Many engineering leaders struggle with casting CNC machining decisions that can make or break their project timelines and budgets. Poor supplier choices lead to quality issues, missed deadlines, and cost overruns that impact your entire production schedule.

Casting CNC machining combines traditional casting processes with precision CNC machining to create high-quality parts with superior dimensional accuracy, improved surface finishes, and reduced lead times compared to standalone manufacturing methods.

I’ve worked with hundreds of projects at PTSMAKE where the right casting CNC approach transformed challenging manufacturing requirements into streamlined production success. This guide walks you through every critical decision point, from supplier evaluation to quality assurance protocols, so you can confidently manage your next casting CNC project.

The Ultimate Guide to Improving Part Quality with Casting CNC Machining

Achieving high-quality parts often involves a trade-off. You might get a complex shape from casting, but the precision can be lacking. That’s where integrated manufacturing shines.

Casting CNC machining bridges this gap. It combines the benefits of both processes. This method is crucial for enhancing overall part quality. It ensures every component meets exact specifications consistently.

The Power of Integration

Combining these two methods offers a powerful solution. You get complex geometries quickly from casting. Then, CNC machining provides the final precision.

| Merkmal | Standalone Casting | Casting + CNC Machining |

|---|---|---|

| Toleranz | Mäßig | Sehr eng |

| Konsistenz | Gut | Ausgezeichnet |

| Oberflächenbehandlung | Raue | Glatt |

This synergy significantly elevates casting cnc machining quality.

The real benefits of this integrated approach become clear when we look at the details. It’s not just about making a part that looks right; it’s about making a part that performs reliably every single time. The precision casting cnc machining benefits extend beyond simple aesthetics.

Key Metrics for Quality Enhancement

Two primary metrics define part quality: dimensional accuracy and surface finish. Casting alone struggles to perfect these. But with CNC machining, we can achieve exceptional results. It allows us to improve part accuracy with cnc machining to levels casting can’t reach.

Achieving Unmatched Dimensional Accuracy

Casting provides a near-net shape, which is a great start. CNC machining then takes over. It removes material with extreme precision, ensuring every feature matches the CAD model perfectly. Tolerances can be tightened significantly. At PTSMAKE, we leverage this hybrid process to deliver parts that meet the most stringent specifications.

Refining the Surface

The process also removes surface irregularities and subsurface issues. This includes small voids or Porosität1 that can compromise structural integrity. The result is a smooth, uniform surface finish that is both functional and visually appealing.

| Defekt Typ | Casting Result | CNC-Bearbeitungslösung |

|---|---|---|

| Oberflächenrauhigkeit | Hoch | Smoothed to spec |

| Dimensional Drift | Möglicherweise | Corrected to tight tolerance |

| Abschiedszeilen | Visible | Removed completely |

Combining casting for near-net shape creation with CNC machining for final precision offers unparalleled quality. This integrated approach enhances dimensional accuracy, refines surfaces, and ensures consistent, defect-free parts for reliable manufacturing outcomes.

How Casting CNC Machining Solves Common Manufacturing Delays

Manufacturing delays are a constant headache. They disrupt timelines and drive up costs. Common issues include long tooling setup times and extensive post-processing.

These bottlenecks can derail even the best-laid plans. But what if there was a better way?

At PTSMAKE, we use casting CNC machining. This hybrid approach streamlines production from start to finish. It helps reduce lead times casting cnc machining by tackling delays head-on. It’s a key manufacturing delays solutions cnc.

Common Manufacturing Delays

| Delay Source | Traditional Process Impact |

|---|---|

| Tooling Setup | Can take weeks or months for complex molds. |

| Materialabfälle | Subtractive methods create significant scrap. |

| Nachbearbeitung | Requires extensive finishing, deburring, and assembly. |

| Bedienungsfehler | Multiple manual handoffs increase risk. |

This process delivers reliable and efficient results.

Streamlining Production with Integrated Workflows

The real advantage lies in combining casting and CNC machining. This integrated process creates a highly efficient workflow. It eliminates many traditional manufacturing steps.

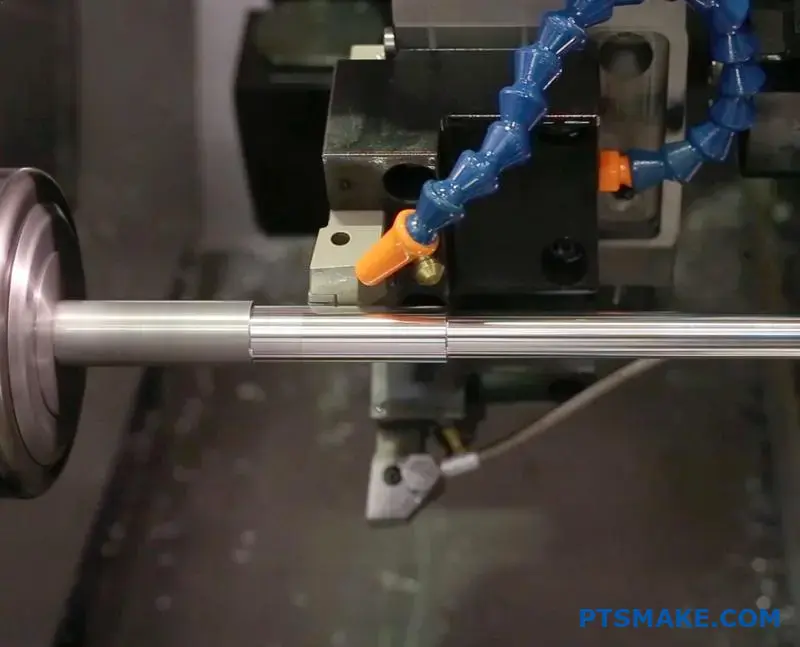

Casting first produces a near-net-shape2 part. This means the initial piece is already very close to the final geometry. The CNC machine then only needs to perform minimal finishing work. It removes small amounts of material to achieve tight tolerances and surface finishes.

