Your project needs that perfect premium look, but you’re stuck choosing between countless finish options. Standard finishes make your product blend into the crowd, while poor finish choices can destroy your brand’s luxury positioning and customer perception.

Brushed gold finish combines corrosion resistance with premium aesthetics, offering superior durability and scratch hiding compared to polished alternatives. This surface treatment uses controlled abrasion patterns with gold coating to create consistent texture and luxury appeal.

I’ve worked with hundreds of engineers who struggle with finish selection for their high-end products. This guide covers everything from technical specifications to manufacturing methods, helping you make informed decisions for your next hardware project.

Why Engineers Choose Brushed Gold Finish: A Technical Perspective

Engineers often look beyond simple aesthetics. A brushed gold finish is selected for solid, practical reasons. It has become one of the engineer-preferred metal finishes.

This choice combines visual appeal with tangible performance. It’s not just about looking good.

Key Engineering Advantages

A primary driver is corrosion resistance. The brushed texture also provides excellent tactile feedback. This finish effectively hides fingerprints and minor scratches. These are key technical benefits of a brushed gold finish.

Comparaison rapide

| Fonctionnalité | Brushed Gold | Chrome poli |

|---|---|---|

| Résistance à la corrosion | Haut | Modéré |

| Fingerprint Masking | Excellent | Pauvre |

| Sensation tactile | Texturé | Lisse |

Beyond the Surface: A Deeper Look

The appeal of a brushed gold finish goes deeper than its appearance. The manufacturing process itself adds significant functional value, enhancing the surface properties of the base material. It is more than just a color.

The Science of the Finish

The brushing technique creates fine, parallel grooves on the metal’s surface. These grooves scatter light, which reduces glare. This is a critical feature for parts used in displays or brightly lit environments. The texture also helps to conceal small signs of wear over time.

For components made from aluminum, the process to achieve this look can be quite advanced. We often use a surface treatment like anodisation1 to create a durable oxide layer first. This protective layer is then infused with a gold-colored dye, ensuring the color is integral to the surface itself, not just a coating.

Functional Aesthetics

Tactile feedback is another important technical benefit. For control knobs or interactive surfaces, the textured feel can guide a user’s hand. It provides confirmation of touch without visual cues.

| Domaine d'application | Key Benefit of Brushed Gold |

|---|---|

| Dispositifs médicaux | Biocompatibility & Durability |

| Électronique grand public | Aesthetics & Fingerprint Resistance |

| Intérieurs automobiles | Low Glare & Premium Feel |

From a technical standpoint, the brushed gold finish offers more than visual luxury. Its engineered properties—including enhanced durability, corrosion resistance, and functional tactile feedback—make it a smart and reliable choice for many demanding applications where performance is paramount.

The Complete Comparison: Brushed Gold vs Polished Gold In Manufacturing

When choosing a gold finish, looks are just the start. The real decision comes down to performance and practicality for your specific product.

Each finish offers a distinct set of properties. These differences directly impact the end-user experience.

Principales différences fonctionnelles

A brushed gold finish is known for its durability. Its texture helps hide minor scratches and daily wear.

Polished gold, while stunning, is more delicate. It tends to show every small imperfection. This choice is critical for OEM products.

Comparaison rapide

| Fonctionnalité | Brushed Gold | Polished Gold |

|---|---|---|

| Durabilité | Hides scratches well | Shows imperfections |

| Réflectivité | Low, matte sheen | Élevé, semblable à un miroir |

| Empreintes digitales | Resists smudges | Shows prints easily |

| Maintenance | Faible | Haut |

A Closer Look at Performance Metrics

When we develop parts for our clients, especially high-touch OEM products, durability is a primary concern. The fine lines in a brushed gold finish are excellent at camouflaging the minor scuffs and abrasions that occur with daily use. This keeps the product looking new for longer.

In contrast, a polished gold surface is less forgiving. Its smooth, mirror-like surface highlights every scratch and swirl. Over time, this can detract from a product’s premium feel, requiring more careful handling by the user.

Visual and Practical Trade-offs

The visual appeal is also a major factor. Polished gold produces a sharp, mirror-like shine due to a phenomenon called Réflexion spéculaire2. This delivers a classic, high-end look but can sometimes create intense glare under direct lighting.

The brushed gold finish, however, diffuses light across its textured surface. This creates a soft, satin sheen that feels modern and subtle. It provides an elegant look without being overpowering.

