正確な仕様を満たす複雑なプラスチック部品の精密な製造ソリューションを見つけるのに苦労していませんか?航空宇宙、医療機器、ロボットなどの重要な用途で、厳しい公差、複雑な形状、安定した品質が必要な場合、従来の製造方法では不十分なことがよくあります。

CNCプラスチック加工は、コンピューター制御の切削工具を使用してプラスチックブロックから材料を除去し、従来の方法では達成できなかった±0.005インチの厳しい公差や複雑な形状の部品を作成することで、精密加工部品を提供します。

適切な製造パートナーを得ることは、プロジェクトの成功を大きく左右します。私は、遅延や品質問題、サプライヤーとのコミュニケーション不全に直面しているエンジニアリングチームと仕事をしてきました。良いニュースは、CNCプラスチック加工の基本を理解することで、より良い決断を下し、よくある落とし穴を避け、調達プロセスを合理化できることです。この精密製造ソリューションについて、すべてのエンジニアが知っておくべきことを説明しましょう。

CNCプラスチック加工プロセスを理解する

デジタル設計がどのようにして物理的な高精度プラスチック部品になるのか、不思議に思ったことはありませんか?このプロセスを誤解すると、コストのかかる材料の無駄やプロジェクトの遅れにつながり、せっかくの素晴らしいアイデアが挫折してしまいます。

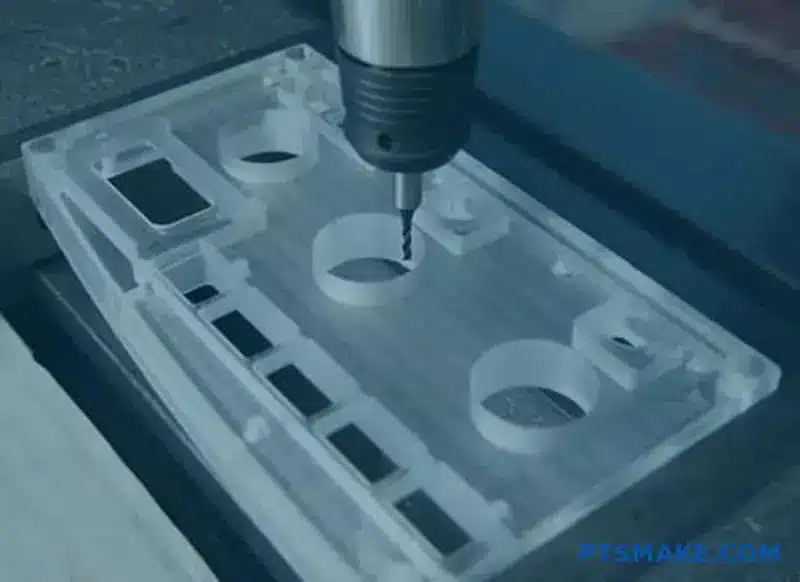

CNCプラスチック加工は、自動化された減法的製造プロセスである。コンピューター制御の機械を使って、デジタルCADモデルに基づいてプラスチックの固まりを正確に切断、穴あけ、成形し、高精度で再現性の高い部品を作ります。

デジタルファイルから物理的部品への旅

CNCプラスチック加工の魔法は、そのシステマティックで自動化されたワークフローにあります。それは、デジタルのコンセプトを信じられないほどの精度で具体的な物体に変換するプロセスです。この変換を可能にする重要なステップを分解してみましょう。

ステップ1:CADモデルの基礎

すべてはデジタル設計図から始まります。コンピュータ支援設計(CAD)ソフトウェアを使用して、エンジニアは部品の詳細な2Dまたは3Dモデルを作成します。このデジタルファイルは単なる画像ではなく、最終部品に必要な正確な寸法、形状、公差が含まれています。CADモデルの品質と精度は、完成部品の品質に直接影響するため、この段階を正しく行うことが重要です。PTSMAKEの過去のプロジェクトでは、明確に定義されたCADファイルがあいまいさをなくし、製造プロセス全体をスピードアップすることがわかりました。

ステップ2:CAMプログラミングとGコード

CADモデルが完成したら、それをCAM(コンピュータ支援製造)ソフトウェアにインポートします。このソフトウェアは、ビジュアルモデルをCNCマシンが理解できる命令セットに変換するトランスレーターとして機能します。Gコードとして知られるこれらの命令は、工具経路や切削速度から主軸回転数や送り速度に至るまで、機械が行うあらゆる動作を指示する。CAMプログラマーはまた、部品を加工する最も効率的な方法を戦略化し、必要な速度を維持しながら、速度を最適化する。 表面仕上げ そして正確さ。このステップでは、マシンが安全かつ効果的に作動するよう、技術的なスキルと実践的な経験を融合させる必要がある。

ステップ 3: 機械のセットアップと材料の準備

Gコードの準備が整ったところで、工程は現場に移る。熟練した機械工が、選択したプラスチック材料のブロックをCNCマシンのワークテーブルに固定する。そして、正しい切削工具を機械の工具ホルダーにセットし、正確に校正する。Gコードが機械のコントローラーに読み込まれ、原点(「ゼロ」位置)が設定される。アライメントや工具の較正にミスがあると、部品の精度が損なわれるため、このセットアップ段階は細心の注意を払う。機械は、計算された一連の動き、つまり 補間1で、希望の形を作る。

| ステージ | 主要機能 | 主要出力 |

|---|---|---|

| CADデザイン | 詳細な2Dまたは3Dのデジタルモデルを作成します。 | .STEP、.STL、または.IGESファイル |

| CAMプログラミング | CADモデルを機械命令に変換する。 | Gコード・プログラム |

| マシンセットアップ | 機械、材料、工具を準備する。 | ワークの固定 |

| 機械加工 | 自動化された材料除去で部品を作る。 | 完成部品 |

プラスチック部品にCNCが好まれる理由

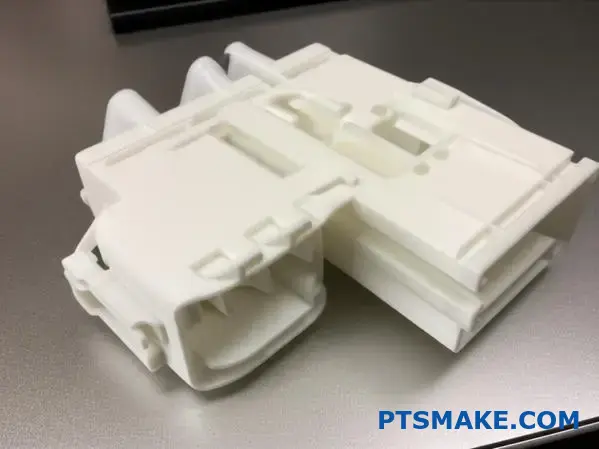

3Dプリンティングや射出成形など他の方法も存在するが、CNCプラスチック加工は、特に試作品や少量から中量の生産において、独自の重要な位置を占めている。その利点は、航空宇宙、医療機器、電子機器など、精度と材料の完全性が譲れない業界では特に明らかです。