This synergy is what makes fast casting cnc machining services possible. We’ve seen it cut down production cycles significantly for our clients. Automated workflows transfer the cast part directly to the CNC machine. This reduces manual handling and potential errors.

Key Optimization Tips

- Design for Manufacturability (DFM): Optimize your design early for both casting and machining. This prevents issues later.

- Auswahl der Materialien: Choose an alloy that is well-suited for both casting fluidity and machinability.

- Integrated Simulation: Use software to simulate the casting and machining process. This helps identify potential problems before production begins.

Our experience at PTSMAKE shows these steps are critical. They ensure a smooth process and predictable delivery times.

This integrated approach directly addresses major delays. By creating a near-net-shape part first, then using precision CNC for finishing, we minimize waste and machine time. This streamlined workflow offers a more reliable and faster path from design to final product.

Top 5 Factors to Evaluate a Casting CNC Machining Supplier

Choosing the right supplier is critical. Their technology directly impacts your project’s success. Outdated equipment often leads to poor quality. Modern machines, on the other hand, ensure precision and efficiency for every part.

Assessing Core Machinery

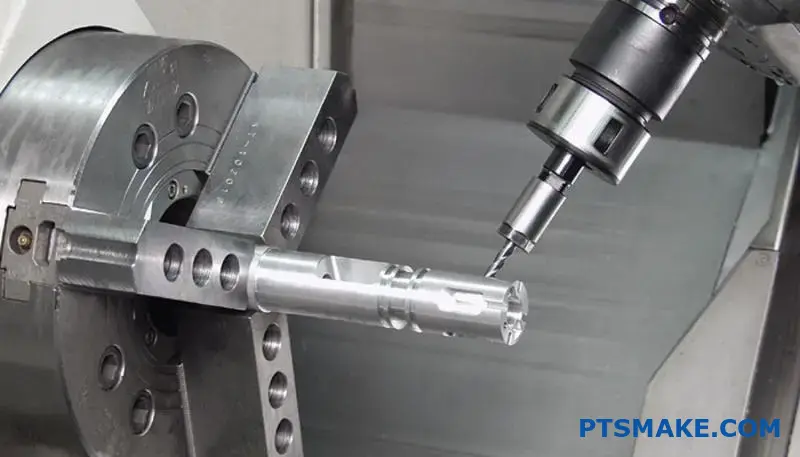

Look beyond the simple machine count. You need to ask about their specific capabilities. Do they operate modern 5-axis CNC machines? This is vital for complex casting CNC machining parts. Also, inquire about their inspection tools.

Key Equipment Checklist

| Ausrüstung | Bedeutung |

|---|---|

| 5-Achsen-CNC-Fräse | Handles complex geometries in one setup. |

| CNC-Drehmaschine | Essential for high-precision turning. |

| CMM-Prüfung | Verifies dimensional accuracy. |

| CAD/CAM Software | Ensures seamless design translation. |

A well-equipped shop is a strong signal. It demonstrates a serious commitment to quality and investment in their craft.

The machinery list is just the beginning when you evaluate a CNC machining vendor. How they integrate this technology is what truly matters. A reliable casting CNC machining partner uses their tools strategically to solve manufacturing challenges, not just to make parts.

Technology and Quality Systems

Advanced equipment significantly reduces manual error. It also helps shorten production lead times. For example, a 5-axis machine can finish a complex part in one single setup. This process avoids tolerance stack-up from multiple fixtures.

At PTSMAKE, we pair our advanced equipment with rigorous quality control protocols. This includes both in-process inspections and final part verification. Our integrated approach ensures that every component meets precise specifications. For us, consistent quality is simply non-negotiable.

A supplier’s proficiency in Geometrische Bemaßung und Tolerierung3 is also critical. This system ensures everyone—from your designer to their machinist—speaks the same technical language, removing ambiguity from drawings.

Technology Evaluation Checklist

| Kriterien | Yes/No | Anmerkungen |

|---|---|---|

| Modern 5-Axis CNC Machines? | Crucial for complex part manufacturing. | |

| CMM for Quality Inspection? | Verifies tolerances and part accuracy. | |

| Use Updated CAD/CAM Software? | Important for file compatibility and efficiency. | |

| ISO 9001 zertifiziert? | Demonstrates a formal quality management system. |

A supplier’s technological capability is a direct measure of their quality and reliability. Modern equipment, paired with robust quality systems, is essential for delivering precise casting CNC machining parts on time and to your exact specifications.

Ensuring Precision and Tolerance in Casting CNC Machined Components

Achieving tight tolerances on cast parts is a challenge. It requires a systematic approach. The process starts long before the CNC machine begins its work. Precision is built-in from the very beginning.

Success depends on controlling every stage. This ensures the final component meets exact specifications.

Design and Process Control

The foundation for precision casting cnc machining tolerances is the initial design. We must account for the material and casting method.

A well-planned process considers every variable.

| Gießverfahren | Pre-Machining Tolerance |

|---|---|

| Sandgießen | ±1.5 mm |

| Feinguss | ±0.4 mm |

| Druckgießen | ±0,2 mm |

This planning prevents costly errors later on.

True precision in casting cnc machining combines smart design with expert execution. It’s not just about the final cut. It’s about planning for it from the casting mold itself.