From a practical standpoint, fingerprints are a significant issue. Polished gold is a magnet for smudges and requires constant cleaning to maintain its appearance. The textured, non-reflective surface of a brushed gold finish is far more forgiving, making it ideal for items that are handled frequently.

Maintenance Routine Comparison

| Type de finition | Fréquence de nettoyage | Effort Required | Application idéale |

|---|---|---|---|

| Brushed Gold | Peu fréquent | Faible | High-touch surfaces |

| Polished Gold | Fréquents | Haut | Decorative, low-contact items |

The choice between brushed and polished gold impacts more than looks. It defines durability and maintenance. Polished gold offers classic shine but requires high care, while a brushed gold finish provides modern aesthetics with superior practicality for everyday products.

How Brushed Gold Finish Impacts Consumer Perception

The rise of the brushed gold finish is more than a fleeting trend. It represents a strategic choice for premium brands. This finish consistently communicates luxury and quality.

Market data confirms its growing popularity. The consumer appeal of brushed gold hardware is strong across multiple industries. It helps elevate a product’s perceived value.

Finish and Market Perception

| Type de finition | Valeur perçue | Candidature commune |

|---|---|---|

| Chrome poli | Standard, Clean | Kitchen, Bath |

| Noir mat | Modern, Minimalist | Electronics, Fixtures |

| Brushed Gold | Premium, Warm | Luxury Goods, Decor |

This choice directly influences how customers see your product.

The Psychology Behind the Shine

The brushed gold finish taps into deep psychological associations. Gold has always signified wealth and prestige. The "brushed" texture adds a modern, sophisticated touch. It also reduces glare and hides fingerprints, making it practical and beautiful.

This trend moved from high-end interior design into consumer electronics and automotive trim. It is one of the most effective premium aesthetic surface finishes. It helps a product stand out in a crowded market, giving it an immediate visual advantage.

At PTSMAKE, we often guide clients on finish selection. The right finish can significantly lift a product’s perceived value3. This allows for better market positioning and potentially higher retail prices. Choosing a finish is a critical product design decision that extends beyond simple aesthetics.

Comparing Premium Finishes

We analyzed key attributes to help our customers decide.

| Attribut | Brushed Gold | Rose Gold | Graphite |

|---|---|---|---|

| Chaleur | Haut | Haut | Faible |

| Modernity | Moyenne-élevée | Moyen | Haut |

| Polyvalence | Haut | Moyen | Haut |

| Timelessness | Moyenne-élevée | Faible-Moyen | Moyen |

This data helps brands make informed decisions. It aligns the product’s look with the target audience’s expectations.

Choosing a brushed gold finish is a data-driven decision. It’s a powerful tool for enhancing a product’s premium appeal. This strategic choice influences consumer perception, brand positioning, and ultimately, sales success. It’s more than aesthetics; it’s smart business.

Top Surface Treatment Techniques To Achieve Brushed Gold Effect

Achieving a true brushed gold finish involves more than just color. It’s about texture and durability. Different industrial processes offer distinct results. Understanding them is key.

You need to know how to achieve a brushed gold finish that meets your project’s demands. Each method has its trade-offs.

Let’s look at the primary techniques we use.

Common Industrial Processes

- Brossage mécanique

- Placage électrolytique

- Anodisation

- Dépôt physique en phase vapeur (PVD)

The choice depends on the base material, budget, and required performance.

| Technique | Avantage principal | Meilleur pour |

|---|---|---|

| Brossage | Creates authentic texture | Base texture creation |

| Placage | Traditional gold appearance | Pièces décoratives |

| Anodisation | Bon pour l'aluminium | Colored aluminum parts |

| PVD | Durabilité extrême | Applications à forte usure |

Knowing how to achieve a brushed gold finish starts with the core industrial processes. Each method offers a different balance of appearance, durability, and cost. At PTSMAKE, we guide clients through these options to find the perfect fit.