比類のない精度と厳しい公差

CNC加工の第一の利点は、その卓越した精度である。この工程はコンピュータ制御され、剛性の高い切削工具を使用するため、一貫して非常に高い精度を達成することができます。 厳しい公差多くの場合、±0.005インチ(0.127mm)以内、あるいはさらに厳しい精度が要求される。このレベルの精度は、医療機器や航空宇宙システムの部品のように、より大きなアセンブリの中で完璧に組み合わされる必要がある部品にとって極めて重要です。材料の反りや収縮が予測できない加工方法とは異なり、CNC加工では、最初の部品から最後の部品まで、信頼性と再現性の高い結果が得られます。

優れた素材特性と汎用性

CNCマシニングは、押し出しまたは鋳造されたプラスチックのソリッドブロックから始まります。これは、3Dプリントで作成された層状構造と比較して、優れた機械的特性を持っています。完成した部品は、原材料の強度、耐薬品性、熱安定性を保持します。このプロセスは、PEEK、デルリン(POM)、ナイロン、アクリル、ポリカーボネートなど、エンジニアリンググレードの膨大な種類のプラスチックにも対応しています。この汎用性により、エンジニアは、自動車部品に高い耐久性が要求される場合でも、医療機器に生体適合性が要求される場合でも、特定の用途に最適な材料を選択することができる。

複雑な形状と優れた表面仕上げ

最新の多軸CNCマシン(3軸、4軸、5軸システムなど)は、成形が難しいか不可能な、信じられないほど複雑な形状、アンダーカット、複雑な特徴を作り出すことができる。この能力は、デザイナーに計り知れない自由を与える。さらに、CNC加工されたプラスチック部品の表面仕上げは、一般的に滑らかで、3Dプリントでよく見られる層線がないため、後処理がほとんど必要ないことが多い。

| 特徴 | CNCプラスチック加工 | 射出成形 |

|---|---|---|

| 理想的な体積 | ロー・トゥ・ミドル(1~10,000人) | 高い(10,000ドル以上) |

| 初期費用 | 低い(カビなし) | 高い(金型コスト) |

| リードタイム | 断食(日) | スロー(週/月) |

| デザインの柔軟性 | 高い(修正が容易) | 低い(改造費が高い) |

CNCプラスチック加工は、デジタルCADファイルをサブトラクティブワークフローによって物理的な部品に変える自動化されたプロセスである。高精度、材料の多様性、優れた機械的特性を持つ複雑な部品を製造する能力で好まれ、多くの産業で理想的なものとなっています。

CNC加工に適したプラスチック材料の選択。

紙の上では完璧に思えたプラスチックを選んだのに、加工中や最終的な用途で失敗したことはありませんか?そのミスマッチがプロジェクト全体を狂わせることもある。

適切なプラスチックの選択には、材料の機械的特性、温度や化学物質などの環境要因に対する耐性、機械加工性などのバランスを慎重に検討する必要があります。この選択は、最終部品の性能、耐久性、プロジェクト全体のコストに直接影響します。

新しいCNCプラスチック加工プロジェクトに取り組むとき、エンジニアとの最初の会話はいつも材料についてです。材料は設計全体の基礎です。これを間違えると、時間と費用が無駄になります。部品の基本的な形状だけでなく、ライフサイクル全体を考える必要があります。

考慮すべき主な材料特性

機械的強度と耐久性

これは、その部品がどのようにストレスに対処するかということです。一定の負荷がかかるのか?衝撃に耐える必要があるか? ポリカーボネートなどの素材 (PC)やPEEKは卓越した耐衝撃性を持ち、保護ハウジングや摩耗性の高い部品に適しています。対照的に、アクリル(PMMA)のような材料はより脆いため、光学的透明性が重要で、衝撃が最小限の用途に適しています。

熱抵抗

動作温度は重要な要素である。常温環境用に設計された部品は、高熱の用途ではすぐに破損する。例えば、アセタール(POM)は優れた潤滑性と剛性を持つが、150℃をはるかに超える温度で強度を維持するPEEKに比べ、低温で変形し始める。当社の社内テストによると、連続使用温度を理解することは譲れません。

耐薬品性

その部品がどのような物質と接触する可能性があるかを考えてください。油や溶剤、洗浄剤にさらされることはありませんか?例えば、ポリプロピレン(PP)は、さまざまな化学物質に対する優れた耐性で知られており、実験器具や液体容器に最適です。ABSのように、特定の溶剤によって損傷を受け、早期故障につながる素材もあります。また 吸湿性2 吸収された水分はその材料の特性を変化させるからである。

PTSMAKEで扱う一般的な素材を簡単に比較してみました:

| 素材 | 引張強度 | 最高使用温度 | 耐薬品性 |

|---|---|---|---|

| ABS | 中程度 | ~80°C | フェア |

| ポリカーボネート(PC) | 高い | ~120°C | フェア |

| アセタール(POM) | 高い | ~90°C | グッド |

| 覗き見 | 非常に高い | ~250°C | 素晴らしい |

核となる特性だけでなく、加工性やコストといった現実的な検討事項も、最終的な決定に大きな役割を果たします。高性能の材料は理想的に見えるかもしれませんが、加工時間とコストが劇的に増加する場合は、プロジェクトにとって最も効果的なソリューションではないかもしれません。そこで、CNCプラスチック加工の経験が非常に重要になるのです。

性能、コスト、加工性のバランス

コストとパフォーマンスのトレードオフ

エンジニアは当然、最高の性能を持つ材料を求めますが、予算は常に現実的なものです。PEEKやUltemのような高性能ポリマーは、ABSやPPのような汎用プラスチックよりもキログラムあたりのコストが大幅に高くなることがあります。重要なのは、「必要な特性」と「あればいい特性」を明確にすることです。過去の多くのプロジェクトで、デルリン(POM)のような中級の材料が、多くの用途で優れた機械的特性とリーズナブルなコストの完璧なバランスを提供することがわかりました。

被削性の影響

機械加工に関しては、すべてのプラスチックが同じように作られているわけではありません。

- 軟質プラスチック: ポリプロピレンのような素材は「グミ」のような状態になることがあり、きれいな切断と厳しい公差を達成するのが難しくなります。切削速度と送り速度が完璧に調整されていないと、溶けたり変形したりすることがあります。

- 硬くて脆いプラスチック: アクリルのような素材は、慎重に扱わないと欠けたり割れたりしやすい。そのため、特殊な工具を使用し、より慎重に加工する必要があります。

- 研磨プラスチック: ガラス繊維入りは、強度が高い反面、工具の摩耗が早く、工具のコストと生産時間が増加します。PTSMAKEの私たちのチームは、効率を維持するために、これらの材料のための特別なプロトコルを開発しました。

