¿Qué es el mecanizado CNC de alto volumen?

¿Alguna vez ha necesitado miles de piezas idénticas y se ha encontrado con que el aumento de la producción introduce incoherencias y una espiral de costes? Ese prototipo inicial era perfecto, pero la producción en serie parece un reto totalmente distinto.

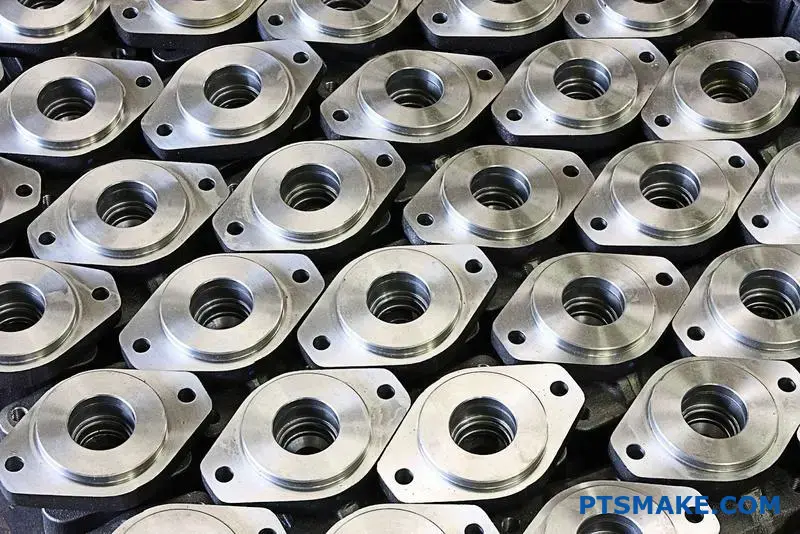

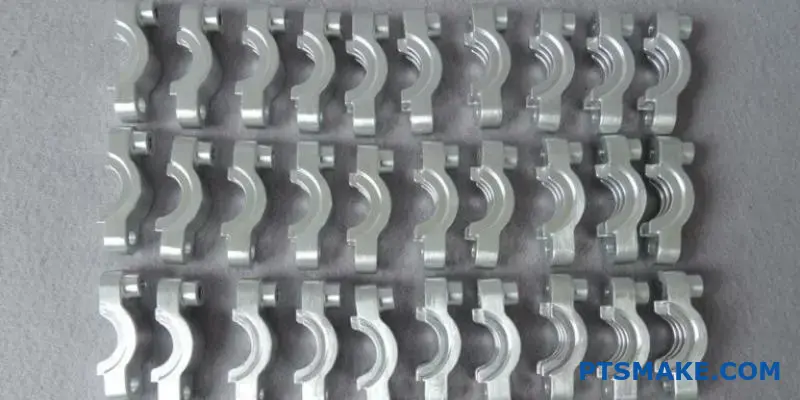

El mecanizado CNC de alto volumen es un proceso de fabricación que utiliza equipos automatizados y controlados por ordenador para producir rápidamente grandes cantidades de piezas idénticas. Es el método ideal para conseguir precisión, uniformidad y rentabilidad cuando se pasa de prototipos a la producción a gran escala.

En esencia, el mecanizado CNC de gran volumen se basa en la eficacia y la repetibilidad. El proceso se basa en gran medida en la automatización para minimizar la intervención humana y maximizar el rendimiento. Una vez que una máquina CNC está programada y equipada para una pieza específica, puede funcionar de forma continua, produciendo miles de componentes que son prácticamente indistinguibles unos de otros. Esto es fundamentalmente diferente del mecanizado de prototipos o de bajo volumen, en el que los ajustes son frecuentes y la atención se centra en la flexibilidad más que en la velocidad. El objetivo principal es reducir el Duración del ciclo1 para cada parte en la medida de lo posible.