Design Considerations for Machining

The casting design must include extra material, or a machining allowance. This ensures the CNC tool has enough stock to remove. It helps achieve a clean, accurate surface.

We also design specific locating points, or datums. These features allow us to securely and repeatedly position the cast part in the CNC fixture. This is critical for tight tolerance cnc machining after casting.

Machining and Inspection Best Practices

Once the part is cast, fixturing is key. A custom, rigid fixture prevents any movement during machining. This stability is essential for maintaining accuracy.

Effective quality control relies on advanced Metrologie4 tools like CMMs and optical scanners. We use in-process inspection to verify dimensions at critical steps, not just at the end. This proactive approach ensures final dimensional accuracy casting cnc.

| Inspektionswerkzeug | Bester Anwendungsfall |

|---|---|

| CMM | Verifying complex internal features |

| 3D Scanner | Capturing overall surface geometry |

| Digitale Messschieber | Quick in-process checks |

This multi-stage verification process guarantees that every part we deliver at PTSMAKE meets the required specifications.

Achieving tight tolerances requires a holistic approach. Success hinges on thoughtful design with proper machining allowances, precise machining with custom fixturing, and comprehensive inspection methods to ensure final dimensional accuracy and function.

The Complete Process of Casting CNC Machining from Design to Delivery

A structured workflow is crucial. It turns a complex design into a physical part. This isn’t just about following steps. It’s about ensuring precision at every stage.

The entire design to delivery casting cnc journey has a clear path. This minimizes errors and delays.

Die vier Kernphasen

We break down the entire manufacturing cycle into four manageable stages. Each stage has its own quality gates. This ensures nothing is overlooked.

Here is a simplified overview of the key steps.

| Bühne | Primärer Schwerpunkt | Wichtigstes Ergebnis |

|---|---|---|

| 1. Entwurfsprüfung | Manufacturability (DFM) | Optimized design for casting and machining |

| 2. Gießen | Creating the near-net shape | A solid, rough part ready for finishing |

| 3. CNC-Bearbeitung | Achieving final tolerances | The part machined to exact specifications |

| 4. Inspection | Qualitätssicherung | A verified part that meets all requirements |

Following these casting cnc machining process steps is our blueprint for success.

The success of any project depends on the seamless integration of each phase. A structured process is not just a guideline; it is a strict protocol that ensures repeatability and quality. Each step directly impacts the next.

Stage 1: Design for Manufacturability (DFM) Review

This is the most critical step. Before any metal is poured, we analyze your CAD model. We check for potential casting defects like porosity. We also plan for the CNC machining after casting workflow. This proactive approach saves significant time and cost.

Stage 2: The Casting Phase

Once the design is approved, we create the mold. We then pour the molten metal to create the "near-net shape." The goal here is to produce a solid part. It needs to have just enough extra material, or stock, for the subsequent machining operations.

Stage 3: Precision CNC Machining

The cast part now moves to our CNC machines. Here, we machine it to the final, precise dimensions. The key challenge is maintaining the part’s Formbeständigkeit5 as material is removed. We develop custom fixtures to hold the part securely. This ensures every feature is machined accurately relative to the design datums.

Stage 4: Quality Assurance and Inspection

Finally, every part undergoes rigorous inspection. We use CMMs and other advanced tools. This verifies that all dimensions and tolerances meet your specifications. This is the final gate before delivery.

| Inspektionsstelle | Tool Used | Zweck |

|---|---|---|

| Post-Casting | X-Ray / Visual | Check for internal and external defects |

| Nachbearbeitung | CMM / Calipers | Verify final dimensions and GD&T |

| Final Audit | All tools | Ensure 100% compliance with prints |

This structured process transforms a design into a delivered component efficiently.

This end-to-end workflow is our commitment to quality. Following these structured casting cnc machining process steps guarantees consistency, reduces rework, and ensures we meet your delivery deadlines without any compromises.

Material Selection Secrets for Durable Casting CNC Machined Parts

Choosing the right material is the foundation of any successful casting CNC machining project. This decision directly influences the final part’s durability, performance, and cost.

It’s a careful balance. You need a material that casts well, machines efficiently, and meets all functional requirements without breaking the budget.

Der Balanceakt

Think of it as a triangle: durability, machinability, and cost are the three corners. Optimizing one often affects the others. Here’s a quick overview of common choices.

| Werkstoff-Gruppe | Dauerhaftigkeit | Bearbeitbarkeit | Relative Kosten |

|---|---|---|---|

| Aluminium-Legierungen | Gut-Ausgezeichnet | Ausgezeichnet | Niedrig bis mittel |

| Zink-Legierungen | Gut | Ausgezeichnet | Niedrig |

| Stahl-Legierungen | Ausgezeichnet | Angemessen-gut | Mittel-Hoch |

This table provides a starting point. Your specific application will determine the best fit from the best alloys for casting CNC.

The ideal material choice goes beyond basic properties. At PTSMAKE, we guide clients through a detailed selection process, creating a comprehensive casting cnc machining material guide for each project.

Common Alloys for Casting and CNC Machining

Let’s look at some popular options. Aluminum alloys like A380 are fantastic. They offer a great strength-to-weight ratio and are very easy to machine after casting. This makes them ideal for complex, lightweight parts.

Zinc alloys, such as Zamak 3, are another excellent choice. They have a lower melting point, which extends die life and reduces energy costs. They provide a smooth surface finish, perfect for parts that need plating.

When strength is critical, we often turn to steel. Stainless steels are common durable materials for cnc machining after casting. However, they are tougher to machine. This can increase tool wear and cycle times due to effects like Kaltverfestigung6.