材料の選択は、加工工程の時間と複雑さに直接影響し、ひいては最終的な部品のコストに影響する。

| 素材 | 相対コスト | 加工難易度 | 一般的なアプリケーション |

|---|---|---|---|

| アクリル(PMMA) | 低い | 中程度(もろい) | レンズ、ライトパイプ、ディスプレイ |

| ポリプロピレン(PP) | 非常に低い | 中程度(グミ状) | リビングヒンジ、液体タンク |

| デルリン(POM) | 中程度 | 簡単 | ギア、ベアリング、治具 |

| 覗き見 | 非常に高い | 難しい | 医療用インプラント、航空宇宙部品 |

最終的に、最良の選択は共同作業による決定です。アプリケーションの要求とプロジェクトの予算について話し合うことで、不必要な費用をかけずに要求される性能を発揮する材料を特定することができます。

適切なプラスチックを選択するには、機械的特性、熱的特性、化学的特性と、予算や生産スケジュールの現実的なバランスを取る必要があります。このような総合的な視点により、CNC加工部品が機能的で耐久性があるだけでなく、費用対効果に優れ、製造可能であることが保証されます。

厳しい公差と複雑な形状の達成。

複雑なカーブやタイトなフィットを持つプラスチック部品を設計したが、それが作れるかどうか心配になったことはないだろうか?わずかな寸法誤差がアセンブリ全体の機能を台無しにしてしまったらどうしよう?

CNCプラスチック加工は、コンピューター制御の精度を利用して複雑な形状を切削し、非常に厳しい公差を達成することで、この問題に直接対処します。特に多軸マシンは、1回のセットアップで複雑な形状を作成することができ、最も要求の厳しいアプリケーションの精度と再現性の両方を保証します。

精度の基礎公差を理解する

エンジニアリングにおいて「公差」とは、単に与えられた寸法の許容可能なばらつきのことである。正確な寸法で製造できるものはないため、公差は「可/不可」の範囲を定義します。多くの用途では、±0.005インチ(0.127mm)の標準公差で十分です。しかし、高性能部品、特に組立部品では、より厳しい公差を達成する必要があります。そこで、CNC加工の精度が不可欠になります。数千分の1インチまで寸法を管理することができ、部品が設計通りに正確にフィットし、機能することを保証します。プラスチックでこのような厳しい公差を維持するには、機械加工中の異なる材料の挙動を深く理解する必要があります。

多軸加工:複雑性への鍵

アンダーカット、角度のある穴、滑らかで有機的な表面を特徴とするデザインの場合、従来の3軸加工では不十分です。そこで、多軸機がCNCプラスチック加工のゲームチェンジャーとなるのです。

多軸加工とは?

3軸加工機がX、Y、Zの直線軸に沿って工具を移動させるのに対し、5軸加工機は2つの回転軸を追加する。これにより、切削工具は事実上あらゆる方向から加工物に接近することができる。機械の制御システムは、CADデータを正確な動きに変換する。 運動学3 を使用することで、ツールパスを完璧なものにすることができます。この機能により、かつては不可能とされていた部品の一体加工が可能になる。

複雑なプラスチック部品の利点

5軸加工の主な利点は、1回のセットアップで複雑な形状を加工できることです。機械でパーツを取り外して再度固定するたびに、誤差が生じるリスクが少なからずあります。1回のクランプでパーツを完成させることで、寸法精度と再現性が飛躍的に向上します。

| 特徴 | 3軸CNC加工 | 5軸CNC加工 |

|---|---|---|

| 部品の複雑さ | シンプル~中程度 | 高度で複雑な形状 |

| セットアップ時間 | 複雑な部品のための複数のセットアップ | しばしばシングルセットアップ |

| 精度 | 良いが、再固定化でミスを犯すリスクがある | 優れた高精度 |

| ツールアクセス | トップダウン・アプローチに限定 | 複数の角度から部品にアクセス可能 |

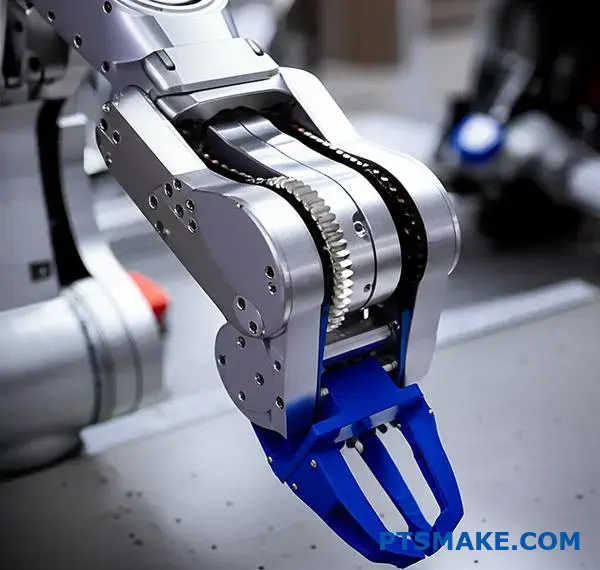

| こんな方に最適 | ハウジング、プレート、基本ブラケット | インペラー、医療用インプラント、ロボットアーム |

プレシジョン・イン・アクション産業別アプリケーション

多くの分野において、厳しい公差を達成することは単なる品質基準ではなく、安全性、信頼性、性能のための基本的な要件です。ほんのわずかでも規格外の部品があれば、システムの故障につながります。PTSMAKEでは、このレベルの精度が譲れないプロジェクトに協力してきました。

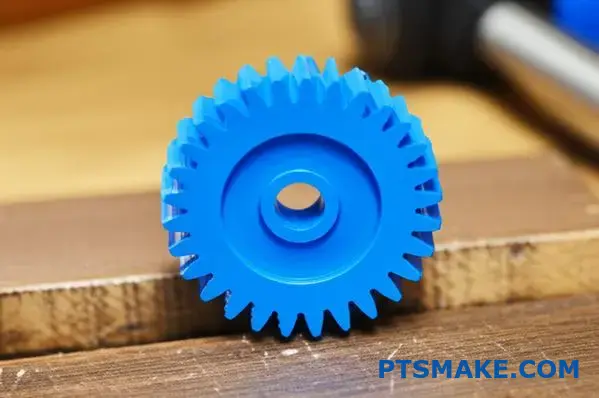

ロボット工学とオートメーション

ロボットアームでは、何十もの機械加工部品が完璧に組み合わされなければなりません。ギア、ジョイント、エンドエフェクターのジョーは、バインディングや余分な摩耗なしに機能するために正確なアライメントを必要とします。デルリン(POM)やPEEKのような安定性と強度に優れた素材を使用し、厳しい公差を保つことで、何百万サイクルにもわたってスムーズで再現性の高い動きを実現しています。