Diferencias clave: Alto volumen frente a bajo volumen

| Característica | Mecanizado de gran volumen | Mecanizado de bajo volumen |

|---|---|---|

| Cantidad | De 1.000 a más de 1.000.000 | De 1 a 1.000 |

| Coste por pieza | Muy bajo | Alta a media |

| Coste de instalación | Alta | Bajo |

| Plazos de entrega | Inicial más largo, posterior más rápido | Rápida configuración inicial |

¿Por qué eligen las empresas este método? La principal razón son las economías de escala. Aunque la inversión inicial en programación, utillajes y herramientas a medida es mayor, el coste por pieza individual disminuye significativamente a medida que aumenta el volumen de producción. En los proyectos que hemos gestionado en PTSMAKE, este método se convierte en la opción más lógica cuando una empresa ha validado su diseño y está lista para entrar en el mercado a gran escala. Es una decisión estratégica que equilibra los costes iniciales con el ahorro a largo plazo y la eficiencia de la producción.

Cuándo elegir el mecanizado CNC de alto volumen

Escenarios ideales

- Lanzamiento de productos: Cuando se introduce un nuevo producto en un mercado de masas.

- Demanda estable: Para piezas con una demanda constante y continuada.

- Reducción de costes: Para reducir el coste por unidad de un componente probado.

Este planteamiento es crucial para sectores como la automoción, la electrónica de consumo y los dispositivos médicos, en los que grandes cantidades de piezas de alta precisión son un requisito constante de las cadenas de montaje.

El mecanizado CNC de gran volumen utiliza la automatización para producir miles de piezas precisas e idénticas de forma eficaz. Aunque conlleva unos costes de configuración iniciales más elevados, este método proporciona importantes economías de escala, reduciendo drásticamente el precio por unidad para series de producción a gran escala en las que la uniformidad es primordial.

Principales ventajas para los directores de fabricación

¿Tiene problemas con la calidad irregular y los plazos de entrega impredecibles en grandes series de producción? ¿Estos problemas descarrilan constantemente su presupuesto y sus plazos de entrega, creando un estrés innecesario para su equipo?

El mecanizado CNC de alto volumen aborda directamente estos retos ofreciendo una velocidad inigualable, una calidad constante y una importante rentabilidad. Reduce drásticamente los plazos de entrega, minimiza la variación entre piezas y disminuye el coste por unidad, todo ello manteniendo un estricto cumplimiento de sus especificaciones.

Rapidez y coherencia gracias a la automatización

La principal ventaja del mecanizado CNC de gran volumen reside en su automatización. Una vez cargado un programa, una máquina puede funcionar continuamente, lo que reduce drásticamente los plazos de producción. Esta misma automatización es la clave de la calidad. Cada pieza se produce a partir del mismo archivo digital exacto, lo que elimina el error humano y la variabilidad habituales en los procesos manuales. Esto garantiza que la máquina precisión volumétrica2 se traduce en cada uno de los componentes, garantizando que cada pieza, desde la primera hasta la diez milésima, cumpla las especificaciones requeridas sin desviaciones. Esto es fundamental para cualquier producción a gran escala en la que la coherencia no sea negociable.

| Métrica | Operaciones manuales | Mecanizado CNC de gran volumen |

|---|---|---|

| Coherencia entre piezas | Bajo | Extremadamente alto |

| Velocidad de producción | Lento | Rápido |

| Potencial de error | Alta | Muy bajo |

| Intensidad laboral | Alta | Baja (Supervisión) |

Rentabilidad y escalabilidad

Aunque hay una inversión inicial en programación y configuración, el coste por pieza en el mecanizado CNC de gran volumen disminuye significativamente a medida que aumenta la cantidad. Este principio de economías de escala es poderoso. La automatización reduce los costes directos de mano de obra, las trayectorias de herramienta optimizadas minimizan el desperdicio de material y la consistencia excepcional casi elimina los gastos por desechos o repeticiones. Esto la convierte en una opción económicamente sólida para grandes pedidos. Además, la escalabilidad está integrada en el proceso. Una vez validado un programa, aumentar la producción es tan sencillo como ejecutarlo en más máquinas o durante más horas. En nuestro trabajo en PTSMAKE, a menudo guiamos a los clientes desde un prototipo verificado hasta la producción a gran escala utilizando el mismo diseño digital, lo que garantiza un aumento predecible y eficiente.

