower carbon content to improve weldability. While its machinability is slightly worse than 304’s due to its toughness, the trade-off is often necessary for long-term durability.

- Best for: Marine hardware, medical devices, chemical processing equipment, and pharmaceutical parts.

- Consideration: The material cost is higher than 304, and it requires slower machining speeds, which can increase the per-part cost.

17-4PH Stainless Steel: The Strength King

17-4PH is in a class of its own. It’s a precipitation-hardening (PH) martensitic stainless steel, which means it can be heat-treated to achieve very high levels of strength and hardness, often comparable to some tool steels. It offers a great combination of high strength, good corrosion resistance (better than 303 but generally less than 316), and good toughness. This unique combination makes it a favorite in the aerospace, defense, and high-performance machinery industries. Machining 17-4PH is typically done in its annealed condition before it is heat-treated to its final hardness.

| Feature | 316/316L Stainless Steel | 17-4PH Stainless Steel |

|---|---|---|

| Primary Advantage | Superior Corrosion Resistance | High Strength & Hardness |

| Heat Treatable | No (Annealed only) | Yes (Precipitation Hardening) |

| Corrosion Resistance | Best | Good to Excellent |

| Machinability | Fair | Fair (in annealed state) |

| Typical Use | Marine, Medical, Chemical | Aerospace, Defense, Molds |

In our projects at PTSMAKE, the choice is clear. If a part will live near the ocean or be exposed to harsh chemicals, we start with 316L. If the primary requirement is extreme tensile strength and wear resistance for a mechanical component, 17-4PH is almost always the answer.

Choosing the right stainless steel grade is a critical first step in any CNC machining project. The selection balances performance needs against budget constraints. For general applications, 304 is a versatile starting point, while 303 offers cost savings on complex parts through better machinability. For more demanding roles, 316L provides superior corrosion resistance for harsh environments, and 17-4PH delivers exceptional strength for high-stress mechanical components. Understanding these key differences ensures your final part is optimized for success.

Surface Finishing Techniques for Stainless Steel CNC Parts.

Have you ever questioned if the finish on your stainless steel CNC part is truly optimized for its environment, or just for looks? Are you confident you’ve selected the best possible treatment?

The most effective surface finishes for stainless steel CNC parts are bead blasting, polishing, passivation, and powder coating. Each technique uniquely enhances properties like corrosion resistance, aesthetics, and cleanability, and the right choice depends entirely on the part’s final application and performance requirements.

When a stainless steel part comes off a CNC machine, its surface is functional but often not fully optimized for its end-use. The choice of finish is not just about aesthetics; it’s a critical engineering decision that impacts performance and lifespan. Let’s break down two of the most common mechanical finishing methods.

Mechanical Finishes: Altering the Surface Texture

Mechanical finishes physically alter the surface of the metal. The two primary methods we use at PTSMAKE are bead blasting and polishing, each offering distinct advantages depending on the project’s goals.

Bead Blasting for a Uniform, Matte Appearance

Bead blasting involves propelling fine media, typically glass beads, at high pressure against the part’s surface. This process removes the thin, discolored layer left from machining and creates a uniform, non-directional, matte finish. It’s excellent for reducing glare, which is a critical requirement in many optical and medical device applications.

The peening action of the beads also helps relieve surface stress induced during the stainless steel CNC machining process. From our testing, this can subtly improve fatigue life. However, its main benefits are aesthetic uniformity and creating an excellent surface for paint or other coatings to adhere to.

Polishing for Smoothness and Cleanability

Polishing uses abrasives to progressively smooth the surface, reducing microscopic peaks and valleys. This can range from a standard #4 brushed finish, common on kitchen appliances, to a #8 mirror finish, which is highly reflective and smooth. A smoother surface is less likely to harbor bacteria or contaminants, making polishing a standard for food-grade, pharmaceutical, and medical parts. It also significantly enhances the passive chromium oxide layer, boosting corrosion resistance against environmental factors that could cause tribocorrosion5.

Choosing between these two often comes down to balancing function with appearance.

| Feature | Bead Blasting | Polishing |

|---|---|---|

| Aesthetics | Uniform, matte, non-reflective | Ranging from satin to mirror-like, reflective |

| Primary Purpose | Create a uniform look, reduce glare | Improve smoothness, cleanability, and shine |

| Roughness (Ra) | Increases surface roughness slightly | Decreases surface roughness significantly |

| Best For | Medical devices, aerospace parts, pre-coating | Food-grade equipment, consumer electronics |

While mechanical finishes modify the surface texture, chemical and applied treatments change the surface chemistry or add a new layer entirely. These methods are essential for maximizing corrosion resistance or altering the part’s color and durability.