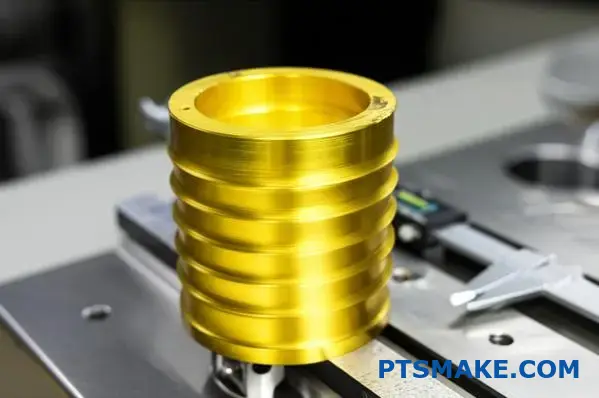

Mechanical Brushing: The Foundation

First, mechanical brushing creates the signature linear texture. This is a physical abrasion process. It’s often the first step before applying a gold-colored coating. The grit of the brush determines the final texture’s fineness.

Coating and Coloring Methods

After brushing, a color layer is applied. Electroplating involves depositing a thin layer of real gold alloy. This gives a classic look but may be less durable for high-wear items. Anodizing is an electrochemical process specific to aluminum. It creates a durable, porous oxide layer that is then dyed gold.

The most robust option is PVD. PVD brushed gold coating methods deposit a thin, hard ceramic layer, like titanium nitride. This is done in a vacuum chamber. This process often uses sputtering4 to transfer the coating material atom by atom, creating an incredibly resilient finish.

| Méthode | Durabilité | Cohérence des couleurs | Substrate Limitation |

|---|---|---|---|

| Placage électrolytique | Modéré | Bon | La plupart des métaux |

| Anodisation | Haut | Très bon | Aluminium seulement |

| Revêtement PVD | Très élevé | Excellent | Most Metals, some Plastics |

Understanding these industrial processes—brushing, plating, anodizing, and PVD—is crucial. Your choice impacts the product’s final look, durability, and cost. Each technique offers a unique path to achieving the desired brushed gold finish for specific applications.

Secrets To Long-Lasting Brushed Gold Finishes For High-Touch Products

The true secret to a durable brushed gold finish lies in the details you can’t see. It’s about more than just the color.

It involves precise control over coating thickness and strategic use of protective layers. These elements are critical.

Le rôle de l'épaisseur du revêtement

Thickness directly impacts wear resistance. A thicker coating isn’t always better; it must be optimized for the product’s use.

Trouver le bon équilibre

For high-touch items, a balance is key. Too thin, and it wears quickly. Too thick, and it might chip or alter dimensions.

| Type d'application | Épaisseur recommandée (microns) | Raison d'être |

|---|---|---|

| Decorative (Low-Touch) | 1-3 µm | Sufficient for appearance |

| Électronique grand public | 3-7 µm | Balances durability and cost |

| High-Touch Hardware | 7-15 µm | Maximum wear resistance |

To achieve truly abrasion-resistant gold coatings, we must look beyond just the gold layer itself. Scratch resistance and protective top coats are just as crucial. They work together to shield the finish from daily wear and tear.

Understanding Scratch Resistance

We measure scratch resistance using standardized tests. This gives us objective data on a finish’s durability. After our internal testing, we found that certain PVD processes significantly outperform traditional plating in this area.

A higher rating means the surface can withstand more physical abuse. This is vital for items like door handles, faucets, and electronic device casings.

Protective Top Coating Strategies

A top coat is a transparent layer applied over the brushed gold finish. It acts as the first line of defense. The right top coat seals the finish, enhancing its resilience without altering the brushed look.

We often recommend specific top coats based on the product’s intended environment and use case.

| Top Coat Type | Principaux avantages | Application idéale |

|---|---|---|

| E-coating (Clear) | Excellente résistance à la corrosion | Faucets, bathroom hardware |

| PVD Clear Coat | Highest scratch resistance | Luxury watches, phone casings |

| Acrylic Lacquer | Cost-effective protection | Interior decorative items |

These strategies ensure the final product has a durable brushed gold finish. The product’s propriétés tribologiques5 are significantly improved, which is essential for any high-touch surface. Choosing the right combination of base coating and top coat is a science we’ve refined through many projects at PTSMAKE.

A durable brushed gold finish depends on a system: optimal coating thickness, verified scratch resistance, and a strategic protective top coat. These elements work together to ensure the product’s appearance and function endure over time, even with frequent use.

What Finishing Tolerances Matter In Brushed Gold CNC Machined Parts?

For a brushed gold finish, surface texture is everything. It’s not just about the final look. It also impacts how the part feels and performs.

The Ra value is a common focus. This number measures the average roughness of a surface. It is a critical metric for brushed gold surface finish Ra requirements.