医療機器

医療用部品にとって、精度は生死に関わる問題です。手術用ガイド、診断用機械部品、カスタムインプラントなどは、設計仕様と正確に一致しなければなりません。お客様との過去のプロジェクトでは、公差がミクロン単位で測定されるウルテムやPEEKのような生体適合性プラスチックから部品を機械加工し、他の部品と完璧に統合し、さらに重要なこととして、患者が安全に使用できるようにしてきました。

自動車部品

現代の自動車は、センサー、コネクター、電子モジュールの複雑なシステムです。これらのコンポーネントのプラスチックハウジングは、狭いスペースに完璧にフィットするだけでなく、振動、湿気、極端な温度から繊細な電子機器を保護する必要があります。効果的なシールを作り、長期的な信頼性を確保するためには、正確なフィットが不可欠です。

| 産業 | 代表的なプラスチック部品 | クリティカル・トレランス要件 |

|---|---|---|

| メディカル | 手術ガイド | 0.025mm(±0.001インチ) |

| ロボット工学 | グリッパージョー | 0.050mm(±0.002インチ) |

| 自動車 | センサーハウジング | ±0.005インチ(0.127mm) |

| 航空宇宙 | 内装コネクター | 0.076mm(±0.003インチ) |

マシンを超えて精度に影響を与える要因

最先端の5軸加工機は重要ですが、それは方程式の一部に過ぎません。真の精度は総合的なアプローチから生まれます。切削工具の選択、切削速度と送り、CAMプログラミングの質、さらには作業場の温度までもが、すべての役割を果たします。熱膨張率のような各プラスチックのユニークな特性を理解することは、CNCプラスチック加工プロセス中の材料の動きを補正するために不可欠です。

複雑な形状のプラスチック部品で厳しい公差を達成することは、医療、ロボット、自動車などの重要な産業にとって不可欠です。高度なCNCプラスチック加工、特に多軸機能は、必要な精度を提供しますが、真の成功は、専門的なプログラミング、材料知識、全体的な製造アプローチにもかかっています。

工具と機械のセットアップのベストプラクティス。

完璧に設計されたプラスチック部品が、表面仕上げの不良や寸法の不正確さのために失敗するのを見たことがあるだろうか。問題は設計にあるのではなく、セットアップにあることが多い。

CNCプラスチック加工で最適な結果を得るには、規律正しいアプローチが必要です。これには、特定のプラスチックに適した切削工具を選択し、正確な機械キャリブレーションを行い、寸法精度と優れた仕上げ面を確保するために、クリーンで整然としたセットアップを維持することが含まれます。

ツール選択の重要な役割

CNCプラスチック加工プロジェクトの成功は、マシンの電源を入れるずっと前から始まっています。それは、作業に適した工具を選ぶことから始まる。金属とは異なり、プラスチックは熱伝導率が低い。間違った工具を使用すると、すぐに材料が溶けるほどの摩擦が発生し、グチャグチャになって部品が台無しになってしまいます。

工具材料:超硬とハイスの比較

ほとんどのプラスチック用途では、高速度鋼(HSS)工具で十分であり、費用対効果も高い。非常に鋭利なエッジに研磨できるため、プラスチックを押すのではなく、きれいに剪断するのに重要です。しかし、ガラス繊維入りナイロンやカーボン繊維入りPEEKのような研磨性の高い強化プラスチックを扱う場合は、超硬工具が不可欠です。PTSMAKEの過去のプロジェクトで、超硬の優れた耐摩耗性が鋭い切れ刃をはるかに長く維持し、溶融や仕上げ不良につながる熱の蓄積を防ぐことがわかりました。鋭利な刃先がなければ、本質的に材料をこすり落とすだけで、精度も表面品質も損なわれてしまいます。

工具の形状:切れ味だけではない

道具の形状は、その素材と同じくらい重要だ。

- フルート・カウント プラスチック用には、フルートが少ない(通常1~2本)方が良い。これにより、切り屑が排出されるスペースが広くなり、切り屑が詰まって溶融し、工具や部品に付着するのを防ぐことができます。

- ヘリックスの角度 螺旋角度を高くすることで、切りくずを引き上げ、カッティングゾーンから遠ざけることができる。

- レーキ角とクリアランス角: ポジティブなすくい角と高い逃げ角が、切削力と摩擦を低減。その結果、より少ない熱でよりきれいな切削が可能になります。私たちの経験では、工具形状のわずかな偏差が最終的な部品に影響を与えることがあります。工具が摩耗していると切削抵抗が増加し、過度の熱が発生するため、内部応力や部品の反りを引き起こす可能性があります。少量の工具 ランナウト4 また、穴や溝が大きくなることもある。

これは、一般的なプラスチックと工具を適合させるために社内で使用している簡単なガイドです:

| プラスチック素材 | 推奨工具 | 主な検討事項 |

|---|---|---|

| アクリル(PMMA) | シングルフルート、ポリッシュ仕上げ | ひび割れを防ぎ、クリアな仕上がりを実現。 |

| デルリン(POM) | 2枚刃、シャープHSS/超硬 | マシンは簡単に、チップの排出に集中する。 |

| PEEK(未充填) | 2フルート超硬、シャープ | 耐摩耗性の工具が必要。 |

| ナイロン(ガラス充填) | 2枚刃超硬、コーティング済み | 耐摩耗性に優れ、コーティングにより工具寿命が延びる。 |

機械の較正とセットアップの手順

優れた工具も、それを保持する機械が適切にセットアップされ、キャリブレーションされていなければ意味がありません。精密なCNCプラスチック加工では、一貫性がすべてであり、その一貫性は、毎回、期待通りに正確に動作する機械から生まれます。これは、「セットして終わり」のプロセスではなく、継続的な注意が必要です。

ファウンデーションマシンレベルと安定性

基本的なことに聞こえるかもしれないが、CNCマシンの物理的な安定性は最も重要である。振動を最小限に抑えるために、機械は完全に水平で、しっかりとした土台の上になければなりません。振動は、良好な表面仕上げの敵です。わずかな振動でも、プラスチック部品の表面にビビリ跡がつくことがあり、特にアクリルやポリカーボネートのような、磨き上げられた外観を必要とする素材では顕著です。特に、アクリルやポリカーボネートのような研磨仕上げが必要な素材では顕著です。

精度を持続させる定期校正

キャリブレーションは、機械の動作が正確であることを保証します。コントローラが10mmの移動を命令すると、軸は正確に10mm移動しなければならない。

- バックラッシュの補償 これにより、ドライブスクリューのわずかな遊びが補正されます。時間の経過とともに、機械的な摩耗がバックラッシュを増加させ、寸法の不正確さにつながります。私たちは定期的にキャリブレーションテストを実施し、バックラッシュの測定と補正を行っています。

- スピンドルと軸のアライメント: スピンドルはマシンベッドに対して完全に垂直でなければなりません。少しでもずれがあると、テーパーのついた壁や、正方形でない形状が生じます。医療機器部品に関する顧客との広範な調査の結果、ほんのわずかなミスアライメントでも、組み立て工程で問題を引き起こす可能性があることがわかりました。