Chemical and Applied Finishes: Enhancing Protection

For applications demanding the highest level of corrosion resistance or a specific aesthetic not achievable with mechanical means, we turn to treatments like passivation and powder coating.

Passivation: Maximizing Inherent Corrosion Resistance

This is arguably the most critical finishing step for stainless steel CNC machining parts intended for corrosive environments. Passivation is not a coating. It is a chemical process using a mild acid (typically nitric or citric acid) to remove free iron and other contaminants left on the surface from cutting tools and handling. This process deepens and strengthens the naturally occurring, passive chromium-oxide layer that gives stainless steel its renowned corrosion resistance.

In past projects with clients in the marine industry, skipping passivation was not an option. A freshly machined stainless part, without passivation, would show signs of rust much faster than a passivated one when exposed to saltwater spray.

Powder Coating: Adding Color and Durability

Powder coating involves applying a dry, powdered polymer to the part electrostatically and then curing it under heat. This melts the powder into a continuous, durable film that is much tougher than conventional paint. It provides excellent protection against scratches, chemicals, and weathering.

While it offers a nearly unlimited color palette, it’s important to remember that it covers the metallic appearance of stainless steel. It’s an ideal choice when the part needs to be a specific color for branding or safety reasons, or when it faces extreme chemical exposure where an additional barrier is beneficial.

Here’s how these two powerful options stack up:

| Feature | Passivation | Powder Coating |

|---|---|---|

| Process Type | Chemical treatment (no added layer) | Applied coating (adds a layer of polymer) |

| Appearance | No significant change to the metal’s look | Opaque, available in many colors and textures |

| Main Benefit | Maximizes natural corrosion resistance | Adds color, durability, and chemical barrier |

| Best For | Medical, aerospace, marine, food processing | Outdoor equipment, automotive parts, branding |

Selecting the right surface finish for stainless steel CNC parts goes beyond simple aesthetics. Techniques like bead blasting and polishing alter the surface texture for functional or visual needs, while passivation is crucial for maximizing the material’s inherent corrosion resistance. For ultimate durability and color options, powder coating provides a tough protective layer. The final choice always depends on the part’s specific application, environment, and performance requirements, ensuring longevity and reliability in the field.

Overcoming Common Challenges in Stainless Steel CNC Machining.

Struggling with snapped tools, poor surface finishes, or parts that are out of spec when machining stainless steel? These frustrations can derail project timelines and inflate costs.

Successfully machining stainless steel hinges on selecting the right carbide tools, using low speeds with high feed rates to manage work hardening, and applying a robust cooling strategy. These steps prevent excessive tool wear and ensure dimensional accuracy.

Stainless steel’s toughness and corrosion resistance make it a fantastic material, but these same properties create significant hurdles in CNC machining. The three biggest culprits are work hardening, tool wear, and heat management. Understanding how to tackle them individually and collectively is the key to success. In our experience at PTSMAKE, a systematic approach that addresses these core issues from the start saves immense time and resources down the line.

Taming Work Hardening

Work hardening, or strain hardening6, is a phenomenon where the material becomes harder and more brittle as it’s plastically deformed during cutting. If you’re not careful, each pass of the tool can harden the surface, making the next pass even more difficult. This is often the root cause of premature tool failure.