Why Ra Defines the Look

A lower Ra value means a smoother surface. But the brushing process adds a specific texture. The real goal is achieving a consistent, uniform appearance, not just ultimate smoothness.

Based on our tests with clients, different Ra values produce distinct aesthetic results.

| Aesthetic Goal | Gamme de Ra typique (μm) | Résultat visuel |

|---|---|---|

| Standard Satin | 0.4 - 0.8 | Classic, soft brushed look |

| Premium Luxury | 0.2 – 0.4 | Finer lines, more reflective |

| Textured Industrial | 0.8 - 1.6 | Coarser, more pronounced lines |

While Ra is a great starting point, it doesn’t tell the whole story. The direction and consistency of the brush lines—known as "lay"—are just as critical for a high-quality brushed gold finish.

Lay: The Directional Component

The brushing process creates a directional grain. This controlled anisotropie6 is what defines the signature brushed look. All lines must be parallel, uniform, and free of defects.

An incorrect lay can make an expensive part look flawed. This happens even if the Ra value is perfectly within specification.

Combining Measurement and Visuals

At PTSMAKE, we use a two-part process. First, a profilometer gives us precise Ra data to confirm we meet the technical drawing requirements.

Second, our quality team performs a visual inspection under specialized lighting. They check for consistent color, depth, and uniformity of the brush lines. This ensures the part looks exactly as the designer intended.

| Méthode d'inspection | Objectif principal | Principaux avantages |

|---|---|---|

| Surface Profilometer | Ra (Roughness Average) | Quantitative data for process control |

| Inspection visuelle | Lay, color, consistency | Qualitative check for aesthetic intent |

| Lightbox Evaluation | Uniformité des couleurs | Ensures consistency across a batch |

Achieving a perfect brushed gold finish requires balancing Ra specifications with visual standards. The direction and consistency of the brush lines are just as crucial as the measured roughness. Both metrology and expert inspection are essential for ensuring superior quality.

How Brushed Gold Enhances Brand Value In High-End Products

The brushed gold finish is moving beyond traditional luxury goods. It is now a powerful tool for brand elevation in unexpected sectors.

I’ve seen this shift firsthand. Companies in robotics, IoT, and lifestyle electronics are using it. This finish signals premium quality.

It transforms a functional device into a statement piece. This is crucial for brands targeting high-end markets. It’s about creating an experience.

| Aspect | Standard Tech Finishes | Luxury Product Finishes (Brushed Gold) |

|---|---|---|

| Perception de l'utilisateur | Utilitarian, functional | Exclusive, sophisticated |

| Message de la marque | Performance-focused | Lifestyle-oriented, premium |

| Target Market | General consumers | Discerning, affluent buyers |

This approach helps products stand out. It creates a perception of superior value before the device is even turned on.

The strategic use of a brushed gold finish is a smart branding move. It communicates a brand’s commitment to quality and design excellence instantly. This finish goes beyond simple color choice.

Redefining High-Tech Aesthetics

In robotics, accents of brushed gold on a precision machine create a stunning contrast. It suggests cutting-edge technology fused with master craftsmanship. This elevates the product’s perceived value significantly. It helps justify a higher price point in a competitive field.

For IoT housings, the goal is seamless integration into a home. A brushed gold finish transforms a smart hub from a plastic gadget into elegant decor. It no longer needs to be hidden.

The Tactile Dimension of Luxury

Lifestyle electronics, like headphones or speakers, benefit immensely. The visual warmth of brushed gold combined with its subtle texture enhances the user’s sensory experience. This tactile quality, or [Haptic Perception]()7, is key to luxury branding. It makes the product feel substantial and well-made.

| Secteur | Approche standard | Brushed Gold Advantage |

|---|---|---|

| Robotique | Industrial gray/white | Signals premium engineering |

| IoT Devices | Inconspicuous plastic | Becomes a design feature |

| Électronique | Black/silver matte | Creates an emotional connection |

At PTSMAKE, we help brands achieve this effect. We ensure the finish is perfectly executed, reflecting the premium quality of the product inside. This attention to detail is what builds a luxury brand.

Applying a brushed gold finish transforms high-tech products from functional tools into luxury lifestyle statements. This aesthetic choice directly supports brand elevation, allowing companies in robotics and electronics to access premium market segments and command higher value.