Para los directores de fabricación, el mecanizado CNC de gran volumen ofrece una potente combinación de ventajas. Proporciona velocidad y calidad inquebrantable gracias a la automatización, reduce los costes por pieza y ofrece una escalabilidad perfecta para satisfacer la demanda fluctuante, lo que lo convierte en una piedra angular de la producción moderna y eficiente.

Industrias que dependen del mecanizado CNC de gran volumen?

¿Se ha preguntado alguna vez cómo consiguen escalar las industrias que exigen millones de piezas idénticas y perfectas? Para ellas, un solo fallo no es sólo un defecto; es un fallo crítico con graves consecuencias.

El mecanizado CNC de alto volumen es la espina dorsal de sectores críticos como el aeroespacial, la automoción, la medicina y la electrónica. Estas industrias dependen de él para producir cantidades masivas de componentes altamente precisos, fiables y complejos, esenciales para la seguridad, el rendimiento y la innovación.

La demanda de precisión es implacable en sectores en los que el fallo no es una opción. El mecanizado CNC de alto volumen responde a este reto ofreciendo uniformidad en millones de piezas, una de las principales razones por las que en PTSMAKE hemos invertido tanto en esta tecnología.

Aeroespacial: Superar los límites de la precisión

En el sector aeroespacial, todos los componentes, desde los álabes de turbina hasta las piezas del tren de aterrizaje, deben cumplir especificaciones extremas. Esta industria confía en el mecanizado CNC por su capacidad para trabajar con aleaciones avanzadas y crear geometrías complejas con tolerancias ajustadas, garantizando que cada pieza sea apta para el vuelo. Completo trazabilidad de los materiales3 también es obligatorio.

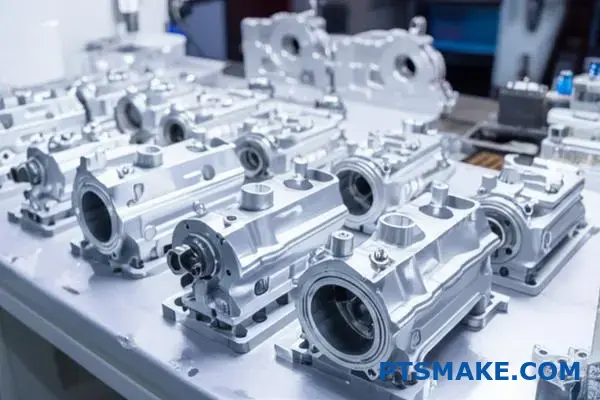

Automoción: Eficiencia a gran escala

La industria del automóvil necesita millones de piezas fiables al año, desde bloques de motor hasta componentes de transmisión. El mecanizado CNC de alto volumen proporciona la velocidad y repetibilidad necesarias para esta escala, manteniendo las líneas de producción en movimiento y los costes competitivos.

| Industria | Requisito clave | Materiales comunes |

|---|---|---|

| Aeroespacial | Precisión y fiabilidad extremas | Titanio, Inconel, aleaciones de aluminio |

| Automoción | Escalabilidad y rentabilidad | Acero, aluminio, hierro fundido |

La necesidad de precisión en grandes volúmenes va mucho más allá del transporte. Por nuestra experiencia en proyectos, los sectores médico y electrónico también dependen en gran medida de este proceso para la innovación y la fiabilidad.

Dispositivos médicos: Mecanizado para la salud y la seguridad

Desde herramientas quirúrgicas personalizadas hasta implantes que salvan vidas, como los marcapasos, el campo de la medicina exige una perfección absoluta. El mecanizado CNC es crucial para crear estos intrincados dispositivos a partir de materiales biocompatibles como el titanio y el PEEK, garantizando que sean seguros y eficaces para el uso de los pacientes a la vez que cumplen estrictas normas reglamentarias.