Leitlinien für die Materialauswahl

To choose wisely, consider these questions:

- What is the part’s operating environment? (e.g., temperature, exposure to chemicals)

- What mechanical loads will it endure? (e.g., tension, impact)

- What is the target production volume and budget?

Here’s a more detailed breakdown based on our experience.

| Alloy Example | Hauptmerkmal | Beste Anwendung |

|---|---|---|

| Aluminium A380 | Lightweight, Good Thermal Conductivity | Electronic Housings, Automotive Parts |

| Zinc Zamak 3 | High Ductility, Excellent Finish | Decorative Hardware, Gears, Brackets |

| Rostfreier Stahl 304 | Korrosionsbeständigkeit, hohe Festigkeit | Medical Devices, Food-Grade Equipment |

Answering these questions helps narrow the options. It ensures the final part not only meets specifications but also delivers long-term value.

Selecting the right material is a strategic decision. It requires balancing durability, machinability, and cost to ensure optimal performance and longevity for your cast and CNC machined parts. The right choice prevents costly failures and redesigns down the line.

Cost-Benefit Analysis: Casting CNC Machining vs. Traditional Methods

In B2B manufacturing, the bottom line is critical. It’s not just about the per-unit price. It’s about the total cost and return on investment (ROI).

Many weigh standalone casting against standalone machining. I believe the real conversation is about their integration. The cost-benefit of casting cnc machining is compelling. It offers efficiency that separate processes cannot match.

Schauen wir uns einen direkten Vergleich an.

Core Cost Factors: A Head-to-Head View

| Faktor | Traditional Methods (Separate) | Integrated Casting & CNC |

|---|---|---|

| Lieferanten-Management | High (Two+ suppliers) | Low (Single supplier) |

| Logistics & Shipping | Multiple transit steps | Gering bis gar nicht |

| Vorlaufzeit | Longer; cumulative delays | Shorter; streamlined process |

| Qualitätskontrolle | Complex; hand-off risks | Simplified; unified standards |

This integrated approach streamlines production significantly.

Beyond the Initial Quote: Uncovering True ROI

A lower price from separate vendors can be deceptive. True cnc machining after casting cost savings appear when you analyze the entire project lifecycle.

Case Study Snapshot: Automotive Component

We worked on a complex aluminum housing project. A client initially used separate casting and machining vendors. They faced high scrap rates due to setup misalignments between the two facilities.

By bringing the entire process to PTSMAKE, we unified the workflow. This eliminated the hand-off errors. We reduced their scrap rate by over 75%, a huge saving.

The Hidden Costs of a Fragmented Supply Chain

Managing multiple suppliers introduces risks. You have shipping costs between the foundry and machine shop. You have potential for transit damage. You also have doubled administrative overhead.

These factors inflate your final costs. A comprehensive analysis considers the Gesamtbetriebskosten7, which includes these indirect expenses. This approach reveals the superior value of an integrated manufacturing partner.

The most significant benefit is often speed. A shorter production cycle means a faster time-to-market. That is a competitive advantage that directly impacts your revenue and ROI. The traditional vs casting cnc machining debate often overlooks this crucial business factor.

Choosing an integrated casting cnc machining process eliminates hidden expenses and streamlines your supply chain. This approach provides better quality control and a superior return on investment, especially for complex B2B projects where precision and reliability are paramount.

Quality Assurance Protocols Every Engineer Should Know for Casting CNC Machining

In casting CNC machining, quality is not an accident. It is the result of a deliberate, structured process. Robust quality assurance protocols are non-negotiable.

They bridge the gap between design intent and the final part. Without them, you risk costly rework, delays, and failure.

Effective QA ensures every component meets exact specifications. It is the foundation of reliability. This process involves detailed inspections, rigorous testing, and complete documentation. Each step builds trust and guarantees performance for every part.

A solid quality assurance plan for casting CNC machining rests on three core pillars. These are inspection, testing, and documentation. Each plays a distinct role in verifying part integrity. Ignoring one pillar weakens the entire structure.

Key Inspection Protocols

First Article Inspection (FAI) is crucial. It confirms the production process can produce a part that meets all requirements. We perform in-process inspections at critical stages. This catches deviations early, before they become major problems. Final inspection is the last gate before shipping.

Erweiterte Prüfmethoden

Visual checks are not enough for complex parts. We rely on advanced testing for data-driven verification. This is where the science of Metrologie8 provides the accuracy we need. Coordinate Measuring Machines (CMM) verify complex geometries against CAD models with micron-level precision. For castings, Non-Destructive Testing (NDT) is essential. Methods like X-ray inspection reveal internal porosity or voids without damaging the part.

Here is a look at some common testing methods:

| Prüfverfahren | Primäre Verwendung | Hauptvorteil |

|---|---|---|

| CMM | Überprüfung der Dimensionen | High accuracy for complex geometry. |

| X-ray (NDT) | Internal Defect Analysis | Reveals hidden flaws in castings. |

| Material Spektrometrie | Überprüfung der Legierungszusammensetzung | Confirms material compliance. |

Die Rolle der Dokumentation

Proper documentation provides traceability and proof of quality. Material certifications, inspection reports, and CMM data are all part of a complete quality file. This documentation is a key element of casting cnc quality control standards.

Robust quality assurance protocols are fundamental. They ensure every part from casting CNC machining processes is reliable, compliant, and fit for purpose. This system of checks, tests, and records is essential for delivering consistent quality.