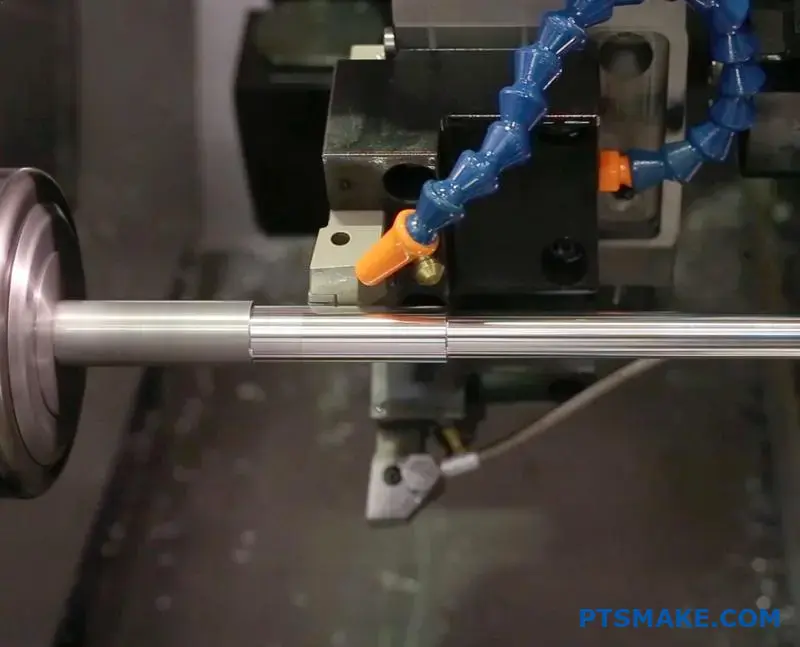

The "Low Speed, High Feed" Mantra

The most effective strategy against work hardening is to maintain a consistent, aggressive cut. We achieve this by using lower cutting speeds combined with higher feed rates. This approach ensures the cutting edge is always getting "under" the previously hardened layer and cutting into fresh, unworked material. Hesitation is your enemy here; a tool that rubs instead of cuts will instantly work-harden the surface.

Maintain a Constant Cut

Any pause or "dwelling" of the tool against the workpiece is detrimental. It generates excessive friction and heat, rapidly hardening the contact area. Programming toolpaths that ensure continuous engagement and avoid abrupt stops is critical for machining stainless steel effectively.

Winning the Battle Against Tool Wear

The inherent abrasiveness and toughness of stainless steel, compounded by work hardening, lead to rapid tool wear. A worn tool not only produces poor surface finishes and inaccurate parts but can also break unexpectedly, potentially damaging the workpiece or even the machine.

Tool Material and Coatings are Crucial

Standard High-Speed Steel (HSS) tools simply don’t last. For any serious stainless steel CNC machining, carbide is the baseline. However, the real performance gains come from advanced coatings.

| Coating Type | Primary Benefit | Best For |

|---|---|---|

| TiAlN | High heat resistance, excellent hardness | High-speed dry or minimum quantity lubrication (MQL) machining |

| AlTiN | Superior hardness and oxidation resistance | Aggressive cutting in difficult alloys |

| TiCN | Low friction, high wear resistance | Lower-speed operations, improved finish |

Choosing the right coating can, in our tests, extend tool life by over 50% compared to an uncoated carbide tool.

Beyond work hardening and tool wear, managing the intense heat generated during the cutting process is a make-or-break factor. Stainless steel has low thermal conductivity, meaning heat doesn’t dissipate quickly from the cutting zone. Instead, it concentrates on the tool and the workpiece, leading to a host of problems.

Keeping Cool: The Art of Heat Management

Excessive heat can cause the material to become gummy, leading to built-up edge (BUE) on the tool. It can also cause thermal expansion in the workpiece, throwing dimensions out of tolerance, and drastically shorten the life of your cutting tools.

Flood vs. High-Pressure Coolant

While traditional flood coolant is better than nothing, high-pressure, through-spindle coolant is a game-changer for stainless steel. It performs two critical functions simultaneously:

- Cooling: It delivers a powerful stream of coolant directly to the cutting edge, where the heat is most intense.

- Chip Evacuation: It blasts chips away from the cutting zone, preventing them from being re-cut, which would generate even more heat and damage the surface finish.

At PTSMAKE, we’ve found that implementing high-pressure coolant systems can increase both tool life and material removal rates significantly, especially in deep pockets or drilling operations.

Process Optimization for Unwavering Quality

A successful outcome depends on more than just speeds, feeds, and coolant. The entire process, from setup to chip control, must be optimized for the unique challenges of stainless steel.

The Power of a Rigid Setup

Vibration is the enemy of precision. Stainless steel requires higher cutting forces, which can easily induce chatter if the setup isn’t rock-solid. This means using high-quality tool holders (like hydraulic or shrink-fit), minimizing tool overhang, and ensuring the workpiece is clamped securely. A rigid setup reduces vibration, improves surface finish, and extends tool life.

Chip Control is Non-Negotiable

Stainless steel tends to produce long, stringy, and tough chips. These chips can wrap around the tool or workpiece, causing catastrophic tool failure or marring the part’s surface.

| Chip Problem | Solution | Why It Works |

|---|---|---|

| Long, Stringy Chips | Use tools with dedicated chip-breaker geometry. | The geometry physically curls and breaks the chip into manageable pieces. |

| Chip Nesting | Implement pecking cycles in drilling or use high-pressure coolant. | It interrupts the cut to break the chip and allows coolant to clear the flute. |

| Re-cutting Chips | Optimize toolpaths and ensure effective coolant flow. | Prevents chips from falling back into the cutting path. |

Mastering chip control is a fundamental skill for any machinist working with stainless steel.