ワークホールディング損傷を与えずに固定する

プラスチックは金属よりもずっと柔らかく、過度のクランプ圧で簡単に破損したり変形したりします。鋸歯状のジョーを持つ標準的なマシンバイスを使用することは、災いの元です。

- 柔らかい顎: 表面を傷つけることなく部品をしっかりと保持するために、アルミニウムや同じプラスチックのブロックから特注のジョーを加工することも多い。

- 真空テーブル: 平らなプラスチックシートの場合、バキュームテーブルは部品全体に均等に分散した保持力を与え、クランプを必要としない。

- フィクスチャリング: 複雑なパーツの場合、カスタム冶具が最適なソリューションになることがよくあります。部品を適切に支持し、加工に適した向きで確実に保持することができます。

以下は、チームが一貫性を維持するのに役立つ、簡略化されたランニング前のチェックリストである:

| チェックポイント | アクション | なぜ重要なのか |

|---|---|---|

| 機械の清浄度 | 作業エリアからすべての切り屑を取り除く。 | チップの干渉を防ぎ、正確なシーティングを保証します。 |

| ツールホルダー&スピンドルテーパー | 工具を挿入する前にきれいに拭いてください。 | 工具の振れを最小限に抑え、最大限の剛性を確保。 |

| ワークシート | 平行線に対して平らであることを確認する。 | Z軸精度を保証し、傾きを防止。 |

| クーラント/エアブラスト | ノズルが正しく向けられていることを確認する。 | 切り屑の排出を助け、溶融を防ぐ。 |

高品質のCNCプラスチック加工には、綿密なセットアップが欠かせません。適切な工具の選択、定期的な機械の較正、スマートなワークホールドストラテジーは、寸法精度、表面仕上げ、部品の完全性に直接影響し、優れた設計をすべての仕様を満たす優れた最終製品に変えます。

プラスチックの切削パラメータの最適化。

プラスチックの加工で、エッジの溶融、表面仕上げの不良、さらには部品のひび割れに苦労していませんか?このような問題によって、プロジェクトに遅れが生じたり、材料の無駄が生じたりしていませんか?

切削速度、送り速度、主軸回転速度、切り込み深さを最適化することは、プラスチック加工を成功させるために譲れません。これらのパラメータは、発熱、表面品質、効率に直接影響し、欠陥を防止し、常に正確で信頼できる結果を得るための基礎を形成します。

CNCプラスチック加工プロジェクトに取り組むとき、私たちが最初にダイヤルインする変数は切削パラメータです。切削パラメータは、チャートから引き出される単なる数値ではなく、工具が材料とどのように相互作用するかを決定する動的な指示のセットです。これを間違えると、加工物を台無しにする最短の方法となる。パラメータを正しく設定することこそ、精密機械加工の真の技が光るところなのです。

コア・デュオ切削速度と送り速度

切削速度(1分あたりの切削速度、SFMで測定)と送り速度(工具が材料を通過する速度)は、基本的に関連しています。プラスチックの場合、目標は部品から熱を逃がすきれいな切りくずを作ることです。よくある間違いは、遅ければ遅いほど安全だと考えることです。多くのプラスチックでは、ゆっくり動かしすぎると工具が効率的に切削できず、代わりに材料とこすれて過度の摩擦と熱が発生します。これは、溶融、工具のガム化、表面仕上げの不良につながります。

異なるプラスチックのバランスを見つける

理想的なバランスは、プラスチックの種類によって大きく異なる。

- より柔らかく、低融点のプラスチック(HDPE、LDPEなど): これらの材料は溶けやすい。当社では、高い送り速度と適度な切削速度を組み合わせて使用することが多い。このアプローチにより、刃先が常に新鮮で冷たい材料に移動し、明確な切りくずが形成され、熱の蓄積を最小限に抑えることができます。

- より硬く、研磨性のあるプラスチック(例えば、PEEK、ガラス充填ナイロン): これらには別の戦略が要求される。切削工具は熱に強い反面、研磨性が高いため工具の摩耗が早い。この場合、切削工具の寿命を維持するために切削速度を下げますが、摩擦を防ぐために送り速度を一定に保ちます。重要なのは 工具摩耗5 熱ストレスの原因となる過度の熱を導入することなく。

PTSMAKEでは、長年のテストに基づき、社内ガイドラインを作成しました。以下は、特定の部品の形状を微調整する前に、ベースラインとしてよく使用する開始点を示す簡略化した表です。

| プラスチックタイプ | 切削速度(SFM) | 送り速度(IPR) | 主な検討事項 |

|---|---|---|---|

| ABS | 600 - 1000 | 0.004 - 0.012 | 溶けやすいので、切りくずの排出をよくすること。 |

| ポリカーボネート(PC) | 500 - 800 | 0.005 - 0.015 | 脆くなることがあるので、過度の工具圧力は避けること。 |

| デルリン®(POM) | 800 - 1200 | 0.005 - 0.020 | マシンは美しく、チップ形成は素晴らしい。 |

| 覗き見 | 400 - 700 | 0.003 - 0.010 | 研磨剤;超硬工具を使用し、摩耗を監視する。 |

この表はガイドの役割を果たしますが、すべてのCNCプラスチック加工がユニークであることを忘れないでください。

切削速度と送りだけでなく、主軸回転速度と切り込み深さは、部品の品質と加工効率に直接影響するもう一つの制御レイヤーを追加します。この2つのパラメータは非常に重要で、切削速度や送り速度と調和するように調整する必要があります。これらを無視すると、せっかくの慎重な計算が台無しになってしまいます。

主軸回転速度と切粉負荷への影響

主軸回転数(RPM)は切削速度に直接関係しますが、最も重要な関係は送り速度です。この2つが相まって、「切りくず処理量」(工具の各切刃によって除去される材料の厚さ)が決まります。プラスチック加工では、適切な切りくず処理量が非常に重要です。

チップ負荷が重要な理由

- 低すぎる: 送り速度に対して主軸回転速度が高すぎると、切りくずの負荷が小さすぎる。工具のフルートは、プラスチックを切削するのではなく、プラスチックと摩擦し、大きな熱を発生させ、溶融につながります。これは、プラスチック部品の不具合でよく見られる問題です。

- 高すぎる: 主軸回転数に対して送り速度が速すぎると、切りくずの負荷が大きくなりすぎる。この場合、切削工具と被削材に大きなストレスがかかり、工具の破損やプラスチックのチッピングを引き起こしたり、粗いビビリ面の仕上がりになったりする可能性があります。

顧客との過去のプロジェクトでは、一貫性のある適度な厚さのチップが理想的だとわかりました。このチップは、熱を効果的に引き寄せて、部品から離れるようにカールするのに十分な強度があります。