The Role of Advanced Software in Optimizing Casting CNC Machining

In modern manufacturing, precision is not optional. For casting CNC machining, advanced software transforms rough castings into high-tolerance parts. It bridges the gap between the initial cast and the final product.

This shift from manual guesswork to digital accuracy is critical. CAD/CAM software is at the heart of this evolution. It ensures every cut is calculated and efficient.

Key Software Features

Software optimization for CNC machining after casting relies on specific tools. These tools address the unique challenges of cast parts.

| Merkmal | Funktion | Impact on Casting Machining |

|---|---|---|

| 3D Model Import | Reads casting scan data or CAD files. | Creates a precise digital twin of the as-cast part. |

| Stock Recognition | Defines the irregular shape of the casting. | Prevents air-cutting and ensures efficient material removal. |

| Toolpath Simulation | Visualizes the entire machining process. | Avoids costly collisions and validates the strategy. |

These features are essential advanced casting CNC machining tools.

Enhancing Design and Simulation

Effective software optimization begins before the machine starts. It starts with a smart digital strategy. CAD/CAM systems allow us to overlay the final part model onto the scanned model of the raw casting. This visual check is invaluable.

It immediately highlights areas with insufficient material. It also shows where excess stock needs removal. This prevents discovering problems mid-production, which saves significant time and resources.

Simulation: The Digital Proving Ground

Simulation is perhaps the most powerful feature. It provides a risk-free environment to test machining strategies. We can verify tool clearances, check for potential gouges, and optimize cutting parameters. This is crucial for complex geometries found in casting CNC machining.

| Workflow Step | Traditionelle Methode | Software-Optimized Method |

|---|---|---|

| Einrichtung | Manual probing and alignment. | Automated alignment using best-fit algorithms. |

| Bearbeitung | Conservative speeds and feeds. | Optimized, dynamic toolpaths based on stock. |

| Verification | Post-process inspection, high scrap risk. | In-process probing and adaptive machining. |

Through our collaborative research with clients, we found that this digital verification step reduces setup times by up to 30%. True accuracy also requires ensuring the machine itself is performing correctly. This is where processes like volumetric verification9 become essential for maintaining the highest tolerances on finished parts.

Advanced CAD/CAM for casting CNC machining is not just about programming. It is a comprehensive tool for process control.

Advanced software is essential for modern casting CNC machining. It integrates design, simulation, and verification to improve accuracy and efficiency. This technology transforms raw castings into precise components by optimizing every step, from initial setup to the final toolpath.

Real-World Case Studies: Success Stories with Casting CNC Machining

Theory is useful, but practical examples show true value. Let’s explore some real-world casting CNC machining case studies.

These stories highlight how combining these two processes solves complex engineering challenges. We will focus on demanding industries.

I will break down each case using a simple format. This helps illustrate the power of this hybrid manufacturing method.

| Industrie | Primäre Herausforderung |

|---|---|

| Medizinische Geräte | Complex geometry with high precision |

| Robotik | Strength-to-weight ratio and durability |

These examples show how success stories in CNC machining after casting are created. They offer a blueprint for solving tough design problems.

Exploring real-world applications of casting CNC machining provides the best insights. These case studies show how the process works in practice.

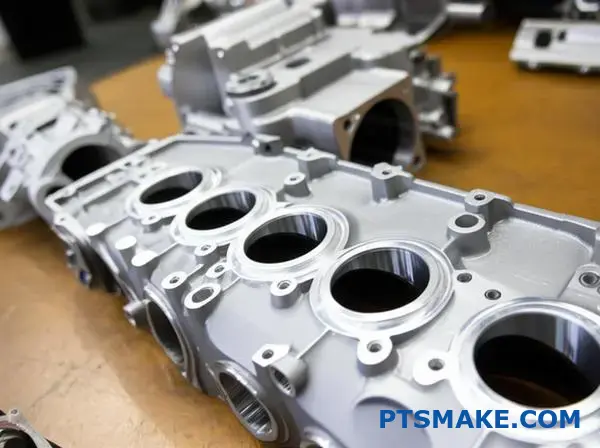

Case Study 1: Medical Diagnostic Device Housing

Das Problem

A client needed a complex housing for a handheld medical scanner. It required internal structural features, thin walls, and precise mounting points. Pure CNC machining was too slow and costly for the planned production volume.

The Solution

We proposed a two-step process. First, die casting created the component’s intricate netznahe Form10. This efficiently formed the overall geometry. Second, targeted CNC machining was used to finish critical features. This included threading holes and milling mating surfaces to tight tolerances.

Das Ergebnis

This approach drastically cut per-unit costs and accelerated production time. The final part met all functional requirements, including medical-grade surface finishes. It was a clear win for efficiency and precision.

Case Study 2: Robotic Arm Joint

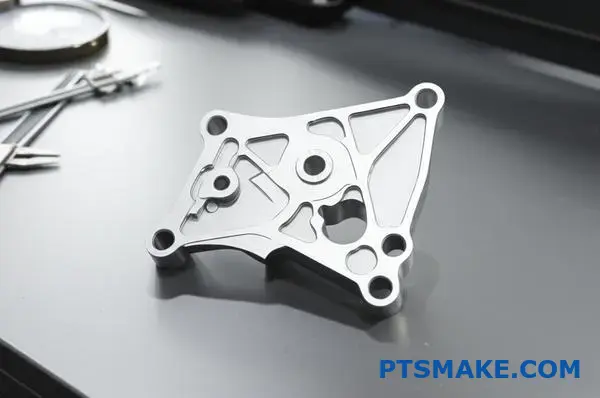

Das Problem

A robotics company was developing a new collaborative robot. A key joint component needed to be strong, lightweight, and incredibly precise to ensure smooth, repeatable movements. The geometry was too complex for casting alone.