Successfully machining stainless steel requires a disciplined approach. Key strategies involve using low speeds and high feed rates to mitigate work hardening, selecting robust coated carbide tools to combat wear, and employing high-pressure coolant for effective heat management. A rigid setup and proactive chip control are foundational elements that ensure consistent quality and process stability. By addressing these challenges systematically, you can achieve precise, high-quality results every time.

Quality Control and Inspection for Stainless Steel CNC Parts?

Ever received a batch of stainless steel parts only to find they’re out of tolerance? That small deviation can halt your entire production line, causing costly delays and headaches.

Effective quality control for stainless steel CNC parts combines in-process checks and final inspections using methods like CMM, visual inspection, and non-destructive testing. This multi-step process is crucial for verifying tight tolerances, ensuring part integrity, and guaranteeing consistent performance in demanding applications.

Quality control isn’t just a final step; it’s a philosophy woven into every stage of the stainless steel CNC machining process. It begins the moment we receive your technical drawings and doesn’t end until the parts are shipped. For us, it’s about prevention, not just detection. A failure to control quality early on snowballs into significant issues, wasting both time and material. Think of it as building a house—you check the foundation before you put up the walls.

The Foundation: In-Process Inspection

We believe in catching potential issues as they happen. In-process inspection means operators and quality engineers check the parts at various points during production. This is far more effective than waiting until a batch of 1,000 parts is finished to find a mistake on the first one.

First Article Inspection (FAI)

Before any full production run, we conduct a First Article Inspection. The first part produced is meticulously checked against every single dimension and specification on the drawing. This FAI report confirms that our setup, tooling, and programming are correct. Only after the FAI is approved do we proceed with the rest of the batch. This step is non-negotiable for ensuring consistency. The language of drawings, especially understanding the nuances of Geometric Dimensioning and Tolerancing (GD&T)7, is critical here.

Routine Checks During Production

Operators perform routine checks using calibrated tools right at the machine. This might happen every tenth part or every hour, depending on the part’s complexity and the required tolerances.

Here’s a look at some basic tools we use for these checks:

| Inspection Tool | Primary Use | Precision Level |

|---|---|---|

| Digital Calipers | Quick external/internal measurements | Moderate (±0.02 mm) |

| Micrometers | High-precision external measurements | High (±0.002 mm) |

| Pin Gauges | Checking small hole diameters | High (Go/No-Go) |

| Height Gauges | Measuring height from a surface plate | High (±0.01 mm) |

These fundamental checks form the backbone of a reliable quality system. They provide immediate feedback, allowing for real-time adjustments to the machining process and preventing the production of a large number of defective parts. It’s a simple but incredibly powerful way to maintain quality throughout the entire stainless steel CNC machining workflow.

While in-process checks are vital, final inspection is where we provide the ultimate verification that your stainless steel parts meet every specification. This stage often involves more advanced equipment and methodologies to catch issues that simpler tools might miss. It’s the final guarantee of quality before the parts leave our facility.

Advanced Inspection Methods

For parts with complex geometries or exceptionally tight tolerances, standard measuring tools aren’t enough. In these cases, we turn to more sophisticated technology.

Coordinate Measuring Machine (CMM)

A CMM is a cornerstone of modern metrology. It uses a probe to measure points on a part’s surface, creating a 3D map of its geometry. This data is then compared directly against the original CAD model. At PTSMAKE, our CMMs can measure features with micron-level accuracy. This is especially critical for stainless steel components used in aerospace or medical devices, where even the slightest deviation can have serious consequences. The CMM provides a comprehensive report that serves as objective proof of dimensional accuracy.

Non-Destructive Testing (NDT)

Sometimes, the most critical defects aren’t on the surface. Non-Destructive Testing allows us to inspect the internal integrity of a part without damaging it. This is crucial for high-stress applications where an internal flaw could lead to catastrophic failure.

Here’s how two common NDT methods compare for stainless steel parts:

| NDT Method | Best For Detecting | How It Works |

|---|---|---|

| Dye Penetrant Inspection (DPI) | Surface-breaking cracks, porosity | A colored dye is applied and seeps into surface flaws. A developer then draws the dye out, making cracks visible. |

| Ultrasonic Testing (UT) | Internal flaws (cracks, voids) | High-frequency sound waves are sent into the material. Echos from flaws are detected and mapped. |

Choosing the right inspection method depends entirely on the part’s application and specifications. For a simple bracket, visual and caliper checks might be sufficient. But for a critical valve component in a high-pressure system, a combination of CMM for dimensional accuracy and UT for material integrity is often necessary. This tailored approach ensures that the quality control process is both effective and efficient.