Electrónica: La escala de la miniaturización

Mire en el interior de cualquier smartphone u ordenador portátil y encontrará innumerables componentes diminutos y complejos. El mecanizado CNC de alto volumen produce las carcasas metálicas, los conectores y los disipadores de calor que son esenciales para el rendimiento y la durabilidad de la electrónica de consumo moderna, satisfaciendo la enorme demanda mundial.

| Industria | Requisito clave | Materiales comunes |

|---|---|---|

| Médico | Biocompatibilidad y esterilizabilidad | Titanio, PEEK, acero inoxidable |

| Electrónica | Miniaturización y estética | Aluminio, cobre, plásticos |

Desde componentes aeroespaciales hasta implantes médicos, las industrias confían en el mecanizado CNC de alto volumen por su precisión y escalabilidad sin igual. Este proceso es esencial para crear los componentes complejos y fiables que impulsan la tecnología moderna y garantizan la seguridad en aplicaciones críticas en todo el mundo.

Garantizar la calidad y la coherencia en grandes tiradas?

¿Alguna vez le ha preocupado que la pieza número diez mil no sea idéntica a la primera? Este temor puede poner en peligro líneas de producción enteras y dañar la reputación de su marca.

Lo conseguimos mediante rigurosos sistemas de control de calidad. Esto implica una combinación de supervisión durante el proceso, protocolos de inspección detallados y el uso de tecnología CNC avanzada para mantener tolerancias estrictas y eliminar la variabilidad en cada pieza de una tirada de producción de gran volumen.

La calidad en el mecanizado CNC de gran volumen no es accidental; está diseñada. En PTSMAKE, nuestro enfoque comienza con un sólido plan de calidad para cada proyecto. No se trata sólo de una comprobación final, sino de un proceso continuo entretejido en el tejido de la producción.

Protocolos de inspección proactiva

Aplicamos una estrategia de inspección en varias fases. Comienza con una exhaustiva Inspección del Primer Artículo (FAI) para verificar la configuración. Una vez que la producción está en marcha, utilizamos el muestreo estadístico para comprobar las piezas a intervalos regulares, garantizando la coherencia de principio a fin. La ciencia de Metrología4 es fundamental en todo este proceso, ya que garantiza que cada medición sea precisa y fiable.

| Fase de inspección | Propósito | Herramientas clave |

|---|---|---|

| Primer artículo | Verificar la configuración y el programa | MMC, Calibres, Calibradores |

| En proceso | Controlar la coherencia | Comparador óptico, Calibradores |

| Control de calidad final | Confirmar la calidad global | Todas las herramientas disponibles |

Las modernas máquinas CNC son fundamentales para mantener la coherencia en la producción a gran escala. No se limitan a seguir un programa estático; son sistemas dinámicos que gestionan y corrigen activamente las posibles desviaciones, lo que resulta crucial en proyectos exigentes.

El papel de los sistemas CNC avanzados

Nuestros avanzados sistemas utilizan circuitos de retroalimentación para eliminar la variabilidad antes de que se convierta en un problema.

Ajustes en tiempo real

Los sensores controlan en tiempo real factores como el desgaste de la herramienta y la dilatación térmica. A continuación, el sistema de control de la máquina realiza microajustes en la trayectoria de corte o la velocidad del husillo de forma automática. Este enfoque proactivo garantiza que cada pieza se mantenga dentro de las estrictas tolerancias especificadas, un aspecto innegociable del mecanizado CNC de gran volumen.

| Característica | Sistemas CNC antiguos | Sistemas CNC avanzados |

|---|---|---|

| Desgaste de herramientas | Controles manuales | Compensación automatizada |

| Precisión posicional | Adivinación en bucle abierto | Retroalimentación en bucle cerrado |

| Control de procesos | En función del operador | Ajustes en función del sistema |

Para garantizar la uniformidad en grandes tiradas, es esencial adoptar un doble enfoque. Los rigurosos protocolos de inspección proporcionan el marco, mientras que los avanzados sistemas CNC con supervisión en tiempo real y capacidad de autocorrección eliminan activamente la variabilidad, garantizando que cada pieza cumpla las especificaciones exactas de la primera a la última.