カットの深さ:効率と品質のトレードオフ

切込み深さ(DOC)とは、1回のパスで工具が被削材にどれだけ深く食い込むかを意味する。材料をより速く除去し、サイクルタイムを短縮するために、切り込み深さを最大にしようとする誘惑に駆られることが多い。しかし、プラスチックの場合、これは悲惨なアプローチになりかねない。

浅いカットと深いカット

深いカットは、大量のエネルギーと工具の圧力を一箇所に集中させる:

- 熱の蓄積: 切断する材料が増えるということは、摩擦が増え、熱も増えるということだ。

- 部品のたわみ: プラスチックは金属ほど剛性が高くない。重切削を行うと、材料が工具から離れて曲がったり、たわんだりすることがあり、その結果、寸法が不正確になることがあります。

- ストレスクラッキング: アクリルやポリカーボネートのような特定のプラスチックは、高い加工力を受けると応力割れを起こしやすい。

ほとんどのCNCプラスチック加工アプリケーションでは、1回の深いパスよりも複数回の浅いパスが好まれます。この戦略は、熱を管理し、工具の圧力を軽減し、最終寸法と表面仕上げをはるかに大きく制御するのに役立ちます。

| パラメータ | アグレッシブ戦略(ハイリスク) | コンサバティブ・ストラテジー(ハイクオリティ) | 成果 |

|---|---|---|---|

| 主軸回転数 | 非常に高い | 中~高 | 熱と切削作用のバランスをとる。 |

| フィード・レート | 非常に高い | 中程度 | 熱を逃がす適切なチップを作る。 |

| 切り込み | ディープ(シングルパス) | シャロー(複数パス) | 応力を低減し、部品のたわみを防止します。 |

このような保守的なアプローチは、書類上では時間がかかるように見えるかもしれないが、スクラップ部品や手戻りを防ぎ、長期的にははるかに効率的で費用対効果の高いものとなる。

切削パラメータの最適化は、高品質のCNCプラスチック加工に不可欠です。切削速度、送り速度、主軸回転速度、切り込み深さへのバランスの取れたアプローチは、熱損傷や欠陥を防ぎ、優れた仕上げ面を確保し、信頼性の高い効率的な生産のための寸法精度を維持します。

ラピッドプロトタイピングと少量生産の利点。

テスト用にいくつかの機能部品が必要なのに、高価で時間のかかる射出成形金型の見積もりに直面したことはありませんか?これはしばしば製品開発における大きなボトルネックとなります。

CNCプラスチック加工は理想的なソリューションであり、忠実度の高い機能的プロトタイプや少量生産品を作成するための比類のないスピードと費用対効果を提供します。高価な金型が不要になるため、迅速な設計の繰り返しと迅速な市場参入が可能になります。

デジタルCADモデルから手に取れる物理的な部品への移行は、製品開発において本当の魔法が起こる場所です。CNCプラスチック加工は強力な橋渡し役となり、この移行をこれまで以上に迅速かつ効率的にします。それは、単にそっくりなモデルを作るということではなく、意図したとおりに機能する部品を作るということなのです。

反復のスピード

プロトタイピングにおけるCNC加工の最も大きな利点のひとつは、スピードです。3D CADファイルから直接加工するため、デザインを受け取ってから数時間以内に材料の切削を開始することができます。金型の作成とテストに何週間も待つ必要はありません。最初のプロトタイプをテストした後に設計上の欠陥が発見された場合、エンジニアはCADモデルを更新するだけです。そして、時にはその日のうちに修正版を加工することができます。この迅速なフィードバックループは非常に貴重で、設計チームは迅速かつ自信を持って製品を改良することができます。PTSMAKEでは、このプロセスにより、金型を必要とする従来の方法と比較して、開発期間が50-70%も短縮されることを見てきました。

生産グレードの材料による機能試験

プロトタイプは、実際の使用条件下でテストする必要があります。CNC加工では、ABS、ポリカーボネート、PEEK、ナイロンなど、最終的な生産部品とまったく同じプラスチックを使用することができます。つまり、強度、耐薬品性、熱安定性など、意味のある機能試験を行うことができるのです。部品は真の 等方性材料特性6そのため、テスト結果は信頼性が高く、最終的な量産製品に直接適用できます。これは、造形方向によって材料特性が変化する可能性がある一部の3Dプリンティング方式にはない重要な利点です。

生産へのギャップを埋める

CNC加工プロトタイプは、大量生産に踏み切る前の完璧な「橋渡し」の役割を果たします。一握りの高品質な機械加工部品でデザインの形状、フィット感、機能を検証することで、高価な射出成形ツールへの投資を大幅にリスク回避することができます。

| 特徴 | CNCプラスチック加工(プロトタイプ) | 射出成形金型(プロトタイプ) |

|---|---|---|

| リードタイム | 1-10日 | 4-8週間 |

| 1-100部品にかかる費用 | 低~中程度 | 極めて高い |

| デザインの柔軟性 | 非常に高い(CADの変更が容易) | 非常に低い(高価な金型修正) |

| 素材の選択 | 幅広い製造用プラスチック | ツールの互換性に限る |

プロトタイピングにとどまらず、CNCプラスチック加工は少量生産のための非常に強力なツールです。すべての製品が100万個生産されるわけではありません。航空宇宙、医療機器、カスタム機械などの産業における多くのアプリケーションでは、高精度部品の小ロットが必要であり、多くの場合、100個から5,000個程度です。このようなシナリオでは、射出成形のような従来の製造方法の経済性は意味をなさない。金型の初期費用がかかるため、部品1個あたりの価格が法外に高くなってしまうのだ。そこで、CNC機械加工が一時的なステップではなく、主要な製造方法となるのです。

金型償却なしの費用対効果

射出成形における唯一最大のコストは、スチール金型そのものである。このコストは、生産する部品の総数で償却、つまり分散される。何十万個もの部品を作るのであれば、部品1個あたりの金型費用は無視できるほど小さくなります。しかし、必要な部品が500個であれば、その金型費用全体を500で割ることになり、単価が非常に高くなります。CNCマシニングは、この問題を完全に回避します。工具は必要ない。コストは機械加工時間、材料費、人件費に基づくため、直線的で予測可能な費用となる。そのため、CNC加工は短納期生産において最も経済的に実行可能な選択肢となります。

オンデマンド製造と在庫管理

CNC加工による少量生産は、より機敏なオンデマンド生産戦略も可能にします。最低注文数量を満たすために何千もの部品を生産し、それを倉庫に保管する代わりに、必要なときに必要な部品を注文することができます。私たちが多くのクライアントの導入を支援しているこのアプローチは、在庫保有コストを削減し、設計が更新された場合に在庫が陳腐化するリスクを最小限に抑え、キャッシュフローを改善します。これは、動きの速い今日の市場に最適なリーン生産方式です。