In stainless steel CNC machining, quality control is not an afterthought but an integral part of the process. From initial drawing review to in-process checks with basic tools and advanced final inspections using CMMs and NDT, every step is crucial. This comprehensive approach ensures that every component meets the required tight tolerances and specifications. It guarantees the reliability and performance of your parts in their final application, preventing costly failures and delays down the line.

Prototyping and Production: From One-Offs to High Volume Runs.

Ever struggled with the jump from a single perfect prototype to thousands of identical production parts? Does the thought of maintaining quality and speed at scale keep you up at night?

Stainless steel CNC machining offers seamless scalability, making it ideal for everything from one-off rapid prototypes to high-volume production runs. This flexibility ensures your project can grow from concept to market without changing manufacturing methods, saving time and ensuring consistency.

The journey from a single idea to a mass-produced product is filled with challenges. One of the biggest is ensuring the part you designed is the part you get, whether you need one or ten thousand. This is where the adaptability of CNC machining truly shines, especially for a material as robust as stainless steel. The digital nature of the process allows for incredible precision and repeatability, which are crucial at every stage.

The Power of Rapid Prototyping

For engineers and product designers, the prototyping phase is where ideas become tangible. The goal is to test form, fit, and function quickly and affordably.

From Digital File to Physical Part

The speed of stainless steel CNC machining is a major advantage for prototyping. A 3D CAD file can be translated into a physical part in a matter of hours or days. This rapid turnaround allows design teams to validate their concepts quickly. Unlike casting or molding, there’s no need for expensive, time-consuming tooling. We can take your design, program our machines, and start cutting metal almost immediately. This allows for rapid iteration, a key component of agile product development. The process is straightforward and eliminates long waits, enabling you to move your project forward faster.

Iterative Design and Validation

Prototypes are rarely perfect on the first try. CNC machining supports an iterative process exceptionally well. If a prototype reveals a design flaw, you can simply adjust the CAD model and machine a new version. This feedback loop is fast and cost-effective. At PTSMAKE, we’ve worked on projects where we produced several iterations of a stainless steel component within a single week, allowing the client to refine their design based on real-world testing. This ability to make small, precise changes without incurring massive tooling costs is invaluable. The Geometric Dimensioning and Tolerancing (GD&T)8 specifications in the design file ensure that each iteration is accurately produced.

| Feature | CNC Machining | 3D Printing (Metal) | Investment Casting |

|---|---|---|---|

| Speed | Fast (Hours to Days) | Moderate (Days) | Slow (Weeks to Months) |

| Material Properties | Excellent (True to bulk) | Good (Can vary) | Excellent (True to bulk) |

| Initial Cost | Moderate | High | Very High (Tooling) |

| Design Changes | Easy & Low-Cost | Easy & Low-Cost | Difficult & High-Cost |

Once the prototype is perfected, the next challenge is scaling up for production. This transition must be managed carefully to maintain quality and control costs. The beauty of using CNC machining for both stages is that the process remains fundamentally the same, which minimizes variables and potential issues. The path from one part to ten thousand is a matter of optimization, not reinvention.

Transitioning to Small-Batch and High-Volume Production

Scaling up isn’t just about making more parts; it’s about making them efficiently and consistently. This is where a manufacturing partner’s expertise becomes critical.