Estrategias de ahorro para proyectos CNC de gran volumen?

¿Lucha constantemente por reducir los costes unitarios en sus proyectos de gran volumen? ¿Parece que las pequeñas ineficiencias que se pasan por alto se acumulan, erosionando constantemente sus márgenes de beneficio a lo largo de una producción prolongada?

Las estrategias eficaces de ahorro de costes para el mecanizado CNC de gran volumen implican un enfoque proactivo. Mediante el mantenimiento preventivo, la inversión en herramientas de alta calidad, la optimización de los flujos de trabajo de producción y el aprovechamiento estratégico de la automatización, puede reducir significativamente los costes por unidad sin comprometer la calidad ni ampliar los plazos de entrega.

Para controlar realmente los costes en la producción de grandes volúmenes, debemos mirar más allá del precio de las materias primas. Son las eficiencias operativas -o la falta de ellas- las que a menudo tienen el mayor impacto. Descuidar el cuidado periódico de los equipos provoca paradas inesperadas, lo que resulta desastroso para los ajustados programas de producción. Según nuestra experiencia, un programa de mantenimiento proactivo es mucho menos costoso que las reparaciones de emergencia reactivas. Del mismo modo, elegir herramientas más baratas y menos duraderas es un falso ahorro. Se traduce en sustituciones frecuentes, mayores paradas de la máquina y posibles defectos de las piezas. Comprender el Tiempo medio entre fallos (MTBF)5 de sus equipos y herramientas es fundamental para construir una línea de producción fiable y rentable.

Mantenimiento preventivo frente a reparaciones reactivas

Un plan de mantenimiento estructurado es crucial. Minimiza las interrupciones inesperadas de la producción, que son especialmente costosas en el mecanizado CNC de gran volumen.

| Tipo de mantenimiento | Impacto en los costes | Impacto en la producción |

|---|---|---|

| Preventivo | Previsible, menor coste | Tiempo de inactividad programado, interrupción mínima |

| Reactivo | Coste elevado e imprevisible | Tiempo de inactividad no programado, interrupción grave |

El valor de las herramientas duraderas

Invertir en herramientas duraderas y de mayor calidad resulta rentable al reducir la frecuencia de los cambios de herramientas y mejorar la consistencia de las piezas.

Más allá del mantenimiento y el utillaje, la optimización del flujo de trabajo y la automatización son las próximas fronteras para la reducción de costes. Un flujo de trabajo racionalizado elimina los cuellos de botella y los movimientos inútiles, garantizando que cada paso, desde la manipulación del material hasta la inspección final, sea lo más eficiente posible. En PTSMAKE, analizamos continuamente nuestro flujo de producción para recortar segundos a los tiempos de ciclo, lo que se traduce en ahorros sustanciales en pedidos grandes. La automatización, ya sea mediante brazos robóticos de carga y descarga o controles de calidad automatizados, aumenta aún más esta eficiencia. Reduce los costes de mano de obra y minimiza la posibilidad de errores humanos, garantizando una calidad uniforme en decenas de miles de piezas. Así es como la fabricación moderna consigue escalabilidad y rentabilidad.

Optimización del flujo de producción

Identificar y resolver los cuellos de botella es clave. Un retraso en una estación puede paralizar toda la línea de producción.

| Estrategia | Beneficio principal | Ejemplo |

|---|---|---|

| Análisis del flujo de trabajo | Tiempo de ciclo reducido | Reorganización de trayectorias de herramientas para cortes más rápidos |

| Automatización | Mayor coherencia | Uso de un cobot para la carga repetitiva de piezas |

Aprovechar la automatización

La automatización reduce la dependencia de la mano de obra y aumenta el rendimiento, por lo que resulta ideal para proyectos de mecanizado CNC de gran volumen.