市場テストとパイロット・ラン

本格的な製品発売に踏み切る前に、企業はしばしば市場テストやパイロット・ランを実施する必要がある。CNCマシニングは、最初の数百個または数千個を生産するのに最適な方法です。ハードツーリングに伴う巨額の先行投資やリスクを負うことなく、製品を迅速に実際の顧客の手に届け、貴重なフィードバックを収集することができます。

| 生産量 | 推奨方法 | 主な検討事項 |

|---|---|---|

| 1-100ユニット | CNCマシニング/3Dプリンティング | スピードと機能テストのニーズ |

| 100~5,000台 | CNC加工 | のための高額な金型費用を回避できる。 少量. |

| 5,000台以上 | 射出成形 | 金型償却後の部品単価が最も低い。 |

CNCプラスチック加工は、ラピッドプロトタイピングにおいて、プロダクショングレードの材料を使用した、工具を使用しない迅速な試作を可能にします。少量生産の場合、高価な射出成形に代わる費用対効果の高い選択肢を提供し、財務リスクを軽減し、オンデマンド製造と迅速な市場参入を可能にします。

CNCプラスチック部品の品質保証と一貫性。

プラスチック部品のバッチを受け取ったとき、1個ごとに品質にばらつきがあり、フラストレーションを感じたことはありませんか?それはプロジェクト全体のスケジュールを狂わせる可能性があります。

CNCプラスチック加工における真の一貫性は、厳格な検査プロトコル、標準化された工程管理、コンピュータ制御技術固有の精度の組み合わせによって達成されます。この体系的なアプローチにより、すべての部品が確実に厳しい設計仕様を満たし、ばらつきを最小限に抑え、性能を保証します。

品質保証は単なる最終段階ではなく、製造プロセス全体を通して組み込まれた哲学です。CADファイルを受け取った瞬間から最終出荷に至るまで、すべての段階でばらつきを排除し、一貫性を確保するように設計されています。公差、材料要件、特定の幾何学的寸法公差(GD&T)を含む設計仕様の包括的なレビューから始まります。

インプロセス品質管理(IPQC)

私たちは品質チェックを最後まで待つことはありません。IPQCは、生産中の一貫性を維持するために非常に重要です。これには、定期的にCNCマシンから直接パーツを取り出し、測定と検査を行うことが含まれます。こうすることで、工具の摩耗、機械のドリフト、微妙な材料のばらつきなど、潜在的な逸脱を早期に発見することができます。このプロアクティブなアプローチにより、大量の規格外部品の生産を防ぎ、時間とリソースを節約することができます。の分野 計測7 は、このような精密測定のための基礎原理を提供し、機器の校正と手法の健全性を保証します。

第一条検査(FAI)

完全な生産を開始する前に、私たちは常に初品検査を実施します。最初に生産される部品は、図面に記載された寸法や仕様のひとつひとつに対して綿密に測定されます。このFAIレポートは、私たちのセットアップ、プログラミング、ツーリングがすべて正しいことを確認する重要な文書です。これは、残りの生産工程における「ゴールデンサンプル」またはベンチマークとして機能します。

| 検査段階 | 目的 | 主な活動 |

|---|---|---|

| 材料の検証 | 原材料がプロジェクトの仕様を満たしていることを確認する。 | 材料証明書をチェックし、必要に応じて硬度試験を行う。 |

| 第一条検査 | 製造セットアップとプロセスを検証する。 | 全寸法のレイアウト、CADや図面との比較。 |

| インプロセス制御 | 生産中の一貫性を監視する。 | 定期的なサンプリング、主要形状の測定、工具の摩耗チェック。 |

| 最終検査 | バッチ全体が品質基準を満たしていることを確認する。 | 抜き取り検査または100%検査、目視検査、書類審査。 |

テクノロジーの役割

最新のCNCマシンは驚くほど精密ですが、それをサポートするシステムがあってこそです。PTSMAKEでは、複雑な形状をミクロン単位の精度で測定するために、高度な三次元測定機(CMM)やその他の校正された検査ツールを使用しています。このデータは合否判定のためだけでなく、プロセスの安定性を分析し、継続的な改善を行うために使用しています。このような技術とプロセスへのコミットメントにより、高品質のCNCプラスチック加工部品を一貫して提供しています。

最終部品の信頼性と一貫性を確保するためには、加工プロセスそのものだけでなく、後工程のステップと堅牢な品質管理システム(QMS)が不可欠です。最も精密に加工された部品であっても、仕上げに一貫性がなかったり、取り扱いが悪かったりすると、その信頼性が損なわれる可能性があります。だからこそ、私たちはこれらの最終段階を、最初の切削加工と同レベルの注意と管理で扱うのです。

標準化された後処理プロトコル

後処理は後付けではなく、部品の機能、外観、耐久性に影響する重要な製造工程です。鋭利なエッジのバリ取り、光学的透明度のための蒸気研磨、均一な艶消し仕上げのためのビーズブラストなど、どの手順においても標準化されたプロトコルに従います。これにより、バッチ内のすべての部品が同じ表面仕上げと美的品質を持つことが保証されます。

表面仕上げの一貫性

一貫した表面仕上げ(Ra)を達成することは、多くの用途、特にシール面を必要とする部品や特殊な美観を要求される部品にとって不可欠です。当社では、以下の方法でこれを管理しています:

- プログラムされたツールパス: CAMソフトウェアの特定の仕上げツールパスを使用して、均一なテクスチャを作成する。

- 管理されたマニュアルプロセス: 手作業による仕上げが必要な場合、当社の技術者は特定の技術について訓練を受け、ばらつきを避けるために管理された研磨剤と工具を使用します。

- 表面粗さ計 表面仕上げが図面の仕様に合っているかどうかを測定し、検証するためにプロフィロメーターを使用します。

この細部へのこだわりが、最後のパーツが最初のパーツとまったく同じように見え、感じられることを保証している。

品質マネジメントシステム(QMS)とトレーサビリティ

ISO9001認証のように確立されたQMSを持つことは、私たちのすべての品質保証活動の枠組みを提供します。これは単に壁に貼られた証明書ではなく、私たちの業務を管理する生きたシステムなのです。その重要な要素がトレーサビリティです。原材料のバッチ番号から、特定の機械やオペレーターの作業まで、私たちは製造した部品の全履歴を追跡することができます。これは、トラブルシューティングや、特に医療や航空宇宙産業において、お客様自身の品質システムに必要な文書を提供する上で非常に貴重なものです。このトレーサビリティは信頼性を高め、長期的な部品の信頼性に関するあらゆる懸念に対応します。信頼される製造パートナーとなることは、PTSMAKEの使命の中核をなすものです。

CNCプラスチック部品の一貫した品質を確保するには、多面的なアプローチが必要です。CNC技術固有の精度と、厳格な工程内検査、詳細なFAIレポート、標準化された後処理を組み合わせています。これにより、すべての部品が厳格な仕様に適合し、最初の部品から最後の部品まで信頼性が保証されます。

サプライヤーとのコミュニケーションと調達プロセスの合理化?