Optimizing for Scalability

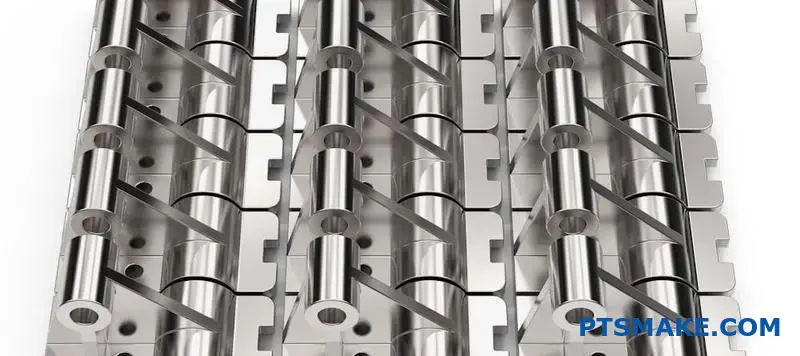

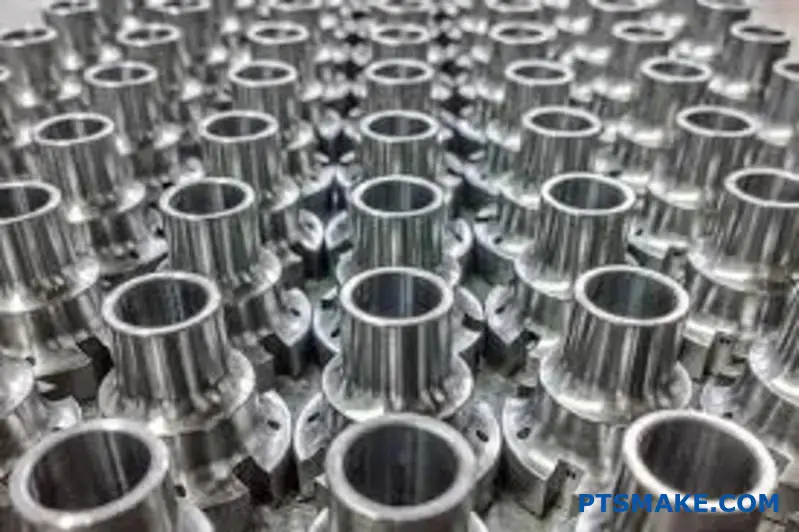

When moving from a single prototype to a production run, the focus shifts to efficiency. For small batches, the setup might be similar to prototyping. However, for high-volume runs, we implement optimizations to reduce cycle time and cost per part. This includes creating custom fixtures to hold multiple parts at once, optimizing toolpaths to minimize machine movement, and selecting specialized cutting tools for longevity and speed. After running simulations, we’ve found that these optimizations can reduce cycle times by as much as 30-40%, a significant saving that we pass on to our clients. This meticulous planning ensures that high-volume stainless steel CNC machining is both fast and cost-effective.

Maintaining Quality and Consistency at Scale

Consistency is non-negotiable in mass production. Every part must meet the same tight tolerances as the approved prototype. We achieve this through a combination of advanced machinery, automation, and rigorous quality control. Automated in-process probing can check critical dimensions during the machining cycle, while post-process inspections using CMMs (Coordinate Measuring Machines) verify that every batch meets specifications. In our experience at PTSMAKE, establishing clear quality control checkpoints from the very beginning is the key to preventing deviations and ensuring that the ten-thousandth part is identical to the first.

| Consideration | Low-Volume / Prototype | High-Volume Production |

|---|---|---|

| Programming | Focus on accuracy | Focus on cycle time efficiency |

| Workholding | Standard vises/clamps | Custom fixtures for multiple parts |

| Tooling | General-purpose tools | Specialized, high-endurance tools |

| Quality Control | Manual inspection of first-off | Automated in-process & batch inspection |

Ultimately, stainless steel CNC machining provides a uniquely flexible manufacturing path. The ability to move seamlessly from a single prototype to full-scale production using the same technology is a powerful advantage. This scalability simplifies the supply chain, ensures design intent is maintained throughout the product lifecycle, and allows for rapid responses to changing market demands. It’s a reliable process for creating high-quality stainless steel parts at any volume, from one-offs to thousands.

Collaborative Engineering: Optimizing Designs for Manufacturability.

Have you ever finalized a design, only to discover it’s incredibly difficult or expensive to actually make? This disconnect between design and production can lead to frustrating delays and budget overruns, derailing your entire project timeline.

Collaborative engineering, especially through Design for Manufacturability (DfM) consultations, bridges this gap. It involves machinists early in the design process to align your vision with practical manufacturing constraints, ensuring cost-effective and efficient production from the start.

The traditional product development cycle often operates in silos. An engineer perfects a design in CAD, then passes it to the manufacturing team, hoping for the best. This "over-the-wall" approach is where problems begin. A feature that looks simple on screen might require complex setups, specialized tooling, or excessive machining time, especially with materials like stainless steel. This is where Design for Manufacturability (DfM) transforms the process from a linear relay race into a collaborative partnership. It’s a proactive approach, not a reactive fix.

The Foundational Principles of DfM

At its core, DfM is about designing parts that are easy to manufacture. This doesn’t mean compromising on function; it means finding the most efficient path to achieve that function. The goal is to reduce complexity wherever possible without sacrificing performance. When it comes to stainless steel CNC machining, this collaboration is even more critical due to the material’s properties.

Simplifying Geometry for Efficiency

One of the first things we look at in a DfM review at PTSMAKE is the part’s geometry. Are there deep pockets with sharp internal corners? These features often require slower machining speeds or even secondary processes like EDM, which adds significant cost. By simply adding a small radius to those corners, we can often use a standard end mill, drastically reducing cycle time. Similarly, unnecessarily tight tolerances in non-critical areas can force machinists to slow down, take extra passes, and increase inspection time. The effects of work hardening9 can be more pronounced with aggressive cuts, so optimizing toolpaths based on simplified geometry is key.