Para reducir costes en proyectos CNC de gran volumen, céntrese en estrategias proactivas. La aplicación de un mantenimiento preventivo, el uso de herramientas duraderas, la optimización de los flujos de trabajo y el aprovechamiento de la automatización reducirán el coste por unidad, al tiempo que mantendrán la alta calidad y la velocidad que esperan sus clientes.

¿Cómo seleccionar el material y el socio adecuados para piezas complejas?

¿Alguna vez se ha sentido atrapado entre las propiedades ideales de un material y su fabricabilidad? Tomar la decisión equivocada sobre el material o el proveedor puede poner en peligro toda su producción de gran volumen.

Para seleccionar el material adecuado, debe analizar sus propiedades mecánicas, térmicas y químicas en función de sus necesidades de diseño. Si busca un socio, analice sus capacidades técnicas, sus procesos de control de calidad y su experiencia demostrada en el mecanizado cnc de grandes volúmenes de piezas como la suya.

Elegir el material adecuado es fundamental. No se trata sólo de elegir una sustancia, sino de definir el rendimiento, la vida útil y el coste de la pieza. Es un acto de equilibrio que requiere un profundo conocimiento de las opciones disponibles.

Criterios clave de selección de materiales

Necesidades mecánicas y térmicas

Considere las fuerzas y temperaturas que soportará la pieza. ¿Necesitará una gran resistencia a la tracción, como el acero, o es más importante la ligereza del aluminio? En el caso de los materiales propiedades anisotrópicas6 es clave, ya que su fuerza puede variar en función de la dirección de la fuerza.

Fabricabilidad frente a coste

Algunos materiales de alto rendimiento son notoriamente difíciles de mecanizar, lo que aumenta los tiempos de ciclo y los costes, especialmente en tiradas de gran volumen. A menudo ayudamos a los clientes a encontrar un material que cumpla 95% sus especificaciones de rendimiento ideales, pero que sea 30% más fácil de mecanizar.

| Material | Característica principal | Lo mejor para |

|---|---|---|

| Aluminio 6061 | Excelente relación resistencia-peso | Bastidores aeroespaciales y de automoción |

| Acero inoxidable 304 | Alta resistencia a la corrosión | Equipamiento médico y alimentario |

| PEEK | Rendimiento a altas temperaturas | Piezas industriales exigentes |

Una vez elegido el material, la selección del socio es igual de importante. El mejor material en manos de un proveedor incapaz dará lugar a piezas desechadas y retrasos en el proyecto. Un buen socio actúa como una extensión de su propio equipo de ingeniería.

Evaluación de un socio de mecanizado CNC

Experiencia técnica y equipos

¿Dispone el socio potencial de la tecnología adecuada? Para geometrías complejas, el mecanizado CNC de 5 ejes suele ser innegociable. En PTSMAKE, nuestra inversión en maquinaria avanzada está impulsada por los complejos retos que nos plantean nuestros clientes. Pida ver su lista de equipos y conozca sus capacidades.

Sistemas de calidad y escalabilidad

¿Cómo garantizan la calidad desde la primera pieza hasta la última en un pedido de mecanizado cnc de gran volumen? Busque sistemas de gestión de calidad sólidos, como la certificación ISO 9001.

| Área de evaluación | En qué fijarse | Por qué es importante |

|---|---|---|

| Lista de equipos | Máquinas CNC de 5 ejes | Permite crear geometrías complejas |

| Certificados de calidad | ISO 9001, AS9100 | Garantiza la coherencia y fiabilidad del proceso |

| Proyectos anteriores | Cartera con piezas similares | Demuestra experiencia práctica y pertinente |

El éxito de la producción de piezas complejas depende de dos decisiones clave: seleccionar el material adecuado equilibrando el rendimiento con la fabricabilidad, y elegir un socio con la experiencia técnica y los sistemas de calidad probados para ofrecer un rendimiento constante, especialmente en pedidos de gran volumen.