Unlocking Customization: Color Matching And Texture Control In Brushed Gold

Achieving the perfect look isn’t just about choosing "gold." True customization lies in the details. It’s about defining the exact hue and texture. This creates a truly unique brushed gold finish.

Tailoring the Gold Spectrum

We can produce a range of custom brushed gold tones. This allows designers to match specific brand colors or aesthetic goals precisely. From subtle champagne to rich yellow gold.

| Gold Tone | Élément d'alliage primaire | Candidature commune |

|---|---|---|

| Or champagne | Palladium or Nickel | Modern, subtle fixtures |

| Yellow Gold | Silver and Copper | Classic, traditional hardware |

| Rose Gold | Cuivre | Trendy, decorative accents |

Defining the Texture

Beyond color, the brushing pattern itself is a key variable. The direction, depth, and consistency of the lines dramatically alter the final appearance and light reflection.

True mastery of color matched brushed metal finishes comes from understanding the underlying science. It’s not just about applying a color; it’s about fundamentally altering the surface properties to achieve a specific, repeatable result. At PTSMAKE, we focus on process control to guarantee consistency.

Achieving Specific Hues

Color is primarily controlled through the finishing process. While base material alloys play a role, surface treatments offer the most flexibility. We often use Dépôt physique en phase vapeur8 (PVD) to apply a thin, durable layer.

By adjusting the target material and gases inside the PVD chamber, we can create precise hues. For rose gold, a titanium and aluminum nitride mix with a specific gas ratio is used. For champagne, the composition is different. This allows for an almost infinite spectrum of custom brushed gold tones.

Controlling Brushing Patterns

Texture control is a mechanical process requiring equal precision. We manipulate several factors to create the desired effect, from fine, satin-like finishes to bold, linear patterns. Our tests show that these parameters are critical.

| Paramètres | Effet sur la finition |

|---|---|

| Abrasive Grit Size | Finer grit creates a softer, satin look. |

| Brushing Speed | Higher speeds can produce a smoother finish. |

| Applied Pressure | More pressure creates deeper, more defined lines. |

| Brush Direction | Can be linear, circular, or cross-hatched. |

This systematic approach ensures that every part we produce meets the exact visual and tactile specifications required by the design.

Achieving a precise brushed gold finish requires expert control over color and texture. By manipulating alloy composition, PVD parameters, and mechanical brushing techniques, manufacturers can deliver highly customized components that meet exact design specifications for any project.

PVD vs Electroplating: Which Method Delivers Superior Brushed Gold?

When choosing a finish, time is a critical factor. So is the final quality and your ability to scale production. The choice between PVD and electroplating often comes down to these three pillars.

Let’s break down how they stack up. This quick electroplated brushed gold comparison provides a high-level view.

| Fonctionnalité | PVD (Physical Vapor Deposition) | Placage électrolytique |

|---|---|---|

| Vitesse du processus | Slower batch process | Faster for high volume |

| Qualité de la finition | Highly consistent, uniform | Can have inconsistencies |

| Évolutivité | Excellent for various volumes | Best for large-scale runs |

A PVD brushed gold finish offers superior consistency. But electroplating can be faster for massive orders.

Diving deeper, the differences become more apparent. The right choice depends entirely on your project’s specific needs and priorities. It’s not just about speed, but about predictable outcomes.

Process Duration Explained

PVD is a batch process. Loading parts into a vacuum chamber, creating the vacuum, and running the coating cycle takes a few hours. This makes the per-piece time seem long for small runs.

Electroplating, however, is often a continuous or semi-continuous process. Parts move along a line through various chemical baths. This results in a faster output per individual part, especially in high-volume manufacturing.

A Closer Look at Finish Quality and Scalability

The quality of a PVD brushed gold finish is its key strength. The process is highly controlled within the vacuum chamber. This results in an exceptionally uniform and repeatable coating.

Electroplating quality relies on constant monitoring of chemical baths. Any fluctuation in chemical balance or current can affect the finish. This can lead to variations in color and thickness across a large batch. The stoichiometry9 of the deposited layer is harder to control.

This table details the nuances we’ve observed in our tests.

| Aspect | PVD Details | Electroplating Details |

|---|---|---|

| Batch Time | 2-4 hours per cycle (includes setup) | Continuous flow, faster part-by-part |

| Contrôle de la qualité | Digital process control ensures high consistency | Relies on chemical bath monitoring, can vary |

| Volume Sweet Spot | Low to high volume, flexible | Best suited for very high, continuous volume |

So, PVD scales flexibly by adding more production cycles. Electroplating scales by enlarging the entire production line for massive, continuous runs.