プロジェクトがサプライヤーとのミスコミュニケーションのループから抜け出せず、コストのかかる遅延や手戻りにつながっていると感じたことはないだろうか。これは、どんなに順調な計画でも頓挫しかねない、よくあるフラストレーションです。

CNCプラスチック加工の調達を合理化するには、明確なコミュニケーションプロトコルを確立し、最初から包括的な技術文書を提供し、統合されたサービスを提供するサプライヤーと提携する必要があります。この積極的なアプローチにより、曖昧さを最小限に抑え、リードタイムを短縮し、プロジェクトが予算内に収まるようにします。

基礎明確で一貫性のあるコミュニケーション

効果的なコミュニケーションとは、単にEメールを送ることではなく、初日からプロジェクトのゴールについて共通の理解を持つことです。あらゆるCNCプラスチック加工プロジェクトにおいて、曖昧さは精度の敵です。前もって詳細な情報を提供すればするほど、プロセス全体がスムーズになります。プロジェクトの成功は、最初の情報交換の質に左右されることが多いのです。

包括的なテクニカル・データ・パッケージ(TDP)の作成

見積もりを依頼する前に、最も強力なツールは完全なテクニカル・データ・パッケージ(TDP)です。これは単なる3Dモデルではありません。堅牢なTDPは、推測の余地を残しません。

- 3D CADファイル: ネイティブファイル(STEPやIGSなど)は必須です。

- 2D技術図面: これらは、重要な寸法、公差、表面仕上げ要件(Ra値など)、材料仕様を明確に定義する必要がある。

- 素材の吹き出し: 具体的に。ABS」だけでなく、「ABS、黒、Lustre-lok L-100」と指定してください。

- 数量とスケジュール: プロトタイプ、パイロット・ラン、大量生産に必要な部品数と目標納期を指定してください。

この最初のディスカッションで重要なのは、以下を徹底的に見直すことだ。 製造可能設計(DFM)8 の原則に従います。経験豊富なサプライヤーは、TDPを分析し、プラスチックの1チップを切り出す前に、部品の品質を向上させ、コストを削減するためのフィードバックを提供します。

コミュニケーション・ケイデンスを確立する

プロジェクトが始まったら、コミュニケーションを途絶えさせないこと。定期的な更新スケジュールに合意する。長いミーティングをする必要はありません。進捗状況の写真や簡単なステータスチェックを添付したシンプルな週刊メールを送るだけで、小さな問題が大きな問題に発展するのを防ぐことができる。

| コミュニケーション不足 | 効果的なコミュニケーションの実践 |

|---|---|

| 曖昧なメールや口頭での指示 | 詳細なTDPと文書 |

| サプライヤーが以下を理解していると仮定すると | 全仕様を確認するためのキックオフ・コールのスケジュール |

| 定期的なアップデートはない | 写真付き週次進捗報告 |

| 質問に対する返答の遅れ | 迅速な回答のための専用窓口 |

最初から明確な期待値を設定することで、信頼と透明性の基盤が築かれ、それが製造プロセス全体を通じて配当される。

統合パートナーの戦略的優位性

1つのサプライヤーを管理するのは大変なことだ。異なる製造工程のために複数のサプライヤーを管理することは、すぐにロジスティクスの悪夢になりかねません。そこで、統合されたソリューションを提供する企業と提携することで、特に、単なるCNCプラスチック加工以上のものを必要とする複雑なプロジェクトでは、大きな利点が得られます。

複雑なサプライチェーンの簡素化

CNC加工によるプロトタイプから始まり、量産用の射出成形に移行するプロジェクトを考えてみよう。CNC工場と別個の成形工場をやりくりすることは、潜在的な失敗の可能性を複数もたらします。2つの連絡先、2つの品質管理システム、2つの出荷スケジュールを管理しなければなりません。PTSMAKEの経験では、このような分断が遅延や品質のばらつきにつながるのを目の当たりにしてきました。1つの統合されたパートナーが、1つの屋根の下でワークフロー全体を処理します。機械加工された試作品から成形品への移行を管理し、設計意図が維持され、品質が一貫していることを保証します。この統一されたアプローチは、お客様にとってすべてを簡素化します。

リードタイムの短縮とプロジェクトのリスク軽減

単一のパートナーと協力することは、プロジェクトのタイムラインに直接的かつプラスの影響を与えます。

- トランジットタイムなし: 機械工場から成形工場に部品を輸送する必要がない。これだけで、数日から数週間を節約することができる。

- 統一された品質管理: 同じ品質チームがプロジェクト全体を監督します。彼らはプロトタイピングの段階から重要な機能を理解し、生産においてもそれが維持されるようにします。

- シームレスなDFM: 機械加工部品のDFMフィードバックを提供したチームは、射出成形金型のツーリングを行っているチームと同じです。このような継続性により、製造に関する知識はすべての段階を通じて継承されます。

| マルチ・サプライヤー・アプローチ | 統合パートナー・アプローチ |

|---|---|

| 複数のコンタクトポイント | 窓口の一本化 |

| 品質にばらつきが生じる可能性 | 一貫した品質管理 |

| 輸送・物流時間の増加 | トランジットの遅延がない |

| 断片的なDFMフィードバック | 最初から最後まで一貫したDFM |

| 管理オーバーヘッドの増加 | プロジェクト管理の合理化 |

最終的に、合理化された調達プロセスとは、単に最低価格を見つけることではありません。複雑さを軽減し、リスクを軽減し、自社のチームの延長として行動できるパートナーを見つけることなのだ。この全体的なアプローチこそが、高品質の製品を市場に送り出すための最速かつ最も信頼できる道なのです。

サプライヤーとの効果的なコミュニケーションは、明確な文書化と定期的なアップデートにかかっています。統合されたサプライヤーと提携することで 複雑なCNCプラスチック加工 プロジェクトは調達をさらに合理化し、複雑さ、リードタイム、ミスの可能性を大幅に削減することで、設計から生産までのよりスムーズな経路を確保する。

滑らかな曲線や正確な複雑形状を実現するために重要なツールパスの計算方法についてご紹介します。 ↩

素材が湿気を吸収する傾向が、その安定性と性能にどのような影響を与えるかをご覧ください。 ↩

高精度加工を可能にする機械運動の基本原理を理解する。 ↩

この小さな欠陥が、パーツの公差と表面仕上げにどのような影響を与えるかをご理解ください。クリックして詳細をご覧ください。 ↩

工具摩耗の種類について学び、加工作業における工具の早期破損をより的確に診断し、予防することができます。 ↩

材料特性があらゆる方向で一貫している理由と、それが部品の強度に重要な理由を理解する。 ↩

このリンクから、計測の科学がどのようにお客様のパーツを正確な仕様に適合させるかをご覧ください。 ↩

DFMの原則を適用することで、どのように設計を最適化し、製造コストを削減し、市場投入までの時間を短縮できるかをご覧ください。 ↩