¿Cómo elegir el socio de mecanizado CNC adecuado?

¿Se siente abrumado intentando encontrar un socio de mecanizado CNC que realmente pueda adaptarse a su proyecto, desde un único prototipo hasta miles de unidades?

Elegir al socio adecuado significa evaluar su experiencia con pedidos de gran volumen, valorar sus equipos y sistemas de calidad y asegurarse de que apoyan todo el ciclo de vida del producto, desde la creación de prototipos hasta la producción a gran escala.

A la hora de elegir un proveedor, es fundamental que sea capaz de gestionar pedidos de gran y pequeño volumen. Un socio que destaque en la creación de prototipos pero flaquee en la producción en serie crea un importante cuello de botella. La transición debe ser perfecta. Esto requiere no sólo maquinaria avanzada, sino procesos establecidos para la escalabilidad. Según nuestra experiencia en PTSMAKE, un verdadero socio mantiene una calidad y precisión constantes desde la pieza uno hasta la diez mil. Comprenden que el éxito de una operación de mecanizado CNC de gran volumen depende de los siguientes factores metrología7 y controles establecidos durante la fase inicial del prototipo.

Evaluación de la capacidad de producción

| Tipo de socio | Creación de prototipos | Producción a gran escala |

|---|---|---|

| Especialista en prototipos | Excelente, entrega rápida | Falta de capacidad, incoherente |

| Socio integrado | Coherente con la producción | Escalable, fiable y rentable |

Más allá de la capacidad de producción, debe examinar su sistema de gestión de la calidad (SGC) y sus prácticas de comunicación. Un SGC sólido, a menudo indicado por certificaciones como ISO 9001, es la base del éxito repetible en la fabricación de grandes volúmenes. Sin embargo, las certificaciones son sólo un punto de partida. Pida ejemplos reales de sus controles de procesos e informes de calidad. La comunicación receptiva es igualmente vital. Un socio que proporcione actualizaciones claras y proactivas puede evitar que problemas menores se conviertan en retrasos importantes. Esta transparencia genera la confianza necesaria para una relación a largo plazo, que es uno de nuestros principios fundamentales.

Atributos clave de los proveedores

Lista de control de calidad y comunicación

- Sólido SGC: ¿Está certificada y, lo que es más importante, se utiliza activamente?

- Controles de procesos: ¿Pueden demostrar cómo mantienen la coherencia?

- Comunicación clara: ¿Son receptivos, transparentes y proactivos?

La elección del socio de mecanizado CNC adecuado consiste en verificar su capacidad de ampliación. Busque experiencia demostrada en la producción de grandes volúmenes, sistemas de calidad sólidos y el compromiso de respaldar su proyecto desde un único prototipo hasta series de fabricación a gran escala.

Tendencias futuras: ¿Automatización, IA y fabricación sostenible?

¿Le cuesta ver cómo afectarán las futuras tendencias de fabricación a su cuenta de resultados? ¿Le preocupa que sus métodos de producción actuales se queden pronto obsoletos y le dejen por detrás de sus competidores?

El futuro del mecanizado CNC de gran volumen está siendo remodelado por la automatización y la IA, que optimizan los procesos para lograr una velocidad y una precisión sin precedentes. Al mismo tiempo, las prácticas sostenibles se están convirtiendo en un nuevo estándar, ofreciendo no solo beneficios medioambientales, sino también una poderosa ventaja competitiva gracias a la mejora de la eficiencia y el ahorro de material.

El panorama de la fabricación de grandes volúmenes está cambiando rápidamente. Estos avances no son solo teóricos; son herramientas prácticas que están empezando a dar resultados tangibles.