The Solution

Investment casting was used to produce the initial part from a high-strength aluminum alloy. This method is ideal for complex shapes. Then, 5-axis CNC machining created the final bearing seats and alignment features.

Das Ergebnis

The finished joint component exceeded performance targets. It achieved the required strength-to-weight ratio while holding tolerances within microns. This demonstrates one of the most effective real-world applications of casting CNC.

These case studies illustrate how combining casting with CNC machining offers a practical, cost-effective solution for complex parts in demanding industries like medical and robotics, balancing initial shape complexity with final precision requirements.

Handling Complex Designs: Tips for Casting CNC Machining Intricate Parts

Machining intricate parts from castings requires careful planning. The initial casting quality directly impacts the final CNC result. Proper design and strategy are key.

Handling complex geometries in casting CNC machining is not just about the machine. It starts with the design phase. We must think ahead.

Design Tips for Machinability

Before any metal is cut, smart design choices are crucial. These choices can simplify the entire process. They also reduce costs and improve part quality.

Below are some key considerations we use at PTSMAKE.

| Design-Aspekt | Recommended Practice | Practice to Avoid |

|---|---|---|

| Entwurfswinkel | Include generous draft angles. | Zero or negative draft angles. |

| Wanddicke | Maintain uniform thickness. | Abrupt changes in thickness. |

| Fillets & Radii | Use large, smooth radii. | Sharp internal corners. |

These simple steps make a huge difference in the final product.

Fortgeschrittene Bearbeitungstechniken

After a good casting, the focus shifts to machining. This is where expertise in handling complex geometries becomes vital for success. It involves more than just a standard program.

Werkzeugweg-Optimierung

Optimizing the toolpath is essential. For intricate parts cnc machining after casting, we use specific strategies. High-Speed Machining (HSM) paths, for example, maintain constant tool engagement. This reduces tool wear and prevents part distortion from heat buildup.

Another key area is the sequence of operations. We often machine critical features first. This establishes a stable reference for subsequent cuts, ensuring high precision. This is a core part of our process at PTSMAKE.

Support and Fixturing

Complex parts often need custom fixtures. These supports prevent vibration and deflection during machining. A poorly supported part will never meet tight tolerances. The fixture design must be rigid yet allow access for the cutting tools. We also consider the effects of Toolpath Interpolation11 on the final surface finish.

Häufig zu vermeidende Fallstricke

Even with a good plan, issues can arise. Knowing the common pitfalls helps prevent costly mistakes in complex casting cnc machining designs.

| Fallstrick | Konsequenz | How to Avoid |

|---|---|---|

| Ignoring Casting Variations | Tool crashes, inaccurate parts. | Probe the casting before machining. |

| Poor Tool Selection | Bad surface finish, long cycles. | Use tools designed for the material. |

| Inadequate Fixturing | Vibration, dimensional errors. | Design robust, custom fixtures. |

Successful casting cnc machining combines smart design, advanced techniques, and proactive problem-solving. Proper planning before and during the process ensures that even the most complex designs are manufactured to specification, a standard we always aim for in our projects.

The Impact of Surface Finish on Casting CNC Machined Product Performance

In casting CNC machining, surface finish is more than just a cosmetic detail. It’s a critical engineering specification. It directly influences a product’s performance, lifespan, and even its perceived value.

A part’s finish affects how it interacts with its environment and other components. For some applications, a rougher texture is acceptable. But for high-performance parts, achieving a precise surface quality is non-negotiable. It dictates everything from friction to fatigue resistance.

Functionality and Application

The required surface finish depends entirely on the part’s function. A smooth surface is not always better. The key is matching the finish to the application.

| Anwendungsbereich | Typical Finish Requirement | Primäre Funktion |

|---|---|---|

| Dynamische Dichtungen | Very Smooth (e.g., Ra 0.4 µm) | Prevent fluid leakage |

| Lageroberflächen | Smooth (e.g., Ra 0.8 µm) | Reduce friction and wear |

| Aesthetic Covers | Polished or Brushed | Enhance visual appeal |

| Grip Handles | Textured or Knurled | Improve user handling |

A part’s functionality is directly tied to its surface texture. For components that move against each other, a smoother cnc machining after casting surface quality minimizes friction and wear, extending the product’s operational life. Think of hydraulic cylinders or bearing housings where a flawless surface is essential.

Conversely, surface imperfections can become initiation points for cracks under cyclic loading. A smoother finish distributes stress more evenly, significantly improving fatigue resistance. This is crucial in aerospace and automotive parts where failure is not an option. The surface texture’s directional characteristic, known as Anisotropie12, also plays a vital role in how a part withstands stress over time.

Achieving the Desired Finish

We control the final casting cnc machined part finish by carefully managing our machining parameters. It’s a balance of science and experience.

Machining Parameter Control

The right combination of tools and machine settings is essential. Sharp cutting tools with the correct geometry produce cleaner cuts. Similarly, adjusting speeds and feeds allows us to refine the surface texture with high precision.

| Parameter | Auswirkungen auf die Oberflächenbeschaffenheit | Allgemeiner Leitfaden |

|---|---|---|

| Schnittgeschwindigkeit | Higher speeds often yield a finer finish | Optimize based on material and tool |

| Vorschubgeschwindigkeit | Lower rates produce a smoother surface | Balance against production time |

| Radius der Werkzeugschneide | A larger radius can create a smoother finish | Choose based on part geometry |

At PTSMAKE, we use standards like Ra (Roughness Average) to define and verify these finishes, ensuring every part we deliver meets the exact engineering specifications.