Your choice hinges on project priorities. PVD provides unmatched finish consistency and is adaptable for various volumes. Electroplating offers a clear speed advantage for large-scale production where minor variations might be acceptable.

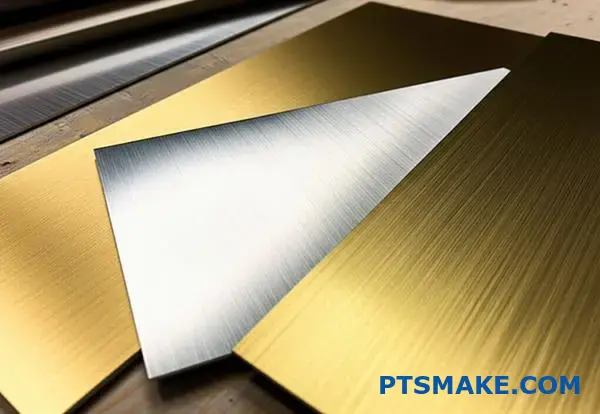

Choosing The Right Substrate Material For A Perfect Brushed Gold Look

The base metal you choose is not just a foundation. It’s a critical ingredient that shapes the final look. The material underneath dramatically influences the warmth, hue, and texture of a brushed gold finish.

Thinking about the best substrate for a brushed gold finish is essential. Your choice impacts more than just appearance. It also affects durability and cost.

Substrate’s Role in Aesthetics

Different metals interact with gold coatings uniquely. This interaction changes the final color. It also affects how light reflects off the surface. A poor choice can ruin the intended design.

Quick Comparison: Base Metals

| Fonctionnalité | Aluminium | Acier inoxydable |

|---|---|---|

| Final Tone | Warmer, Softer Yellow | Cooler, Sharper Gold |

| Texture | Softer Lines | Crisper Brushes |

| Poids | Léger | Plus lourd |

When we talk about achieving the perfect brushed gold finish, the conversation must start with the substrate. The base metal dictates the final character of the product. Two common choices we often work with at PTSMAKE are aluminum and stainless steel. Each brings a distinct personality to the gold finish.

Aluminum: For a Warmer Look

Aluminum is naturally softer and has a slight warmth. This quality translates to the final finish. A brushed gold finish on aluminum often appears richer and deeper. The brushing lines can also look softer.

This material’s unique surface free energy10 affects coating adhesion. It results in a very uniform and consistent appearance. It’s an excellent choice for decorative parts where a luxurious, warm tone is desired.

Stainless Steel: For a Cooler Finish

Stainless steel, on the other hand, is harder and has a cool, almost blueish undertone. This base gives the brushed gold finish a crisper, more contemporary feel. The color can appear brighter and more reflective.

The hardness of steel allows for very sharp and defined brush lines. This makes it ideal for modern designs. It’s often used in high-wear applications due to its superior durability.

Detailed Substrate Impact Analysis

Based on our tests, here’s a more detailed breakdown:

| Caractéristique | Aluminum Substrate | Stainless Steel Substrate |

|---|---|---|

| Color Hue | Warmer, slightly reddish-yellow | Cooler, bright, modern yellow |

| Brushing Detail | Softer, more blended lines | Sharper, more defined lines |

| Réflexion de la lumière | Diffused, satin-like sheen | Crisp, higher reflectivity |

| Meilleur pour | Decorative trim, consumer electronics | Fixtures, architectural elements |

The substrate is not a passive carrier. It actively shapes the final brushed gold finish. Aluminum creates a warm, soft aesthetic, while stainless steel produces a cool, sharp look. Your choice fundamentally defines the product’s final color, texture, and character.