Strategic Material and Process Selection

Your choice of stainless steel grade has a huge impact. For instance, 303 stainless steel is formulated for superior machinability, while 316 offers better corrosion resistance but is tougher to machine. An early conversation can help balance these needs. If the part doesn’t require the extreme corrosion resistance of 316, switching to 304 or 303 could lead to substantial cost savings in machining time and tool life.

| Aspect | Design-First Approach | DfM-Collaborative Approach |

|---|---|---|

| Cost | Discovered during quoting; often high | Optimized during design; controlled |

| Lead Time | Prone to delays from redesigns | Streamlined and predictable |

| Quality | Risk of manufacturing defects | Higher consistency and reliability |

| Innovation | Limited by designer’s knowledge | Enhanced by machinist’s expertise |

The benefits of applying DfM principles go far beyond just preventing problems; they create tangible value. By involving your manufacturing partner early, you unlock opportunities for optimization that are invisible from a design-only perspective. This collaboration transforms the manufacturing process from a simple service into a strategic advantage, directly impacting your bottom line and time-to-market. In my experience, the most successful projects are always the ones where communication between the design and production teams starts on day one.

The Tangible Returns of Early Collaboration

Engaging in a DfM review isn’t just about making a machinist’s job easier; it’s about making your product better, cheaper, and faster to produce. The insights gained can ripple through the entire project, leading to significant improvements that compound over the production lifecycle. It’s a small investment of time upfront that pays huge dividends.

Driving Down Costs and Accelerating Production

Cost reduction through DfM is multi-faceted. It’s not just about cheaper materials. It’s about minimizing machine time, reducing tool wear, and lowering scrap rates. In one of our projects, a client’s design for a stainless steel housing had a wall thickness that varied slightly. By standardizing it, we were able to use a single tool for the entire operation, eliminating a tool change and reducing the cycle time by nearly 25%. This is a classic DfM win. These small adjustments prevent late-stage redesigns, which are the number one killer of project timelines. A manufacturable design moves smoothly from prototype to full-scale production without costly and time-consuming back-and-forth revisions.

Enhancing Part Performance and Reliability

Sometimes, a DfM consultation can even improve the final part’s performance. A machinist understands how material behaves under stress during the CNC machining process. They can provide feedback on feature orientation to align with the material’s grain structure, improving strength. Or they might suggest slight changes to avoid thin walls that could warp during machining, ensuring better dimensional stability and a more reliable final product.

| Design Feature | Common Pitfall | DfM Recommendation | Impact on Machining |

|---|---|---|---|

| Internal Corners | Sharp, 90-degree corners | Add radius > tool radius | Allows continuous toolpath, faster |

| Wall Thickness | Too thin or inconsistent | Maintain uniform thickness | Reduces vibration and warp risk |

| Hole Depth | Exceeds 6x diameter | Reduce depth or use step drills | Prevents tool breakage, improves chip evacuation |

| Tolerances | Unnecessarily tight | Loosen on non-critical features | Reduces machine time and inspection cost |

Ultimately, collaborative engineering is not an extra step but a foundational strategy for successful product development. Embracing early DfM consultations transforms your design into a cost-effective, high-quality, and manufacturable product. This integrated approach bridges the gap between design intent and manufacturing reality, ensuring your stainless steel CNC machining projects are set up for success from the very beginning. By working together, we can turn a great design into a great product efficiently and reliably.

Sustainability and Cost Efficiency in Stainless Steel CNC Machining?

Are you concerned that adopting sustainable manufacturing practices will inevitably increase your project costs? It’s a common fear that pits environmental responsibility against your bottom line.

Achieving both sustainability and cost efficiency in stainless steel CNC machining is not just possible, it’s a strategic advantage. This is accomplished by leveraging stainless steel’s high recyclability and long lifespan, combined with smart strategies for waste reduction and process optimization.

The Inherent Sustainability of Stainless Steel

When we talk about sustainable manufacturing, the material itself is the most logical starting point. Stainless steel has a powerful built-in advantage that many other materials lack. It’s not just about its performance in the final product; its entire lifecycle offers benefits that align perfectly with both environmental and financial goals. In our projects at PTSMAKE, we always encourage clients to consider the long-term value, and stainless steel consistently proves its worth.