The correct surface finish casting cnc machining is a critical engineering decision, not an afterthought. It directly impacts functionality, durability, and customer satisfaction, ensuring your product performs reliably and meets its intended design life.

Environmental and Sustainability Aspects of Casting CNC Machining

In manufacturing, sustainability is now a core business strategy. It’s not just about compliance. It’s about creating value.

Eco-friendly casting CNC processes improve efficiency and reduce costs. They also strengthen your brand’s reputation. This is key for building trust in B2B partnerships.

The Shift to Green Manufacturing

The environmental impact of CNC machining after casting is a major concern. Adopting sustainable practices is essential. This move helps meet regulations and customer demands for greener products.

Schwerpunktbereiche

We focus on three main areas: reducing waste, saving energy, and recycling materials. Each step offers a chance for improvement.

| Practice Area | Traditionelle Methode | Nachhaltiger Ansatz |

|---|---|---|

| Material Use | High scrap rates | Near-net-shape casting, scrap recycling |

| Energie | Continuous machine operation | Energy-efficient machines, smart scheduling |

| Abfall | Single-use coolants | Coolant recycling systems, MQL |

Adopting sustainable casting CNC machining is a practical decision. It aligns with global regulations and strengthens the supply chain. At PTSMAKE, we guide partners toward eco-friendly choices that don’t compromise quality.

Regulations and Compliance

Navigating environmental regulations like RoHS and REACH is crucial. Compliance is not just a legal requirement. It’s a baseline for market access, especially in Europe and North America. It shows a commitment to safety and responsibility.

Sustainable Techniques in Action

Material Recycling

We prioritize materials that can be easily recycled. For instance, aluminum and steel chips from the CNC process can be remelted and reused for new castings. This creates a closed-loop system, significantly reducing raw material demand.

Energy Efficiency and Waste Reduction

Modern CNC machines consume less power. After discussing with our equipment suppliers, we found that new models can reduce energy use by up to 20%. Combining them with smart production scheduling minimizes idle time. This lowers the overall environmental impact of CNC machining after casting. A thorough Ökobilanz13 helps identify these opportunities.

| Sustainability Benefit | Impact on B2B Partnership |

|---|---|

| Reduced Material Cost | More competitive pricing for your parts. |

| Einhaltung von Vorschriften | Ensures your products meet international standards. |

| Verbessertes Markenimage | Strengthens your corporate social responsibility profile. |

| Prozess-Effizienz | Leads to more reliable and timely deliveries. |

Sustainable casting and CNC machining practices create a more resilient and responsible supply chain. They go beyond simple compliance, offering tangible benefits like cost savings and enhanced brand reputation, which are vital for strong, long-term B2B partnerships.

Budget Management Strategies for Large-Scale Casting CNC Machining Orders

Managing large-scale casting CNC machining orders requires strict budget control. Success isn’t just about technical skill; it’s about financial planning. Effective budgeting ensures profitability.

It prevents cost overruns that can sink a project. We will explore key strategies for this. This includes bulk pricing, process optimization, and risk mitigation. Mastering these will protect your bottom line.

Initial Budgeting Tips

First, create a detailed cost breakdown. Never rely on rough estimates. Separate material costs from labor and overhead. This clarity is your foundation.

| Kostenkategorie | Beschreibung |

|---|---|

| Direkte Kosten | Raw materials, casting, direct labor |

| Indirekte Kosten | Tooling, machine wear, quality control |

| Overhead | Management, facility costs |

Understanding Core Expenses

Focus on the major cost drivers. Material selection and machining time are often the largest expenses. Optimizing these areas offers the greatest savings potential.

Effective cost management for large orders goes beyond simple spreadsheets. It involves a proactive and strategic approach to every stage, from design to delivery. At PTSMAKE, we focus on optimizing the entire value chain.

Advanced Cost Management Techniques

We always advise clients to consider process optimization early. Small design changes can drastically reduce machining time after casting. This is a key part of cost management cnc machining after casting. For example, simplifying a complex curve or adjusting a hole’s position can save hours of machine work across a large batch.

Another critical area is risk mitigation. What happens if a raw material price spikes? Or if a key piece of equipment fails? Building a contingency fund, typically 5-10% of the total budget, is essential. It provides a buffer against unforeseen challenges without derailing the project’s financial health. Precision in drawings using systems like Geometrische Dimensionierung und Tolerierung (GD&T)14 also reduces errors and rework costs.

Negotiation and Supplier Partnership

Building a strong partnership with your supplier is vital. It’s not just about getting the lowest price. A good partner will help you find cost savings.

Here are negotiation points we often discuss with clients:

| Negotiation Point | Potenzielle Auswirkungen |

|---|---|

| Bulk Material Purchase | 5-15% reduction in material costs |

| Long-Term Contract | Price stability and priority scheduling |

| Zahlungsbedingungen | Improved cash flow management |

A transparent dialogue about large-scale casting cnc machining costs ensures both parties are aligned for success.

Effective budgeting for large-scale casting CNC machining projects is a blend of detailed planning, strategic optimization, and strong supplier relationships. This approach not only ensures profitability but also fosters successful, long-term project outcomes.

Effective Communication with Your Casting CNC Machining Partner for Better Outcomes

Clear communication is the bedrock of any successful manufacturing project. A great design can easily fail due to simple misunderstandings.

This is especially true in casting and CNC machining. Every detail matters. Misinterpreting a tolerance or a timeline can lead to costly rework. Strong communication prevents these errors.