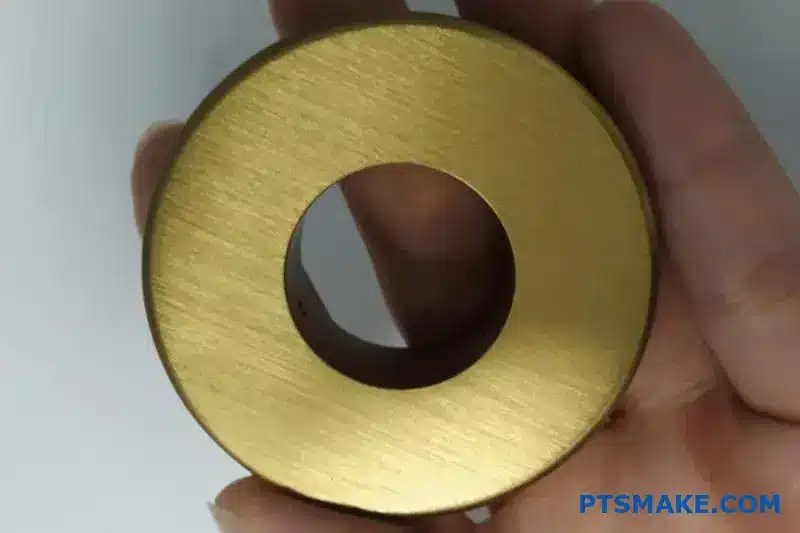

Tolerance Stack-Up Concerns When Combining Brushed Gold With CNC Machining

When designing dimension-critical parts, many engineers overlook a key detail. The surface finish is not just for appearance.

A brushed gold finish adds a tangible layer of material. This added thickness directly impacts the final dimensions.

This is crucial for tight CNC part tolerances. If a part is machined to its nominal size, the finish can push it outside the acceptable range. This can cause major assembly problems later on.

| Fonctionnalité | Dimension Before Finish | Dimension After Finish |

|---|---|---|

| Diamètre extérieur | 50.00 mm | 50.05 mm |

| Inner Hole | 10.00 mm | 9.95 mm |

This seemingly small change is where tolerance issues begin.

The thickness of a brushed gold finish is not perfectly uniform. It can vary based on the part’s shape and the plating process itself. This variability adds another layer of complexity to achieving precise CNC part tolerances.

Corners and edges might accumulate more plating. Recessed areas or deep holes might receive less. This inconsistency can be a hidden source of failure for parts that need to fit together perfectly. At PTSMAKE, we always clarify if dimensions are pre- or post-plating.

Le Substrate geometry11 plays a significant role in how evenly the coating is applied. Failing to account for this can lead to unexpected interference fits or loose connections.

| Fonctionnalité | Specified Tolerance | Finish Variation | Potential Mismatch |

|---|---|---|---|

| Diamètre de l'arbre | +/- 0.02 mm | +/- 0.01 mm | Up to 0.03 mm |

| Alésage du palier | +/- 0.02 mm | +/- 0.01 mm | Up to 0.03 mm |

This table shows how a small finish variation can consume a significant portion of the total tolerance budget. This is a classic example of tolerance stack-up.

The thickness of a brushed gold finish is a critical dimensional feature, not just a cosmetic layer. It must be factored into all CNC part tolerances from the initial design phase to prevent costly assembly failures and ensure proper functionality.

Brushed Gold Finish For MedTech: Cleanroom And Wear Standards

In MedTech, a finish isn’t just about looks. It’s about safety and performance. Medical brushed gold finish compliance is non-negotiable.

Parts must meet stringent standards. This ensures they are safe for patient contact. It also guarantees they function correctly in sterile environments.

Principaux cadres réglementaires

We must consider several key standards. Each one addresses a different aspect of medical device safety and quality.

| Standard | Objectif principal | Relevance to Brushed Gold Finish |

|---|---|---|

| ISO 13485 | Systèmes de gestion de la qualité | Ensures process control and traceability. |

| ISO 10993 | Biocompatibilité | Confirms material safety for patient contact. |

| ISO 14644 | Salles blanches | Dictates cleanliness levels during manufacturing. |

These regulations guide every step. From material selection to final packaging, compliance is paramount for any brushed gold finish.

When we talk about medical brushed gold finish compliance, we’re navigating a complex landscape. It’s not enough for a part to look good. It must perform safely under demanding clinical conditions. This is where specific international standards become our roadmap.

Biocompatibility and Surface Interaction

The most critical standard is ISO 10993. This series of standards evaluates the Biocompatibilité12 of materials. It ensures that the device, including its brushed gold surface, will not cause adverse reactions when in contact with the human body. This involves testing for cytotoxicity, sensitization, and irritation.

Our process at PTSMAKE validates that the plating and finishing steps introduce no harmful residues.