Optimización de procesos basada en IA

La automatización impulsada por la inteligencia artificial ya no es ciencia ficción. En mecanizado CNC de gran volumenLos algoritmos de IA analizan en tiempo real grandes cantidades de datos procedentes de los sensores de las máquinas. Esto permite realizar ajustes autónomos de las velocidades de corte, los avances y las trayectorias de las herramientas, maximizando la eficiencia y minimizando el desgaste de las herramientas. También estamos viendo cómo se utiliza la IA para el mantenimiento predictivo, que nos alerta de posibles fallos de la máquina antes de que se produzcan, evitando costosos tiempos de inactividad. Se trata de pasar de la resolución reactiva de problemas a la optimización proactiva, un concepto que también impulsa innovaciones como diseño generativo8. Este enfoque inteligente garantiza una calidad y un rendimiento constantes, lo que es fundamental para las grandes series de producción.

| Aspecto | Mecanizado tradicional | Mecanizado mejorado con IA |

|---|---|---|

| Control de procesos | Ajustes manuales por parte de los operarios | Optimización autónoma en tiempo real |

| Mantenimiento | Programado o reactivo | Predictivo y proactivo |

| Garantía de calidad | Controles de postproducción | Control y corrección durante el proceso |

Más allá de hacer los procesos más inteligentes, el futuro también pasa por hacerlos más integrados y responsables. Estamos asistiendo a una convergencia de tecnologías y a un creciente énfasis en el impacto medioambiental.

Sistemas híbridos y fabricación ecológica

Uno de los avances más interesantes es la fabricación híbrida, que combina procesos aditivos (como la impresión 3D) y procesos sustractivos (mecanizado CNC) en un único sistema automatizado. Esto nos permite crear piezas muy complejas con canales internos o estructuras reticulares ligeras y, a continuación, mecanizar superficies críticas con tolerancias estrictas, todo en una sola máquina.

Prácticas respetuosas con el medio ambiente

La sostenibilidad también se está convirtiendo en un motor clave de la innovación. En PTSMAKE exploramos activamente soluciones ecológicas con nuestros clientes. Esto incluye el uso de metales reciclables, la implantación de maquinaria energéticamente eficiente y la adopción de fluidos de corte biodegradables. Estas prácticas ecológicas no sólo reducen la huella medioambiental de una empresa, sino que a menudo suponen un importante ahorro de costes gracias a la reducción de residuos y el menor consumo de energía, lo que genera un doble beneficio.

El futuro del mecanizado CNC de gran volumen viene definido por soluciones inteligentes, integradas y sostenibles. La optimización basada en IA mejora la eficiencia y evita los tiempos de inactividad, mientras que la fabricación híbrida y las prácticas ecológicas proporcionan una clara ventaja competitiva al permitir diseños complejos y reducir los costes operativos.

Comprenda cómo la optimización del tiempo de ciclo repercute directamente en sus costes de producción y en la velocidad de entrega. ↩

Descubra cómo esta métrica crítica garantiza la precisión de cada pieza en toda la tirada de producción de gran volumen. ↩

Descubra cómo el seguimiento del recorrido de un material desde su origen hasta la pieza final garantiza la calidad y la conformidad en sectores de fabricación críticos. ↩

Comprender la ciencia de la medición y su papel fundamental en la precisión de la fabricación. ↩

Aprenda cómo el cálculo de esta métrica puede ayudar a predecir los fallos de los equipos y optimizar eficazmente su programa de mantenimiento. ↩

Comprender cómo las propiedades de los materiales pueden variar en función de la dirección, lo que resulta crucial para diseñar piezas de materiales compuestos resistentes y fiables. ↩

Descubra cómo la metrología de precisión es esencial para garantizar la calidad y la uniformidad de miles de piezas mecanizadas. ↩

Descubra cómo los algoritmos de IA generan diseños de piezas óptimos en función de los requisitos de rendimiento, los materiales y los métodos de fabricación. ↩