The Power of Recyclability

One of the most significant environmental benefits of stainless steel is its 100% recyclability. Unlike plastics or other materials that degrade with each recycling cycle, stainless steel can be melted down and reformed into new, high-quality material indefinitely. This "closed-loop" system has a massive impact. It dramatically reduces the need for mining new iron ore and other raw materials, a process that is energy-intensive and environmentally disruptive. In the world of stainless steel cnc machining, this means we can often source raw material with a high percentage of recycled content without any compromise on quality. This not only lowers the carbon footprint of the final part but can also lead to more stable material pricing, shielding projects from the volatility of raw resource markets.

Longevity: The Ultimate Green Feature

A product that lasts longer is inherently more sustainable. Stainless steel’s renowned corrosion resistance and durability mean that parts machined from it have an exceptionally long service life. Think about it: a part that doesn’t rust, weaken, or fail prematurely doesn’t need to be replaced. This simple fact reduces the total number of parts that need to be manufactured over time, saving an immense amount of material, energy, and cost. It’s a core principle of a Life Cycle Assessment10 — a longer-lasting component has a smaller overall environmental footprint. For industries from medical devices to aerospace, where reliability is non-negotiable, this longevity is a critical factor that delivers both performance and sustainability.

Balancing the Triangle: Cost, Quality, and Sustainability

Achieving sustainability is not just about the material; it’s about the entire manufacturing process. True cost efficiency in stainless steel cnc machining comes from a holistic approach where process optimization, waste reduction, and quality control work in harmony. It’s a misconception that you have to sacrifice one for the others. In my experience, improvements in one area often lead to gains in the others. For example, a more efficient process that uses less energy also reduces machining time, directly lowering operational costs.

Strategies for Waste and Energy Reduction

Every bit of wasted material or energy is a drain on both the environment and the budget. We focus heavily on a few key areas to combat this.

- Swarf Management: The metal chips, or swarf, generated during machining are not trash. We meticulously collect, clean, and segregate our stainless steel swarf for recycling. This not only prevents waste from going to landfill but also creates a revenue stream that helps offset operational costs.

- Coolant Optimization: Cutting fluids are essential, but their disposal can be an environmental and financial burden. We utilize high-quality, long-life coolants and invest in filtration and recycling systems to extend their usability. This reduces the frequency of replacement and the volume of chemical waste generated.

- Energy Efficiency: Modern CNC machines are far more energy-efficient than older models. Beyond equipment, optimizing toolpaths with advanced CAM software ensures the machine runs for the shortest possible time, consuming less electricity per part produced. This is a clear win-win for cost and sustainability.

A Framework for Balanced Decisions

Making the right trade-offs is crucial. We often use a simple framework to help clients understand how different strategies impact their goals.

| Strategy | Impact on Cost | Impact on Sustainability | Impact on Quality |

|---|---|---|---|

| Using Recycled-Content Steel | Lower raw material cost | High (reduces carbon footprint) | No negative impact |

| Toolpath Optimization | Lower (less machine time) | Moderate (less energy) | Higher (better surface finish) |

| Coolant Recycling | Lower (less fluid purchase/disposal) | High (reduces chemical waste) | Maintained/Improved |

| Near-Net-Shape Stock | Higher initial stock cost | High (less material waste) | No negative impact |

As the table shows, many sustainable practices directly improve cost-efficiency and can even enhance quality. For instance, optimized toolpaths not only cut energy use but often result in a superior surface finish, potentially eliminating the need for secondary finishing operations. This synergy is where the real value lies.

In stainless steel CNC machining, sustainability and cost efficiency are not opposing forces. By choosing a highly recyclable and durable material like stainless steel, you’ve already won half the battle. When combined with smart manufacturing strategies like optimizing material usage, recycling waste streams, and reducing energy consumption, you can create a process that is both environmentally responsible and financially sound. This approach delivers high-quality parts that align with modern economic and ecological demands.

Learn the science behind stainless steel’s self-healing protective layer to improve your material selection process. ↩

Explore how material selection directly influences patient safety and the long-term success of medical devices. ↩

Learn the principles of machine motion that enable the intricate, precise movements of advanced 5-axis systems. ↩

Click here to learn how a steel’s internal crystal structure impacts its real-world performance. ↩

Learn how surface interactions affect both wear and corrosion to optimize part longevity in demanding applications. ↩

Understand how this metallurgical property affects cutting forces and learn techniques to manage it effectively. ↩

Click to understand how this symbolic language on drawings ensures parts function and fit perfectly. ↩

Learn how this symbolic language ensures your design intent is perfectly translated into a physical part. ↩

Understand how this material property impacts tool life and machining strategies for stainless steel. ↩

Explore this concept to understand the full environmental impact of a product from raw material to disposal. ↩