Cleanroom Manufacturing Protocols

For devices used in sterile fields, ISO 14644 is key. This standard governs the classification of air cleanliness in cleanrooms. Manufacturing a brushed gold part destined for a surgical tool means controlling particulates at every stage.

| Compliance Area | Exigence | Impact on Brushed Gold Finish |

|---|---|---|

| Approvisionnement en matériaux | Medical-Grade Substrates | Ensures underlying material is safe. |

| Plating Process | Controlled Chemistry | Prevents leaching of toxic elements. |

| Final Cleaning | Validated Procedures | Removes all manufacturing residues. |

| Emballage | Cleanroom Environment | Maintains sterility until use. |

We handle these parts in certified cleanroom environments. This prevents contamination that could compromise patient safety. It’s a level of detail that defines medical-grade manufacturing.

Achieving a compliant brushed gold finish requires strict process control. Adherence to ISO 10993 and ISO 14644 is essential. This guarantees patient safety and device integrity within sterile medical settings, which is our top priority.

When To Use Brushed Gold Instead Of Anodized Champagne Finishes

Choosing between gold-toned finishes can be tough. It’s more than just color. It involves material, process, and desired performance. Engineers need to weigh these factors carefully.

The debate of brushed gold vs anodized finish is common. Each has its place.

Key Visual Differences

A brushed gold finish provides a classic, rich metallic look. Anodized champagne offers a more modern, subtle sheen. The choice impacts the final product’s feel.

| Fonctionnalité | Brushed Gold | Anodized Champagne |

|---|---|---|

| Esthétique | Warm, traditional | Cool, contemporary |

| Texture | Fine directional lines | Smooth, matte |

| Material Feel | Plated metal feel | Integral aluminum |

Understanding these distinctions is the first step in making the right call for your project. It sets the tone for the entire design.

The decision goes beyond appearance. It’s fundamentally about the manufacturing process and material compatibility. This is where we guide our clients most.

A true brushed gold finish is typically a secondary process. It’s often applied over materials like stainless steel or brass. Processes like PVD coating or electroplating are used.

Anodizing, however, is an electrochemical process. It is exclusive to aluminum. It converts the metal surface into a durable, corrosion-resistant, anodic oxide finish. The finish is integral to the aluminum [substrate](error code: 500)13, not just a coating.

Technical Comparison

Here at PTSMAKE, we help clients evaluate the technical trade-offs. The best choice depends entirely on the application’s specific requirements.

| Spécifications | Brushed Gold (PVD/Plating) | Anodized Champagne |

|---|---|---|

| Durabilité | High (Varies by process) | Excellent (Harder than base aluminum) |

| Matériau | Steel, Brass, Zinc, etc. | Aluminium seulement |

| Coût | Généralement plus élevé | More cost-effective for aluminum |

| Cohérence | Can have slight variations | Highly repeatable and uniform |

The brushed gold vs anodized finish decision hinges on these points. If you’re not using aluminum, anodizing isn’t an option. If durability on aluminum is key, anodizing is a strong contender.

Your choice between a brushed gold finish and anodized champagne depends on the base material, budget, and desired durability. Brushed gold offers classic appeal on various metals, while anodizing provides an integrated, tough finish specifically for aluminum parts.

Elevate Your Projects with PTSMAKE’s Brushed Gold Finish Experts

Ready to achieve flawless brushed gold finish for your next hardware or OEM project? Contact PTSMAKE now for a fast, precise, and reliable quote! Let our 20+ years of experience in CNC machining and finishing deliver the premium quality your brand deserves.

Learn more about the electrochemical process of anodization and how it enhances metal surfaces. ↩

Understand how different light reflections can influence the perceived quality and user experience of your final product. ↩

Learn how this psychological concept influences purchasing decisions and product pricing strategies. ↩

Explore this advanced coating technique to understand its impact on surface durability and performance. ↩

Learn how these properties impact the wear and friction resistance of your product’s surface finish. ↩

Learn how this directional property affects the visual appeal and reflectivity of brushed metal surfaces. ↩

Discover how a product’s texture and feel influence a customer’s perception of its overall quality and worth. ↩

Learn the technical details of how this coating process achieves consistent, durable colors on metal parts. ↩

Learn how precise material ratios in coatings affect durability and color consistency in your final product. ↩

Learn how this property influences coating adhesion and the quality of your final finish. ↩

Learn how the part’s initial shape influences final coating uniformity and dimensional accuracy. ↩

Understand the essential tests that ensure materials are safe for human contact. ↩

Learn how the base material’s properties influence the selection and performance of surface finishes. ↩