Warum es wichtig ist

Good communication with your casting CNC machining partner builds trust. It ensures everyone is aligned. This reduces risks and keeps the project on track from start to finish.

| Communication Pitfall | Beste Praxis |

|---|---|

| Vague RFQs | Detailed RFQs with 3D models |

| Infrequent Updates | Scheduled Weekly Check-ins |

| Assumption-based Decisions | Formal Written Approvals |

Effective supplier collaboration in CNC machining is not optional. It is essential for achieving the precision and quality you expect.

The quality of your project communication directly impacts the final part. Vague instructions lead to flawed parts. It’s a simple cause-and-effect relationship I’ve seen play out many times. Strong partnerships are built on clarity and transparency.

Mastering the Request for Quotation (RFQ)

Your RFQ is the first and most critical communication. A detailed RFQ sets the stage for success. It should include 3D CAD files, material specifications, required tolerances, surface finishes, and desired quantities. Ambiguity here is your enemy. At PTSMAKE, a detailed RFQ allows us to provide a more accurate quote and production plan. This avoids surprises later.

Best Practices for Collaboration

Regular updates are non-negotiable for effective supplier collaboration in CNC machining. Scheduled check-ins, whether daily or weekly, keep both teams synchronized. It’s also important to use the right tools. While email is common, project management platforms offer better tracking and transparency. Asynchronous communication15 becomes vital when working across different time zones, ensuring progress continues around the clock.

| Werkzeug | Bester Anwendungsfall | Nutzen Sie |

|---|---|---|

| Formal documentation, RFQs | Creates a paper trail | |

| Phone/Video Calls | Urgent issues, complex discussions | Immediate clarification |

| Project Platforms | Task tracking, progress updates | Centralized information |

This structured approach to casting CNC machining project communication removes guesswork and builds a reliable partnership. It ensures every specification is met.

Effective communication with your casting CNC machining partner is crucial. It minimizes errors, prevents delays, and builds the trust needed for a successful long-term relationship. It aligns expectations with reality, ensuring a smooth process from RFQ to final delivery.

Building Long-Term Trust with a Reliable Casting CNC Machining Provider

Finding a supplier is transactional. Building a partnership is strategic. A truly trusted casting cnc machining provider becomes an extension of your team.

This relationship is not built overnight. It requires effort from both sides. It is founded on reliability, consistency, and shared project goals.

Key Pillars of Trust

True partnerships are built on several core principles. Each one is critical for success.

| Trust Factor | Beschreibung |

|---|---|

| Transparenz | Open communication about capabilities, timelines, and challenges. |

| Quality History | A proven track record of delivering parts that meet spec. |

| Konsistenz | Reliable performance project after project. |

These factors create a foundation for a strong working relationship.

A long-term partnership moves beyond simple price negotiations. It focuses on creating mutual value. When you find a reliable cnc machining after casting partner, you invest in future success.

This shift in mindset is crucial. Instead of just placing orders, you start collaborating on solutions. This collaboration leads to better designs, improved efficiency, and cost savings over time. It creates a stronger operational backbone for your company.

The Real Value of Long-Term Partnerships

The benefits extend far beyond a single project. They impact your entire production process. A partner who understands your needs can anticipate challenges before they arise.

This proactive approach improves your overall Widerstandsfähigkeit der Lieferkette16.

Our analysis shows that long-term casting cnc machining relationships reduce lead times by an average of 15-20% after the first year of collaboration. This is due to streamlined communication and established processes.

| Relationship Type | Schwerpunkt | Ergebnis |

|---|---|---|

| Kurzfristig | Lowest price per part | Inconsistent quality, communication delays. |

| Langfristig | Overall value & reliability | Smoother operations, better innovation. |

Ultimately, investing in trust pays dividends in quality and efficiency.

Building trust with a casting CNC machining provider is a strategic investment. It transforms transactions into a collaborative partnership, ensuring reliability, consistent quality, and better long-term value for your most critical projects.

Accelerate Your Success with PTSMAKE Casting CNC Machining

Ready to achieve consistent quality and fast turnarounds for your casting CNC machining projects? Contact PTSMAKE for a rapid, reliable quote—our experts deliver precision and value from prototype to production. Take the next step: send your inquiry now and experience trusted B2B manufacturing excellence!

Learn how identifying this casting defect can significantly improve your part’s strength and overall performance. ↩

Learn how getting closer to the final shape reduces machining time and boosts overall production efficiency. ↩

Erfahren Sie, wie diese symbolische Sprache sicherstellt, dass Ihre Designabsicht perfekt in ein physisches Teil umgesetzt wird. ↩

Explore the science of measurement and its critical role in modern manufacturing for ensuring quality and precision. ↩

Understand how material properties and cooling rates affect part accuracy after casting. ↩

Learn how this effect impacts machining speeds, tool life, and project costs. ↩

Learn how this concept reveals the full financial impact of your manufacturing decisions. ↩

Explore the science of measurement to understand how we guarantee part accuracy and precision. ↩

Learn how this calibration ensures machine accuracy across its entire working volume. ↩

Learn more about how this casting technique minimizes material waste and subsequent machining time. ↩

Discover how interpolation methods directly influence machine movement and final part accuracy. ↩

Understand how the direction of surface texture patterns can affect a part’s functional performance and lifespan. ↩

Learn to assess the full environmental impact of your product from start to finish. ↩

Discover how precise tolerancing definitions can significantly reduce your final manufacturing costs. ↩

Discover how this communication style can enhance efficiency in global manufacturing partnerships. ↩

Learn how strong supplier relationships can protect your operations from disruption. ↩